- DL manuals

- Echo

- Trimmer

- ES-210 - SERIAL NUMBER 07001001-07999999

- Operator's Manual

Echo ES-210 - SERIAL NUMBER 07001001-07999999 Operator's Manual

Summary of ES-210 - SERIAL NUMBER 07001001-07999999

Page 1

Shred 'n' vac ® operator's manual model es-210 serial number 07001001 - 07999999 x753000920 03/03 x7531131700 warning danger read rules for safe operation and all instructions carefully. Echo provides this operator's manual which must be read and understood for proper and safe operation..

Page 2

2 t able of c ontents introduction ............................................................... 2 - the operator's manual ....................................... 2 manual safety symbols and important information .. 3 safety ............................................................................

Page 3: 'N' V

3 s hred 'n' v ac ® o perator ' s m anual important note m anual s afety s ymbols and i mportant i nformation throughout this manual and on the product itself, you will find safety alerts and helpful information messages preceded by symbols or key words. The following is an explanation of those symb...

Page 4

4 international symbols s afety i nstructions personal condition and safety equipment physical condition your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and...

Page 5: 'N' V

5 s hred 'n' v ac ® o perator ' s m anual extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals, may be brought about by exposure to vibration and cold. Exposure to vibration and cold m...

Page 6

6 safe operation determine operation area • review area to be cleared. Look for potential hazards such as stones or metal objects. • spectators and fellow workers must be warned, and children and animals prevented from coming nearer than 15 m (50 ft.) while the blower is in use. • take wind conditio...

Page 7: 'N' V

7 s hred 'n' v ac ® o perator ' s m anual d escription contents 1 - power head 1 - straight pipe 1 - pipe with nozzle 1 - shred 'n' vac ® suction tube 1 - elbow pipe 1 - debris bag 1 - operator's manual 1 - warranty registration card 1 - echo emissions and warranty statement 1 - t-wrench 1 - echo po...

Page 8

8 15. Primer bulb - pumping primer bulb before starting engine draws fresh fuel from the fuel tank, priming the carburetor for starting. Pump primer bulb until fuel is visible and flows freely in the clear fuel tank return line. Pump bulb an additional 4 or 5 times. 16. Choke - choke is located on t...

Page 9: 'N' V

9 s hred 'n' v ac ® o perator ' s m anual a ssembly warning danger never perform maintenance or assembly procedures with engine running, or serious personal injury may result. Blower application install blower pipes 1. Align grooves in straight pipe with pegs on blower housing and slide pipe onto ho...

Page 10

10 5. Align grooves in discharge elbow with pegs on blower, and slide elbow (d) on to blower. Turn elbow counterclockwise to lock in place. Elbow must angle back toward operator position as shown. 6. Place debris bag opening over flared end of elbow, and cinch bag (e) securely with velcro strap. D e.

Page 11: 'N' V

11 s hred 'n' v ac ® o perator ' s m anual handling fuel warning danger fuel is very flammable. Use extreme care when mixing, storing or handling or serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks...

Page 12

12 a b c d o peration • provide all operators of this equipment with the operator's manual and instructions for safe operation. • before starting the unit, equip yourself and any other person working within the 15 m (50 ft.) safety zone with the required protective equipment and clothing. Starting c...

Page 13: 'N' V

13 s hred 'n' v ac ® o perator ' s m anual a b starting warm engine the starting procedure is the same as cold start except do not close the choke. 1. Stop switch move stop switch button (a) away from the stop position. 2. Throttle position lever move throttle position lever (b) forward to idle posi...

Page 14

14 blower operation warning danger always wear safety glasses, hearing protection and a face filter mask or serious personal injury may result. . Do not point the blower pipe in the direction of people or pets. Never operate unit without either housing cover grill or vacuum tube installed on unit se...

Page 15: 'N' V

15 s hred 'n' v ac ® o perator ' s m anual shred ' n ' vac ® operation warning danger flying debris hazard. Never operate unit as a vacuum unless discharge elbow is installed and debris bag is securely cinched to elbow. Failure to follow instructions can result in serious injuries. 1. Adjust debris ...

Page 16

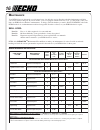

16 m aintenance your echo blower is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your blower achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for maintenance....

Page 17: 'N' V

17 s hred 'n' v ac ® o perator ' s m anual air filter level 1. Tools required: 25-50 mm (1-2 in.) medium bristle brush. Parts required: 90008 repower tm air and filter kit note clean daily. 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filt...

Page 18

18 spark plug level 2. Tools required: 3/4 in. Spark plug deep socket, feeler gauge (preferably a wire gauge), parts required: spark plug, ngk bpmr-8y 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with a new one. Do not sand blast to clea...

Page 19: 'N' V

19 s hred 'n' v ac ® o perator ' s m anual cleaning cylinder fins 1. Remove spark lead and spark plug. 2. Remove four 3 mm hex screws, side handle and recoil starter. 3. Remove engine cover (five screws), pull cover away from engine. Loosely install spark plug to prevent dirt from entering cylinder....

Page 20

20 cylinder exhaust port level 3. Important the cylinder exhaust port must be inspected and cleaned of excess carbon every 3 months or 90 hours of operation in order to maintain this engine within the emissions durability period. Echo strongly recommends that you return your unit to your echo dealer...

Page 21: 'N' V

21 s hred 'n' v ac ® o perator ' s m anual carburetor adjustment engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break-in period your engine performance will increase and exhaust emissions will stabil...

Page 22

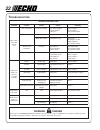

22 warning danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by ground- ing spark plug against cylinder, otherwise serious personal injury may result. T roubleshooting t r a h c g n i t o o h s e l b u o r t m e l b o r p k c e h c s u t a ...

Page 23: 'N' V

23 s hred 'n' v ac ® o perator ' s m anual 1. Store unit in a dry, dust free place, out of the reach of children. Warning danger do not store where fuel fumes may accumulate or reach an open flame or sparks. S torage warning danger during operation the muffler or catalytic muffler and surrounding co...

Page 24: Www.Echo-Usa.Com

Dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. Echo, incorporated 400 oakwood road lake zurich, il 60047 www.Echo-usa.Com s ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo produc...