- DL manuals

- Echo

- Trimmer

- HCA-2400

- Operator's Manual

Echo HCA-2400 Operator's Manual

H

EDGE

C

LIPPER

O

PERATOR

'

S

M

ANUAL

1

Shaft Hedge Clipper

Operator's Manual

MODELS:

SHC-1700

- Type 1

- S/N 001001 & Up

SHC-1700

- Type 1E

- S/N 501001 - 504767

SHC-2100

- Type 1

- S/N 001001 & Up

SHC-2100

- Type 1E

- S/N 501001 - 506455

SHC-2400

- Type 1

- S/N 001001 & Up

SHC-2400

- Type 1E

- S/N 00501001 &Up

HCA-2400

- Type 1E - S/N 00501001 &Up

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's Manual and a

Safety Manual. Both must be read and understood for proper and safe operation. Failure to do so could

result in serous injury.

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

99922202875

04/97

X7502248800

Summary of HCA-2400

Page 1

H edge c lipper o perator ' s m anual 1 shaft hedge clipper operator's manual models: shc-1700 - type 1 - s/n 001001 & up shc-1700 - type 1e - s/n 501001 - 504767 shc-2100 - type 1 - s/n 001001 & up shc-2100 - type 1e - s/n 501001 - 506455 shc-2400 - type 1 - s/n 001001 & up shc-2400 - type 1e - s/n...

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3

H edge c lipper o perator ' s m anual 3 s afety general description important see description and specification sections for full description and illustration of model variation in power head, and handle type. Important the enclosed message provides information necessary for the protection of the un...

Page 4

4 this unit is not designed to insulate against hazards associated with the contact of wires carrying electrical current. To avoid possible injury/death due to electrical shock or other hazards. Do not operate unit if any wires warning danger (power, telephone, cable, etc.) are closer than 15 feet (...

Page 5

H edge c lipper o perator ' s m anual 5 equipment before operation a complete check of the unit must be performed; - check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. - inspect fuel lines, tank and area around carburetor for fuel leaks. Do not operate unit if lea...

Page 6

6 personal condition and safety equipment warning danger hedge clipper users risk injury to themselves and others if the shaft hedge clipper is used improperly and or safety precautions are not followed. Proper clothing and safety gear must be worn when operating a shaft hedge clipper. Physical cond...

Page 7

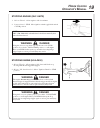

H edge c lipper o perator ' s m anual 7 hot humid weather heavy protective clothing can increase operator fatigue which may lead to heat stroke. Schedule heavy work for early morning or late afternoon hours when temperatures are cooler. 50 feet (15 meters) grip stance safe operation determine operat...

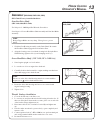

Page 8

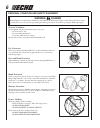

8 operation (hca) - never adjust blade angle of hca while standing. - only adjust cutting angle with hca resting flat on the ground, with the engine stop switch in the "stop" position. - adjust cutting angle by moving locking lever (a) up. Depress blade indexing lever (b) and change blade angle with...

Page 9

H edge c lipper o perator ' s m anual 9 to reduce the risk of rsi/cts, do the following: • avoid using your wrist in a bent, extended or twisted position. Instead try to maintain a straight wrist position. Also, when grasping, use your whole hand, not just the thumb and index finger. • take periodic...

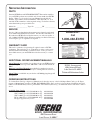

Page 10

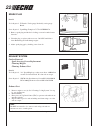

10 hca-2400 3 4 6 19 20 3 6 9 3 4 6 7 20 21 22 9 18 8 shc-1700, 2100 powerhead 14 15 12 10 11 13 16 17 10 11 16 12 15 13 14 23 19 8 8 9 shc-2400, hca-2400 powerhead 4 1 2 5 9 14 19 3 6 20 shc-2400 shc-2100 shc-1700 24 20 5 17.

Page 11

H edge c lipper o perator ' s m anual 11 1. Safety manual - read and understand this manual before operation. Keep manual in a safe location as a reference for safe operating techniques. 2. Operator's manual - read and understand this manual before operation. Keep manual in a safe location for futur...

Page 12

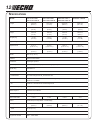

12 s pecifications l e d o m 1 e p y t 0 0 7 1 - c h s e 1 e p y t 0 0 7 1 - c h s 1 e p y t 0 0 1 2 - c h s e 1 e p y t 0 0 1 2 - c h s 1 e p y t 0 0 4 2 - c h s e 1 e p y t 0 0 4 2 - c h s e 1 e p y t 0 0 4 2 - a c h h t g n e l m m 5 3 3 1 ) . N i 5 . 2 5 ( m m 6 1 8 1 ) . N i 5 . 1 7 ( m m 0 9 1...

Page 13

H edge c lipper o perator ' s m anual 13 a ssembly ( hca-2400, shc-2100, 2400) shc-1700 is factory assembled in the box. Gear box/drive shaft (shc-2100, 2400, hca-2400) tools required: 8mm open end wrench, screwdriver parts required: power head/drive shaft assembly and gear box/blade assembly. Note ...

Page 14

14 p re -o peration fuel fuel requirements gasoline - use 89 octane [ ] (mid-grade or higher) gasoline or gasohol known to be good quality. Gasohol may contain up to 10% ethyl (grain) alcohol or 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methanol (wood alcohol) is not approved. Two s...

Page 15

H edge c lipper o perator ' s m anual 15 important stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days, ninety (90) days when a fuel stabilizer is added. Important stored two-stroke fuel may separate. Always shake fuel con- tainer thoroughly before each use. Equipment c...

Page 16

16 o peration ( shc models) - before starting the unit, equip yourself and any other person working within the 50 ft. (15 m) safety zone with the required protective equipment and clothing. - during operation, the complete unit, especially the gear box, drive shaft housing and power head muffler are...

Page 17

H edge c lipper o perator ' s m anual 17 starting cold engine warning danger blades should not move at idle. If blades move, readjust carbure- tor according to carburetor adjustment instructions in the manual or see your echo dealer, otherwise serious personal injury may result. 1. Ignition switch -...

Page 18

18 starting warm engine the starting procedure is the same as cold start except do not close the choke. Note if engine does not start after 4 pulls, use cold start procedure. Warning danger blades should not move at idle. If blades move, readjust carburetor according to carburetor adjustment instruc...

Page 19

H edge c lipper o perator ' s m anual 19 stopping engine ( shc units ) 1. Release throttle. Allow engine to idle for a minute 2. Ignition switch - stop. Move ignition switch toggle/slide switch to stop position. Note shc-1700, 2100 with front handle interlock will automatically shut unit off when re...

Page 20

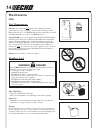

20 maintenance intervals m aintenance your echo product is designed to provide many hours of trouble free service. Regular scheduled maintenance will help achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for m...

Page 21

H edge c lipper o perator ' s m anual 21 air filter level 1. Tools required: cleaning brush, 1" or 2" medium bristle paint brush. Parts required: (shc models) 90008 repower tm air & fuel filter kit. (hca-2400) 90030 repower tm air & fuel filter kit. 1. Close choke (cold start position). This prevent...

Page 22

22 spark plug level 2. Tools required: t-wrench. Feeler gauge. Preferably a wire gauge. Brush. Parts required: spark plug, champion cj-7y or ngk bpm-7a 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with a new one. Do not sand blast to cle...

Page 23

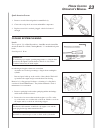

H edge c lipper o perator ' s m anual 23 spark arrestor screen 1. Remove screen holder and gasket from muffler body. 2. Clean carbon deposits from screen and muffler components. 3. Replace screen if it is cracked, plugged or has holes burned through. Cooling system cleaning level 3. Tools required: ...

Page 24

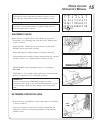

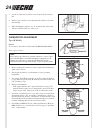

24 3. Use the wooden stick or brush to remove dirt from the cylinder fins. 4. Remove grass and leaves from the grid between the recoil starter and fuel tank. 5. When installing the engine cover, be certain the tab of the metal deflector shield is in the slot of the cover. Carburetor adjustment type ...

Page 25

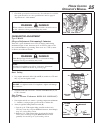

H edge c lipper o perator ' s m anual 25 7. Check idle speed and reset if necessary. If a tachometer is available, idle speed should be set to the specification found on page 12 "specifications" of this manual. Warning danger when carburetor adjustment is completed, blades should not move at idle, o...

Page 26

26 c. Final setting - set needle at mid point between lean rich drop-off points. (3) d. Turn 1/8 turn ccw (out) making mixture slightly richer. (4) 3. High speed adjustment. Adjust hi needle (a) with tachometer to achieve the specifications found on page 12 "specifications" of this manual. 4. Check ...

Page 27

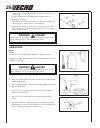

H edge c lipper o perator ' s m anual 27 shc-1700, 2100, 2400, hca-2400 tools required: grease gun with lithium grease, rag. Parts required: lithium based grease. 1. Clean dirt from grease fittings. 2. Carefully pump grease in each fitting. Do not force grease. Too much pressure will force grease pa...

Page 28

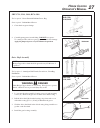

28 sharpening blades level 1. Tools required: flat file, small screwdriver parts required: gear box gasket, lithium based grease. Note blade sharpening requires removal of blades from the unit. Step by step instruction are included in the service manual that apply to your model. Note hedge clipper b...

Page 29

H edge c lipper o perator ' s m anual 29 4. Remove the old starter rope and prepare the new rope by first heating both ends to prevent fraying. 5. Pass one end of the rope through the opening of the drum and tie a knot. Press knot and end of rope in cavity of drum. 6. Thread the rope through the eye...

Page 30

30 h 9. Install drum. The loop in the spring must engage the slot in the drum. Replace the screw and washer. 10. Hold the rope in the notch (h) and rotate the drum counterclock- wise several turns. 11. Hold the drum to prevent it from rewinding, pull the excess rope taught with the handle and allow ...

Page 31

H edge c lipper o perator ' s m anual 31 3. Remove accumulation of grease, oil, dirt and debris from exterior of unit. 4. Perform all periodic lubrication and services that are required. 5. Tighten all the screws and nuts. 6. Drain the fuel tank completely and pull the recoil starter handle several ...

Page 32

Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 dealer? Call 1-800-432-echo echo, incorporated 400 oakwood road lake zurich, il 60047 technical publications orders s ervicing i nformation parts genuine echo parts and echo repower ™ parts and assemblies for your echo products are avail...