- DL manuals

- Echo

- Other

- PAS-260 PRO - 08-00

- Operator's Manual

Echo PAS-260 PRO - 08-00 Operator's Manual

Pro Attachment Series

Operator's Manual

MODELS,

PAS-260

Serial Number 003001001 & Up

X7502095800

X750001860

08/00

WARNING

DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's

Manual with this unit and a separate Operator's Manual and Safety Manual (if available)

with the attachment. All manuals must be read and understood for proper and safe

operation. Failure to do so could result in serious injury.

Summary of PAS-260 PRO - 08-00

Page 1

Pro attachment series operator's manual models, pas-260 serial number 003001001 & up x7502095800 x750001860 08/00 warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual with this unit and a separate operator's manual and safety manual (if availabl...

Page 2: –

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual as well as your attachment operator's manual and safety manual (if available) before operation. You will find these manuals ...

Page 3

P ro a ttachment s eries o perator ' s m anual 3 s afety decals locate these safety decals on your unit. The complete unit illustration, found in the "description" section, will help you locate them. Make sure the decals are legible and that you understand and follow the instructions on them. If a d...

Page 4: Warning

4 international symbols symbol description/application symbol form/shape symbol description/application symbol form/shape hot surface carburetor adjustment - idle speed carburetor adjustment - high speed mixture symbol description/application symbol form/shape symbol description/application symbol f...

Page 5

P ro a ttachment s eries o perator ' s m anual 5 spark arrestor - catalytic muffler / muffler • the muffler or catalytic muffler controls the exhaust noise and emissions. The spark arrestor screen prevents hot, glowing particles of carbon from leaving the muffler. Make sure the spark arrestor screen...

Page 6

6 personal condition and safety equipment warning danger pro attachment series users risk injury to themselves and others if the pro attachment series unit is used improperly and or safety precautions are not followed. Proper clothing and safety gear must be worn when operating a pro attachment seri...

Page 7

P ro a ttachment s eries o perator ' s m anual 7 safe operation determine operation area • provide all operators of this equipment with the operator's manuals and instructions for safe operation. • review the area where you will be operating. Look for hazards that could contribute to unsafe conditio...

Page 8

8 extended operation / extreme conditions vibration and cold -- it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sensatio...

Page 9

P ro a ttachment s eries o perator ' s m anual 9 emission control epa phase ii the emission control system for these engines are em (engine modification). D escription the echo product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, other assembly ma...

Page 10

10 1 15 3 4 5 6 7 8 9 10 11 12 13 14 16 17 2.

Page 11

P ro a ttachment s eries o perator ' s m anual 11 1. Power head - includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Muffler, spark arrestor - the muffler controls the exhaust noise while the spark arrestor prevents hot, glowing particles of carbon from leaving the muff...

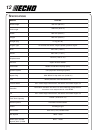

Page 12

12 s pecifications l e d o m 0 6 2 - s a p h t g n e l t f a h s ) . N i 8 . 9 2 ( m m 6 5 7 h t g n e l t i n u ) . N i 4 . 0 4 ( m m 5 2 0 1 h t d i w ) . N i 4 8 . 9 ( m m 0 5 2 t h g i e h ) . N i 4 8 . 9 ( m m 0 5 2 ) y r d ( t h g i e w ) . B l 0 . 9 ( g k 1 . 4 e p y t e n i g n e e n i g n e...

Page 13

P ro a ttachment s eries o perator ' s m anual 13 echo approved optional attachments warning danger • use only echo approved attachments for pro attachment series models. Serious injury may result from the use of non approved attachment combinations. Read and comply with all safety instructions list...

Page 14: - O

14 p re - o peration fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stroke oil - a two-stroke engine oil meet...

Page 15

P ro a ttachment s eries o perator ' s m anual 15 mixing instructions 1. Fill an approved fuel container with half of the required amount of gasoline. 2. Add 2-stroke oil to gasoline. 3. Close container and shake to mix oil with gasoline. 4. Add remaining gasoline and remix. 5. Install fuel containe...

Page 16

16 equipment check before operation a complete check of the unit and attachment must be performed; • check for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. • inspect fuel lines, tank and area around carburetor for fuel leaks. Do not operate unit if leaks are found. • check...

Page 17

P ro a ttachment s eries o perator ' s m anual 17 o peration • provide all operators of this equipment with the operator's manuals and instructions for safe operation. • before starting the unit, equip yourself and any other person working within the specified safety zone provided in your attach- me...

Page 18

18 4. Start - pull rope. Lay the unit on a flat clear area and pull the recoil starter handle (e) until engine fires. 5. Open choke - run. Move the choke lever to the open-run position. Restart engine if necessary and allow to warn up running at idle for several minutes. Note if engine does not star...

Page 19

P ro a ttachment s eries o perator ' s m anual 19 stopping engine 1. Release throttle. Allow engine to idle for a minute. 2. Stop switch - stop. Move stop switch button/lever (a) to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold s...

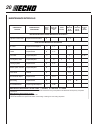

Page 20

20 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h y l r a e y 0 0 6 s r u o h s e r u d e c o r p e c n...

Page 21

P ro a ttachment s eries o perator ' s m anual 21 air filter level 1. Tools required: 25 or 50 mm (1 or 2 in.) medium bristle paint brush parts required: 90030 repower tm air and fuel filter kit 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air...

Page 22

22 warning danger do not perform maintenance on the muffler until engine and muffler are completely cool, otherwise serious personal injury may occur. Spark plug level 2. Tools required: screwdriver, feeler gauge (preferably a wire gauge), soft metal brush. Parts required: 90065 repower tune-up kit ...

Page 23

P ro a ttachment s eries o perator ' s m anual 23 1. Remove spark plug lead. 2. Remove two (2) muffler cover screws and muffler cover (a). 3. Remove screw and arm rest (b). 4. Remove engine cover (c). Important do not use a metal scraper to remove dirt from the cylinder fins. 5. Use brush to remove ...

Page 24

24 1. Remove muffler cover (a). 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 3. Remove spark arrestor screen cover (b), muffler gasket (c), screen gasket (d) and screen (e) from muffler body. 4. Clean carbon deposits from screen and muffler components. 5. R...

Page 25

P ro a ttachment s eries o perator ' s m anual 25 note every unit is run at the factory and the carburetor is set in compli- ance with epa phase ii emission regulations. This carburetor does not have acceleration and high speed adjustment needles. 1. Check idle speed and reset if necessary. If a tac...

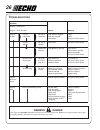

Page 26

26 t roubleshooting m e l b o r p d r a h s t r a t s - - e n i g n e t r a t s t o n s e o d - - e n i g n e e s u a c y d e m e r e n i g n e s k n a r c t a l e u f r o t e r u b r a c t a l e u f o n r o t e r u b r a c d e g g o l c r e n i a r t s l e u f d e g g o l c e n il l e u f r o t e r...

Page 27

P ro a ttachment s eries o perator ' s m anual 27 s torage long term storage (over 30 days) warning danger during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious p...

Page 28

Dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8 - 5 mon - fri c.S.T. S ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo products are available only from an authorized echo dealer. When you do need to buy par...