- DL manuals

- Echo

- Blower

- PB-2155

- Operator's Manual

Echo PB-2155 Operator's Manual

X753001880

04/04

MODEL

PB-2155

PB-2455

Serial Number 001001 & UP

OPERATOR'S MANUAL

MANUEL D'UTILISATION

BEDIENUNGSANLEITUNG

MANUALE D'ISTRUZIONI

WARNING, SEE OPERATOR'S MANUAL

LIRE SOIGNEUSEMENT CE MANUEL AVANT TOUTE UTILISATION

ACHTUNG SIEHE BEDIENUNGSANLEITUNG

ATTENZIONE, LEGGETE IL MANUALE D'ISTRUZIONI

ENGLISH

ITALIANO

DEUTSCH

FRANÇAIS

X7531134600

Summary of PB-2155

Page 1

X753001880 04/04 model pb-2155 pb-2455 serial number 001001 & up operator's manual manuel d'utilisation bedienungsanleitung manuale d'istruzioni warning, see operator's manual lire soigneusement ce manuel avant toute utilisation achtung siehe bedienungsanleitung attenzione, leggete il manuale d'istr...

Page 2

2 warning danger read rules for safe operation and instructions carefully. Echo provides this operator's manual which must be read and understood for proper and safe operation. T able of c ontents introduction ............................................................... 2 - the operator's manual ...

Page 3

3 p ower b lower o perator ' s m anual m anual s afety s ymbols and i mportant i nformation throughout this manual and on the product itself, you will find safety alerts and helpful, information messages preceded by symbols or key words. The following is an explanation of those symbols and key words...

Page 4

4 decals locate these safety decals on your unit. The illustration shows their location. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot be read, a new one can be ordered from your echo dealer. See parts ordering instructions for specif...

Page 5

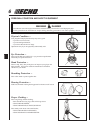

5 p ower b lower o perator ' s m anual equipment before operation a complete check of the unit must be performed: - check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. - inspect fuel lines, tank and area around carburettor for fuel leaks. Do not operate unit if lea...

Page 6

6 physical condition -- your judgment and physical dexterity may not be good: - if you are over tired or sick, - if you are taking medication, - if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protection -- wear goggles that meet ansi z 87.1 eye pro...

Page 7

7 p ower b lower o perator ' s m anual hot humid weather -- heavy protective clothing can increase operator fatigue which may lead to heat stroke. Schedule heavy work for early morning or late afternoon hours when temperatures are cooler. Safe operation setup/check operation area -- - review area to...

Page 8

8 extended operation / extreme conditions vibration and cold -- it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sensatio...

Page 9

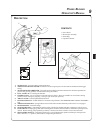

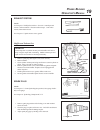

9 p ower b lower o perator ' s m anual 1. Spark plug - provides spark to ignite fuel mixture. 2. Throttle position lever - pull back to increase engine speed. Friction washers maintain throttle trigger setting. 3. Muffler/spark arrester - the spark arrester muffler controls the exhaust noise while t...

Page 10

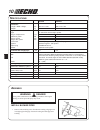

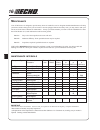

10 pb-2155 pb-2455 dimensions : length x width x height mm 330 x 215 x 340 330 x 215 x 340 weight kg 4.0 4.3 engine : type air cooled two stroke single cylinder engine displacement ml (cm 3 ) 21.2 23.6 maximum power kw 0.51 0.69 engine speed r/min 7,000 - 8,000 7,000 - 8,000 engine idle speed r/min ...

Page 11

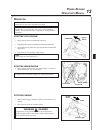

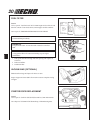

11 p ower b lower o perator ' s m anual screw install vacuum tube ( optional ) warning danger never perform maintenance or assembly proce- dures with engine running. When removing grid, stop engine. When applying as blower, fasten grid securely. 1. Remove a screw until fan grid is free. Pull fan gri...

Page 12

12 p re -o peration fuel fuel requirements -- • fuel is a mixture of regular grade petrol and an air-cooled 2-stroke engine oil of reputable brand name. Minimum 89 octane unleaded petrol is recommended. Do not use fuel containing methyl alcohol or more than 10 % of ethyl alcohol. • recommended mixtu...

Page 13

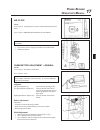

13 p ower b lower o perator ' s m anual o peration important check unit for loose nuts, bolts and screws daily. Important recoil starter: use short pulls - only 1/2-2/3 of rope length for starting. Do not allow the rope to snap back in. Always hold the unit firmly. Starting cold engine 1. Move ignit...

Page 14

14 operating blower warning danger always wear safety glasses, hearing protection and a face filter mask or serious personal injury may result. Do not point the blower pipe in the direction of people or pets. Read the safety section carefully. Important to avoid engine damage due to over revving, do...

Page 15

15 p ower b lower o perator ' s m anual operating vacuum (option) warning danger • always wear safety glasses and use a face filter mask. (read the safe operation section carefully.) • do not point the blower pipe in the direction of people or pets. • never operate unit without fan grid secured by t...

Page 16

16 component/system maintenance before every daily or 3 months 6 months yearly procedure use refuel every or or or 4 hours 100 hours 300 hours 600 hours air filter inspect/clean/replace • • r fuel filter inspect/clean/replace • r fuel line inspect/replace • carburettor adjust/ replace and adjudt • r...

Page 17

17 p ower b lower o perator ' s m anual air filter level 1. Tools required: cleaning brush, 25 mm or 50 mm medium bristle paint brush. Parts required: 90008 repower air & fuel filter kit. Note clean daily. 1. Close choke, remove wing nut, air cleaner cover and air filter. 2. Brush dust off filter. C...

Page 18

18 final adjustment important limiter caps prevent exceeding emission limits and over rich adjustment, but not over lean adjustment, which can cause engine failure: do not exceed recommended high speed engine rev during operation, or for long periods during adjustment. 1. Start engine, run at idle f...

Page 19

19 p ower b lower o perator ' s m anual exhaust system level 3. Tools required: phillips screwdriver. Scrench. 10 mm open end wrench. Soft metal brush. Wooden carbon scraper. 3 mm allen wrench, 4 mm allen wrench. Parts required: spark arrester screen, gasket. Muffler and exhaust port important carbo...

Page 20

20 fuel filter level 1. Tools required: fuel line hook. 203-254 mm length of wire with one end bent into a hook. Clean cloth, funnel, and an approved fuel container. Parts required: 90008 repower air & fuel filter kit note check fuel filter periodically. Important keep fuel tank clean - do not allow...

Page 21

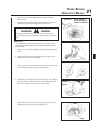

21 p ower b lower o perator ' s m anual untie knot starter handle eyelet 1. Remove four (4) screws holding starter assembly on engine, remove starter. 2. Hold starter drum in place and cut off or untie knot. Allow the drum to slowly turn until all spring tension is relieved. Warning danger the sprin...

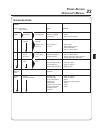

Page 22

22 pawl notch (a) 8. Hold the drum pawl side up and wind the rope on the drum anticlockwise, four (4) turns. 9. Install drum. The loop in the spring must engage the slot in the drum. Replace the screw and washer. 10. Hold the rope in the notch and rotate the drum anticlockwise several turns. 11. Hol...

Page 23

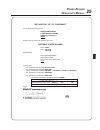

23 p ower b lower o perator ' s m anual trouble engine - starts hard cause remedy - does not start engine fuel at no fuel • fuel filter clogged • clean or replace. Cranks carburettor at carburettor • fuel line clogged • clean. • carburettor • see your echo dealer. Fuel at no fuel at • carburettor • ...

Page 24

24 s torage long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: 1. Store unit in a dry, dust free place, out of the reach of children. Warning danger do not store in...

Page 25

25 p ower b lower o perator ' s m anual gb declaration “ce” of conformity the undersigned manufacturer: kioritz corporation 7-2 suehirocho 1-chome ohme ; tokyo 198-8711 japan declares that the hereunder specified new unit: portable power blower brand : echo type : pb-2155 pb-2455 assembled by: echo,...

Page 26

26.

Page 27

27 p ower b lower o perator ' s m anual.

Page 28

Kioritz corporation 7-2 suehirocho 1-chome, ohme, tokyo, 198, japan phone: 81-428-326118 fax: 81-428-32-6145 echo, incorporated 400 oakwood road lake zurich, il 60047-1564 u.S.A..