- DL manuals

- Echo

- Blower

- PB-403

- Operator's Manual

Echo PB-403 Operator's Manual

Summary of PB-403

Page 1

Power blower operator's manual model: pb-403 serial number 05001001 & up warning danger read rules for safe operation and all instructions carefully. Echo provides this operator's manual which must be read and understood for proper and safe operation. X750002402 11/01 x7501126102.

Page 2

2 t able of c ontents introduction ............................................................... 2 - the operator's manual ....................................... 2 manual safety symbols and important information .. 3 safety ............................................................................

Page 3: Category I

3 p ower b lower o perator ' s m anual important note m anual s afety s ymbols and i mportant i nformation throughout this manual and on the product itself, you will find safety alerts and helpful, information messages preceded by symbols or key words. The following is an explanation of those symbol...

Page 4

4 international symbols symbol description/application symbol form/shape symbol description/application symbol form/shape hot surface carburetor adjustment - idle speed carburetor adjustment - high speed mixture symbol description/application symbol form/shape symbol description/application symbol f...

Page 5

5 p ower b lower o perator ' s m anual equipment • check unit for loose/missing nuts, bolts, and screws. Tighten and/or replace as needed. • inspect fuel lines, tank, and area around carburetor for fuel leaks. Do not operate unit if leaks are found. • do not use blower if any part is missing or dama...

Page 6

6 safe operation warning danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions and can cause serious injury or death. • review area to be cleared. Look for potential hazards such as stones or metal objects. • spectators and fellow...

Page 7

7 p ower b lower o perator ' s m anual d escription contents 1 - power head 1 - flex pipe 1 - pipe with swivel 1 - straight pipe 1 - curved pipe 1 - operator's manual 1 - warranty registration card 1 - echo emissions and warranty statement 1 - plastic bag 2 - clamps w/screws 2 - cable ties 1 - bottl...

Page 8

8 1. Safety decal - lists important safety precautions. 2. Spark plug - provides spark to ignite fuel mixture. 3. Spark arrestor - catalytic muffler / muffler - the muffler or catalytic muffler controls exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carbon f...

Page 9

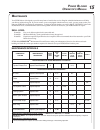

9 p ower b lower o perator ' s m anual s pecifications l e d o m 3 0 4 - b p h t g n e l ) . N i 6 . 2 1 ( m m 0 2 3 h t d i w ) . N i 3 . 7 1 ( m m 0 4 4 t h g i e h ) . N i 8 . 8 1 ( m m 0 8 4 ) y r d ( t h g i e w ) . B l 5 . 0 2 ( g k 3 . 9 e p y t e n i g n e e n i g n e e n il o s a g r e d n ...

Page 10

10 a ssembly warning danger never perform maintenance or assembly procedures with engine running or serious personal injury may result. Install blower pipes 1. Assemble clamps (a) onto both ends of flexible pipe (b). 2. Assemble straight pipe with swivel (c) into flexible pipe (b). 3. Position throt...

Page 11

11 p ower b lower o perator ' s m anual p re -o peration fuel fuel requirements gasoline - use 89 octane [r+m/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two s...

Page 12

12 o peration • provide all operators of this equipment with the operator's manual and instructions for safe operation. • check unit for loose nuts, bolts and screws daily. • recoil starter: use short pulls - only 1/2-2/3 of rope length for starting. Do not allow the rope to snap back in. Always hol...

Page 13

13 p ower b lower o perator ' s m anual starting warm engine 1. Stop switch slide stop switch (a) forward to run position. 2. Recoil starter pull recoil starter handle (e) and engine should start. Do not use choke (c). Note if engine does not start after 5 pulls, use cold start procedures. Stopping ...

Page 14

14 operating blower warning danger always wear safety glasses, hearing protection, a face filter mask and take all safety precautions or serious personal injury may result. Do not point the blower pipe in the direction of people or pets. Read the safety section carefully. Important to avoid engine d...

Page 15

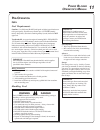

15 p ower b lower o perator ' s m anual m aintenance your echo blower is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your blower achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an...

Page 16

16 air filter level 1. Tools required: 25 - 50 mm (1 - 2 in.) medium bristle paint brush. Parts required: air filter p/n a226000030 note clean daily. 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumulated dirt fr...

Page 17

17 p ower b lower o perator ' s m anual 0.65 mm (0.026 in.) spark plug level 1. Tools required: 3/4 in. Spark plug deep socket, feeler gauge (preferably a wire gauge) parts required: spark plug , ngk bpm-8y p/n 15901019830 1. Remove spark plug , and check for fouling, worn and rounded center electro...

Page 18

18 cleaning cylinder fins 1. Remove engine cover (five screws), pull cover away from engine. Clean cylinder fins (b) to allow cooling air to pass freely. Exhaust system spark arrestor screen level 2. Tools required: cross head screwdriver parts required: spark arrestor screen p/n 14586206720, (1) ga...

Page 19

19 p ower b lower o perator ' s m anual carburetor adjustment - general engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break-in period your engine performance will increase and exhaust emissions will...

Page 20

20 initial adjustment 1. With engine off, turn hi speed screw (c) counterclockwise to stop. 2. Turn lo speed screw (b) midway between stops. 3. Turn idle screw (a) until tip of screw just touches throttle plate; then turn three (3) turns clockwise. Final adjustment important limiter caps prevent exc...

Page 21

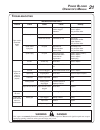

21 p ower b lower o perator ' s m anual t roubleshooting warning danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark near an open spark plug opening, otherwise serious personal injury may result. T r a h c g n i t o o h s e l b u o r t m e l ...

Page 22

22 2. Place the stop switch in the "stop" position. 3. Remove accumulation of grease, oil, dirt and debris from exterior of unit. 4. Perform all periodic lubrication and services that are required. 5. Tighten all screws and nuts. 6. Drain the fuel tank completely and pull the recoil starter handle s...

Page 23: Notes

23 p ower b lower o perator ' s m anual notes.

Page 24

Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 www.Echo-usa.Com dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. S ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo p...