- DL manuals

- Echo

- Kitchen Appliances

- PB-610

- Operator's Manual

Echo PB-610 Operator's Manual

Summary of PB-610

Page 1

Power blower operator's manual model pb-610 warning danger read rules for safe operation and all instructions carefully. Echo provides this operator's manual which must be read and understood for proper and safe operation. X753002790 12/06 x7531122000

Page 2: ’

2 t able of c ontents introduction .................................................................. 2 - the operator's manual .......................................... 2 safety ............................................................................ 3 - manual safety symbols and important inf...

Page 3

3 p ower b lower o perator ' s m anual important the enclosed message provides information necessary for the protection of the unit. Note this enclosed message provides tips for use, care and maintenance of the unit. S afety manual safety symbols and important information important note throughout t...

Page 4

4 physical condition your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protection wear eye protection that meets ansi z87.1 or ce requi...

Page 5

5 p ower b lower o perator ' s m anual repetitive stress injuries it is believed that overusing the muscles and tendons of the fingers, hands, arms, and shoulders may cause soreness, swelling, numbness, weakness, and extreme pain in those areas. Certain repetitive hand activities may put you at a hi...

Page 6

6 emission control label (located on engine) (example only, information on label varies by family). Product emission durability the 300 hour emission durability compliance period is the time span selected by the manufacturer certifying the engine emissions output meets applicable emissions regulatio...

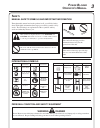

Page 7: Category III

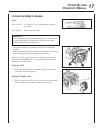

7 p ower b lower o perator ' s m anual 1 2 3 4 5 6 7 8 10 11 12 9 13 14 hot decal (near muffler) general warning decal (located on top of blower housing) p/n 89016006361 p/n 89016009461 72 category iii db(a) measured at 50 ft. (15m) per ansi b175.2 p/n x508000150 sound label (located on blower housi...

Page 8

8 1. Air cleaner - contains replaceable air filter element. 2. Spark plug - provides spark to ignite fuel mixture. 3. Spark arrestor - catalytic muffler / muffler - the muffler or catalytic muffler controls exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carb...

Page 9

9 p ower b lower o perator ' s m anual a ssembly warning danger never perform maintenance or assembly procedures with engine running or serious personal injury may result. Install blower pipes / stick handle 1. Assemble clamps (a) onto both ends of flexible pipe (b). 2. Assemble swivel pipe (c) into...

Page 10

10 o peration notice: use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor performance, or severe engine damage and void the product warranty. Read and follow instructions in the storage section of this manual. Fuel warning alternative fuels, such...

Page 11

11 p ower b lower o perator ' s m anual o i t a r 1 : 0 5 - x i m li o o t l e u f . S . U c i r t e m s a g l i o s a g l i o s n o ll a g . Z o .L f r e ti l . C c 1 2 5 6 . 2 2 . 5 3 1 4 8 0 2 0 8 0 6 1 0 0 4 mixing instructions 1. Fill an approved fuel container with half of the required amount ...

Page 12

12 d 4. Recoil starter pull recoil starter handle (d) and engine should start. 5. Choke move choke (b) to run ( ) position and if necessary, restart engine. Note if engine does not start after 5 pulls, repeat instructions 2-5. Note allow engine to warm up before use. Starting warm engine the startin...

Page 13

13 p ower b lower o perator ' s m anual note never use a higher speed setting than necessary to perform a task. Remember, the higher the engine speed, the louder the blower noise. Minimize dust by using blower at lower speeds and by dampening material with water/mist when necessary. Keep debris on y...

Page 14

14 m aintenance your echo unit is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your unit achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for maintenance. To ...

Page 15

15 p ower b lower o perator ' s m anual warning danger allow the engine and muffler to completely cool before performing any maintenance activity. Air filter level 1. Tools required: 25 - 50mm (1 - 2 in.) cleaning brush parts required: tune up kit p/n 90071c note always brush dirt and debris away fr...

Page 16

16 spark plug level 1. Tools required: 3/4 in. Spark plug deep socket, feeler gauge parts required: repower tm tune up kit p/n 90071 important use only ngk bpm-8y spark plug (bpmr-8y in canada) otherwise severe engine damage may occur. 1. Remove spark plug and check for fouling, or worn and rounded ...

Page 17

17 p ower b lower o perator ' s m anual cooling systems cleaning level 2. Tools required: 25 - 50 mm (1 - 2 in.) cleaning brush, cross head screwdriver parts required: none, if you are careful. Important to maintain proper engine operating temperatures, cooling air must pass freely through the cylin...

Page 18

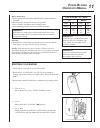

18 a d c b e exhaust system spark arrestor screen level 2. Tools required: cross head screwdriver, soft metal brush parts required: spark arrestor screen. Gaskets (3) important carbon deposits in muffler will cause a drop in engine output and overheating. Spark arrestor screen must be checked period...

Page 19

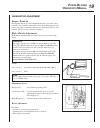

19 p ower b lower o perator ' s m anual carburetor adjustment engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break-in period your engine performance will increase and exhaust emissions will stabilize...

Page 20

20 initial adjustment 1. With engine off, turn hi speed screw (c) counterclockwise to stop. 2. Turn lo speed screw (b) midway between stops. 3. Turn idle screw (a) until tip of screw just touches throttle plate; then turn three (3) turns clockwise. Final adjustment important limiter caps prevent exc...

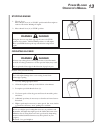

Page 21

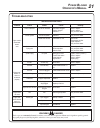

21 p ower b lower o perator ' s m anual t r a h c g n i t o o h s e l b u o r t m e l b o r p k c e h c s u t a t s e s u a c y d e m e r - s k n a r c e n i g n e / d r a h s tr a t s t' n s e o d tr a t s r o t e r u b r a c t a l e u f r o t e r u b r a c t a l e u f o n d e g g o l c r e n i a r...

Page 22

22 2. Place the stop switch in the "stop" position. 3. Remove accumulation of grease, oil, dirt and debris from exterior of unit. 4. Perform all periodic lubrication and services that are required. 5. Tighten all screws and nuts. 6. Drain the fuel tank completely and pull the recoil starter handle s...

Page 23

23 p ower b lower o perator ' s m anual s pecifications model ---------------------------------------------------------- pb-610 length ------------------------------------------------------------ 325 mm (12.8 in.) width ------------------------------------------------------------- 520 mm (20.5 in.) ...

Page 24

Dealer? Call 1-800-432-echo 1-800-432-3246 or www.Echo-usa.Com echo, incorporated 400 oakwood road lake zurich, il 60047 www.Echo-usa.Com consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. 11001001/11999999 12001001/12999999 additional or replacement manuals safety manuals in engli...