- DL manuals

- Echo

- Edger

- PE-2000 Type 1

- Operator's Manual

Echo PE-2000 Type 1 Operator's Manual

P

OWER

E

DGER

O

PERATOR

'

S

M

ANUAL

1

Power Edger

Operator's Manual

MODELS

PE-2000 Type 1/1E

Serial Number 001001 & Up

PE-2000 Type 2E

Serial Number 508036 & Up

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's Manual

and a Safety Manual. Both must be read and understood for proper and safe operation.

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

PE-2400 Type 1/1E

Serial Number 001001 & Up

PE-3100 Type 1/1E

Serial Number 001001 & Up

89869555332

12/98

X7532271103

Summary of PE-2000 Type 1

Page 1

P ower e dger o perator ' s m anual 1 power edger operator's manual models pe-2000 type 1/1e serial number 001001 & up pe-2000 type 2e serial number 508036 & up warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must ...

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operations tips and ...

Page 3: & I

P ower e dger o perator ' s m anual 3 m anual s afety s ymbols & i mportant i nformation throughout this manual and on the product itself, you will find safety alerts and helpful, information messages preceded by symbols or key words. The following is an explanation of those symbols and key words an...

Page 4

4 warning danger this unit can be dangerous and cause serious injury if improperly used. To reduce injury risk to operator, helpers and bystanders, read and understand the operator's and safety manuals, which are provided in spanish. International symbols symbol description/application symbol form/s...

Page 5: Attachments

P ower e dger o perator ' s m anual 5 fuel warning danger fuel is very flammable. Use extreme care when mixing, storing or handling or serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks/cans may be u...

Page 6

6 personal condition & safety equipment warning danger edger users risk injury to themselves and others if the edger is used improperly and or safety precautions are not followed. Proper clothing and safety gear must be worn when operating a edger. Eye protection — wear eye protection that meets ans...

Page 7

P ower e dger o perator ' s m anual 7 hot humid weather -- heavy protective clothing can increase operator fatigue which may lead to heat stroke. Schedule heavy work for early morning or late afternoon hours when temperatures are cooler safe operation determine operation area • review the area to be...

Page 8

8 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sensations ...

Page 9

P ower e dger o perator ' s m anual 9 13 15 16 17 19 pe-2000 d escription emission control the emission control system for this engine is em (engine modification). An emission control label is located on the engine. (this is an example only, information on label varies by engine family). Important e...

Page 10

10 c pe-2400 pe-3100 contents __ 1, edger assembly __ 1, power head __ 1, drive shaft assembly __ 1, plastic bag (co-pack) __ 1, operators manual __ 1, safety manual __ 1, warranty registration card __ 1, echo emissions and warranty statement __ 1, 50:1 1 gal. Echo oil mix __ 1, front handle __ 4, 5...

Page 11

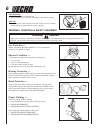

P ower e dger o perator ' s m anual 11 1. Debris shield/flap - mounted over the cutting attachment. Helps protect operator by deflecting debris produced during the edging operation. 2. Blade - rotates to provide cutting action. 3. Wheel - adjustable up/down, sets depth of blade. 4. Guard decal (see ...

Page 12

12 s pecfications * certain internal combustion engines operated in forest, brush and/or grass-covered areas in washington, oregon, idaho, california, minnesota, new jersey and maine must be equipped with a spark arrestor. This requirement also applies to all u.S. Forest service lands. In some of th...

Page 13

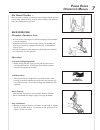

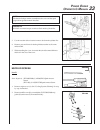

P ower e dger o perator ' s m anual 13 a ssembly drive shaft / power head tools required: 8mm x 10mm open end wrench (pe-2000, pe-2400), 4mm hex wrench (pe-3100) 1. Stand engine on a level surface. 2a. (pe-2000/2400) loosen the two bolts (a) at drive shaft end of engine. 2b. (pe-3100) loosen two bol...

Page 14

14 front handle tools required:cross-head screwdriver 1. Assemble front handle and bracket loosely to drive shaft. 2. Position front handle in comfortable operating position and tighten screws. Pe-2400 pe-3100 front handle note steps 5, 6 & 7 required for pe-2400 and pe-3100 only. 5. Connect ignitio...

Page 15

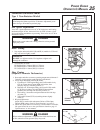

P ower e dger o perator ' s m anual 15 p re -o peration fuel fuel requirements -- gasoline - use 89 octane [ ] gasoline known to be good quality. Gasoline may contain up to 10% ethanol (grain alcohol) or 15% mtbe (methyl tertiary-butyl ether). Gasoline containing methanol (wood alcohol) is not appro...

Page 16

16 o peration • before starting the unit, equip yourself and any other person working within the 50 ft. (15m) safety zone with the required protective equipment and clothing. • provide all operators of this equipment with the operator's manual and instruction for safe operation. • during operation, ...

Page 17

P ower e dger o perator ' s m anual 17 4. Starting - lay trimmer on a flat, clear area. Firmly grasp throttle grip with left hand and fully depress throttle trigger to wide open position. Rapidly pull recoil starter handle/rope (d) until engine fires (or maximum five [5] pulls). 5. After engine fire...

Page 18

18 if engine does not stop, close choke to stall engine. Have your echo dealer inspect and repair stop switch before using edger again or serious personal injury may result. Stopping engine 1. Release throttle trigger and allow engine to idle. 2. Place stop switch in stop position. Warning danger pe...

Page 19

P ower e dger o perator ' s m anual 19 5. Before edging, plan your direction of travel so that the unit will always be positioned on your right side and so that you walk on a hard surface whenever possible. 6. Hold edger as shown. Warning danger before edging, be sure to read and understand the enti...

Page 20

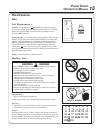

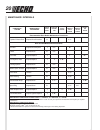

20 maintenace intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h y l r a e y 0 0 6 s r u o h s e r u d e c o r p e c n ...

Page 21

P ower e dger o perator ' s m anual 21 fuel filter level 1 . Parts required: (pe-2000) 90008 repower air & fuel filter kit (pe-2400/3100) 90030 repower air & fuel filter kit warning danger fuel is very flammable. Use extreme care when mixing, storing or handling. 1. Use a clean rag to remove loose d...

Page 22

22 spark plug level 2. Parts required: spark plug, ngk bpmr-7a 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with a new one. Do not sand blast to clean. Remaining sand will damage engine. 3. Adjust spark plug gap by bending outer electrod...

Page 23

P ower e dger o perator ' s m anual 23 note the throttle linkage remains assembled to the cover and the spark plug lead and grommet remain installed. Important do not use a metal scraper to remove dirt from the cylinder fins. 3. Use the wooden stick or brush to remove dirt from the cylinder fins. 4....

Page 24

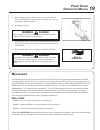

24 3. Clean carbon deposits from screen and muffler components. 4. Replace screen if it is cracked, plugged or has holes burned through. 5. Reassemble parts with new gasket in reverse order. Pe-3100 d e b carburetor adjustment type 1e emission models level 2. Parts required: none. Note every unit is...

Page 25

P ower e dger o perator ' s m anual 25 carburetor adjustment type 1 non-emission models note if carburetor has limiter caps follow "carburetor adjustment" proce- dures for type 1e models on previous page. Idle speed adjustment turn "idle" speed adjustment screw (c) cw (clockwise) until cutting attac...

Page 26

26 8. Install outer adapter (e) and nut (d). Tighten nut (d) firmly, counterclockwise (ccw). Important never reuse old split pin. 9. Install new split pin (a) (#89850201130) to secure nut. Lubrication level 1. Parts required: lithium base grease. Note grease gear case every 50 hours of use. Replace ...

Page 27

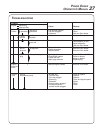

P ower e dger o perator ' s m anual 27 t roubleshooting remedy muffler wet with fuel engine does not crank no fuel at cylinder spark at end of plug wire no spark at end of plug wire spark at plug no spark at plug engine cranks fuel at carburetor no fuel at carburetor open choke clean/replace air fil...

Page 28

28 s s s s s torage torage torage torage torage long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: 1. Store unit in a dry, dust free place, out of the reach of chil...

Page 29: Notes

P ower e dger o perator ' s m anual 29 notes.

Page 30

30 echo, incorporated 400 o akwood r oad l ake z urich , il 60047 pe-2000 type 1e s/n 001001 & up part number 99922202766 pe-2000 type 2e s/n 001001 & up part number 99922202991 pe-2400 type 1e s/n 001001 & up part number 99922202767 pe-3100 type 1e s/n 001001 & up part number 99922202929 ordering i...