- DL manuals

- Echo

- Trimmer

- PE-230

- Operator's Manual

Echo PE-230 Operator's Manual

Power Edger

Operator's Manual

MODELS

PE-230

Serial Number 03001001 - 04999999

PE-260

Serial Number 03001001 - 04999999

WARNING

DANGER

X750001850

08/00

X7502095700

Read rules for safe operation and instructions carefully. ECHO provides an

Operator's Manual and a Safety Manual. Both must be read and understood for

proper and safe operation.

Summary of PE-230

Page 1

Power edger operator's manual models pe-230 serial number 03001001 - 04999999 pe-260 serial number 03001001 - 04999999 warning danger x750001850 08/00 x7502095700 read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and u...

Page 2: Warning

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operations tips and ...

Page 3

P ower e dger o perator ' s m anual 3 s afety decals locate these safety decals on your unit. The complete unit illustration found in the "description" section, will help you locate them. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot ...

Page 4

4 symbol description/ application symbol form/ shape symbol description/ application symbol form/ shape hot surface carburetor adjustment - idle speed carburetor adjustment - high speed mixture symbol description/ application symbol form/ shape symbol description/ application symbol form/ shape read...

Page 5: Warning

P ower e dger o perator ' s m anual 5 • check that front handle is adjusted for safe, comfortable operation. See assembly for proper adjustment. Warning danger • use only echo approved attachments. Serious injury may result from the use of a non approved attachment combination. Read and comply with ...

Page 6: Warning

6 important spilled fuel is a leading cause of hydrocarbon emissions. Some states may require the use of automatic fuel shut-off containers to reduce fuel spillage. Contact your echo dealer for ordering information. After refueling; • wipe any spilled fuel from the unit. • move at least 3 m (10 ft.)...

Page 7

P ower e dger o perator ' s m anual 7 hand protection -- wear no-slip, heavy duty work gloves to improve your grip on the edger handles. Gloves also reduce the transmission of machine vibration to your hands. Hearing protection -- echo recommends wearing hearing protection whenever unit is used. Pro...

Page 8

8 operation warning danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions and can cause serious injury or death. Use proper clothing & equipment • before starting the unit, equip yourself and any other person working within the 15...

Page 9

P ower e dger o perator ' s m anual 9 extended operation / extreme conditions vibration and cold -- it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may...

Page 10

10 d escription the echo product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, shield installation and other assembly may be necessary. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missin...

Page 11

P ower e dger o perator ' s m anual 11 12 13 15 16 17 18 19 14 20 pe-230 21 22 1 2 3 4 5 6 7 8 9 10 11 pe-230

Page 12

12 1 2 3 4 5 6 7 8 9 10 11 pe-260 12 13 15 16 17 18 19 14 20 pe-260 21 22.

Page 13

P ower e dger o perator ' s m anual 13 1. Power head - factory assembled. Includes the engine, clutch, fuel system, ignition system and starter. 2. Stop switch - "slide switch" mounted on top of the throttle trigger housing. Move switch forward to run, back to stop. 3. Front handle - the front handl...

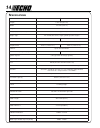

Page 14

14 s pecifications l e d o m 0 3 2 - e p 0 6 2 - e p h t g n e l ) . N i 1 . 9 6 ( m m 5 5 7 1 h t d i w ) . N i 4 . 2 1 ( m m 5 1 3 t h g i e h ) . N i 2 . 1 1 ( m m 5 8 2 ) d a e h r e t t u c / w y r d ( t h g i e w ) . B l 8 . 3 1 ( g k 2 . 6 e p y t e n i g n e e n i g n e e n i l o s a g r e d...

Page 15

P ower e dger o perator ' s m anual 15 a ssembly drive shaft / power head tools required: 4 mm hex wrench parts required: power head, drive shaft assembly 1. Loosen, the bolt (a) at engine drive shaft clamp. 2. Carefully fit drive shaft assembly to engine making sure that inner drive shaft engages i...

Page 16

16 c a b d e throttle linkage and ignition leads pe-260 1. Close choke and remove air filter cover. 2. Loosen nut (a) and place threaded end of throttle linkage in bracket slot. Finger tighten nut (a). 3. Place inner cable in slot of carburetor swivel (b) and tighten nut (a). 4. Check throttle for f...

Page 17

P ower e dger o perator ' s m anual 17 p re -o peration fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stroke...

Page 18

18 important spilled fuel is a leading cause of hydrocarbon emissions. Some states may require the use of automatic fuel shut-off containers to reduce fuel spillage. Contact your echo dealer for ordering information. After refueling; • wipe any spilled fuel from the unit. • move at least 3 m (10 ft....

Page 19: Warning

P ower e dger o perator ' s m anual 19 determine operation area warning danger inspect starting area for hazards such as rocks, glass, debris etc. Which could be contacted by the cutting attachment when starting. Keep helpers and bystanders at least 15 m (50 ft.) from starting area, otherwise seriou...

Page 20: Warning

20 starting cold engine warning danger the cutting attachment should not rotate at idle. If attachment rotates, readjust carburetor according to "carburetor adjustment" instructions in this manual or see your echo dealer, otherwise serious personal injury may result. 1. Stop switch - start/run. Move...

Page 21: Warning

P ower e dger o perator ' s m anual 21 starting warm engine the starting procedure is the same as cold start except do not close the choke. Note if engine does not start after 5 pulls, use cold start procedure. Warning danger when engine starts, the cutting attachment may rotate even with the thrott...

Page 22: Warning

22 stopping engine 1. Release throttle. Allow engine to idle for a minute. 2. Stop switch - stop. Move stop switch button (a) backward to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold start position - to stall engine. Have your e...

Page 23: Warning

P ower e dger o perator ' s m anual 23 7. When starting to edge, run the engine at full throttle, and lower the blade gently into the ground, being careful not to hit the concrete with the blade. 8. Don't force the blade. Move as quickly as the blade will allow. Warning danger the complete unit, spe...

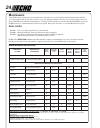

Page 24

24 m aintenance your echo edger is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your edger achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for maintenance. T...

Page 25

P ower e dger o perator ' s m anual 25 air filter level 1. Tools required: cleaning brush, 25 or 50 mm (1 or 2 in.) medium bristle paint brush. Parts required: (pe-230) 90008 repower tm air & fuel filter kit. (pe-260) 90030 repower tm air & fuel filter kit.. 1. Close choke (cold start position). Thi...

Page 26

26 0.65 mm (0.026 in.) warning danger catalytic mufflers operate at extremely high temperatures. Muffler area must be kept clean. Do not perform maintenance on the muffler until engine and muffler are completely cool, otherwise serious personal injury may occur. Spark plug level 2. Tools required: t...

Page 27

P ower e dger o perator ' s m anual 27 1. Remove spark plug lead. 2. Remove two (2) muffler cover screws and muffler cover (a). 3. Remove screw and arm rest (b). 4. Remove cylinder cover (c). Important do not use a metal scraper to remove dirt from the cylinder fins. 5. Use brush to remove dirt from...

Page 28

28 spark arrestor screen 1. Remove two (2) muffler cover screws and muffler cover (a). 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 3. Remove spark arrestor screen cover (b), screen holder (c), gasket (d) and screen (e) from muffler body. 4. Clean carbon de...

Page 29: Warning

P ower e dger o perator ' s m anual 29 note every unit is run at the factory and the carburetor is set in compli- ance with epa phase ii regulations. This carburetor does not have acceleration and high speed adjustment needles. 1. Check idle speed and reset if necessary. If a tachometer is avail- ab...

Page 30

30 4. Remove blade nut (d) in a clockwise direction using box wrench supplied. Remove outer blade adapter (e), blade (f) and inner blade adapter (b). 5. Remove plug (g) and grease gear housing. Do not over fill - grease will emerge between pto shaft (c) and seal when over full. Note shield cover not...

Page 31

P ower e dger o perator ' s m anual 31 t roubleshooting warning danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark near an open spark plug opening, otherwise serious personal injury may result. M e l b o r p d r a h s t r a t s - - e n i g n...

Page 32: Warning

32 long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: 1. Store unit in a dry, dust free place, out of the reach of children. Warning danger do not store in enclosur...

Page 33: Notes

P ower e dger o perator ' s m anual 33 notes.

Page 34: Notes

34 notes.

Page 35: Notes

P ower e dger o perator ' s m anual 35 notes.

Page 36

Dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8 - 5 mon - fri c.S.T. Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 www.Echo-usa.Com s ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo product...