- DL manuals

- Echo

- Pole Saw

- Power Pruner PPT-265S

- Operator's Manual

Echo Power Pruner PPT-265S Operator's Manual

Summary of Power Pruner PPT-265S

Page 1

Power pruner tm operator's manual model: ppt-265s warning x770001241 09/08 x7702092901 read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and understood for proper and safe operation..

Page 2

2 copyright© 2008 by echo, incorporated all rights reserved. I ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job dependability. Read and understand this manual and the safety manual you found in the same package. You will find...

Page 3: Ower

P ower p runer tm o perator ' s m anual 3 s afety m anual s afety s ymbols and i mportant i nformation hot surface symbol description/application symbol form/shape symbol description/application symbol form/shape read and understand operator's manual. Wear eyes, ears and head protection fuel and oil...

Page 4

4 physical condition your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protection wear eye protection that meets ansi z87.1 or ce re- q...

Page 5: Ower

P ower p runer tm o perator ' s m anual 5 danger all over head electrical conductors and communications wires can have electricity flow with high voltages. This unit is not insulated against electrical current. Never touch wires directly or indirectly when pruning, otherwise serious injury or death ...

Page 6

6 keep a solid stance • maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not work in odd positions or on ladders. Do not overreach. • operate the power pruner tm only from the ground or out of an ap- proved bucket lift. • always evaluate the branch...

Page 7: Ower

P ower p runer tm o perator ' s m anual 7 equipment warning serious injury may result from the use of non approved guide bar and saw chain combinations. Echo, inc. Will not be responsible for the failure of cutting devices or accessories which have not been tested and approved by echo for use with t...

Page 8

8 an emission control label is located on the engine. (this is an example only, information on label varies by engine family). Product emission durability the 300 hour emission durability compliance period is the time span selected by the manufacturer certifying the engine emissions output meets app...

Page 9: Ower

P ower p runer tm o perator ' s m anual 9 1 12 11 10 2 9 8 7 6 5 4 p/n x505002371 3 p/n x505002361.

Page 10

10 1. Power head - includes the engine, clutch, fuel system, ignition system and starter. 2. Throttle trigger - spring loaded to return to idle when released. During acceleration press trigger gradu- ally for best operating technique. 3. Shoulder harness - an adjustable strap that suspends the unit ...

Page 11: Ower

P ower p runer tm o perator ' s m anual 11 c ontents due to packaging restriction the echo product you have purchased requires some assembly. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missing parts. Use the contents list to check for mi...

Page 12

12 4. Align flexible drive shaft coupler with engine socket and slide together until locating hole in shaft is visible through locating hole in engine housing. 5. Install locating screw (b) and tighten clamping bolts (a). B a a e f throttle linkage and ignition leads 1. Install throttle linkage cabl...

Page 13: Ower

P ower p runer tm o perator ' s m anual 13 d c c i e f d warning saw chain is sharp! Always wear gloves when handling assembly, otherwise serious personal injury may result. 1. Loosen the two (2) screws (c) and locator screw (d) on cutting attachment. 2. Loosen clamp knob (e) turning counter clockwi...

Page 14

14 saw chain tension adjustment warning always disconnect spark plug wire before servicing cutting attach- ment. Wear gloves when handling saw chain, otherwise serious personal injury may result. To adjust saw chain tension 1. Move stop switch to stop position. 2. Disconnect spark plug lead. 3. Loos...

Page 15: Ower

P ower p runer tm o perator ' s m anual 15 notice: use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor performance, or severe engine damage and void the product warranty. Read and follow instructions in the storage section of this manual. Fuel wa...

Page 16

16 mixing instructions 1. Fill an approved fuel container with half of the required amount of gasoline. 2. Add the proper amount of 2-stroke oil to gasoline. 3. Close container and shake to mix oil with gasoline. 4. Add remaining gasoline, close fuel container, and remix. Important spilled fuel is a...

Page 17: Ower

P ower p runer tm o perator ' s m anual 17 automatic oiling system 1. Wipe debris from around oil fill cap. 2. Remove oil fill cap and fill reservoir with a quality, low viscosity guide bar and saw chain oil. Note the discharge volume of the automatic oiler is preset to deliver 3 to 4 cc/min. At nor...

Page 18

18 c b d d a starting cold engine warning the attachment will operate immediately when the engine starts and could result in loss of control and possible serious injury. Keep movable parts of the attachment off the ground and away from objects that could become entangled or thrown. 1. Stop switch mo...

Page 19: Ower

P ower p runer tm o perator ' s m anual 19 starting warm engine the starting procedure is the same as cold start except do not close the choke, and do not depress throttle trigger to wide open position. Warning the attachment should not move at idle, otherwise serious personal injury may result. Not...

Page 20

20 stopping engine 1.Throttle. Release throttle trigger, and allow engine to return to idle before stopping engine. 2.Stop switch. Move stop switch button (a) backward to stop position. Warning if engine does not stop when stop switch is moved to stop posi- tion, close choke - cold start position - ...

Page 21: Ower

P ower p runer tm o perator ' s m anual 21 warning moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop before removing obstruc...

Page 22

22 air filter level 1. Tools required: cleaning brush 25 or 50 mm (1 or 2 in.) parts required: air filter 1. Close choke (cold start position [ ]). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumulated dirt from air cleaner area. 2. Remove air filte...

Page 23: Ower

P ower p runer tm o perator ' s m anual 23 spark plug level 2. Tools required: 10x19mm (13/32x3/4in) t-wrench, feeler gauge, soft metal brush parts required: spark plug ngk bpm-8y important use only ngk bpm-8y spark plug (bpmr-8y in canada) oth- erwise severe engine damage may occur. 1. Remove spark...

Page 24

24 exhaust system spark arrestor screen level 2. Tools required: cross head screwdriver, 4mm hex wrench, soft metal brush parts required: spark arrestor screen, gasket 1. Remove muffler cover screw and muffler cover (a). 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering c...

Page 25: Ower

P ower p runer tm o perator ' s m anual 25 exhaust port cleaning level 2. Tools required: 4mm hex wrench, 8mm wrench, wood or plastic scraper parts required: as needed: heat shield 1. Remove spark plug lead from spark plug, and remove muffler cover (1 screw). 2. Place piston at top dead center. Remo...

Page 26

26 carburetor adjustment engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break- in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can be adjusted as requ...

Page 27: Ower

P ower p runer tm o perator ' s m anual 27 guide bar and saw chain replacement warning never try to replace or adjust guide bar and saw chain with engine running. Always disconnect spark plug wire before servicing guide bar and saw chain. This saw chain is very sharp, wear heavy gloves to protect yo...

Page 28

28 a b to adjust saw chain tension 1. Move stop switch to stop position. 2. Disconnect spark plug lead. 3. Loosen two gearcase cover nuts (a) until finger tight. 4. Hold the bar nose up, and turn the adjuster screw (b) clockwise un- til the chain fits snugly against the underside of the bar, as show...

Page 29: Ower

P ower p runer tm o perator ' s m anual 29 important chain and guide bar gauge size must be identical. Use bar/chain combinations shown in table above. Ppt-265 power pruner b&c combinations bar p/n chain p/n chain type links pitch gauge standard 12" regular bar p/n 12aocd3744 m91vx44g 91 44 3/8" .05...

Page 30

30 filing saw chain level 2. Tools required: 4 mm (5/32 in.) round file, flat file, depth gauge important dull or damaged cutters will result in poor cutting performance, increased vibration, and premature saw chain failure. Warning always stop engine and disconnect spark plug wire before servic- in...

Page 31: Ower

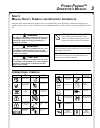

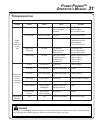

P ower p runer tm o perator ' s m anual 31 t roubleshooting danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by ground- ing spark plug near cylinder plug hole, otherwise serious personal injury may result. T r a h c g n i t o o h s e l b u...

Page 32

32 2. Place the stop switch in the "off" position. 3. Remove accumulation of grease, oil, dirt and debris from exterior of unit. Important some tree sap and resins are corrosive. Thoroughly wash the guide bar and sprocket areas after each use, then coat metal parts with light oil. 4. Perform all per...

Page 33: Ower

P ower p runer tm o perator ' s m anual 33 s pecifications model ---------------------------------------------------- ppt-265s length (standard) ------------------------------------------ 1.96 m (6 ft. 5 in.) length (extended) ----------------------------------------- 2.41 m (7 ft. 11 in.) length w/...

Page 34

34 notes.

Page 35: Ower

P ower p runer tm o perator ' s m anual 35 notes.

Page 36

Consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 www.Echo-usa.Com additional or replacement manuals safety manuals in english/spanish or english/french are available, free of charge, from your echo dealer or at www. E...