- DL manuals

- Echo

- Other

- PPT-260 - 08-00

- Operator's Manual

Echo PPT-260 - 08-00 Operator's Manual

P

OWER

P

RUNER

TM

O

PERATOR

'

S

M

ANUAL

1

Power Pruner

TM

Operator's Manual

MODEL:

PPT-260

Serial Number 03001001

- 03999999

WARNING

DANGER

X750002130

08/00

X7502096000

Read rules for safe operation and instructions carefully. ECHO provides an Operator's

Manual and a Safety Manual. Both must be read and understood for proper and safe

operation.

Summary of PPT-260 - 08-00

Page 1

P ower p runer tm o perator ' s m anual 1 power pruner tm operator's manual model: ppt-260 serial number 03001001 - 03999999 warning danger x750002130 08/00 x7502096000 read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read...

Page 2: Warning

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3: Ower

P ower p runer tm o perator ' s m anual 3 the circle with the slash symbol means whatever is shown within the circle is prohibited. This symbol accompanied by the words warning and danger calls attention to an act or condition that can lead to serious personal injury to operator and bystanders. M an...

Page 4: Warning

4 symbol description/application symbol form/shape symbol description/application symbol form/shape hot surface carburetor adjustment - idle speed carburetor adjustment - high speed mixture symbol description/application symbol form/shape symbol description/application symbol form/shape read and und...

Page 5: Ower

P ower p runer tm o perator ' s m anual 5 • check that the cutting attachment, guide bar and saw chain is firmly attached and in safe operating condition. • only use echo approved guide bar and saw chain. • only use one echo approved extension on the pruner. • do not hit rocks, stones, tree stumps a...

Page 6: Warning

6 personal condition & safety equipment physical condition -- your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protection -- wear eye ...

Page 7: Ower

P ower p runer tm o perator ' s m anual 7 safe operation warning danger all over head electrical conductors and communications wires can have electricity flow with high voltages. Never touch wires directly or indirectly when pruning, otherwise serious injury or death may result. Determine operation ...

Page 8

8 keep a firm grip • grip power pruner tm with both hands with thumbs and fingers encircling the handle, and lower shaft tube. Keep a solid stance • maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not work in odd positions or on ladders. Do not ov...

Page 9: Ower

P ower p runer tm o perator ' s m anual 9 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold ma...

Page 10

10 d escription due to packaging restriction the echo product you have purchased requires some assembly. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missing parts. Use the contents list to check for missing parts. Important engine informa...

Page 11: Ower

P ower p runer tm o perator ' s m anual 11 1 12 11 10 2 3 9 14 15 16 17 18 19 20 21 13 8 7 6 5 4 22 23 24.

Page 12

12 1. Power head - includes the engine, clutch, fuel system, ignition system and starter. 2. Throttle trigger - spring loaded to return to idle when released. During acceleration press trigger gradually for best operating technique. 3. Shoulder harness - an adjustable strap that suspends the unit fr...

Page 13: Ower

P ower p runer tm o perator ' s m anual 13 s pecifications l e d o m 0 6 2 - t p p ) d r a d n a t s ( h t g n e l ) . N i 7 . 0 . T f 9 ( m 6 7 . 2 ) d e d n e t x e ( h t g n e l ) . N i 0 5 7 . 9 , . T f 2 1 ( m 0 9 . 3 n o i s n e t x e / w h t g n e l ) . T f 7 1 ( m 4 4 . 5 h t d i w ) . N i 6...

Page 14

14 b a c e d a a ssembly shaft tube / power head tools required: 10x19mm (13/32x3/4in) t-wrench, 8x10 mm wrench, 4 mm hex wrench parts required: power head, shaft tube assembly; cutting attach- ment 1. Loosen bolt (a). 2. Match square socket in engine shaft with square power transmis- sion shaft (b)...

Page 15: Ower

P ower p runer tm o perator ' s m anual 15 e d f g h g h i j 2. Loosen center clamp knob (f) turning counter clockwise. 3. Pull upper shaft tube (g) out of fiberglass lower shaft tube 127-152 mm (5-6 in.), then slide (g) back into fiberglass lower shaft tube exposing inner power transmission shaft (...

Page 16

16 p re -o peration fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stroke oil - a two-stroke engine oil meeti...

Page 17: Ower

P ower p runer tm o perator ' s m anual 17 important echo premium 2-stroke oil may be mixed at 50:1 ratio for applica- tion in all echo engines sold in the past regardless of ratio specified in those manuals. Mixing instructions 1. Fill an approved fuel container with half of the required amount of ...

Page 18

18 important stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days, ninety (90) days when a fuel stabilizer is added. Important stored two-stroke fuel may separate. Always shake fuel container thoroughly before each use. Lubricating the guide bar and saw chain automatic o...

Page 19: Ower

P ower p runer tm o perator ' s m anual 19 15 m (50 ft.) equipment check before operation a complete check of the unit must be performed; • check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. • inspect fuel lines, tank and area around carburetor for fuel leaks. Do ...

Page 20

20 o peration warning danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions which can cause serious injury or death. • provide all operators of this equipment with the operator's manual, and instructions for safe operation. • befo...

Page 21: Ower

P ower p runer tm o perator ' s m anual 21 5. Move choke lever to “run” position and pull recoil starter handle/ rope (d) until engine starts and runs. Allow unit to warm up at idle for several minutes. Note if engine does not start with choke in “run” position after 5 pulls, repeat instructions. 6....

Page 22

22 blade hits rear branch not correct correct guide against branch not correct pruning techniques the power pruner tm is designed for light to medium trimming of limbs and branches up to 203 mm (8 in.) in diameter. Follow these tips for successful operation. • plan cut carefully. Check direction bra...

Page 23

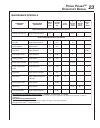

P ower p runer tm o perator ' s m anual 2 3 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h y l r a e y ...

Page 24

24 air filter level 1. Tools required: 25 or 50 mm (1 or 2 in.) medium bristle paint brush parts required: 90030 repower tm filter kit 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumu- lated dirt from the air cl...

Page 25: Ower

P ower p runer tm o perator ' s m anual 25 warning danger do not perform maintenance on the muffler until engine and muffler are completely cool, otherwise serious personal injury may occur. Spark plug level 2. Tools required: 10x19mm (13/32x3/4in) t-wrench, feeler gauge, (preferably a wire gauge), ...

Page 26

26 1. Remove spark plug lead. 2. Remove two (2) muffler cover screws and muffler cover (a). 3. Remove screw and arm rest (b). 4. Remove engine cover (c). Important do not use a metal scraper to remove dirt from the cylinder fins. 5. Use brush to remove dirt from the cylinder fins. 6. Remove grass an...

Page 27: Ower

P ower p runer tm o perator ' s m anual 27 spark arrestor screen 1. Remove muffler cover (a). 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 3. Remove spark arrestor screen cover (b), gasket (c), gasket (d) and screen (e) from muffler body. 4. Clean carbon de...

Page 28

28 warning danger when carburetor adjustment is completed, the cutting attach- ment should not turn at idle, otherwise serious personal injury may result. Note every unit is run at the factory and the carburetor is set in compli- ance with epa emission regulations. This carburetor does not have acce...

Page 29: Ower

P ower p runer tm o perator ' s m anual 29 filing saw chain level 3. Tools required: 4.5 mm round file p/n 89751001130; flat file p/n 89751100230; depth gauge p/n 89751400232. Important dull or damaged cutters will result in poor cutting performance, increased vibration and premature saw chain failu...

Page 30

30 t roubleshooting warning danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark near an open spark plug opening, otherwise serious personal injury may result. M e l b o r p d r a h s t r a t s - - e n i g n e t r a t s t o n s e o d - - e n i...

Page 31: Ower

P ower p runer tm o perator ' s m anual 31 long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: 1. Store unit in a dry, dust free place, out of the reach of children....

Page 32

Dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8 - 5 mon - fri c.S.T. Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 www.Echo-usa.Com s ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo product...