- DL manuals

- Echo

- Pole Saw

- PPT-2620

- Operator's Manual

Echo PPT-2620 Operator's Manual

X7507820600

© 2/2017 ECHO Inc.

ENGLISH

Operator’s Manual

Specifications, descriptions and illustrative material in this literature are

as accurate as known at the time of publication, but are subject to

change without notice. Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

PPT-2620 / H

POWER PRUNER

TM

Burn Hazard

The muffler or catalytic muffler and surrounding cover may

become extremely hot. Always keep clear of exhaust and

muffler area, otherwise serious personal injury may occur.

The engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive

harm.

Users of this equipment risk injury to themselves and others

if the unit is used improperly and/or safety precautions are

not followed. Echo provides an operator’s manual and a

safety manual. Both must be read and understood for proper

and safe operation. Failure to do so could result in serious injury.

Note: This product complies with CAN ICES-2/NMB-2.

Summary of PPT-2620

Page 1

X7507820600 © 2/2017 echo inc. English operator’s manual specifications, descriptions and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice. Illustrations may include optional equipment and accessories, and may not ...

Page 2: Table of Contents

Table of contents ppt-2620 2 x7507820600 © 2/2017 echo inc. Table of contents table of contents ........................................................................................ 2 introduction ................................................................................................. 4 ...

Page 3: Ppt-2620

Ppt-2620 table of contents x7507820600 3 © 2/2017 echo inc. English maintenance ............................................................................................. 32 skill levels......................................................................................... 33 maintenance interv...

Page 4: Introduction

Introduction ppt-2620 4 x7507820600 © 2/2017 echo inc. Introduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job dependability. Read and understand this manual and the safety manual. Keep the manuals in a safe place for future refere...

Page 5: Ppt-2620

Ppt-2620 safety x7507820600 5 © 2/2017 echo inc. English echo consumer product support if you require assistance or have questions concerning the application, operation, or maintenance of this product, call the echo consumer product support department at 1-800-673-1558 from 8:00 am to 5:00 pm (centr...

Page 6: Safety

Safety ppt-2620 6 x7507820600 © 2/2017 echo inc. The safety alert symbol accompanied by the wrod “warning” calls attention to an act or condition which can lead to serious personal injury or death if not avoided. The safety alert symbol accompanied by the word “caution” calls attention to an act or ...

Page 7: Ppt-2620

Ppt-2620 safety x7507820600 7 © 2/2017 echo inc. English finger severing do not operate closer than 15 m (50 ft.) from electrical hazard. Avoid all power lines. This unit is not insulated against electrical current. Plan retreat path from falling objects. Do not allow flames or sparks near fuel igni...

Page 8: Safety

Safety ppt-2620 8 x7507820600 © 2/2017 echo inc. Personal condition and safety equipment users of this product risk injury to themselves and others if the unit is used improperly and/or safety precautions are not followed. Proper clothing and safety gear must be worn when operating unit. Physical co...

Page 9: Ppt-2620

Ppt-2620 safety x7507820600 9 © 2/2017 echo inc. English proper clothing wear snug-fitting, durable clothing: • pants should have long legs, shirts should have long sleeves. • do not wear shorts. • do not wear ties, scarves, jewelry, or clothing with loose or hanging items that could become entangle...

Page 10: Safety

Safety ppt-2620 10 x7507820600 © 2/2017 echo inc. It is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals, may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sensations, followed ...

Page 11: Ppt-2620

Ppt-2620 safety x7507820600 11 © 2/2017 echo inc. English • take periodic breaks to minimize repetition and rest your hands. • reduce the speed and force with which you do the repetitive movement. • do exercises to strengthen the hand and arm muscles. • immediately stop using all power equipment and...

Page 12: Safety

Safety ppt-2620 12 x7507820600 © 2/2017 echo inc. • operate the power prunertm only from the ground or out of an approved bucket lift. • always evaluate the branches to be pruned for hazards such as loose dead branches which may fall and strike the operator or helpers. Remove hazards before pruning....

Page 13: Ppt-2620

Ppt-2620 safety x7507820600 13 © 2/2017 echo inc. English kickback may occur when the moving saw chain at the nose or tip of the guide bar touches an object, or when the wood closes in and pinches the saw chain in the cut. In some cases this may cause a lightning-fast reverse action, kicking the gui...

Page 14: Safety

Safety ppt-2620 14 x7507820600 © 2/2017 echo inc. • do not hit rocks, stones, tree stumps, and other foreign objects with the saw chain. • do not cut into the ground with the saw chain. • if cutting attachment end strikes an obstruction, stop engine immediately and inspect saw chain for damage. • do...

Page 15: Ppt-2620

Ppt-2620 emission control x7507820600 15 © 2/2017 echo inc. English emission control (exhaust & evaporative) carb and epa emissions control information the emission control system for the engine is em (engine modification) and, if the second to last character of the engine family on the emission con...

Page 16: Description

Description ppt-2620 16 x7507820600 © 2/2017 echo inc. Description locate the safety decal(s) on your unit. Make sure the decal(s) is legible and that you understand and follow the instructions on it. If a decal cannot be read, a new one can be ordered from your echo dealer. 1 1 2 3 4 5 6 7 8 9 10 1...

Page 17: Ppt-2620

Ppt-2620 description x7507820600 17 © 2/2017 echo inc. English 1. Power head - factory assembled to the drive shaft assembly. Includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Throttle handle - for right hand - contains stop switch, throttle lockout, and throttle trigg...

Page 18: Description

Description ppt-2620 18 x7507820600 © 2/2017 echo inc. 16. Fuel tank - contains fuel and fuel filter. 17. Fuel tank cap - covers and seals fuel tank opening. 18. Purge bulb - pumping purge bulb before starting engine draws fresh fuel from the fuel tank, purging air from the carburetor. Pump purge bu...

Page 19: Ppt-2620

Ppt-2620 contents x7507820600 19 © 2/2017 echo inc. English contents the echo product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, some assembly may be necessary. After opening the carton, check for damage. Immediately notify your retailer or echo...

Page 20: Assembly

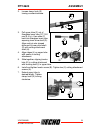

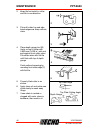

Assembly ppt-2620 20 x7507820600 © 2/2017 echo inc. Assembly drive shaft/handle assembly 1. Remove protective caps from handle assembly. 2. Loosen clamping bolts (a) on drive shaft. 3. Pull flexible drive shaft coupler (b) 2-3 inches out of handle assembly. 4. Align flexible drive shaft coupler with...

Page 21: Ppt-2620

Ppt-2620 assembly x7507820600 21 © 2/2017 echo inc. English 2. Loosen clamp knob (e) turning counterclockwise. 3. Pull upper tube (f) out of fiberglass lower tube 127-152 mm (5-6 in.), then slide (f) back into fiberglass lower tube exposing inner drive shaft (g). Align and join star shaped drive end...

Page 22: Assembly

Assembly ppt-2620 22 x7507820600 © 2/2017 echo inc. Saw chain adjustment always disconnect spark plug wire before servicing cutting attachment. Wear gloves when handling saw chain, otherwise serious personal injury may result. 1. Move stop switch to stop position. 2. Disconnect spark plug lead. 3. L...

Page 23: Ppt-2620

Ppt-2620 operation x7507820600 23 © 2/2017 echo inc. English 8. Keep chain properly tensioned at all times. Note: all chains require frequent adjustment. 9. Connect spark plug lead. Operation moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from...

Page 24: Operation

Operation ppt-2620 24 x7507820600 © 2/2017 echo inc. Fuel requirements gasoline - use 89 octane [r+m/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 10% ethanol (grain alcohol) or 15% mtbe (methyl tertiary-butyl ether). Gasoline containing methanol (wood alcoho...

Page 25: Ppt-2620

Ppt-2620 operation x7507820600 25 © 2/2017 echo inc. English mixing instructions 1. Fill an approved fuel container with half of the required amount of gasoline. 2. Add the proper amount of 2-stroke oil to gasoline. 3. Close container and shake to mix oil with gasoline. 4. Add remaining gasoline, cl...

Page 26: Operation

Operation ppt-2620 26 x7507820600 © 2/2017 echo inc. Lubricating the guide bar and saw chain automatic oiling system 1. Wipe debris from around oil fill cap. 2. Remove oil fill cap and fill reservoir with a quality, low viscosity guide bar and saw chain oil. To prevent plastic deterioration, do not ...

Page 27: Ppt-2620

Ppt-2620 operation x7507820600 27 © 2/2017 echo inc. English note: very little visible oil on the saw chain will provide sufficient lubrication. Starting cold engine the attachment will operate immediately when the engine starts, and could result in possible serious injury. Keep movable parts of the...

Page 28: Operation

Operation ppt-2620 28 x7507820600 © 2/2017 echo inc. 4. Recoil starter lay the unit on a flat area and keep movable attachment parts clear of all obstacles. Firmly grasp throttle handle and throttle trigger lockout with left hand and fully depress throttle trigger to wide open position. Rapidly pull...

Page 29: Ppt-2620

Ppt-2620 operation x7507820600 29 © 2/2017 echo inc. English note: if attachment moves, readjust carburetor according to “carburetor adjustment” instructions in this manual or see your echo dealer. 1. Stop switch move stop switch button (a) forward away from the stop position. 2. Purge bulb pump pur...

Page 30: Operation

Operation ppt-2620 30 x7507820600 © 2/2017 echo inc. Stopping engine 1. Throttle release throttle trigger and allow engine to return to idle before shutting off engine. 2. Stop switch move stop switch button (a) backward to stop position. If engine does not stop when stop switch is moved to stop pos...

Page 31: Ppt-2620

Ppt-2620 operation x7507820600 31 © 2/2017 echo inc. English pruning techniques shoulder harness (if included) your harness may appear different than the harness shown. 1. Loosen the harness clamp screw. 2. Put the harness on and attach it to the unit. 3. Adjust the harness for comfortable operation...

Page 32: Maintenance

Maintenance ppt-2620 32 x7507820600 © 2/2017 echo inc. • when ready to cut: hold the cutting shoe against the branch. This will prevent whipping of the branch. Do not use back and forth sawing action. • look out for branches immediately behind the branch being cut. If saw chain hits a rear branch da...

Page 33: Ppt-2620

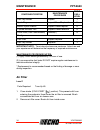

Ppt-2620 maintenance x7507820600 33 © 2/2017 echo inc. English your echo unit is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your unit achieve that goal. If you are unsure or are not equipped with the necessary tools, we recommend that you take you...

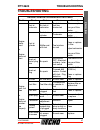

Page 34: Maintenance

Maintenance ppt-2620 34 x7507820600 © 2/2017 echo inc. Important note - time intervals shown are maximum. Actual use and your experience will determine the frequency of required maintenance. Maintenance procedure notes: (1) apply lithium based grease every 25 hours of use. (2) low evaporative fuel t...

Page 35: Ppt-2620

Ppt-2620 maintenance x7507820600 35 © 2/2017 echo inc. English assure throttle wire retaining clip (a) remains in place as shown when removing or installing air filter cover. 3. Remove foam pre-filter (b) and air filter and clean as indicated below: 4. Foam pre-filter • clean foam filter in water/ d...

Page 36: Maintenance

Maintenance ppt-2620 36 x7507820600 © 2/2017 echo inc. Fuel is very flammable. Use extreme care when mixing, storing or handling, or serious personal injury may result. 1. Use a clean rag to remove loose dirt from around fuel cap and empty fuel tank. 2. Pull the fuel filter from the fuel tank. Do no...

Page 37: Ppt-2620

Ppt-2620 maintenance x7507820600 37 © 2/2017 echo inc. English 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with a new one. Do not sand blast to clean. Remaining sand will damage engine. 3. Adjust spark plug gap by bending outer electrod...

Page 38: Maintenance

Maintenance ppt-2620 38 x7507820600 © 2/2017 echo inc. • dust and grass build up on the outside of the cylinder. This build up insulates the engine and prevents the heat from leaving. Removal of cooling passage blockages or cleaning of cooling fins is considered “normal maintenance.” any failure att...

Page 39: Ppt-2620

Ppt-2620 maintenance x7507820600 39 © 2/2017 echo inc. English 1. Remove spark plug lead. 2. Remove muffler cover (a). 3. Place piston at top dead center (tdc) to prevent carbon or dirt from entering cylinder. 4. Remove spark arrestor screen cover (b), gasket (c), and screen (d), from muffler body. ...

Page 40: Maintenance

Maintenance ppt-2620 40 x7507820600 © 2/2017 echo inc. 3. Use a wood or plastic scraping tool to clean deposits from cylinder exhaust port (c). Never use a metal tool to scrape carbon from the exhaust port. Do not scratch the cylinder or piston when cleaning the exhaust port. Do not allow carbon par...

Page 41: Ppt-2620

Ppt-2620 maintenance x7507820600 41 © 2/2017 echo inc. English if the engine is adjusted for operation above 1,100 feet asl, the carburetor must be re-adjusted when operating the engine below 1,100 feet asl, otherwise severe engine damage may result. Note: every unit is run at the factory and the ca...

Page 42: Maintenance

Maintenance ppt-2620 42 x7507820600 © 2/2017 echo inc. When carburetor adjustment is completed, the cutting attachment should not move at idle, otherwise serious personal injury may result. Lubrication flexible drive shaft level 1. 1. Loosen clamping screws (a) on driveshaft coupling. 2. Remove hand...

Page 43: Ppt-2620

Ppt-2620 maintenance x7507820600 43 © 2/2017 echo inc. English guide bar and saw chain replacement never try to replace or adjust guide bar and saw chain with engine running. Always disconnect spark plug wire before servicing guide bar and saw chain. This saw chain is very sharp, wear heavy gloves t...

Page 44: Maintenance

Maintenance ppt-2620 44 x7507820600 © 2/2017 echo inc. 2. Remove guide bar cover (c). 3. Gently brush debris from inside guide bar cover and from around sprocket. 4. Hold the bar nose up. Install guide bar cover (c). Install the guide bar nuts (a). Tighten the rear nut first, then tighten the front ...

Page 45: Ppt-2620

Ppt-2620 maintenance x7507820600 45 © 2/2017 echo inc. English check bar part number on your power pruner. Chain and guide bar gauge size must be identical. Use bar and chain combinations shown in table above. Dull or damaged cutters will result in poor cutting performance, increased vibration, and ...

Page 46: Maintenance

Maintenance ppt-2620 46 x7507820600 © 2/2017 echo inc. 2. Keep file horizontal in cutter and file in one direction. 3. File until cutter top and side bevel edges are sharp without nicks. 4. Place depth gauge tool (b) firmly on top of cutter with 0.635 mm (0.025 in.) slot and end against front cutter...

Page 47: Ppt-2620

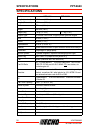

Ppt-2620 troubleshooting x7507820600 47 © 2/2017 echo inc. English troubleshooting engine problem troubleshooting chart problem check status cause remedy engine starts hard or engine does not start fuel at carburetor no fuel at carburetor fuel strainer or fuel line obstructed clean or replace see yo...

Page 48: Storage

Storage ppt-2620 48 x7507820600 © 2/2017 echo inc. Fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by grounding spark plug near cylinder plug hole, otherwise serious personal injury may result. Storage during operation the muffler or catalytic m...

Page 49: Ppt-2620

Ppt-2620 storage x7507820600 49 © 2/2017 echo inc. English some tree sap and resins are corrosive. Thoroughly wash the guide bar and sprocket areas after each use, then coat metal parts with light oil. 4. Perform all periodic lubrication and services that are required. 5. Tighten all the screws and ...

Page 50: Specifications

Specifications ppt-2620 50 x7507820600 © 2/2017 echo inc. Specifications model ppt-2620 ppt-2620h length (standard) 2,716 mm (107 in.) length (extended) 3,704 mm (146 in) width 273 mm (11 in.) height 260 mm (10 in.) weight (dry) 7.9 kg (17.4 lb.) 7.7 kg (17 lb.) engine type air cooled, two-stroke, s...

Page 51: Ppt-2620

Ppt-2620 specifications x7507820600 51 © 2/2017 echo inc. English clutch engagement speed 4,100 wide open throttle speed (w.O.T.) 11,250 guide bar and saw chain (91) 305 mm (12 in.); 9.53 mm (3/8 inch) pitch chain, 0.050 gauge model ppt-2620 ppt-2620h.

Page 52: Product Registration

Product registration ppt-2620 52 x7507820600 © 2/2017 echo inc. Product registration thank you for choosing echo power equipment please go to http://www.Echo-usa.Com/warranty/register-your-echo to register your new product on-line. It's fast and easy! Note: your information will never be sold or mis...

Page 53: Ppt-2620

Ppt-2620 product registration x7507820600 53 © 2/2017 echo inc. English.

Page 54: Notes

Notes ppt-2620 54 x7507820600 © 2/2017 echo inc. Notes.

Page 55: Ppt-2620

Ppt-2620 notes x7507820600 55 © 2/2017 echo inc. English.

Page 56: Echo, Incorporated

Echo, incorporated 400 oakwood road lake zurich, il 60047 www.Echo-usa.Com e60415001001 - e60415999999 e60515001001 - e60515999999.