- DL manuals

- Echo

- Lawn and Garden Equipment

- PPT-266H

- Operator's Manual

Echo PPT-266H Operator's Manual

Specifications, descriptions and illustrative material in this literature are as accurate as known at the time

of publication, but are subject to change without notice. Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

Operator’s Manual

X7712091200

© 10/2014 ECHO Inc.

x7722271404 / x772000

PPT-266/H

POWER PRUNER

TM

Burn Hazard

The muffler or catalytic muffler and surrounding cover may become extremely hot.

Always keep clear of exhaust and muffler area, otherwise serious personal injury may

occur.

The engine exhaust from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Users of this equipment risk injury to themselves and others if the unit is used

improperly and/or safety precautions are not followed. ECHO provides an operator’s

manual and a safety manual. Both must be read and understood for proper and safe

operation. Failure to do so could result in serious injury.

Summary of PPT-266H

Page 1

Specifications, descriptions and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice. Illustrations may include optional equipment and accessories, and may not include all standard equipment. Operator’s manual x771209...

Page 2: Table of Contents

2 x7712091200 © 10/2014 echo inc. Table of contents ppt-266/h table of contents table of contents............................................................................................................................................... 2 introduction ...............................................

Page 3: Introduction

Ppt-266/h introduction x7712091200 3 © 10/2014 echo inc. Introduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job dependability. Read and understand this manual and the safety manual. You will find both easy to use and full of helpf...

Page 4: Safety

4 x7712091200 © 10/2014 echo inc. Safety ppt-266/h additional or replacement manuals replacement operator, safety manuals, and parts catalogs are available from your echo dealer or at www.Echo-usa.Com or by contacting echo inc., 400 oakwood road, lake zurich, il 60047 (800-673-1558). Always check th...

Page 5

Ppt-266/h safety x7712091200 5 © 10/2014 echo inc. International symbols symbol description symbol description symbol description symbol description read and understand owners manual. Fuel and oil mixture carburetor adjustment - low speed mixture carburetor adjustment - high speed mixture wear eye, ...

Page 6

6 x7712091200 © 10/2014 echo inc. Safety ppt-266/h personal condition and safety equipment users of this product risk injury to themselves and others if the unit is used improperly and/or safety precautions are not followed. Proper clothing and safety gear must be worn when operating unit. Physical ...

Page 7

Ppt-266/h safety x7712091200 7 © 10/2014 echo inc. • do not operate unit barefooted. Keep long hair away from engine and air intake. Retain hair with cap or net. Heavy protective clothing can increase operator fatigue, which may lead to heat stroke. Schedule heavy work for early morning or late afte...

Page 8

8 x7712091200 © 10/2014 echo inc. Safety ppt-266/h repetitive stress injuries (rsi) it is believed that overusing the muscles and tendons of the fingers, hands, arms, and shoulders may cause soreness, swelling, numbness, weakness, and extreme pain in those areas. Certain repetitive hand activities m...

Page 9

Ppt-266/h safety x7712091200 9 © 10/2014 echo inc. Keep a firm grip • always hold throttle handle and support handle with thumbs and fingers tightly encircling the handles. Keep a solid stance • maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not ...

Page 10

10 x7712091200 © 10/2014 echo inc. Safety ppt-266/h if the saw chain does strike a foreign object, immediately stop the engine, inspect and repair the power pruner tm if necessary. Equipment use only echo attachments. Serious injury may result from the use of a non-approved attachment combination. E...

Page 11

Ppt-266/h emission control (exhaust & evaporative) x7712091200 11 © 10/2014 echo inc. Emission control (exhaust & evaporative) epa 2010 and later and/or c.A.R.B. Tier iii the emission control system for the engine is em (engine modification) and, if the second to last character of the engine family ...

Page 12: Description

12 x7712091200 © 10/2014 echo inc. Description ppt-266/h description locate the safety decal(s) on your unit. Make sure the decal(s) is legible and that you understand and follow the instructions on it. If a decal cannot be read, a new one can be ordered from your echo dealer. See parts ordering ins...

Page 13

Ppt-266/h description x7712091200 13 © 10/2014 echo inc. Ppt-266h 1 2 4 5 6 8 9 10 11 12 7 hot labels shaft label handle label.

Page 14

14 x7712091200 © 10/2014 echo inc. Description ppt-266/h 1. Power head – factory assembled to the drive shaft assembly. Includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Throttle trigger – controls engine speed. Spring loaded to return to idle when released. During acc...

Page 15: Contents

Ppt-266/h contents x7712091200 15 © 10/2014 echo inc. Contents due to packaging restriction the echo product you have purchased requires some assembly. After opening the carton, check for damage. Immediately notify your retailer or echo dealer of damaged or missing parts. Use the contents list to ch...

Page 16: Assembly

16 x7712091200 © 10/2014 echo inc. Assembly ppt-266/h assembly drive shaft/handle assembly 1. Remove protective caps from handle assembly. 2. Loosen clamping bolts (a) on drive shaft. 3. Pull flexible drive shaft coupler (b) 2-3 inches out of handle assembly. 4. Align flexible drive shaft coupler wi...

Page 17

Ppt-266/h assembly x7712091200 17 © 10/2014 echo inc. Throttle linkage and ignition leads 1. Close choke and remove air filter cover. 2. Place throttle linkage (c) through adjustment fixture (d) and install wire end into large carburetor throttle swivel hole (e). Check throttle for freedom of moveme...

Page 18

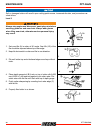

18 x7712091200 © 10/2014 echo inc. Assembly ppt-266/h 1. Loosen the two (2) screws (a) and remove locator screw (b) on cutting attachment. 2. Loosen clamp knob (e) turning counterclockwise. 3. Pull upper tube (f) out of fiberglass lower tube 127-152 mm (5-6 in.), then slide (f) back into fiberglass ...

Page 19: Operation

Ppt-266/h operation x7712091200 19 © 10/2014 echo inc. 3. Loosen two guide bar nuts (a) until finger tight. Always loosen guide bar nuts before turning the chain tension adjuster, otherwise the clutch cover and tensioner will be damaged. 4. Hold the bar nose up, and turn the adjuster screw (b) clock...

Page 20

20 x7712091200 © 10/2014 echo inc. Operation ppt-266/h fuel requirements gasoline - use 89 octane [r+m/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 10% ethanol (grain alcohol) or 15% mtbe (methyl tertiary-butyl ether). Gasoline containing methanol (wood alco...

Page 21

Ppt-266/h operation x7712091200 21 © 10/2014 echo inc. Spilled fuel is a leading cause of hydrocarbon emissions. Some states may require the use of automatic fuel shut-off containers to reduce fuel spillage. After use • do not store a unit with fuel in its tank. Leaks can occur. Return unused fuel t...

Page 22

22 x7712091200 © 10/2014 echo inc. Operation ppt-266/h starting cold engine the attachment will operate immediately when the engine starts, and could result in possible serious injury. Keep movable parts of the attachment away from objects that could become entangled or thrown, and surfaces that cou...

Page 23

Ppt-266/h operation x7712091200 23 © 10/2014 echo inc. 6. Throttle trigger after engine warm-up, gradually depress throttle trigger to increase engine rpm to operating speed. Starting warm engine the starting procedure is the same as cold start except do not close the choke, and do not depress throt...

Page 24

24 x7712091200 © 10/2014 echo inc. Operation ppt-266/h 3. Recoil starter lay the unit on a flat area and keep movable attachment parts clear of all obstacles. Rapidly pull the recoil starter handle (d) until the engine fires. Note: if engine does not start after 5 pulls, use cold start procedure. St...

Page 25

Ppt-266/h operation x7712091200 25 © 10/2014 echo inc. • plan cut carefully. Check direction branch will fall. • plan retreat path from falling branch. Cut branches bounce when striking ground. • long branches should be removed in several pieces. • do not stand directly beneath branch being cut. • w...

Page 26: Maintenance

26 x7712091200 © 10/2014 echo inc. Maintenance ppt-266/h maintenance moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop befor...

Page 27

Ppt-266/h maintenance x7712091200 27 © 10/2014 echo inc. Air filter level 1 1. Close choke (cold start [ ] position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumulated dirt from air cleaner area. 2. Remove air filter cover and air filter retaine...

Page 28

28 x7712091200 © 10/2014 echo inc. Maintenance ppt-266/h fuel filter level 1 fuel is very flammable. Use extreme care when mixing, storing or handling, or serious personal injury may result. 1. Use a clean rag to remove loose dirt from around fuel cap and empty fuel tank. 2. Use a hook to pull the f...

Page 29

Ppt-266/h maintenance x7712091200 29 © 10/2014 echo inc. Cooling system level 2 to maintain proper engine operating temperatures, cooling air must pass freely through the cylinder fin area. This flow of air carries combustion heat away from the engine. Overheating and engine seizure can occur when: ...

Page 30

30 x7712091200 © 10/2014 echo inc. Maintenance ppt-266/h exhaust system spark arrestor screen level 2 1. Remove spark plug lead. 2. Remove muffler cover (a). 3. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 4. Remove spark arrestor screen (d), gasket (c) and ex...

Page 31

Ppt-266/h maintenance x7712091200 31 © 10/2014 echo inc. Carburetor adjustment level 2 engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break-in period your engine performance will increase and exhaust...

Page 32

32 x7712091200 © 10/2014 echo inc. Maintenance ppt-266/h 1. Loosen clamping screws (a) on driveshaft coupling. 2. Remove handle and flexible drive shaft. 3. Remove flexible drive shaft (b). 4. Wipe flex shaft clean and apply a thin coating of grease. 5. Slide flex shaft into handle. Leave 2–3 inches...

Page 33

Ppt-266/h maintenance x7712091200 33 © 10/2014 echo inc. 5. Install chain on guide bar with cutters on top of bar facing toward bar tip. 6. Install guide bar and chain on gear case, engaging chain with drive sprocket (e). 7. Turn tension adjustment screw (c) to ensure chain tension adjuster pin fits...

Page 34

34 x7712091200 © 10/2014 echo inc. Maintenance ppt-266/h dull or damaged cutters will result in poor cutting performance, increased vibration, and premature saw chain failure. Level 2 always stop engine and disconnect spark plug wire before servicing guide bar and saw chain. Always wear gloves when ...

Page 35

Ppt-266/h maintenance x7712091200 35 © 10/2014 echo inc. 7. Apply clean oil and rotate saw chain slowly to wash away filings. 8. If saw chain is coated or clogged with resin, clean in kerosene, then soak in oil. 6 55 top plate angle top plate cutting angle depth gauge.

Page 36: Troubleshooting

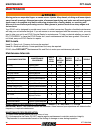

36 x7712091200 © 10/2014 echo inc. Troubleshooting ppt-266/h troubleshooting fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by grounding spark plug near cylinder plug hole, otherwise serious personal injury may result. Engine problem troublesho...

Page 37: Storage

Ppt-266/h storage x7712091200 37 © 10/2014 echo inc. Storage during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. ...

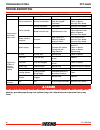

Page 38: Specifications

38 x7712091200 © 10/2014 echo inc. Specifications ppt-266/h specifications model ppt-266 ppt-266h length (standard) 2.72 m (8 ft. 11 in.) length (extended) 3.71 m (12 ft. 2 in.) length w/extension 4.93 m (16 ft. 2 in.) width 0.25 m (9.8 in.) height 0.25 m (9.7 in.) weight (dry) 8.4 kg (18.5 lb.) 8.2...

Page 39: Warranty Statements

Ppt-266/h warranty statements x7712091200 39 © 10/2014 echo inc. Warranty statements echo limited warranty statement for product sold in usa and canada beginning 01/01/2010 echo's responsibility echo incorporated’s limited warranty, provides to the original purchaser that this echo product is free f...

Page 40

40 x7712091200 © 10/2014 echo inc. Warranty statements ppt-266/h echo does not offer an over the counter exchange program. Any echo product re-built other than by echo or sold through an unauthorized dealer, or an unauthorized outlet store, is sold without echo’s limited warranty coverage. The echo ...

Page 41: Product Registration

Ppt-266/h product registration x7712091200 41 © 10/2014 echo inc. Product registration thank you for choosing echo power equipment please go to http://www.Echo-usa.Com/warranty/register-your-echo to register your new product on-line. It's fast and easy! Note: your information will never be sold or m...

Page 42: Notes

42 x7712091200 © 10/2014 echo inc. Notes ppt-266/h notes.

Page 43

Ppt-266/h notes x7712091200 43 © 10/2014 echo inc..

Page 44

Echo, incorporated 400 oakwood road lake zurich, il 60047 www.Echo-usa.Com 44 e20514001001/e20514999999 (h) e20614001001/e20614999999.