- DL manuals

- Echo

- Blower

- Pro Attachment ES-210

- Operator's Manual

Echo Pro Attachment ES-210 Operator's Manual

Summary of Pro Attachment ES-210

Page 1

Shred 'n' vac ® operator's manual model es-210 x753002973 11/09 x7531135903 warning read rules for safe operation and all instructions carefully. Echo provides this operator’s manual, which must be read and understood for proper and safe operation..

Page 2: ’

2 t able of c ontents introduction ....................................................................... 2 - the operator’s manual ............................................... 2 safety ................................................................................ 3 - manual safety symbols and...

Page 3: 'N' V

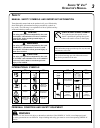

3 s hred 'n' v ac ® o perator ' s m anual international symbols symbol description/application symbol form/shape symbol description/application symbol form/shape read and understand operator's manual. Fuel and oil mixture symbol description/application symbol form/shape symbol description/applicatio...

Page 4

4 physical condition your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protection wear eye protection that meets ansi z87.1 or ce requi...

Page 5: 'N' V

5 s hred 'n' v ac ® o perator ' s m anual danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions and can cause serious injury or death. Read the manuals • provide all users of this equipment with the operator’s manual and safety ma...

Page 6

6 e mission c ontrol ( exhaust & evaporative ) epa 2010 and later and/or c.A.R.B. Tier iii the emission control system for the engine is em/twc (engine modification and 3-way catalyst) and for the fuel tank the control system is evap (evaporative emissions) or n (for nylon tank). Evaporative emissio...

Page 7: 'N' V

7 s hred 'n' v ac ® o perator ' s m anual locate these safety decals on your unit. Make sure the decals are legible and that you understand and follow the instruc- tions on them. If a decal cannot be read, a new one can be ordered from your echo dealer. See parts ordering instructions for specific i...

Page 8

8 1. Stop switch - "slide switch" mounted on top of handle. Push forward to start and run. Slide back to stop. 2. Throttle trigger - spring loaded to return to idle when released. During acceleration, press trigger gradu- ally for best operating technique. 3. Spark plug - provides spark to ignite fu...

Page 9: 'N' V

9 s hred 'n' v ac ® o perator ' s m anual a a ssembly required tools: screwdriver warning never perform maintenance or assembly procedures with engine running, or serious personal injury may result. Blower application install blower pipes 1. Align grooves in straight pipe with pegs on blower housing...

Page 10

10 d e 5. Align grooves in discharge elbow with pegs on blower, and slide elbow (d) on to blower. Turn elbow counterclockwise to lock in place. Elbow must angle back toward operator position as shown. 6. Place debris bag opening over flared end of elbow, and cinch bag (e) securely with velcro strap....

Page 11: 'N' V

11 s hred 'n' v ac ® o perator ' s m anual handling fuel danger fuel is very flammable. Use extreme care when mixing, storing or handling or serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks/cans ma...

Page 12

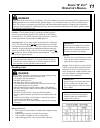

12 a b c d e starting cold engine 1. Stop switch move stop switch button (a) away from the stop position. 2. Throttle position lever move throttle position lever (b) midway between idle and full throttle positions. 3. Choke move choke (c) to cold start ( ) position. 4. Purge bulb pump purge bulb (d)...

Page 13: 'N' V

13 s hred 'n' v ac ® o perator ' s m anual starting warm engine the starting procedure is the same as cold start except do not close the choke. 1. Stop switch move stop switch button (a) away from the stop position. 2. Throttle position lever move throttle position lever (b) forward to idle position...

Page 14

14 read the safety section carefully. Important to avoid engine damage due to over-revving, do not block blower pipe. 1. Use only during appropriate hours. 2. Allow the engine to warm up at a fast idle for a few minutes. 3. Control engine speed with throttle trigger (f), or for continu- ous use, set...

Page 15: 'N' V

15 s hred 'n' v ac ® o perator ' s m anual shred ‘ n ’ vac ® operation warning flying debris hazard. Never operate unit as a vacuum unless discharge elbow is installed and debris bag is securely cinched to elbow. Failure to follow instructions can result in serious injuries. 1. Adjust debris bag str...

Page 16

16 your echo blower is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your blower achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for maintenance. To help you ...

Page 17: 'N' V

17 s hred 'n' v ac ® o perator ' s m anual fuel filter level 1. Tools required: 200-250 mm (8-10 in.) length of wire with one end bent into a hook. Clean rag, funnel, and an approved fuel container. Parts required: repower tm air and filter kit danger fuel is very flammable. Use extreme care when mi...

Page 18

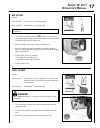

18 0.65 mm (0.026 in.) cooling system level 2. Tools required: 25-50 mm (1-2 in.) cleaning brush, 3 mm hex wrench, cross head screwdriver parts required: none, if you are careful. Important to maintain proper engine operating temperatures, cooling air must pass freely through the cylinder fin area. ...

Page 19: 'N' V

19 s hred 'n' v ac ® o perator ' s m anual exhaust system spark arrestor screen level 2. Tools required: cross head screwdriver, 3 mm hex wrench, soft metal brush parts required: spark arrestor screen, gasket important carbon deposits in muffler will cause a drop in engine output and overheating. Sp...

Page 20

20 a b exhaust port cleaning level 2. Tools required: 4 mm hex wrench., wood or plastic scraper parts required: as needed: heat shield 1. Remove spark plug lead from spark plug, and remove engine cover (5 screws). 2. Place piston at top dead center. Remove muffler (a) and heat shield (b). 3. Use a w...

Page 21: 'N' V

21 s hred 'n' v ac ® o perator ' s m anual shredder blade level 1. Warning never remove vacuum tube or open fan guard when shred ‘n’ vac® is running or serious personal injury may result. Always wear heavy-duty work gloves when working in shredder blade area. 1. With engine stopped, remove spark plu...

Page 22

22 carburetor adjustment engine break-in new engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be made. During the break- in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can be adjusted as requ...

Page 23: 'N' V

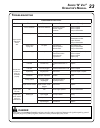

23 s hred 'n' v ac ® o perator ' s m anual t roubleshooting danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by ground- ing spark plug near cylinder plug hole, otherwise serious personal injury may result. T r a h c g n i t o o h s e l b u...

Page 24

24 s torage warning during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. Long term storage (over 30 days) do not s...

Page 25: 'N' V

25 s hred 'n' v ac ® o perator ' s m anual s pecifications model ---------------------------------------------------- es-210 hand held length ------------------------------------------------------ 330 mm (13.0 in.) (w/o vacuum attachment) width (w/rear handle) ------------------------------------- 2...

Page 26

26 w arranty s tatements echo limited warranty statement for product sold in usa and canada beginning 01/01/2010 echo's responsibility echo incorporated’s limited warranty, provides to the original purchaser that this echo product is free from defects in material and workmanship. Under normal use an...

Page 27: 'N' V

27 s hred 'n' v ac ® o perator ' s m anual purchased repair parts, short blocks and accessories • 90-day residential, or non-income producing warranty • 30-day commercial, institutional, agricultural, industrial, income producing, or rental application warranty attention two-stroke engine power prod...

Page 28

28 echo incorporated emission control warranty statement for echo and shindaiwa brands the environmental protection agency (epa) and the california air resources board (c.A.R.B.) and echo incorporated (echo inc.) are pleased to explain the emission control system warranty on your 2010 and later equi...

Page 29: 'N' V

29 s hred 'n' v ac ® o perator ' s m anual notes.

Page 30

30 notes.

Page 31: 'N' V

31 s hred 'n' v ac ® o perator ' s m anual notes.

Page 32

Echo, incorporated 400 oakwood road lake zurich, il 60047-1564 www.Echo-usa.Com consumer product support 1-800-673-1558 8:30 - 4:30 m on - f ri c.S.T. P08711003923/p08711999999 p11012001001/p11012999999 dealer? Call 1-800-432-echo 1-800-432-3246 or www.Echo-usa.Com s ervicing i nformation parts / se...