- DL manuals

- Echo

- Trimmer

- Pro Attachment Series PAS-265

- Operator's Manual

Echo Pro Attachment Series PAS-265 Operator's Manual

Pro Attachment Series

TM

Operator's Manual

MODEL

PAS-265

X7502024003

wArning

Read rules for safe operation and instructions carefully. ECHO provides an Operator's

Manual with this unit and a separate Operator's Manual and Safety Manual (if avail-

able) with the attachment. All manuals must be read and understood for proper and

safe operation. Failure to do so could result in serious injury.

X750010523

12/09

Summary of Pro Attachment Series PAS-265

Page 1

Pro attachment series tm operator's manual model pas-265 x7502024003 warning read rules for safe operation and instructions carefully. Echo provides an operator's manual with this unit and a separate operator's manual and safety manual (if avail- able) with the attachment. All manuals must be read a...

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual as well as your attachment operator's manual and safety manual (if available) before operation. You will find these manuals ...

Page 3

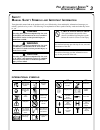

P ro a ttachment s eries tm 3 o perator ' s m anual international symbols symbol description/application symbol form/shape symbol description/application symbol form/shape hot surface carburetor adjust- ment - idle speed carburetor adjust- ment - high speed mixture symbol description/application sym...

Page 4

4 vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals, may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sen- sations, followed by loss of color and numbne...

Page 5

P ro a ttachment s eries tm 5 o perator ' s m anual repetitive stress injuries it is believed that overusing the muscles and tendons of the fingers, hands, arms, and shoulders may cause soreness, swelling, numbness, weakness, and extreme pain in those areas. Certain repetitive hand activities may pu...

Page 6

6 equipment warning use only echo approved attachments for pro attachment series tm models. Serious injury may result from the use of a non-approved attachment combination. Read and comply with all safety instructions listed in this manual and attachment manual. Warning moving parts can amputate fin...

Page 7

P ro a ttachment s eries tm 7 o perator ' s m anual hot decal (near muffler) 11 18 15 12 13 14 16 17 shaft decal spanish decal english translation d escription locate these safety decals on your unit. Make sure the decals are legible and that you understand and follow the instruc- tions on them. If ...

Page 8

8 1. Power head - includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Spark arrestor muffler or spark arrestor muffler with catalyst - the muffler or catalytic muffler controls exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carbo...

Page 9

P ro a ttachment s eries tm 9 o perator ' s m anual 1 - power head w / upper drive shaft assembly 1 - plastic bag (co-pack) - 1, operator's manual - 1, warranty registration card - 1, safety glasses - 1, barrier bar a ssembly attachment shaft assembly tools required: none parts required: pas attachm...

Page 10

10 tools required: screwdriver. Parts required: barrier bar handle adjustment note label shows minimum spacing for front handle location. 1. Stand in a comfortable operating position with attachment assem- bled, and position front handle for comfortable operation. Tighten handle screws. Barrier bar ...

Page 11

P ro a ttachment s eries tm 11 o perator ' s m anual.

Page 12

12 notice: use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor performance, or severe engine damage and void the product warranty. Read and follow instructions in the storage section of this manual. Warning alternative fuels, such as e-15 (15% et...

Page 13

P ro a ttachment s eries tm 13 o perator ' s m anual important stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days, ninety (90) days when a fuel stabilizer is added. Important stored two-stroke fuel may separate. Always shake fuel container thor- oughly before each use....

Page 14

14 starting cold engine warning the attachment will operate immediately when the engine starts and could result in loss of control and possible serious injury. Keep movable parts of the attachment off the ground and away from objects that could become entangled or thrown. 1. Stop switch move stop sw...

Page 15

P ro a ttachment s eries tm 15 o perator ' s m anual starting warm engine the starting procedure is the same as cold start except do not close the choke, and do not depress throttle trigger to wide open position. Warning the attachment should not move at idle, otherwise serious personal injury may r...

Page 16

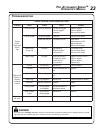

16 maintenance intervals m aintenance warning moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop before removing obstructions...

Page 17: Warning

P ro a ttachment s eries tm 17 o perator ' s m anual air filter level 1. Tools required: 25 or 50 mm (1 or 2 in.) cleaning brush parts required: repower tm air & fuel filter kit 1. Close choke (cold start position [ ]). This prevents dirt from entering the carburetor throat when the air filter is re...

Page 18

18 spark plug level 2. Tools required: t-wrench, feeler gauge, soft metal brush parts required: repower tm tune-up kit important use only ngk bpm-8y spark plug (bpmr-8y in canada) other- wise severe engine damage may occur. 1. Remove spark plug and check for fouling, worn and rounded center electrod...

Page 19

P ro a ttachment s eries tm 19 o perator ' s m anual important do not use a metal scraper to remove dirt from the cylinder fins. 5. Use brush to remove dirt from the cylinder fins. 6. Remove grass and leaves from the grid between the recoil starter and fuel tank. 7. Assemble components in reverse or...

Page 20

20 exhaust port cleaning level 2. Tools required: 4mm hex wrench, wood or plastic scraper parts required: as needed: heat shield 1. Remove spark plug lead from spark plug, and remove engine cover (2 screws). 2. Place piston at top dead center. Remove muffler (a) and heat shield (b). 3. Use a wood or...

Page 21

P ro a ttachment s eries tm 21 o perator ' s m anual level 2. Tools required: screwdriver, tachometer (echo p/n 99051130017) parts required: none note every unit is run at the factory and the carburetor is set in compli- ance with emission regulations. Carburetor adjustments, other than idle speed, ...

Page 22

22 lubrication level 1. Tools required: 5 mm hex wrench, clean rag parts required: power blendx tm 8 oz. (p/n 91014) or lithium base grease. Drive shaft upper important the drive shaft must be lubricated with high temperature auto- motive grease every 25 hours of operation, otherwise drive shaft ass...

Page 23

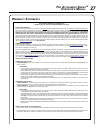

P ro a ttachment s eries tm 23 o perator ' s m anual danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark by ground- ing spark plug near cylinder plug hole, otherwise serious personal injury may result. T roubleshooting t r a h c g n i t o o h...

Page 24

24 s torage long term storage (over 30 days) warning during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. Do not s...

Page 25

P ro a ttachment s eries tm 25 o perator ' s m anual s pecifications model ----------------------------------------------- pas-265 unit length -------------------------------------------- 1036 mm (40.8 in.) width --------------------------------------------------- 248 mm (9.8 in.) height -----------...

Page 26

26 echo approved optional attachments warning • use only echo approved attachments for pro attachment series tm models. Serious injury may result from the use of non-approved attachment combinations. Read and comply with all safety instructions listed in this manual and in the attachment manual. Not...

Page 27

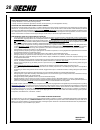

P ro a ttachment s eries tm 27 o perator ' s m anual echo limited warranty statement for product sold in usa and canada beginning 01/01/2010 echo's responsibility echo incorporated’s limited warranty, provides to the original purchaser that this echo product is free from defects in material and work...

Page 28

28 purchased repair parts, short blocks and accessories • 90-day residential, or non-income producing warranty • 30-day commercial, institutional, agricultural, industrial, income producing, or rental application warranty attention two-stroke engine power product owners this echo two-stroke engine p...

Page 29

P ro a ttachment s eries tm 29 o perator ' s m anual echo incorporated emission control warranty statement for echo and shindaiwa brands the environmental protection agency (epa) and the california air resources board (c.A.R.B.) and echo incorporated (echo inc.) are pleased to explain the emission c...

Page 30

30 notes.

Page 31

P ro a ttachment s eries tm 31 o perator ' s m anual notes.

Page 32

Consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 www.Echo-usa.Com s75411001001/s75411999999 s67911001001/s67911999999 s86312001001/s86312999999 dealer? Call 1-800-432-echo 1-800-432-3246 or www.Echo-usa.Com s ervicing...