- DL manuals

- Echo

- Saw

- QV-670

- Instruction Manual

Echo QV-670 Instruction Manual

Summary of QV-670

Page 1

Instruction manual quikvent ™ system warning read the instructions carefully and follow the rules for safe operation. Failure to do so could result in serious injury. Qv-670

Page 2: Warning

The engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Warning copyright © 2002 all rights reserved. Warning some dust created by power sanding, sawing, grinding, drilling, and other construction activities ...

Page 3: Contents

1 contents page no. Safety ......................................................................................................................... 2 description ................................................................................................................. 7 operation (pre-ventil...

Page 4: Safety

2 safety this symbol means “do not do” whatever is shown. This symbol is used on danger signs to attract attention. This symbol is used on caution signs to attract attention. Danger although this manual uses safety symbols to highlight the most serious potential hazards, all instructions must be fol...

Page 5: Safety

3 safety this example of a note sign contains the echo definition of the signal word “note” read and understand the echo chainsaw safety manual before using this saw follow fire department regulations the safety manual included with your quikvent™ system and this instruction manual, covers terminolo...

Page 6: Safety

4 safety follow all maintenance procedures follow all maintenance procedures outlined in the maintenance section of this manual to ensure that the saw will operate safely and will start and operate when needed. Caution do not operate system in a confined area. Avoid carbon monoxide wear protective c...

Page 7: Safety

5 safety clear work area make sure that hazardous debris such as glass or wire is cleared from the area to be ventilated. Keep a safe distance from co-workers make sure there is another person nearby when operating the system, but also make sure they are at a safe distance. Operate safely avoid oper...

Page 8: Safety

6 safety use correct technique 1. With a basic understanding of kickback, you can reduce or eliminate the element of surprise. Sudden surprise contributes to accidents. 2. Keep a good firm grip of the saw with both hands, the right hand on the rear handle, and the left hand on the front handle. When...

Page 9: Description

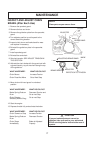

7 description controls trigger lockout lever muffler choke knob rear handle air cleaner cover sprocket guard firebrand bar and chain chain oil cap skid plate fan cover throttle trigger cylinder cover chain brake, hand guard starter grip ignition switch fuel cap front handle.

Page 10: Safe Starting Techniques

8 operation (pre-ventilation procedures) safe starting techniques 1. Know how to stop: keep hold of the rear handle, but release trigger and flick the switch to “stop.” 2. Hold the saw down securely on a flat surface with bar and chain in the clear. After setting the controls, hold the top of the fr...

Page 11: Safe Operation Tips

9 operation (pre-ventilation procedures) safe operation tips (ventilation procedures) 1. Follow all fire department procedures on safe ventilation techniques and on avoidance of cutting near gas and electric services. 2. Keep both hands on handles when engine is running. 3. Always operate the saw at...

Page 12

10

Page 13

11.

Page 14

12.

Page 15: Troubleshooting

1 3 troubleshooting trouble 1. Engine fails to start. 2. Engine hard start. 3. Engine misses. Cause no fuel in tank. Fuel filter clogged. Fuel line clogged. Spark plug shorted or fouled. Spark plug broken (cracked porcelain or electrodes broken). Ignition lead wire shorted, broken or disconnected fr...

Page 16: Troubleshooting

1 4 cause air cleaner clogged. Carburetor out of adjustment. Muffler clogged. Clogged exhaust ports. Poor compression. Insufficient oil in fuel mixture. Airflow obstructed. Spark plug incorrect heat range. Worn bearings, piston rings or cylinder walls. Carburetor main adjustment too “lean”. Engine o...

Page 17: Maintenance

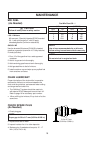

1 5 maintenance maintenance schedule required care clean entire system tighten nuts and bolts clean air filter inspect chain sharpen chain adjust chain tension adjust chain brake refill fuel tank test saw mix fuel check spark plug inspect muffler assembly drain and replace fuel replace fuel filter r...

Page 18: Sharpen Chain (As Needed)

1 6 sharpen chain (as needed) 1. Follow instructions included with sharpening kit. 2. Refer to page 19 for echo part number. Note do not sharpen carbide chain with standard file. Maintenance clean air filter (after each use) 1. Close choke. 2. Off the cleaner cover latch, and remove air filter cover...

Page 19: Maintenance

1 7 maintenance note clean parts as you remove them. Inspect and adjust chain brake (after each use) 1. Remove the sprocket guard. 2. Remove the bar and chain. 3. Remove the guide bar plate from the sprocket guard. 4. Turn adjuster position to set its peak to the correct tensioning location. 5. Insp...

Page 20: Maintenance

1 8 maintenance test saw (after each use/weekly) 1. Start the engine and make practice cut in a piece of 3/4 inch thick plywood. Make cuts using the ventilating procedure outlined in this manual. 2. Replace faulty parts and make necessary adjustments. Note for assistance in diagnosing problems, cons...

Page 21: Maintenance

1 9 maintenance note do not mix fuel in engine fuel tank. Note use of non-recommended oils or failure to follow mixing instructions voids the warranty. Check spark plug (as needed) 1. Check plug gap. Note proper gap is 0.6 to 0.7 mm (0.024 to 0.028 in) 2. Inspect electrode for wear. 3. Inspect insul...

Page 22: Maintenance

20 maintenance inspect muffler assembly (as needed) 1. Inspect spark arrestor screen for holes or warpage. 2. Inspect muffler body, bolts and screws. 3. Replace damaged parts. Replace fuel filter (as needed) 1. Pick up fuel filter through fuel tank opening with a piece of steel wire. 2. Remove filte...

Page 23: Maintenance

21 maintenance clean cylinder fins (as needed) note clogged fins will cause poor engine cooling. 1. Remove screws and remove starter assembly from housing. 2. Pull starter rope out 1 - 1/2 feet and prevent drum from rewinding. 3. Grasp the rope between notch and cover and wind both rope and drum one...

Page 24: Maintenance

22 maintenance turn automatic oiler clockwise to increase oil output or counterclockwise to decrease output. Adjust automatic oiler (as needed) 1. Remove oil tank cap. 2. Add oil : echo high detergent oil. 3. Install oil tank cap. Refill chain oil tank (after each use) note if chain runs dry of oil ...

Page 25: Assembly

Assembly mounting guide bar and chain • remove the sprocket guard with outer side plate, leaving the inner side plate in position. • mount the guide bar ensuring that the chain tensioner fits in the hole provided. • holding the bar in this position, feed the chain around the sprocket and into the gu...

Page 26: Specifications

2 4 specifications qv-670 mass with bar and chain, full fuel and oil kg 8.7 (19.2 lb.) powerhead only, dry kg 7.2 (15.9 lb.) engine type air-cooled two-stroke single cylinder displacement ml (cm³) 66.7 (4.07 cu. In.) bore × stroke mm 50 × 34 (1.97 × 1.34 in.) compression ratio 7.6 : 1 bearings heavy...

Page 27: Echo, Incorporated

Usa x750-002 80 1 x750316-3602 echo, incorporated 400 oakwood road, lake zurich, illinois 60047-1564 phone : 847-540-8400 printed in japan 0603me 0173 es.