- DL manuals

- Echo

- Trimmer

- SHC-2100

- Operator's Manual

Echo SHC-2100 Operator's Manual

H

EDGE

C

LIPPER

O

PERATOR

'

S

M

ANUAL

1

Shaft Hedge Clipper

Operator's Manual

MODEL

SHC-2100

Serial Number 0517101 & Up

X750004210

01/02

X7502253400

WARNING

DANGER

Read rules for safe operation and instructions carefully. ECHO provides an

Operator's Manual and a Safety Manual. Both must be read and understood for

proper and safe operation. Failure to do so could result in serous injury.

Summary of SHC-2100

Page 1

H edge c lipper o perator ' s m anual 1 shaft hedge clipper operator's manual model shc-2100 serial number 0517101 & up x750004210 01/02 x7502253400 warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and ...

Page 3

H edge c lipper o perator ' s m anual 3 s afety decals locate this safety decal on your unit. The complete unit illustration found in the "description" section, will help you locate them. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot ...

Page 4

4 international symbols symbol description/application symbol form/shape symbol description/application symbol form/shape hot surface carburetor adjustment - idle speed carburetor adjustment - high speed mixture symbol description/application symbol form/shape symbol description/application symbol f...

Page 5

H edge c lipper o perator ' s m anual 5 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals, may be brought about by exposure to vibration and cold. Exposure to vibration and cold may...

Page 6

6 safe operation warning danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions and can cause serious injury or death. Provide all users of this equipment with the operator's manual and instructions for safe operation. Keep a solid...

Page 7

H edge c lipper o perator ' s m anual 7 d escription the echo product you have purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, some assembly of shc-2100 is required. After opening the carton, check for damage. Immediately notify your retailer or echo dea...

Page 8

8 1. Power head - factory assembled. Includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Stop switch - mounted on top of the throttle trigger housing. Move switch forward to run, back to stop. 3. Front hand (left) handle - adjustable for proper cutting attitude and opera...

Page 9

H edge c lipper o perator ' s m anual 9 s pecifications l e d o m 0 0 1 2 - c h s h t g n e l ) . N i 5 . 1 7 ( m m 6 1 8 1 h t d i w ) . N i 5 . 8 ( m m 6 1 2 t h g i e h ) . N i 3 . 9 ( m m 5 3 2 * ) y r d ( t h g i e w ) . B l 9 . 2 1 ( g k 8 . 5 e p y t e n i g n e e n i g n e e n i l o s a g r ...

Page 10

10 a ssembly gear housing assembly / drive shaft tools required: 8mm x 10mm open end wrench, 4 mm hex wrench parts required: power head/drive shaft assembly and gear housing assembly. Note hedge clipper blades are very sharp. Wear gloves to protect hands. 1. Slide the gear housing assembly on the dr...

Page 11

H edge c lipper o perator ' s m anual 11 p re -o peration fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stro...

Page 12

12 o peration starting cold engine warning danger blades should not move at idle. If blades move, readjust carbure- tor according to carburetor adjustment instructions in the manual or see your echo dealer, otherwise serious personal injury may result. Note refer to the hedge clipper safety manual f...

Page 13

H edge c lipper o perator ' s m anual 13 starting warm engine the starting procedure is the same as cold start except do not close the choke. Note if engine does not start after 5 pulls, use cold start procedure. Warning danger blades should not move at idle. If blades move, readjust carburetor acco...

Page 14

14 stopping engine 1. Release throttle and allow engine to return to idle before shutting off engine. 2. Move stop switch button (a) backward to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold start position - to stall engine. Have...

Page 15

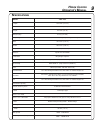

H edge c lipper o perator ' s m anual 15 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h y l r a e y 0 0...

Page 16

16 air filter level 1. Tools required: 25 or 50 mm (1 or 2 in.) medium bristle paint brush parts required: 90008 repower tm air & fuel filter kit 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumu- lated dirt from...

Page 17

H edge c lipper o perator ' s m anual 17 spark plug level 2. Tools required: t-wrench. Feeler gauge, preferably a wire gauge. Brush. Parts required: spark plug, ngk bpm-7a p/n 15901010630 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace with...

Page 18

18 1. Remove spark plug lead from the spark plug and throttle linkage end from the carburetor swivel. 2. Remove the four screws that retain the engine cover. Two at the top of the starter, two on either side of the front. Lift the cover from the engine and lay to the front of the hedge clipper. Note...

Page 19

H edge c lipper o perator ' s m anual 19 carburetor adjustment emission models (with limiter caps) level 2. Tools required: screwdriver, tachometer (echo p/n 99051130017). Parts required: none. Note every unit is run at the factory and the carburetor is set in compli- ance with emission regulations....

Page 20

20 lubrication blades level 1. Tools required: clean rag, brush , oil can, (2) 10 mm wrenches. Parts required: 20w engine oil (lubrication), 50-50 mixture of kerosene and 20w oil (cleaning). Warning danger blades are very sharp. Wear gloves to protect hands, otherwise serious personal injury may res...

Page 21

H edge c lipper o perator ' s m anual 21 drive shaft assembly note hedge clipper drive shaft should be greased every 25-50 hours of operation. Tools required: 8 mm open end wrench, screwdriver, clean rag, small brush. Parts required: echo ® lube tm (p/n 91014) or lithium based grease. Warning danger...

Page 22

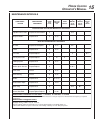

22 t roubleshooting warning danger fuel vapors are extremely flammable and may cause fire and/or explosion. Never test for ignition spark near an open spark plug opening, otherwise serious personal injury may result. T r a h c g n i t o o h s e l b u o r t m e l b o r p e n i g n e m e l b o r p k c...

Page 23: Warning

H edge c lipper o perator ' s m anual 23 s torage warning danger during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious personal injury may result. Long term stora...

Page 24

Dealer? Call 1-800-432-echo or www.Echo-usa.Com s ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo products are available only from an authorized echo dealer. When you do need to buy parts always have the model number and serial number of the unit w...

Page 25

1 models: serial number manual numbers modelo: nÚmeros de serie numero de pieza shc-2100 0517101 & up x7502253400 / x750004210 supplement to operator's manual suplemento del manual del operador this supplement contains important information. Please keep with your operator's manual. Este suplemento c...

Page 26

2 d warning danger inspect starting area for hazards such as rocks, glass, debris etc. Which could be contacted by the cutting attachment when starting. Keep helpers and bystanders at least 15 m (50 ft.) from starting area, other- wise serious personal injury may result. 4. Lay the unit on a flat cl...