- DL manuals

- Echo

- Brush Cutter

- SRM-2400 TYPE 1E - 09-99

- Operator's Manual

Echo SRM-2400 TYPE 1E - 09-99 Operator's Manual

Grass Trimmer/Brush Cutter

Operator's Manual

MODELS,

Type 1E

SRM-2400

Serial Number 562682 & Up

SRM-2410

Serial Number 503485 & Up

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's Manual and a

Safety Manual. Both must be read and understood for proper and safe operation.

X7532279701

89861154131

09/99

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

Summary of SRM-2400 TYPE 1E - 09-99

Page 1

Grass trimmer/brush cutter operator's manual models, type 1e srm-2400 serial number 562682 & up srm-2410 serial number 503485 & up warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and understood for pro...

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the- job-dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3: & I

G rass t rimmer /b rush c utter o perator ' s m anual 3 s afety general description important see description and specification sections for full description and illustration of model variation in power head, handle type, harness and debris shield/cutting attachment. Important the enclosed message p...

Page 4

4 debris shield decal decals locate these safety decals on your unit. The complete unit illustration, found in the "description" section, will help you locate them. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot be read, a new one can ...

Page 5

G rass t rimmer /b rush c utter o perator ' s m anual 5 international symbols equipment before operation a complete check of the unit must be performed; • check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. • inspect fuel lines, tank and area around carburetor for ...

Page 6

6 fuel warning danger fuel is very flammable. Use extreme care when mixing, storing or handling or serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks/cans may be under pressure. Always loosen fuel ca...

Page 7

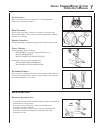

G rass t rimmer /b rush c utter o perator ' s m anual 7 eye protection -- wear eye protection that meets ansi z87.1 or ce requirements whenever you operate the trimmer. Hand protection -- wear no-slip, heavy duty work gloves to improve your grip on the brush cutter handles. Gloves also reduce the tr...

Page 8

8 operation use proper clothing & equipment - before starting the unit, equip yourself and any other personworking within the 15m (50 ft.) safety zone with the required protective equipment and clothing. Avoid hot surfaces - during operation, the complete unit, especially the drive shaft housing and...

Page 9

G rass t rimmer /b rush c utter o perator ' s m anual 9 extended operation / extreme conditions vibration and cold -- it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibr...

Page 10

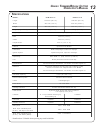

10 models 2410 1e 2400 1e √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ d escription the echo product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, shield installation and other assembly may be ...

Page 11

G rass t rimmer /b rush c utter o perator ' s m anual 11 safety video 1 2 25 3 4 7 5 6 8 9 20 12 13 14 15 16 17 18 19 10 11 5 11 21 22 23 24 important engine information engine family : teh021ub24ra displacement : 23.6 cc this engine meets u.S. Epa phi and 1995 - 1999 california emission regulations...

Page 12

12 1. Operator's manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future reference, i.E., operation, maintenance, storage and specifications. 2. Safety manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future ...

Page 13

G rass t rimmer /b rush c utter o perator ' s m anual 13 * install and use u-handle when operating any model with blade. M o d e l s r m -2 4 0 0 1 e s r m -2 4 1 0 1 e l e n g th 1 5 0 0 m m (5 9 .0 i n.) 1 5 0 0 m m (5 9 .0 in .) w id th 3 3 0 m m (1 3 .0 in .) 6 0 0 m m (2 3 .6 i n .) h e ig h t ...

Page 14

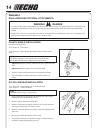

14 plastic shield installation (for nylon line operation) tools required: screwdriver. Parts required: plastic shield, shield plate, three (3) 5mm x 15mm screws. Note the plastic shield is for use with the nylon line head only. Install metal shield when using plastic or metal blades. 1. (srm-2410) r...

Page 15

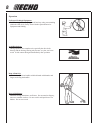

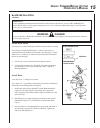

G rass t rimmer /b rush c utter o perator ' s m anual 15 blade installation all models. Important if non-standard monofilament head, metal/plastic blade or cultivator etc. Is used, the carburetor must be re-set or serious engine damage may occur. See "carburetor adjustment" pages 31 and "specifica- ...

Page 16

16 harness clamp installation note some models require installation of harness clamp. If your unit does not have a clamp, follow these directions. Tools required: screwdriver, 8 x 10mm open end wrench. Parts required: harness clamp, 4 x 18mm hexagon head bolt, link, spacer. 6. Remove shield and gear...

Page 17

G rass t rimmer /b rush c utter o perator ' s m anual 17 a b e d c f g j h front handle installation tools required: screwdriver. Parts required: none 1. Position front handle for comfortable operation and secure with screws. U - handle installation tools required: 8mm x 10mm open end wrench, slotte...

Page 18

18 400 mm (15-3/4 in.) 220 mm (8-5/8 in.) engine end k c e d a o b n m l 8. Position lower u-handle bracket (k) 400mm (15-3/4 in.) from engine end of drive shaft. Secure with three (3) 5mm x 30mm bolts. 9. Position harness hook 220mm (8-5/8 in.) from engine end of drive shaft assembly. Do not tighte...

Page 19

G rass t rimmer /b rush c utter o perator ' s m anual 19 r r r r r n n n n n p p p p p q q q q q a b srm-2410 14b. Connect ignition stop lead (a). Install ground lead with bolt (b). 15. Remove left side clutch case bolt (p). Install metal bracket clamp (q) with curved end down. Install throttle link...

Page 20: - O

20 p re - o peration operation with blades preparing the trimmer/brush cutter for blade use warning danger blade use demands specific brush cutter configuration. Operation without specified shield and harness can result in serious personal injury. Plastic and nylon blades require "blade conversion k...

Page 21

G rass t rimmer /b rush c utter o perator ' s m anual 21 8 tooth weed/grass blade (p/n 69600120331) is designed for grass, garden debris and thick weeds. Do not use this blade for brush or heavy woody growth, 3/4" in. (19 mm) diameter or larger. Brush/clearing blade(p/n 69500120330) is designed for ...

Page 22

22 r + m 2 fuel fuel requirements gasoline - use 89 octane [ ] gasoline or gasohol known to be good quality. Gasohol may contain up to 10% ethyl (grain) alcohol or 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stroke oil - a two-stroke engine o...

Page 23

G rass t rimmer /b rush c utter o perator ' s m anual 23 s m t w t f s 1 2 3 4 5 6 7 8 9 10 1112 13 14 15 16 17 1819 20 21 22 23 24 2526 27 28 29 30 31 15m (50 ft.) important stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days, ninety (90) days when a fuel stabilizer is...

Page 24

24 o peration • provide all operators of this equipment with the operator's manual and instructions for safe operation. • before starting the unit, equip yourself and any other person working within the 15m (50 ft.) safety zone with the required protective equipment and clothing. • during operation,...

Page 25

G rass t rimmer /b rush c utter o perator ' s m anual 25 c d d 5. Open choke - run. Move the choke lever back to the open - run position. Restart engine if necessary and allow to warm up running at idle for several minutes. Note if engine does not start with choke in “run” position after 4 pulls, re...

Page 26

26 stopping engine 1 . Release throttle. Allow engine to idle for a minute. 2 . Stop switch - stop. Move stop switch button (a) backward to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold start position - to stall engine. Have your...

Page 27

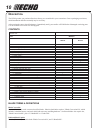

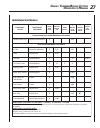

G rass t rimmer /b rush c utter o perator ' s m anual 2 7 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o ...

Page 28

28 air filter level 1. Tools required: cleaning brush, 1" or 2" medium bristle paint brush. Parts required: 90030 repower tm air & fuel filter kit. 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accumulated dirt from...

Page 29

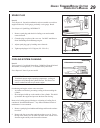

G rass t rimmer /b rush c utter o perator ' s m anual 29 a 0.65 mm 0.65 mm 0.65 mm 0.65 mm 0.65 mm (0.026 in.) (0.026 in.) (0.026 in.) (0.026 in.) (0.026 in.) spark plug level 2. Tools required: scrench (combination socket wrench & screw driver supplied with unit) feeler gauge, preferably a wire gau...

Page 30

30 note the throttle linkage remains assembled to the cover and the spark plug lead and grommet remain installed. 3. Use the wooden stick or brush to remove dirt form cylinder fins. 4. Remove grass and leaves from the grid between the recoil starter and fuel tank. 5. Assemble components in reverse o...

Page 31

G rass t rimmer /b rush c utter o perator ' s m anual 31 carburetor adjustment type 1e emission models level 2. Tools required: screwdriver, tachometer (echo p/n 99051130017). Parts required: none. Note every unit is run at the factory and the carburetor is set in compli- ance with epa phase 1 and c...

Page 32

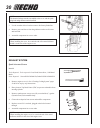

32 nylon line replacement level 1. Tools required: head locking tool (if head is to be removed) parts required: echo 0.095" nylon trimmer line 40 feet (12m) long. 1. Hold drum (a) and turn spool (b) cw (clockwise) until it stops. Pull spool from drum. Do not push in on spool when turning. 2. Use one...

Page 33

G rass t rimmer /b rush c utter o perator ' s m anual 33 sharpening metal blades three styles of metal blades are approved for use on the echo brushcutter. The 8-tooth blade can be sharpened during normal maintenance. The clearing blade and 80 tooth blade require profes- sional service. Before sharp...

Page 34

34 t roubleshooting problem engine -- starts hard engine -- does not start cause remedy engine cranks fuel at carburetor no fuel at carburetor fuel strainer clogged fuel line clogged carburetor clean clean see your echo dealer fuel at cylinder no fuel at cylinder carburetor see your echo dealer muff...

Page 35

G rass t rimmer /b rush c utter o perator ' s m anual 35 s torage long term storage (over 30 days) do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage mainte- nance which includes the following: 1. Store unit in a dry, dust free place, out ...

Page 36

S ervicing i nformation parts -- genuine echo parts and echo repower tm parts and assemblies for your echo products are available only from an authorized echo dealer. When you do need to buy parts always have the model number, type number and serial number of the unit with you. You can find all thre...