- DL manuals

- Echo

- Brush Cutter

- SRM-260 - 12-00

- Operator's Manual

Echo SRM-260 - 12-00 Operator's Manual

Grass Trimmer/Brush Cutter

Operator's Manual

MODELS,

SRM - 260

SRM - 260S

Serial Number 04001001 - 04999999

WARNING

DANGER

Read rules for safe operation and instructions carefully. ECHO provides an

Operator's Manual and a Safety Manual. Both must be read and understood for

proper and safe operation. Failure to do so could result in serous injury.

X7502096100

X750002010

12/00

Summary of SRM-260 - 12-00

Page 1

Grass trimmer/brush cutter operator's manual models, srm - 260 srm - 260s serial number 04001001 - 04999999 warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and understood for proper and safe operation....

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the- job-dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3

G rass t rimmer /b rush c utter o perator ' s m anual 3 this symbol accompanied by the words warning and danger calls attention to an act or condition that can lead to serious personal injury to operator and bystanders. The circle with the slash symbol means whatever is shown within the circle is pr...

Page 4

4 shaft decal warning danger • this unit can be dangerous and cause serious injury if improperly used. To reduce injury risk to operator, helpers and bystanders, read and understand the operator's and safety manuals. • blindness can occur from objects that are thrown or ricocheted even with shield i...

Page 5

G rass t rimmer /b rush c utter o perator ' s m anual 5 equipment warning danger • use only echo approved attachments. Serious injury may result from the use of a non approved attachment combination. Read and comply with all safety instructions listed in this manual and safety manual. • echo, inc. W...

Page 6

6 fuel warning danger fuel is very flammable. Use extreme care when mixing, storing or handling, otherwise serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks/cans may be under pressure. Always loosen...

Page 7

G rass t rimmer /b rush c utter o perator ' s m anual 7 physical condition -- your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protect...

Page 8

8 safe operation determine operation area • provide all operators of this equipment with the operator's manual and instructions for safe operation. • review the area to be trimmed. Look for hazards that could contribute to unsafe conditions. • spectators and fellow workers must be warned, and childr...

Page 9

G rass t rimmer /b rush c utter o perator ' s m anual 9 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibrati...

Page 10

10 blade terms and definitions blade convertible models (srm-260, 260s) can be converted to utilize blades. Plastic/nylon blades require a, "blade conversion kit" p/n 99944200415, which includes a shoulder harness, and steel shield with necessary attaching hardware. Steel/metal blades require combin...

Page 11

G rass t rimmer /b rush c utter o perator ' s m anual 11 3 4 5 6 7 8 9 10 11 1 2 12 14 15 16 17 18 19 20 13 21.

Page 12

12 1. Operator's manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future reference, i.E., operation, maintenance, storage and specifications. 2. Safety manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future ...

Page 13

G rass t rimmer /b rush c utter o perator ' s m anual 13 s pecifications * install and use u-handle when operating any model with blade. L e d o m 0 6 2 - m r s s 0 6 2 - m r s d a e h r e t t u c o / w h t g n e l ) . N i 7 . 0 7 ( m m 5 9 7 1 h t d i w ) . N i 4 8 . 9 ( m m 0 5 2 t h g i e h ) . N...

Page 14

14 a ssembly plastic shield installation (for nylon line operation) tools required: screwdriver. Parts required: plastic shield, shield plate, three (3) 5mm x 15mm screws. Note the plastic shield is for use with the nylon line head only. Install metal shield when using plastic or metal blades. 1. Re...

Page 15

G rass t rimmer /b rush c utter o perator ' s m anual 15 accessory installation blade conversion kit p/n 99944200415, u-handle / blade conversion kit p/n 99944200521. Note refer to operation with blades page 19 for correct accessory / blade equipment requirements. Warning danger you must install a u...

Page 16

16 metal shield installation tools required: 8mm x 10mm open end wrench, screwdriver. Parts required: metal shield, bracket, 3 - 5mm x 15mm screws w/captivated flat and lockwasher (metal shield to gear housing), 2 - 5mm x 8mm screws, 4 - 5mm nuts, 4 - 5mm lockwashers (bracket to shield and bracket t...

Page 17

G rass t rimmer /b rush c utter o perator ' s m anual 17 5. Loosen bolt (e) and pull drive shaft assembly from clutch case. 6. Loosen two (2) rear handle screws (f) and pull rear handle (g) from the drive shaft assembly. 7. Loosen four (4) screws (h) and remove front handle. 8. Position lower u-hand...

Page 18

18 m 13. Place throttle linkage in slot in bracket. One nut on each side of bracket. Finger tighten both nuts (d). 14. Attach inner cable to swivel (c). Check throttle for freedom of movement and that wide open throttle / low idle extremes are adjusted properly. If adjustment cannot be achieved with...

Page 19: - O

G rass t rimmer /b rush c utter o perator ' s m anual 19 p re - o peration operation with blades preparing the trimmer/brush cutter for blade use warning danger blade use demands specific brush cutter configuration. Operation without specified shield and harness can result in serious personal injury...

Page 20

20 plastic/nylon blades may be used where ever the nylon line head is used. Do not use this blade for heavy weeds or brush! Blade conversion kit p/n 99944200415 is required for use with nylon blades. 8 tooth weed/grass blade (p/n 69600120331) is designed for grass, garden debris and thick weeds. Do ...

Page 21

G rass t rimmer /b rush c utter o perator ' s m anual 21 fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two strok...

Page 22

22 important spilled fuel is a leading cause of hydrocarbon emissions. Some states may require the use of automatic fuel shut-off containers to reduce fuel spillage. Contact your echo dealer for ordering information. After refueling; • wipe any spilled fuel from the unit. • move at least 3 m (10 ft....

Page 23

G rass t rimmer /b rush c utter o perator ' s m anual 23 equipment check before operation a complete check of the unit must be performed; • check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed. • inspect fuel lines, tank and area around carburetor for fuel leaks. Do ...

Page 24

24 o peration • provide all operators of this equipment with the operator's manual, and instructions for safe operation. • refer to the safety manual provided with the unit for proper trimming and brush cutting techniques. • during operation, the bearing housing, and the muffler or catalytic muffler...

Page 25

G rass t rimmer /b rush c utter o perator ' s m anual 25 3. Primer - pump bulb. Pump primer bulb (c) until fuel is visible and flows freely in the clear fuel tank return line. Pump bulb an additional 4 or 5 times. 4. Start - pull rope. Lay the trimmer on a flat clear area and pull the recoil starter...

Page 26

26 stopping engine 1. Release throttle. Allow engine to idle for a minute. 2. Stop switch - stop. Move stop switch button (a) backward to stop position. Warning danger if engine does not stop when stop switch is moved to stop position, close choke - cold start position - to stall engine. Have your e...

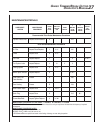

Page 27

G rass t rimmer /b rush c utter o perator ' s m anual 27 maintenance intervals / t n e n o p m o c m e t s y s e c n a n e t n i a m e r u d e c o r p d ' q e r l l i k s l e v e l r o y l i a d e r o f e b e s u y r e v e l e u f e r 3 s h t n o m 0 9 r o s r u o h 6 s h t n o m 0 7 2 r o s r u o h...

Page 28

28 air filter level 1. Tools required: cleaning brush, 25 or 50 mm (1 or 2 in.) medium bristle paint brush. Parts required: 90030 repower tm air & fuel filter kit. 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the air filter is removed. Brush accum...

Page 29

G rass t rimmer /b rush c utter o perator ' s m anual 29 0.65 mm (0.026 in.) warning danger do not perform maintenance on the muffler until engine and muffler are completely cool, otherwise serious personal injury may occur. Spark plug level 2. Tools required: t-wrench (combination socket wrench & s...

Page 30

30 1. Remove spark plug lead. 2. Remove two (2) muffler cover screws and muffler cover (a). 3. Remove screw and arm rest (b). 4. Remove engine cover (c). Important do not use a metal scraper to remove dirt from the cylinder fins. 5. Use brush to remove dirt from the cylinder fins. 6. Remove grass an...

Page 31

G rass t rimmer /b rush c utter o perator ' s m anual 31 1. Remove engine cover (a). See “cleaning cooling system” pages 29 & 30 for step by step instructions. 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 3. Remove spark arrestor screen cover (b), screen ho...

Page 32

32 1. Check idle speed and reset if necessary. If a tachometer is avail- able, idle speed screw (a) should be set to the specifications found on page 13 "specifications" of this manual. Turn idle screw (a) clockwise to increase idle speed; counter clockwise to decrease idle speed. Warning danger whe...

Page 33

G rass t rimmer /b rush c utter o perator ' s m anual 33 nylon line replacement level 1. Tools required: head locking tool (if head is to be removed) parts required: echo 0.095" nylon trimmer line 12 m (40 feet) long. 1. Hold drum (a) and turn spool (b) cw (clockwise) until it stops. Pull spool from...

Page 34

34 sharpening metal blades three styles of metal blades are approved for use on the echo brush cutter. The 8-tooth blade can be sharpened during normal maintenance. The clearing blade and 80 tooth blade require professional service. Before sharpening, closely inspect blade for cracks (look at the bo...

Page 35

G rass t rimmer /b rush c utter o perator ' s m anual 35 m e l b o r p d r a h s t r a t s - - e n i g n e t r a t s t o n s e o d - - e n i g n e e s u a c y d e m e r e n i g n e s k n a r c t a l e u f r o t e r u b r a c t a l e u f o n r o t e r u b r a c d e g g o l c r e n i a r t s l e u f d...

Page 36

36 s torage long term storage (over 30 days) warning danger during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. D...

Page 37: Notes

G rass t rimmer /b rush c utter o perator ' s m anual 37 notes.

Page 38: Notes

38 notes.

Page 39: Notes

G rass t rimmer /b rush c utter o perator ' s m anual 39 notes.

Page 40

S ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your echo products are available only from an authorized echo dealer. When you do need to buy parts always have the model number and serial number of the unit with you. You can find these numbers on the engin...