- DL manuals

- Echo

- Trimmer

- SRM - 2601

- Operator's Manual

Echo SRM - 2601 Operator's Manual

Grass Trimmer/Brush Cutter

Operator's Manual

MODELS,

SRM - 2601

SRM - 2610

Serial Number 001001 & Up

WARNING

DANGER

WARNING

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

Read rules for safe operation and instructions carefully. ECHO provides an Operator's

Manual and a Safety Manual. Both must be read and understood for proper and safe

operation. Failure to do so could result in serous injury.

X7502090701

89851957731

02/00

Summary of SRM - 2601

Page 1

Grass trimmer/brush cutter operator's manual models, srm - 2601 srm - 2610 serial number 001001 & up warning danger warning the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Read rules for safe operatio...

Page 2: —

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job- dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and s...

Page 3

G rass t rimmer /b rush c utter o perator ' s m anual 3 this symbol accompanied by the words warning and danger calls attention to an act or condition that can lead to serious personal injury to operator and bystanders. The circle with the slash symbol means whatever is shown within the circle is pr...

Page 4

4 international symbols shaft decal warning danger • this unit can be dangerous and cause serious injury if improperly used. To reduce injury risk to operator, helpers and bystanders, read and understand the operator's and safety manuals. • blindness can occur from objects that are thrown or ricoche...

Page 5

G rass t rimmer /b rush c utter o perator ' s m anual 5 equipment warning danger • use only echo approved attachments. Serious injury may result from the use of a non approved attachment combination. Read and comply with all safety instructions listed in this manual and safety manual. • echo, inc. W...

Page 6

6 fuel warning danger fuel is very flammable. Use extreme care when mixing, storing or handling, otherwise serious personal injury may result. • use an approved fuel container. • do not smoke near fuel. • do not allow flames or sparks near fuel. • fuel tanks/cans may be under pressure. Always loosen...

Page 7

G rass t rimmer /b rush c utter o perator ' s m anual 7 physical condition -- your judgment and physical dexterity may not be good: • if you are tired or sick, • if you are taking medication, • if you have taken alcohol or drugs. Operate unit only if you are physically and mentally well. Eye protect...

Page 8

8 safe operation determine operation area • provide all operators of this equipment with the operator's manual and instructions for safe operation. • review the area to be trimmed. Look for hazards that could contribute to unsafe conditions. • spectators and fellow workers must be warned, and childr...

Page 9

G rass t rimmer /b rush c utter o perator ' s m anual 9 extended operation / extreme conditions vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibrati...

Page 10

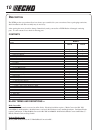

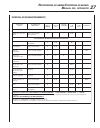

10 contents list i t e m s models 2610 1e 2601 1e √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ 1 - power head 1 - drive shaft assembly 1 - plastic bag (co-pack) - 1, operator's manual - 1, safety manual - 1, warranty registration card - 1, limit...

Page 11

G rass t rimmer /b rush c utter o perator ' s m anual 11 emission control -- the emission control system for this engine is em (engine modification). Emission control label located on engine (example only, information on label varies by family). 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 20 21 22 23...

Page 12

12 1. Operator's manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future reference, i.E., operation, maintenance, storage and specifications. 2. Safety manual - included in plastic bag (co-pack). Read before operation and keep in a safe place for future ...

Page 13

G rass t rimmer /b rush c utter o perator ' s m anual 13 s pecifications m o d e l s r m -2 6 0 1 1 e s r m -2 6 1 0 1 e l e n g th 1 8 0 0 m m (7 0 .9 in .) 1 8 0 0 m m (7 0 .9 in .) w id th 3 1 5 m m (1 2 .4 in .) 6 0 0 m m (2 3 .6 i n.) h e ig h t 2 8 5 m m (11 .0 in .) 2 8 5 m m (11 .0 in .) w e...

Page 14

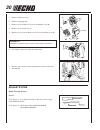

14 a ssembly drive shaft / power head tools required: 4 mm hex wrench parts required: power head, drive shaft assembly 1. Loosen, the bolt (a) at engine drive shaft clamp. 2. Carefully fit drive shaft assembly to engine making sure that inner drive shaft engages into clutch mount. Note lower gear ho...

Page 15

G rass t rimmer /b rush c utter o perator ' s m anual 15 b a plastic shield installation (for nylon line operation) tools required: screwdriver. Parts required: plastic shield, shield plate, three (3) 5mm x 15mm screws. Note the plastic shield is for use with the nylon line head only. Install metal ...

Page 16

16 note for srm-2610 handle assembly refer to "u-handle installation page 18 instructions 1, 10, 12 - 16. Accessory installation blade conversion kit p/n 99944200415, u-handle / blade conversion kit p/n 99944200521, muffler bracket kit p/n 10099057730. Note refer to operation with blades page 20 for...

Page 17

G rass t rimmer /b rush c utter o perator ' s m anual 17 install metal shield tools required: 8mm x 10mm open end wrench, screwdriver. Parts required: metal shield, bracket, 3 - 5 mm x 15 mm screws w/captivated flat and lockwasher (metal shield to gear housing), 2 - 5 mm x 8 mm screws, 4 - 5 mm nuts...

Page 18

18 u - handle installation tools required: 8mm x 10mm open end wrench, screwdriver, 3mm and 4mm hex wrench, pliers parts required: u-handle/blade conversion kit p/n 99944200521. Note for model srm-2610 use steps 1, 10, 12 - 16. 1. Close choke and remove air filter cover. 2. Disconnect ignition stop ...

Page 19

G rass t rimmer /b rush c utter o perator ' s m anual 19 12. Route throttle linkage and ignition lead assembly around front of u-handle bracket and clip to drive shaft as shown. 13. Place throttle linkage (e) through adjustment fixture (f) and install wire end into large carburetor throttle swivel h...

Page 20: - O

20 p re - o peration operation with blades preparing the trimmer/brush cutter for blade use warning danger blade use demands specific brush cutter configuration. Operation without specified shield and harness can result in serious personal injury. Plastic and nylon blades require "blade conversion k...

Page 21

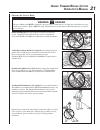

G rass t rimmer /b rush c utter o perator ' s m anual 21 choosing the correct blade warning danger the type of blade used must be matched to the type and size of material cut. An improper or dull blade can cause serious personal injury. Blades must be sharp. Dull blades increase the chance of kick o...

Page 22

22 fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline or gasohol known to be good quality. Gasohol may contain up to 10% ethyl (grain) alcohol or 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is not approved. Two stroke oil - a two-s...

Page 23

G rass t rimmer /b rush c utter o perator ' s m anual 23 after refueling; • wipe any spilled fuel from the unit. • move at least 3 m (10 ft.) from refueling location before starting. After use; • do not store a unit with fuel in its tank. Leaks can occur. Return unused fuel to an approved fuel stora...

Page 24

24 determine operation area warning danger inspect starting area for hazards such as rocks, glass, debris etc. Which could be contacted by the cutting attachment when starting. Keep helpers and bystanders at least 15 m (50 ft.) from starting area, otherwise serious personal injury may result. • befo...

Page 25

G rass t rimmer /b rush c utter o perator ' s m anual 25 2. Close choke - cold start. Move choke lever (b) to cold start position. 3. Primer - pump bulb. Pump primer bulb (c) 10 times until fuel is visible in the “clear” fuel return line (d). 4. Start - pull rope. Lay the trimmer on a flat clear are...

Page 26

26 2. Primer - pump bulb.Pump primer bulb (c) until fuel is visible in the "clear" fuel return line (d). 3. Start - pull rope.Lay the trimmer on a flat clear area and pull the recoil starter handle (e) until the engine fires. Stopping engine 1. Release throttle. Allow engine to idle for a minute. 2....

Page 27

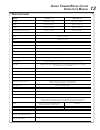

R ecortadora de hierba /c ortadora de maleza m anual del operador 2 7 intervalos de mantenimiento / e t n e n o p m o c a m e t s i s e d o t n e i m i d e c o r p o t n e i m i n e t n a m s a i r a s e c e n e d l e v i n d a d i l i b a h e t n e m a i a i d e d s e t n a o r a s u r a g r a c l ...

Page 28

28 warning danger fuel is very flammable. Use extreme care when mixing, storing or handling. 1. Use a clean rag to remove loose dirt from around fuel cap and empty fuel tank. 2. Use the “fuel line hook” to pull the fuel line and filter from the tank. 3. Remove the filter from the line and install th...

Page 29

G rass t rimmer /b rush c utter o perator ' s m anual 29 spark plug level 2. Tools required: t-wrench (combination socket wrench & screw driver supplied with unit) feeler gauge, preferably a wire gauge. Soft metal brush. Parts required: spark plug, ngk bpm-7y p/n 99944500071 1. Remove spark plug and...

Page 30

30 1. Remove air filter cover (a). 2. Remove spark plug lead. 3. Remove two (2) muffler cover screws and muffler cover (b). 4. Remove screw and arm rest (c). 5. Remove two (2) front cylinder cover screws and cylinder cover (d). Important do not use a metal scraper to remove dirt from the cylinder fi...

Page 31

G rass t rimmer /b rush c utter o perator ' s m anual 31 1. Remove engine cover (a). See “cleaning cooling system” pages 29 & 30 for step by step instructions. 2. Place piston at top dead center (tdc) to prevent carbon/dirt from entering cylinder. 3. Remove spark arrestor screen cover (b), screen ho...

Page 32

32 a lubrication level 1. Tools required: 8 mm open end wrench, screwdriver, clean rag. Parts required: lithium base grease. Gear housing 1. Clean all loose debris from gear box. 2. Remove plug (a) and check level of grease. 3. Add grease if necessary, do not over fill. Nylon line replacement level ...

Page 33

G rass t rimmer /b rush c utter o perator ' s m anual 33 3. Hold the spool, opening toward you. Place index finger between the two strands and wind line, tightly and evenly, in direction of arrow marked "cc". 4. Stop when approximately 15-20 cm (6 - 8 in.) line (c) remains and place ends of line in ...

Page 34

34 sharpening metal blades three styles of metal blades are approved for use on the echo brush cutter. The 8-tooth blade can be sharpened during normal maintenance. The clearing blade and 80 tooth blade require professional service. Before sharpening, closely inspect blade for cracks (look at the bo...

Page 35

G rass t rimmer /b rush c utter o perator ' s m anual 35 t roubleshooting problem engine -- starts hard engine -- does not start c ause r emedy engine c ranks fuel at carburetor no fuel at carburetor fuel strainer clogged fuel line clogged c arburetor c lean c lean see your e c ho dealer fuel at cyl...

Page 36

36 s torage long term storage (over 30 days) warning danger during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. D...

Page 37: Notes

G rass t rimmer /b rush c utter o perator ' s m anual 37 notes.

Page 38: Notes

38 notes.

Page 39: Notes

G rass t rimmer /b rush c utter o perator ' s m anual 39 notes.

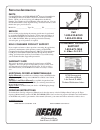

Page 40

Echo, incorporated 400 o akwood r oad l ake z urich , il 60047 dealer? Call 1-800-432-echo 1-800-432-3246 echo incorporated 400 oakwood road lake zurich, il 60047 technical publications orders s ervicing i nformation parts genuine echo parts and echo repower tm parts and assemblies for your echo pro...