- DL manuals

- Echo

- Trimmer

- SRM-3400

- Operator's Manual

Echo SRM-3400 Operator's Manual

Grass Trimmer/Brush Cutter

Operator's Manual

MODEL

SRM-3400

Serial Number 541793 & Up

WARNING

DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Operator's

Manual and a Safety Manual. Both must be read and understood for proper and safe

operation.

X7502124703

89861155833

12/01

Summary of SRM-3400

Page 1

Grass trimmer/brush cutter operator's manual model srm-3400 serial number 541793 & up warning danger read rules for safe operation and instructions carefully. Echo provides an operator's manual and a safety manual. Both must be read and understood for proper and safe operation. X7502124703 898611558...

Page 2

2 i ntroduction welcome to the echo family. This echo product was designed and manufactured to provide long life and on-the-job dependability. Read and understand this manual and the safety manual you found in the same package. You will find both easy to use and full of helpful operating tips and sa...

Page 3

G rass t rimmer /b rush c utter o perator ' s m anual 3 this symbol accompanied by the words warning and danger calls attention to an act or condition that can lead to serious personal injury to operator and bystanders. The circle with the slash symbol means whatever is shown within the circle is pr...

Page 4

4 4 shaft decal warning danger • this unit can be dangerous and cause serious injury if improperly used. To reduce injury risk to operator, helpers and bystanders, read and understand the operator's and safety manuals. • blindness can occur from objects that are thrown or ricocheted even with shield...

Page 5

G rass t rimmer /b rush c utter o perator ' s m anual 5 s afety i nstructions personal condition and safety equipment warning danger trimmer/brush cutter users risk injury to themselves and others if the trimmer/brush cutter is used improperly and or safety precautions are not followed. Proper cloth...

Page 6

6 equipment warning danger use only echo approved attachments. Serious injury may result from the use of a non approved attachment combination. Echo, inc. Will not be responsible for the failure of cutting devices, attachments or accessories which have not been tested and approved by echo. Read and ...

Page 7

G rass t rimmer /b rush c utter o perator ' s m anual 7 e mission c ontrol the emission control system for these engines is em (engine modifica- tion). An emission control label is located on the engine. (this is an example only, information on label varies by engine family). Important engine inform...

Page 8

8 14 13 15 16 18 19 20 17 12 21 7 8 9 10 5 6 4 1 2 3 11.

Page 9

G rass t rimmer /b rush c utter o perator ' s m anual 9 1. Power head - includes the engine, clutch, fuel system, ignition system and recoil starter. 2. Grip - rear (right hand) handle. 3. Throttle trigger lockout - this lever must be held during acceleration. Operation of the throttle trigger is pr...

Page 10

10 s pecifications * install and use u-handle when operating any model with blade. L e d o m 0 0 4 3 - m r s h t g n e l ) . N i 2 . 0 6 ( m m 0 3 5 1 h t d i w ) . N i 0 . 3 1 ( m m 0 3 3 t h g i e h ) . N i 2 . 0 1 ( m m 0 6 2 d a e h r e t t u c / w ) y r d ( t h g i e w ) . B l 7 . 5 1 ( g k 1 ....

Page 11

G rass t rimmer /b rush c utter o perator ' s m anual 11 a ssembly drive shaft / power head tools required: 8mm x 10mm open end wrench, 4 mm hex wrench parts required: power head, drive shaft assembly 1. Stand powerhead upright on a level surface. 2. Loosen, the two (2) bolts at engine drive shaft c...

Page 12

12 blade installation important if non-standard monofilament head, metal/plastic blade or cultivator etc. Is used, the carburetor must be re-set or serious engine damage may occur. See "carburetor adjustment" page 27and "specification" page 10 of this manual for proper adjustment setting. A b nylon ...

Page 13

G rass t rimmer /b rush c utter o perator ' s m anual 13 install blade tools required: locking tool, scrench. Parts required: upper plate w/ 20mm pilot, lower plate, 10mm nut w/lh threads, 2mm x 25mm split pin (cotter pin). 3. Install upper plate (d) on splined pto shaft. Blade installation requires...

Page 14

14 a b c 8. Install harness clamp. A. Slightly spread clamp and slide up shaft. B. Install single link using spacer, do not tighten at this time. 9. Install gear housing and shield and front handle. 10. Balance unit. A. Put on harness and attach unit to harness. B. Slide clamp up or down until unit ...

Page 15

G rass t rimmer /b rush c utter o perator ' s m anual 15 2. Position front handle for comfortable operation and secure screws. U - handle installation tools required: 8mm x 10mm open end wrench, screwdriver. Parts required: u-handle kit p/n 35130455830. 1. Close choke and remove air filter cover. 2....

Page 16

16 11. Install upper u-handle and bracket on lower bracket and secure with one (1) 8mm x 55mm bolt (l) and large circular washer. 12. Secure throttle linkage and ignition leads to drive shaft with cable ties supplied. 13. Install power head and align gear box, power head and u-handles. Tighten all s...

Page 17: - O

G rass t rimmer /b rush c utter o perator ' s m anual 17 p re - o peration operation with blades preparing the trimmer/brush cutter for blade use warning danger blade use demands specific brush cutter configuration. Operation without specified shield and harness can result in serious personal injury...

Page 18

18 8 tooth weed/grass blade is designed for grass, garden debris and thick weeds. Do not use this blade for brush or heavy woody growth, 19 mm (3/4 in.) diameter or larger. P/n 69600121431 brush/clearing bladeis designed for cutting brush and woody growth up to 76 mm (3 in.) diameter. P/n 6950012143...

Page 19

G rass t rimmer /b rush c utter o perator ' s m anual 19 fuel fuel requirements gasoline - use 89 octane [ ] (mid grade or higher) gasoline or gasohol known to be good quality. Gasohol may contain up to 10% ethyl (grain) alcohol or 15% mtbe (methyl tertiary-butyl ether). Gasohol containing methyl (w...

Page 20

20 o peration starting cold engine warning danger the cutting attachment should not rotate at idle. If attachment rotates, readjust carburetor according to "carburetor adjustment" instructions in this manual or see your echo dealer, otherwise serious personal injury may result. Note refer to grass t...

Page 21

G rass t rimmer /b rush c utter o perator ' s m anual 21 starting warm engine warning danger the cutting attachment should not rotate at idle. If attachment rotates, readjust carburetor according to "carburetor adjustment" instructions in this manual or see your echo dealer, otherwise serious person...

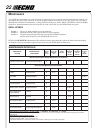

Page 22

2 2 m aintenance your echo unit is designed to provide many hours of trouble-free service. Regular scheduled maintenance will help your unit achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an echo service dealer for maintenance. To...

Page 23

G rass t rimmer /b rush c utter o perator ' s m anual 23 air filter level 1. Tools required: 25-50mm (1or 2 in.) medium bristle paint brush. Parts required: 90030 repower tm air & fuel filter kit. 1. Close choke (cold start position). This prevents dirt from entering the carburetor throat when the a...

Page 24

24 spark plug level 2. Tools required: scrench (combination socket wrench & screw driver) feeler gauge, preferably a wire gauge. Brush. Parts required: spark plug, ngk bpm-7a p/n 15901010630 1. Remove spark plug and check for fouling, worn and rounded center electrode. 2. Clean the plug or replace w...

Page 25

G rass t rimmer /b rush c utter o perator ' s m anual 25 3. Use the wooden stick or brush to remove dirt from the cylinder fins. 4. Remove grass and leaves from the grid between the recoil starter and fuel tank. Exhaust system spark arrestor screen level 2. Tools required: cross head screwdriver. Sc...

Page 26

26 carburetor adjustment level 2. Tools required: screwdriver, tachometer (echo p/n 99051130017). Parts required: none. Note every unit is run at the factory and the carburetor is set in compli- ance with emission regulations. In addition, the carburetor is equipped with hi and lo needle adjustment ...

Page 27

G rass t rimmer /b rush c utter o perator ' s m anual 27 a lubrication level 1. Tools required: 8 mm open end wrench, screwdriver, clean rag. Parts required: echo ® lube tm 8 oz. (p/n 91014) or lithium base grease. Gear housing 1. Clean all loose debris from gear box. 2. Remove plug (a) and check le...

Page 28

28 5. When approximately 15-20 cm ( 6- 8in.) of line remains, place lines in spool notches (d). 6. Place spool in housing against spring; thread line ends through housing eyelets (e). 7. Align cover tabs with tab holes in housing and push until tabs snap lock into place. 8. Pull on both lines until ...

Page 29

G rass t rimmer /b rush c utter o perator ' s m anual 29 t r a h c g n i t o o h s e l b u o r t m e l b o r p e n i g n e m e l b o r p k c e h c s u t a t s e s u a c y d e m e r e n i g n e - s k n a r c / d r a h s t r a t s t' n s e o d t r a t s r o t e r u b r a c t a l e u f r o t e r u b r ...

Page 30

30 s torage warning danger during operation the muffler or catalytic muffler and surrounding cover become hot. Always keep exhaust area clear of flammable debris during transportation or when storing, otherwise serious property damage or personal injury may result. Long term storage (over 30 days) d...

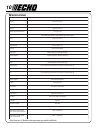

Page 31: Notes

G rass t rimmer /b rush c utter o perator ' s m anual 31 notes.

Page 32

Echo, incorporated 400 o akwood r oad l ake z urich , il 60047-1564 www.Echo-usa.Com dealer? Call 1-800-432-echo or www.Echo-usa.Com consumer product support 1-800-673-1558 8:30 - 4:30 mon - fri c.S.T. S ervicing i nformation parts genuine echo parts and echo repower™ parts and assemblies for your e...