- DL manuals

- Eclipse

- Transmitter

- 705

- Installation and operating manual

Eclipse 705 Installation and operating manual

Summary of 705

Page 1

® guided wave radar level transmitter installation and operating manual ™ 705 software v3.X.

Page 2

2 unpacking unpack the instrument carefully. Make sure all components have been removed from the foam protection. Inspect all components for damage. Report any concealed damage to the carrier within 24 hours. Check the contents of the car- ton/crates against the packing slip and report any discrep- ...

Page 3

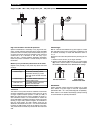

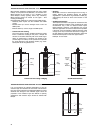

Size: 38 mm (1 1/2") or adjustable wrench customer supplied brackets are recommended per each 3 m length. (required for wgh § 19 installations.) not important min 25 mm (1") from tank bottom 3 overfill safe and overfill proof eclipse 7md/7ml, 7mr/7mm and 7mt/7mn coaxial gwr probes are “overfill safe” i...

Page 4

4 mounting overfill safe and overfill proof eclipse twin rod gwr probes use software to ignore level readings in the transitioning zone at the top of the gwr probe. The maximum level is a minimum of 150 mm (6") below the process connection. This may include utilizing a nozzle or spool piece to raise t...

Page 5

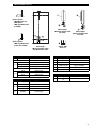

5 mounting 13 mm Ø (0.50") 1 3 2 4 7m7/7m5 probe can be shortened in field. A.Raise the weight (1) to expose the two securing devices (2) b.Loosen the two #10-32 set screws (3) on both securing devices using a 2.5 mm (3/32") hex wrench and slide the securing devices off of the probe c. Slide the tfe ...

Page 6

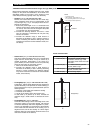

6 mounting single rod (7mf - 7mh - 7mj) / single cable (7m1 - 7m2) gwr probes size: 38 mm (1 1/2") or adjustable wrench size: 38 mm (1 1/2") or adjustable wrench high level shutdown and overfill protection special consideration is necessary in any high level shut- down / overfill protection applicatio...

Page 7

7 mounting shortening of probe length single rod/cable probes can be shortened safely in the field. Make sure to adapt the probe length/ 4-20 ma settings in the menu and the re-install of a bottom spacer when applicable. Single cable probes can be safely shortened in the field using below procedure. M...

Page 8

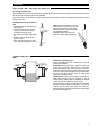

8 mounting do not insulate the high frequency connector in case of high temperature applications insulation wrong good max +150 °c (+300 °f) max +100 °c (+212 °f) for ex d unit 360° rotatable: position for optimum wiring/viewing max. Rotation 270° size: 38 mm (1 1/2") or adjustable wrench recommende...

Page 9

9 wiring caution: power must be switched off before wiring the unit. – + is ® – loop current is 0 % 100 % positive supply to (+) terminal negative supply to (-) terminal shield wire to green grounding screw (resistance to ground must be standard shielded twisted pair cable recommended. Non shielded ...

Page 10

10 display action comment units! Cm units cm units! Cm configuration note: when connected to an approved barrier, the intrinsically safe electronics of the eclipse allow to remove the covers with power switched on – even if the area is known to be hazardous 2 line – 8 characters lcd default display ...

Page 11

11 20 ma level (100%-point) reference point probe type probe length offset safety zone inch or cm dielectric of medium blocking distance 4 ma level (0%-point) terminology before starting offset = cm or inches the offset is the distance between reference point (e.G. Bottom of tank) and end of probe. ...

Page 12

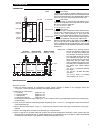

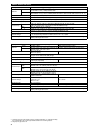

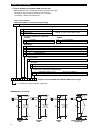

12 = quick start up menu: step by step procedure – eclipse 705: level only screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 7 10 12 13 16 17 *status* *level* *%output* *loop* level xx.X %output xx.X% loop xx.Xx ma 5 prbmodel (select) meastype (select) 6 prbmount (select) 9 probe ln xxx.X ...

Page 13

13 menu: step by step procedure – eclipse 705: level only screen action comment di ag no st ic s 23 26 27 28 29 30 poll adr xx trim 4 xxxx 25 trim lvl xx.X 24 loop mode trim 20 xxxx loop tst xx.X ma lvlticks xxxxx new pass xxx 31 32 language mdl705ht ver xx.Xx 33 dispfact (select) 18 19 20 21 22 blo...

Page 14

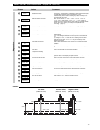

14 = quick start up menu: step by step procedure – eclipse 705: level & volume screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 8 11 12 13 19 20 *status* *volume* *%output* *loop* volume xxx %output xx.X% loop xx.Xx ma 5 level xxx meastype (select) 7 prbmount (select) 6 prbmodel (select) ...

Page 15

15 menu: step by step procedure – eclipse 705: level & volume screen action comment ad va nc ed c on fig ur at io n di ag no st ic s 26 29 30 31 32 33 poll adr xx trim 4 xxxx 28 trim lvl xx.X 27 loop mode trim 20 xxxx loop tst xx.X ma lvlticks xxxxx new pass xxx 34 35 language mdl705ht ver xx.Xx 21 2...

Page 16

16 = quick start up menu: step by step procedure – eclipse 705: interface screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 8 11 12 15 18 19 *status* *ifclevel* *%output* *loop* ifclevel xx.X %output xx.X% loop xx.Xx ma 5 level xxx meastype (select) 7 prbmount (select) 6 prbmodel (select) ...

Page 17

17 menu: step by step procedure – eclipse 705: interface screen action comment 26 25 30 31 32 35 poll adr xx ifcthrs (select) 24 threshld trim 20 xxxx loop tst xx.X ma 28 29 trim lvl xx.X 27 loop mode trim 4 xxxx lvlticks xxxxx new pass xxx 36 37 language mdl705ht ver xx.Xx 33 34 ifcticks xxxx mediu...

Page 18

18 = quick start up menu: step by step procedure – eclipse 705: interface & volume screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 7 13 16 19 22 23 *status* *ifcvol* *%output* *loop* ifclevel or ifc vol %output xx.X% loop xx.Xx ma 6 volume xx.X level xxxx 5 ifclvl xxxx 12 probe ln xxx.X ...

Page 19

19 menu: step by step procedure – eclipse 705: interface & volume screen action comment 31 29 34 35 36 39 loop mode 30 poll adr xx ifcthrsh (select) 28 threshld trim 20 xxxx loop tst xx.X ma lvlticks xxxxx new pass xxx 40 41 language mdl705ht ver xx.Xx 37 38 ifcticks xxxx medium 24 25 26 27 blockdis...

Page 20

20 menu: step by step procedure: advanced configuration screen action comment di ag no st ic s 1 3 4 6 7 8 dispfact select run time xx h 2 history (current status) history reset fidticks xxxx 5 hf cable (select) 14 ifc ampl xxx fidsprd x fid type (select) 9 10 20 fid gain xxx window xxx 11 conv fct ...

Page 21

21 for more details about the use of pact ware ™ and fdt technology, refer to instruction manual 59-601 pact ware ™ – configuration and troubleshooting what is fdt, pactware and dtm power transmitter hart connections 24 v dc pc with hart serial interface • fdt (field device tool) is a new interface c...

Page 22

22 pact ware ™ – configuration and troubleshooting echo curve patterns normal oil/water interface below screens are examples of the most typical echo curves that occur in normal operation / error condition. Normal signal pulses from oil over water level with blocking distance correction signal pulse ...

Page 23

23 configuration using hart ® important : the digital hart ® communication is superimposed on the 4-20 ma loop and requires a min. Load resistance of 250 Ω and a max load resistance of 450 Ω. + + - - junction control room display power supply current meter 250 Ω l connections check hart ® connection...

Page 24

24 configuration using hart ® 1 calibration 2 basic setup 3 advanced setup 4 diagnostics 5 review 1 device setup 2 level 3 % range 4 loop 5 device variables 1 tag 2 descriptor 3 date 4 message 5 poll address 6 final asmbly num 1 model 2 manufacturer 3 magnetrol s/n 4 firmware version 5 tag 6 descrip...

Page 25

25 maintenance troubleshooting symptom problem solution level, % output and loop values are all inaccurate. Basic configuration data is questionable. Reconfigure the probe length « prb ln » and offset « offset ». Check also the probe model « prb model » / probe mount « prb mount » 1) ensure the level ...

Page 26

26 maintenance display message action comment ok none normal operating mode initial none program is initializing, level reading held at 4 ma set point. This is a transient condition. Dryprobe none normal message for a dry probe. End of probe signal is being detected. Weaksgnl 1) set transmitter to l...

Page 27

27 maintenance display message action comment hivolalm verify strapping table is entered correctly. Level more than 5% above highest point in strapping table. Slopeerr consult factory ramp circuit generating improper voltage loopfail consult factory note: in case of loop failure, error signal will f...

Page 28

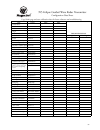

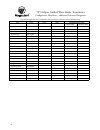

28 maintenance troubleshooting applications: level troubleshooting applications: interface most frequent application problems that may occur, media buildup on the probe and stratification, are covered here. Media buildup on the probe is not a problem in most cases–eclipse circuitry typically works ve...

Page 29

29 maintenance troubleshooting applications: single rod type gwr probe most frequent application problems that may occur, media buildup on the probe and stratification, are covered here. Significant buildup on the probe is not a problem in most cases–eclipse circuitry typically works very effectively....

Page 30

30 replacement parts 1 2 3 4 3 5 5 3 caution: the electronic module connects to the antenna via the “high frequency connector”. This part is extremely sensitive and brittle and requires to be handled very careful. It is recommended to exchange complete amplifier heads instead of electronic modules in...

Page 31

31 replacement parts 11 8 9 8 9 8 9 7 6 10 10 12 9 cable weight 7m1 single flexible cable 7m7 dual flexible cable bottom spacer - 7mf/7mj single rod gwr probe - 7mg cage gwr probe (2"/dn50) cable weight 7m2 single flexible cable for solids spacer 7mb twin rod cable weight 7m5 dual flexible cable for sol...

Page 32

32 transmitter specifications functional/physical ¿ foundation fieldbus™ and profibus pa™ units. ¡ for atex flameproof enclosure units use ex d bushing material stycast 2057 fr. ¬ not applicable for foundation fieldbus™ and profibus pa™ units. Description specification power (at terminals) hart ® : - we...

Page 33

33 transmitter specifications performance description specification reference conditions with a 1,8 m (72") coaxial type gwr probe reflection from liquid, with dielectric in center of selected range, at +20 °c (70 °f) with cfd threshold ¿ linearity ¡ coaxial/twin lead probes single lead probes accurac...

Page 34

34 probe specifications ¿ transition zone (zone with reduced accuracy) is dielectric dependent; ε r = dielectric permitivity. It is recommended to set 4-20 ma signal outside transition zone. ¡ see graphs at page 39 and 40. Description 7mr/7mm: overfill protection coaxial probe materials probe 316/316...

Page 35

35 probe specifications ¿ transition zone (zone with reduced accuracy) is dielectric dependent; ε r = dielectric permitivity. It is recommended to set 4-20 ma signal outside transition zone / blocking distance. ¡ see graphs at page 39 and 40. Description 7mf (industrial): standard single rod 7mj: ht...

Page 36

36 probe specifications ¿ transition zone (zone with reduced accuracy) is dielectric dependent; ε r = dielectric permitivity. It is recommended to set 4-20 ma signal outside transition zone / blocking distance. ¡ see graphs at page 39 and 40. Description 7m1 (liquids) / 7m2 (solids): single flexible ...

Page 37

37 probe specifications description 7mt/7mn: interface gwr probe materials probe 316/316l (1.4401/1.4404), hastelloy ® c (2.4819) or monel ® (2.4360) process seal teflon ® with viton ® gflt, aegis pf 128 or kalrez ® 4079 (consult factory for alternatives) spacers teflon ® probe diameter small coax ins...

Page 38

38 description 7mb: standard twin rod gwr probe materials probe 316/316l (1.4401/1.4404), hastelloy ® c (2.4819) or monel ® (2.4360) process seal teflon ® with viton ® gflt, aegis pf 128 or kalrez ® 4079 (consult factory for alternatives) spacers teflon ® probe diameter two 13 mm (0.5") Ø rods – 22,2 ...

Page 39

39 temperature - pressure rating for eclipse probe seal process temperature (°c) pr oc es s pr es su re (b ar ) process temperature (°c) pr oc es s pr es su re (b ar ) 7mr/7mm, 7mt/7mn, 7mg probes 7md/7ml probes small coax process temperature (°c) pr oc es s pr es su re (b ar ) process temperature (...

Page 40

40 temperature - pressure rating for eclipse probe seal “o”-ring material max process min process max process not recommended for recommended for applications temperature temperature pressure applications viton ® 200°c @ 16 bar -40 °c (-40 °f) 70 bar @ 20 °c ketones (mek, acetone), skydrol fluids, ge...

Page 41

41 dimensions in mm (inches) - twin rod dimensions in mm (inches) - dual compartment housing 7mb with threaded 2" bsp (g 2") connection 7mb with threaded 2" npt connection 7mb with flanged connection 83 (3.28) 105 (4.12) 256 (10.08) 103 (4) 126 (4.96) 129 (5.08) 256 (10.08) 256 (10.08) 102 (4.00) 2 c...

Page 42

42 dimensions in mm (inches) - coaxial gwr probes 137 (5.39) 144 (5.68) 83 (3.28) 105 (4.12) 256 (10.08) 256 (10.08) 102 (4.00) 102 (4.00) 2 cable entries 45° 7mr / 7mt with threaded connection probe insertion length bsp probe insertion length npt 162 (6.38) 171 (6.73) 83 (3.28) 105 (4.12) 256 (10.0...

Page 43

43 dimensions in mm (inches) - coaxial gwr probes coaxial gwr probe, end view venting holes for level a b c d e venting holes for interface slots for 7mr-a, 7md-a/v/w (order per “x” description) 50 (1.97) 20 (0.79) 4 (0.16) dim. Small coax mm (inch) large coax mm (inch) a 305 (12) 305 (12) b Ø 6,4 (...

Page 44

44 dimensions in mm (inches) - hygienic 109 (4.28) 43° view 52 (2.05) 58 (2.28) 108 (4.25) 95 (3.75) 102 (4.00) 89 (3.50) 70 (2.75) 2 holes Ø 9,5 (0.37) cable entry cable entry 19 (0.75) 840 or 3660 (33 or 144) 60 (2.36) 60 (2.36) 175 (6.89) 43° 43° remote electronics integral electronics 52 (2.05) ...

Page 45

45 dimensions in mm (inches) - cable gwr probe 7m1 with threaded connection 41 (1.61) 59 (2.32) probe insertion length npt probe insertion length bsp 610 (24) 7m5 with threaded connection 93 (3.66) 111 (4.37) probe insertion length npt probe insertion length bsp 76 (3) 7m7 with threaded connection 6...

Page 46

46 dimensions in mm (inches) - cage gwr probe probe insertion length teflon ® spacer Ø 13 (0.50) rod probe insertion length peek spacer Ø 19 (0.75) rod probe insertion length peek spacer Ø 25 (1) rod 7mg - 2" cage 7mg - 3" cage 7mg - 4" cage spacer (end view) 49 (1.90) 187 (7.37) 187 (7.37) Ø 71 (2.8...

Page 47

47 model identification 1. Code for eclipse 705 transmitter head/electronics 7 5 0 5 power complete code for eclipse 705 transmitter head/electronics 5 24 v dc, two wire loop powered basic model number 7 0 5 eclipse 705 guided wave radar transmitter output and electronics accessories a digital displ...

Page 48

48 model identification 1. Code for eclipse 705 transmitter head/electronics 7 5 0 5 complete code for eclipse 705 transmitter head/electronics cable entry 1 m20 x 1,5 (2 entries - 1 plugged) 0 3/4" npt (2 entries - 1 plugged) 4 1/2" npt (1 entry) mounting / housing material / approval ¿ 1 1 weather...

Page 49

49 model identification 7 m material of construction - wetted parts (including process connection flange when applicable) complete code for eclipse 705 gwr probe a 316/316l (1.4401/1.4404) stainless steel b hastelloy c (2.4819) c monel (2.4360) e 316/316l (1.4401/1.4404) stainless steel 0,4 µm ra (15...

Page 50

50 model identification 7 m complete code for eclipse 705 gwr probe process seal - material 0 viton ® gflt 1 epdm (ethylene propylene) peek ® & epdm ‘o’-rings for 7mh 2 kalrez ® 4079 3 hsn (highly saturated nitrile) 4 buna-n 5 neoprene ® 6 chemraz ® 505 7 polyurethane 8 aegis pf 128 a kalrez ® 6375 ...

Page 51

51 model identification 7 m complete code for eclipse 705 gwr probe insertion length 0 6 0 min 60 cm (24") 6 1 0 max 610 cm (240") – max 450 cm (177") for 7mq / 7ms rigid gwr probes: specify per cm (0.39") increment 0 3 0 min 30 cm (12") 1 8 0 max 180 cm (72") for 3/4" tri-clamp ® process connection...

Page 52

52 model identification 2. Code for eclipse ® 705 top/bottom gwr probe and cage additional dimensions are provided (see drawings at bottom of this page): - dimension a: top of process connection up to 20 ma range - dimension b: bottom of process connection up to 4 ma range - level range, if differen...

Page 53

53 copy blank page and store calibration data for future reference and troubleshooting. Item screen value value vessel name vessel # process medium tag # electronics serial # troubleshooting probe serial # working value non-working value level « level » volume (optional) « volume » interface (option...

Page 54

54 copy blank page and store calibration data for future reference and troubleshooting. Item screen value value troubleshooting correct value incorrect value # of fiducial ticks « fidticks » fiducial spread « fid sprd » sys code « sys code » fiducial type « fid type » fiducial gain « fid gain » wind...

Page 55: Notes

55 notes.

Page 56: Important

Important service policy owners of magnetrol products may request the return of a control; or, any part of a control for complete rebuilding or replacement. They will be rebuilt or replaced promptly. Magnetrol international will repair or replace the control, at no cost to the purchaser, (or owner) ...