- DL manuals

- Eclipse

- Measuring Instruments

- EGA4

- User Manual

Eclipse EGA4 User Manual

Summary of EGA4

Page 1

Eclipse ega4 combustion analyzer instruction manual 924-2 4/24/07.

Page 2

Instruction manual mm850481 ed. 03a 2 introductory note n ote : t his manual is valid for instruments with serial number 124012 and firmware rev . 1. Xx 2 or higher this manual has all the information you need to install, operate and maintain the flue gas analyzers ega4 and its accessories. Eclipse ...

Page 3

Instruction manual mm850481 ed. 03a 3 table of contents 1 general description .........................................................................................................................5 1.1 ordering code ....................................................................................

Page 4

Instruction manual mm850481 ed. 03a 4 7.4 smoke measurement.................................................................................................................................................27 7.4.1 smoke index data input....................................................................

Page 5: Features & Benefits

Instruction manual mm850481 ed. 03a 5 1 general description ega4 is designed to satisfy the market needs; but they are the result of the advanced research and experience of eclipse. Ega4 is a multigas compact palm-top multifunction instrument. The micro-processor based instrument includes a flue gas...

Page 6

Instruction manual mm850481 ed. 03a 6 1.1 ordering code 7826 – a – b – cc – d – eee – f – ggg – h each ega4 is equipped with a o 2 sensor, internal 250 memory, realtime clock capabilities, usb serial cable, electrovalve for autozero quick start-up, magnetic rubber holster, rechargeable battery pack,...

Page 7

Instruction manual mm850481 ed. 03a 7 1.2 specifications type: 2, 3 or 4 cells palm-top flue gas analyzer/boiler tuning unit. Calibration: automatic 60 seconds calibration procedure at instrument switching-on. Optional autozero electrovalve for quick start-up. Self-diagnosis: sensors efficiency test...

Page 8

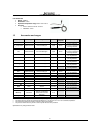

Instruction manual mm850481 ed. 03a 8 low draft probe x range: r200pa x resolution: 0.1pa x operative temperature range: from +5 to +45 °c x accuracy from +10 pa to -10 pa: r0.5 pa elsewere: r3 pa 1.3 accuracies and ranges parameter sensor type range resol. Max response accuracy o 2 electrochemica...

Page 9

Instruction manual mm850481 ed. 03a 9 2 general 2.1 keypad & display the tactile keyboard allows the operator to enter the main operative mode and all other complementary or auxiliary modes following the menu driven instructions. The high contrast graphic lcd (40x56 mm), equipped with an automatic b...

Page 10

Instruction manual mm850481 ed. 03a 10 2.8 smoke measurement smoke index measurement is done by using a hand pump (supplied as an accessory), the results cam be memory stored and printed in the report. 2.9 remote temperature probe a remote pt100 probe is available for combustion air temperature meas...

Page 11

Instruction manual mm850481 ed. 03a 11 3 physical description the ega4 portable analyzer consists of a rugged and compact case, a mother board with all base function circuits, 2, 3 or 4 electrochemical cells, a gas pump, a keyboard, an lcd backlighted display, a li-ion rechargeable battery pack and,...

Page 12

Instruction manual mm850481 ed. 03a 12 4 principle of operation the ega4 analyzer is based on the following functional blocks: microcontroller impact printer keyboard display 250 memory power supply li-ion battery battery charger input external probe input pt100 tair input gas outlet p2 - 'p p1 – dr...

Page 13

Instruction manual mm850481 ed. 03a 13 4.1.1 gas sampling probe the sampling probe consists of a steel tube and a handle of thermoinsulating material. A positioning cone allows to place the probe in holes with a diameter from 11 to 16 mm. The gas temperature is acquired using a thermocouple type k w...

Page 14

Instruction manual mm850481 ed. 03a 14 the oxidation process produces an output electrical signal proportional to the gas concentration. The signal is evaluated by the electronics, converted to digital, processed by the microprocessor, displayed and printed with a 0.1% volume resolution. The flue ga...

Page 15

Instruction manual mm850481 ed. 03a 15 caution i f a single tube gas sampling probe is used for p ressure / draft measurements , be sure that it is clean and dry before connection to the pressure input . Caution a +300 h p a ( or –300 h p a ) over - pressure can permanently damage the pressure senso...

Page 16

Instruction manual mm850481 ed. 03a 16 5 recommendations the analyzer should be used in environments where the temperature is between -5°c and +45°c. When the analysis are completed, before switch the instrument off, remove the probe from the gas pathway and wait about 30 seconds cleaning the pneuma...

Page 17

Instruction manual mm850481 ed. 03a 17 6 connections 6.1 electro-pneumatic connections to prepare the instrument for operation connect the sampling probe to the instrument: x plug the pneumatic connector of the probe to the gas inlet connector. If you are using the gas sampling probe with draft opti...

Page 18

Instruction manual mm850481 ed. 03a 18 tair probe caution f or a correct gas analysis , no air must reach the flue gas as a result of non - gas - tight connection points between the heat producer and the measurement site ( probe ). T he flue gas and exhaust gas pathways must be checked for gas - tig...

Page 19

Instruction manual mm850481 ed. 03a 19 6.3.1.1 installing the usb driver x close all the active windows and/or applications. X if you computer runs in windows™xp or windows™ xp sp1, temporally disconnect the pc from the web. To do this, temporally remove the network cable from your pc, if connected,...

Page 20

Instruction manual mm850481 ed. 03a 20 x select the second option: “install from a list or a specific location (advanced)”, then click “next” x select the option referring to the following page, flagging “search for the best driver in these locations”. Press “browse” to select the file path. X selec...

Page 21

Instruction manual mm850481 ed. 03a 21 7 operations 7.1 basic operation all the procedures and programming operations on the ega4, can be made using the keyboard and the display. N ote : all numeric values shown in the figures of this manual are indicative and listed as an example . The analyzer sho...

Page 22

Instruction manual mm850481 ed. 03a 22 o2 : 20.9 % so2 : 1000 co : 2000ppm cxhy: 5.00 ta : 20 °c lam : 0.99 tg : 400 °c no2 : 100 k : 95.7 % co2 : 10.2 nox: 500ppm per : 10.5 ref o 2 graph – function box status bar menu&measure area the menu and measure area displays the analysis data, the menu and ...

Page 23

Instruction manual mm850481 ed. 03a 23 co reference 0.0 escape – the “ s” symbol below the first digit is the cursor. You can move the cursor between the digit using the [ w] and [x] keys. You can change the selected digit using [ s] and [t]. If “9” or “0” values are exceeded, the left digit is incr...

Page 24

Instruction manual mm850481 ed. 03a 24 7.2 flue gas analysis connect the gas probe to the analyzer as shown in chapter 7. Do not insert the probe in the chimney. Switch the analyzer on pressing the [on] key. The display will show the following page: ega 4 serial no: 91257 version: 10.0.9 if you pres...

Page 25

Instruction manual mm850481 ed. 03a 25 x insert the probe in chimney. Stop it using the retaining cone and adjust the immersion depth for a gas sampling in the middle of the exhaust gas connection pipe. X press the [analysis] (f1) key to begin the measurements. The following page will be shown: o2 2...

Page 26

Instruction manual mm850481 ed. 03a 26 o2 10.9 % co2 8.1 % co 5.3 % tg 123.0°c effn -------- effg -------- ref. O2 – graphic dilution system can be used to extend the sensor measuring range up to 10%. 7.3 pressure/draft measurement if the internal pressure sensor is installed (table e=2 on ordering ...

Page 27

Instruction manual mm850481 ed. 03a 27 press [escape] (f1) to return to the previous page. Now you can proceed with the smoke index measurement and/or the gas analysis. The memory stored value will be printed together the analysis. 7.3.1 burner pressure measurement using the burner pressure probe,...

Page 28

Instruction manual mm850481 ed. 03a 28 it is important to measure the true combustion air temperature to have a correct boiler efficiency computation. The ega4 has a auxiliary rtd input to measure simultaneously the air temperature. A pt100 with a 6 meters long cable can be connected on the right si...

Page 29

Instruction manual mm850481 ed. 03a 29 press [menu] to display the following page: menu measure ion. Curr temperature gas velocity escape – use the [ s] and [t] keys to move the cursor symbol to “gas velocity” option. Press the [enter] key. Gas velocity f k vel: 1.000 dens.: 1.000 kg/m3 escape –...

Page 30

Instruction manual mm850481 ed. 03a 30 x press [enter] to manually change the 'p value. The instrument will display the gas speed. Press [escape] to the previous page menu. Note: f or the best speed calculation , do not change the burner rate between the two measurements . T he o ptimum conditions w...

Page 31

Instruction manual mm850481 ed. 03a 31 switch the analyzer on. Keeping the [help] key down; press the [ x] key to bypass the autozero procedure. Press [print] then press the [feed] key for paper feed. Press the [escape] key when the paper will came out for same centimeters. Close the cover inserting...

Page 32

Instruction manual mm850481 ed. 03a 32 x use the [s] and [t] keys to move the cursor symbol to “tightness test” option. X press the [enter] key to select the option. Press [escape] (f2) to return to the previous menu. Select test 0.3 hpa parameters test type : a start test escape – zero x select “pa...

Page 33

Instruction manual mm850481 ed. 03a 33 7.9.2 test b (programmable) this optional operative mode allows operator to find pipe leakage. The difference from test a is the possibility for the use of programmable the time, to see ( the next paragraph).To set and run leak test, press the [menu] key from m...

Page 34

Instruction manual mm850481 ed. 03a 34 measure tightness test gas leak probe ambient co t+rh% probe escape – next use the [ s] and [t] keys to move the cursor symbol to “tightness test” option. Press the [enter] key to select the option. Press [escape] (f2) to return to the previous menu. Select t...

Page 35

Instruction manual mm850481 ed. 03a 35 legend p1-p2-p3-p4 mmh 2 o measures of pressure ǻp : difference of pressure ǻt : difference of time 7.10 ambient co probe (option) this optional external probe allows ambient co monitoring for personnel safety. When connected to the analyzer, it monitor continu...

Page 36

Instruction manual mm850481 ed. 03a 36 use the [ s] and [t] keys to move the cursor symbol to “measure” option. Press the [enter] key to select the option. Press [escape] (f2) to return to the previous menu. Measure tightness test gas leak probe ambient co t+rh% probe escape – next use the [ s] ...

Page 37

Instruction manual mm850481 ed. 03a 37 measure tightness test gas leak probe ambient co t+rh% probe escape – next use the [ s] and [t] keys to move the cursor symbol to “gas leak probe” option. Press the [enter] key to select the option. Press [escape] (f2) to return to the previous menu. Connect ...

Page 38

Instruction manual mm850481 ed. 03a 38 8 memory management the standard configuration include an internal memory to store up to 250 complete gas analysis divided by tags (max. 40 tags). Each analysis includes 10 gas concentration values, data and time. Each tag includes one or more analysis data, 16...

Page 39

Instruction manual mm850481 ed. 03a 39 x you can set 3 rows of personal data of the selected tag by pressing [id tag] (f1). In this case the following page will be displayed: id tag r1 plant 1 r2 boiler 1 r3 customer 1 escape – x select the row you wan to modify and press [enter]. X type in your tex...

Page 40

Instruction manual mm850481 ed. 03a 40 press the [enter] key to select the option. press [escape] (f1) to return to the previous menu without save the selection. 8.5 dbgas 2004 dbgas 2004 is a pc windows compatible software to manage all checks and measures activities on boilers and to transfer da...

Page 41

Instruction manual mm850481 ed. 03a 41 to install the software: insert the dbgas 2004 cd-rom in your drive; follow the instructions on the screen to install the software. If the dbgas 2004 setup program does not start automatically, follow these steps: click the start button point to run w...

Page 42

Instruction manual mm850481 ed. 03a 42 8.5.1 gasconfig installation gasconfig has been designed to work with operating systems windows 9x/me/xp/nt. Minimum requirements are: pentium cpu with 16mbyte ram 20 mbytes free space on hard disk color monitor 800x600 cd-rom drive microsoft mouse or a com...

Page 43

Instruction manual mm850481 ed. 03a 43 after selecting which port to operate on, set the data transfer rate (expressed in baud) and the right address. Attention s et the same data transfer rate and the same address both on pc and on the instrument , otherwise no data transfer will happen note: s hou...

Page 44

Instruction manual mm850481 ed. 03a 44 service 3 services information lines can be programmed for factory co-ordinates. (we suggest having eurotron phone and fax numbers). 8.5.3 transfer configuration to pc before any configuration changes, we suggest transferring the gas analyzer configuration to t...

Page 45

Instruction manual mm850481 ed. 03a 45 9 configuration many parameters can be modified using the instrument keyboard. Pressing the [setup] key, you can change the current fuel, include or exclude the co cell, change the technical unit, set the alarms, etc. The configuration p1 --- fuel --- > lpg co ...

Page 46

Instruction manual mm850481 ed. 03a 46 press [escape] (f1) to return to the previous menu. The measuring units selectable for gas are: ppm, mg/m3, mg/kwh, g/gj. The measuring units selectable for temperature are: °c, °f. The measuring units selectable for pressure are: hpa, mbar, mmh2o, inh2o. 9.2...

Page 47

Instruction manual mm850481 ed. 03a 47 header printer r1 r2 r3 r4 escape – select the r1, r2, r3, and r4 rows and press [enter] to insert or change the text. Press [escape] (f2) to return to the previous page. 9.3.2 sensor diagnostic the “sensor diagnostic” option, allows you to read the actual stat...

Page 48

Instruction manual mm850481 ed. 03a 48 10 maintenance the ega4 analyzer has been developed and manufactured using high quality components. A correct, systematic maintenance will prevent damage and will increase substantially the life of the instrument, giving excellent results. Anomalous conditions ...

Page 49

Instruction manual mm850481 ed. 03a 49 10.2 error messages the instrument performs the autodiagnostic procedure when switched on. When measuring it checks also for anomalous conditions. If analyzer founds trouble, it display a message on lcd. Sometime these messages corresponds to a unrecoverable pr...

Page 50

Instruction manual mm850481 ed. 03a 50 set-up pag.1 clock serial port analysis par. P decay time – next press the [next] (f1) key to change menu page. Set-up pag.2 printer test clock test test output test keyboard – next use the [ s] and [t] keys to move the cursor symbol to the desired option. Pr...

Page 51

Instruction manual mm850481 ed. 03a 51 10.3.2 serial port selecting this option, you can set the baud rate and the id number for instrument in infrared serial communication. Serial address : 0 baud-rate : 9600 escape – use the [ s] and [t] keys to move the cursor symbol to the desired option. Pres...

Page 52

Instruction manual mm850481 ed. 03a 52 10.4 firmware upgrade in order to upgrade the firmware of the instrument proceed as follows: 1 - install the st167flash program from the cd. 2 - connect the infrared interface adapter to the serial port of the pc with the supplied cable (note back the serial po...

Page 53

Instruction manual mm850481 ed. 03a 53 11 certificates 11.1 warranty terms eclipse warrants its products against defects in materials and workmanship for the period declared from the date of the original retail purchase. This warranty applies to the original purchaser only. If the unit should malfun...

Page 54

Instruction manual mm850481 ed. 03a 54 appendix a1 example the following steps show how you can make a quick measurement using the ega4 portable analyzer. 1. Switch ega4 on. It will begin the autozero and the autodiagnostic procedure. System error and trouble will be displayed if encountered. Ega 4 ...

Page 55

Instruction manual mm850481 ed. 03a 55 index a accuracies and ranges; 8 alarms; 46 ambient co probe; 35 ambient co probe; 7; 10 ambient t+rh probe; 7 analysis data print; 30 analysis parameters; 51 appendix; 54 autozero valve option; 24 auxiliary measurements; 14 b barcode pen reader; 10 basic opera...

Page 56

Instruction manual mm850481 ed. 03a 56 other measurements; 15 p p decay time; 51 paper and ribbon change; 30 physical description; 11 power supply; 16 pressure and draft; 14 pressure decay procedure; 31 pressure sensor; 9 pressure/draft measurement; 26 principle of operation; 12 r recall memory; 39 ...

Page 57

Offered by: power equipment company 2011 williamsburg road richmond, virginia 23231 phone (804) 236-3800 fax (804) 236-3882 www.Peconet.Com.