- DL manuals

- Eclipse

- Floor Machine

- PE300BU

- Operator's Manual

Eclipse PE300BU Operator's Manual

Summary of PE300BU

Page 1

Uhs battery burnisher pe300bu operator’s manual.

Page 3: Notice

Notice proper maintenance is necessary with all battery powered floor machines. Following the scheduled maintenance procedures found in your operation manual will provide many years of uninterrupted service. In addition to the scheduled maintenance procedures listed it is recommended to have your ma...

Page 4: ! For Your Safety !

In this operation manual you will find three statements that you must read and observe to ensure safe operation of this machine. Danger! Indicates that the possibility of severe bodily injury or death can occur if danger! Statements are ignored. Read and observe all danger! Statements included in th...

Page 5: Table Of Contents

Quick reference specifications..........................................5 safety precautions..............................................................6 operator responsibility.......................................................7 test for operator-ear sound pressure level.................7 tes...

Page 6

6 notes: ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ______________________________________________...

Page 7: Quick Reference

7 quick reference specifications: l voltage: 36vdc (qty. 3 - 12vdc batteries) l burnish rate: ±31,200 ft 2 /hr (2899 m 2 /hr) [24”] ±42,900 ft 2 /hr (3985 m 2 /hr) [30”] l overload protection: resettable breakers l operating time: approximately 3 hours l pad pressure: adjustable routine maintenance ...

Page 8

8 safety precautions anyone operating the machine should read the following carefully and be informed of potentially dangerous operating conditions. Operators should be familiar with the location and use of all safety devices on the machine. Do not use the machine if it is not in proper operating co...

Page 9

9 this machine is manufactured for commercial use only. This machine is designed and manufactured for burnishing indoor hard floor surfaces. Amano pioneer eclipse does not recommend use of this machine in any environment other than an indoor environment. Battery powered floor equipment is designed a...

Page 10: Machine Preparation

10 unpacking the machine the machine is shipped boxed on a wooden pallet. To unpack machine: 1. Cut and remove bands holding the box to the pallet. 2. Remove staples attaching the box to the platform at the bottom edge of the box. 3. With two people, one at either end of the box, lift box straight u...

Page 11

11 connecting the batteries 1. Place the batteries in the machine oriented as shown in diagram. 2. Connect the batteries as shown in the battery connection diagram. 3. Danger! Incorrect connection of batteries can cause explosion and/or serious injury. 4. Double check battery connections. 5. Connect...

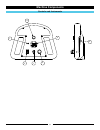

Page 12: Machine Components

12 controls and instruments rf044800 051112 2 4 7 3 1 5 6 2 1 3 4 machine components.

Page 13

13 300bu traction model 1. Key switch - turns the machine on/off. 2. Handle lever - when the lever is engaged the machine will move forward. If the burnish switch is on, the pad will also start turning. If the burnish head is tilted up into the pad change position, the burnish motor will not engage....

Page 14

14 onboard battery charger to charge the batteries, first drive the machine to a flat, dry, well-ventilated area then turn the machine off. If using lead acid batteries, check the water level in all the battery cells (see battery maintenance section). If the level is low, add just enough distilled w...

Page 15

15 battery charger fault codes fault description remedy no display no display on the charger, no led indicators. Check that the plug is connected to an operating wall outlet. Check fuse. 20a fuse mp265100. A incorrect battery connection or no battery connection. Check the connection and the polarity...

Page 16

16 how the machine works the burnish components of the machine are: l burnish pad holder l burnish pad l burnish motor l dust collection bag as the machine moves forward, the burnish pad shines the floor. Any excess dirt or wax gets picked up by the pad and distributed into the dust collection bag v...

Page 17

17 dust bag removal the machine has two dust bag options. A re-usable cloth bag and a disposable paper bag. Monitor the dust bag carefully and empty/change as needed. The dust collection system will not operate effectively when the dust bag is full. Under heavy burnishing conditions the dust bag sho...

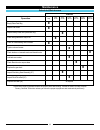

Page 18: Maintenance

18 maintenance interval operation daily every 25 hrs every 50 hrs every 100 hrs every 200 hrs every 500 hrs every 1000 hrs empty/clean dust bag l inspect pad holder l inspect battery water level (lead acid only) l check wiring harness for fray or cut l check for loose/missing nuts or screws l tighte...

Page 19

20 body & battery cover the body may be cleaned with a damp cloth to remove dust and scuff marks. More stubborn scuff marks on the tank exterior can be removed with a vinyl cleaner battery maintenance the batteries are deep cycle 12 volt batteries. The lifetime of the batteries is limited by the num...

Page 20

20 rear casters each of the two rear casters has two grease fittings. Lubricate each caster with a grease gun every 100 hours of machine operation belt maintenance (30” models) 1. Push machine to level surface. 2. Turn machine off and disconnect the battery pack. 3. Lift up on the front of the deck,...

Page 21: Alarm Codes (Traction Only)

21 *given the following alarm codes, troubleshooting should only be done by a amano pioneer eclipse factory certified technician. A programming handset may be required for troubleshooting. Number of flashes description possible cause 1 (fast) low battery voltage the battery needs charging or there i...

Page 22

22 machine troubleshooting problem possible cause remedy machine will not turn on breaker tripped push breaker button to reset incorrect battery connection check batteries are wired together correctly via the battery connection diagram, check the anderson connectors are plugged together on-board bat...

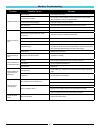

Page 23: Machine Specifications

23 voltage: 36vdc (qty. 3 - 12vdc batteries) sound level: vibration: less than 2.5 m/s 2 forward speed: 3.25 mph (5.23 km/h) reverse speed: 1.5 mph (2.4 km/h) burnish motor: 2.5 hp (1.86 kw) permanent magnet transaxle: .25 hp (186 watts) battery charger: 36v 25a on-board wheels: 8 in. (20.3 cm) soli...

Page 24: Pe300Bu

Pe300bu battery burnisher parts manual notes: ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ _________...

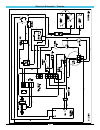

Page 25

25 electrical schematic - traction.

Page 26

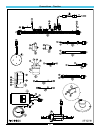

26 connections - traction.

Page 27

27 connections - traction (continued) item ref. No. Description qty a mp432200 harness, main, traction 1 b mp432100 harness, c.Panel, traction 1 c mp426800 harness, motor, burnish 1 d mp427000 harness, switch, tilt 1 e mp427200 cable, battery, solenoid 1 f1 mp424200 motor, 2000 rpm, asm. (30”) 1 f2 ...

Page 28

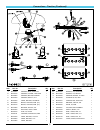

28 skirt, deck & axle bracket assembly rf044600 093013 12 10 9 11 13 14 9 7 8 23 20 18 19 25 24 22 16 17 21 2 3 3 4 5 1 6.

Page 29

29 item ref. No. Description qty 1a mp425200 skirt, 20”, asm. 1 1b mp434200 skirt, 24”, asm. 1 2 nb050600 bolt, hex, 1/4” x 2-1/2” 1 3 nb3350 washer, flat, 1/4” 2 4 mx1045 nut, hex, 1/4” 1 5a mp139800 edging, wear, skirt (20”) 6 ft 5b mp139800 edging, wear, skirt (24”) 7 ft 6 mp6600 felt, velcro, bl...

Page 30

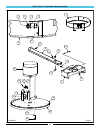

30 main bottom assembly - traction rf044400 041713 5 12 3 2 7 6 9 10 13 14 14 13 12 12 4 1 11 14 13 12 8.

Page 31

31 main bottom assembly - traction (continued) item ref. No. Description qty 1a mp424400 bracket, axle, asm. (20”) 1 1b mp440800 bracket, axle, asm. (24”) 1 2 mp424500 transaxle, 36v, asm. 1 3 pg001801 bracket, transaxle 2 4 nb6545 bolt, hex, 5/16” x 1” 4 5 nb3265 nut, lock, 5/16” 4 6 ba003300 key, ...

Page 32

32 main rear assembly rf044100 013113 5 6 7 7 6 5 4 2 7 6 5 3 1 10 11 12 14 13 20 21 17 18 16 19 15 9 8 6.

Page 33

33 main rear assembly (continued) item ref. No. Description qty 1 mp422901 plate, mount, shock 1 2 mp206000 ball, stud, 10mm 1 3 nb3265 nut, lock, 5/16” 1 4a mp434500 spring, gas (24”) 1 4b mp450300 spring, gas (30”) 1 5 nb9267 washer, flat, 5/16” 9 6 nb6111 washer, lock, 5/16” 11 7 nb9745 bolt, hex...

Page 34

Main top assembly 34 rf049900 070914 10 4 5 6 7 11 9 8 1 2 3 22 19 18 26 17 20 21 24 25 23 16 15 12 14 13 27.

Page 35

Main top assembly (continued) 35 item ref. No. Description qty 1 mp423201 lever, handle, left 1 2 mp423202 lever, handle, right 1 3 nb6390 pin, roll, 1/4” x 1-1/8” 2 4 mp431401 plate, cover, rear 1 5 nb9267 washer, flat, 5/16” 4 6 nb6111 washer, lock, 5/16” 4 7 nb9745 bolt, hex, 5/16” x 3/4” 4 8 nb9...

Page 36

Main front assembly 36 rf044200 102813 22 23 24 20 19 18 5 1 16 17 6 2 15 14 12 13 11 8 7 10 19 20 9 4 21 3 6 30 34 31 33 28 32 27 33 27 10* 25 26.

Page 37

Main front assembly (continued) 37 item ref. No. Description qty 1 nb039704 pin, clevis, 1/2” x 4-1/2” 1 2 nb025600 pin, presto, 3/32” x 1-5/8” 1 3 mp423301 latch, tilt 1 4 nb026200 bolt, shld, 3/8” x 1/2” 1 5 nb038600 bolt, shld, 3/8” x 3-1/2” 1 6 nb3265 nut, lock, 5/16” 2 7a mp435000 pad holder, 2...

Page 38

30” deck assembly 38 rf050000 071014 11 34 15 27 13 12 24 31 26 30 26 25 28 20 22 17 19 8 18 16 9 8 21 18 8 19 14 23 8 29 10 32 33 2 3 4 5 6 7 36 39 37 38 35 1.

Page 39

30” deck assembly (continued) item ref. No. Description qty 1 mp456700 shroud, 30”, asm. 1 2 mp237100 bushing, flanged, 1/2” 2 3 mp318400 switch, micro, 12v 1 4 nb9625 screw, #4 x 3/4” 2 5 nb007000 nut, lock, #4 2 6 mp424200 motor, 2000 rpm, asm. 1 7 ba003200 key, 3/16” x 1” 1 8 mx1075 washer, lock,...

Page 40

30” skirt, pulley & tensioner assembly 40 rf050100 071014 12 15 11 9 11 10 16 17 13 14 18 20 19 7 6 6 8 5 2 3 3 4 1.

Page 41

30” skirt, pulley & tensioner assembly (continued) 41 item ref. No. Description qty 1 mp459800 skirt, 30”, asm. 1 2 nb050600 bolt, hex, 1/4” x 2-1/2” 1 3 nb3350 washer, flat, 1/4” 2 4 mx1045 nut, hex, 1/4” 1 5 mp449300 molding, blk, w/ adhesive 90” 6 mp140000 dot, felt 4 7 mp373100 washer, rubber 2 ...

Page 42: Limited Warranty

42 to qualify for this warranty (1) machine must be registered at the time of purchase on a form provided by amano pioneer eclipse corporation. Your amano pioneer eclipse distributor is responsible for the registration of your machine. Please cooperate with your distributor in supplying necessary in...

Page 44

Amano pioneer eclipse corporation 1 eclipse rd l po box 909 sparta, north carolina 28675 l usa www.Pioneereclipse.Com +1-336-372-8080 1-800-367-3550 fax +1-336-372-2913 © 2017 amano pioneer eclipse corporation lt070700 300bu_aust_d ec machinery directive 2006/42/ec, ec restriction of hazardous subst...