Summary of Winnox WX Series

Page 1

Winnox burners wx series version 1.00 no. 111, 8/26/05 installation guide.

Page 2

2 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 c opyright d isclaimer n otice l iability and w arranty copyright 2005 by eclipse, inc. All rights reserved worldwide. This publication is protected by federal regulation and shall not be copied, distributed, transmitted, transcribed...

Page 3

3 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 about this manual a udience this manual has been written for people who are already familiar with all aspects of a nozzle-mix burner and its add-on components, also referred to as the burner system. these aspects are: installatio...

Page 4

4 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 d ocument c onventions h ow to g et h elp there are several special symbols in this document. You must know their meaning and importance. The explanation of these symbols follows below. Please read it thoroughly. D danger: indicates ...

Page 5

5 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 table of contents 1 2 3 4 5 about this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 introduction . . . . . . . . . . . . . ...

Page 6

6 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 introduction the winnox version 1.00 is a nozzle-mix type, low-emissions burner designed for direct air heating, indirect air heating, and oven applications up to 1600 °f (875 °c). The burner package includes a combustion air blower ...

Page 7

7 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 i ntroduction this section is provided as a guide for the safe operation of the winnox burner system. All involved personnel should read this section carefully before operating this system. D danger: the winnox burners, described her...

Page 8

8 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 only qualified personnel, with good mechanical aptitude and experience on combustion equipment, should adjust, maintain, or troubleshoot any mechanical or electrical part of this system. The best safety precaution is an alert and tra...

Page 9

9 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 i ntroduction in this chapter you will find information and instructions needed to install the burner and system components. Handling inspect the system, make sure the components are clean and free of damage. Use the appropriate supp...

Page 10

10 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 gas piping all gas piping must comply with all applicable local codes and/ or standards, which may include: nfpa standard 54 csaz662-03, can/csa b149.1 en 746-2, en969 where to get the standards: nfpa: national fire protection...

Page 11

11 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 air supply provide an opening in the burner room of at least one square inch per 3000 btu/hr (5 cm 2 per 1 kw) to supply the burner intake with fresh, outdoor, combustion air. If there are corrosive fumes or materials in the surroun...

Page 12

12 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 fiber insulation chamber insulation 1 3 2 combustor slots chamber wall make sure the chamber wall 2 is strong enough to support the weight of the burner 3. If necessary, reinforce the mounting area. N note: the slots in the combusto...

Page 13

13 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 figure 3.4 optional start piping g as p iping 1 5 1 c 2 3 4 supply piping inlet pressure to the ratio regulator must stay within specified limits. Refer to the appropriate winnox data sheet. locate the valve train close to the bur...

Page 14

14 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 c heck l ist a fter i nstallation to verify the system was properly installed, perform the following checks: 1. Be sure there are no leaks in the gas lines. 2. Be sure all the components contained in the flame monitoring and control...

Page 15

15 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 i ntroduction in this chapter, you will find instructions on how to adjust, start, and stop the burner system. Become familiar with burner control methods before attempting to make adjustments.. D danger: the winnox burners, describ...

Page 16

16 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 open in this direction only closed open bac k 5. Activate the pressure switches and other limit interlocks. Be sure the switches fail as intended in the event of a power failure. D danger if simulated limits or simulated flame failu...

Page 17

17 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 low fire air adjustment procedure: 1. Start combustion air blower. 2. Drive control motor to low fire position. 3. Measure air differential pressure between tap (c ) and combustion chamber. N note: the pressure tap is in the open po...

Page 18

18 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 step 3: ignite the burner low fire start w warning: these procedures are written with the assumption the burner has a flame monitoring control system installed and operating. A proper purge cycle must be part of the system and purge...

Page 19

19 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 low fire start with piloting option: 1. Drive control motor to low fire. 2. Be sure combustion air blower is running. 3. Turn bias adjusting screw 1 on ratio regulator spring column three complete (360°) turns counter-clockwise (up)...

Page 20

20 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 figure 4.8 manual bv adjustment set screw outer dial full open 75% open bias adjusting screw cw for more gas set low fire gas procedure: w warning: this procedure is written with the assumption the burner has a flame monitoring cont...

Page 21

21 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 step 5: set high fire gas set high fire gas procedure 1. Set manual gas bv to 75% open. N note: to adjust manual bv: a. Loosen set screw. B. Turn outer dial. C. Tighten set screw. 2. With burner lit, drive control motor to high fire...

Page 22

22 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 step 6: verify settings setting verification: 1. With burner lit, drive control motor to high fire. 2. Wait for the chamber to reach normal operating conditions (e.G. Chamber temperature, process flows, etc.). 3. Measure high fire f...

Page 23

23 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 i ntroduction this chapter is divided into two sections: maintenance procedures troubleshooting guide preventive maintenance is the key to a reliable, safe and efficient system. The core of any preventive maintenance system is a lis...

Page 24

24 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 yearly checklist 1 5 1 c 1 1. Leak test the safety shut-off valves for tightness of closure. 2. Test the pressure switch settings by checking the switch movements against pressure settings and comparing these with the actual impulse...

Page 25

25 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 t roubleshooting p rocedures start-up sequence runs but burner does not light. Restore the power to the ignition transformer. Repair or replace the wiring to the igniter. Clean the igniter. Clean the threads on the igniter and the b...

Page 26

26 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 repair the leak in the loading line. The burner is erratic and does not respond to adjustment. Contact your eclipse representative or eclipse combustion for further information. The burner is unstable or produces soot, smoke, or exc...

Page 27

27 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 problem possible cause solution check incoming gas pressure. Adjust gas pressure if necessary. Check pressure switch setting and operation. Have a qualified electrician troubleshoot and correct the problem. Cannot initiate a start s...

Page 28

28 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 appendix c onversion f actors metric to english. From to multiply by cubic meter (m 3 ) cubic foot (ft 3 ) 35.31 cubic meter/hour (m 3 /h) cubic foot/hour (cfh) 35.31 degrees celsius (ºc) degrees fahrenheit (ºf) (ºc x 1.8) + 32 kilo...

Page 29

29 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 winnox main gas shutoff valve train gas cock solenoid valve (normally closed) pressure regulator eclipse combustion, inc. Strongly endorses nfpa as a minimum gas cocks are used to manually shut off the gas supply on both sides of th...

Page 30

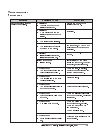

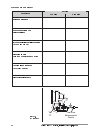

30 eclipse winnox wx series v1, installation guide no. 111, 8/26/05 main gas pressure gas pressure into the ratio regulator bypass fuel differential pressure: tap e - chamber highfire input: fuel flow measurement device flame signal strength loading line pressure: tap c - chamber low fire high f...

Page 31

Offered by: burnerparts.Com 2011 williamsburg road richmond, virginia 23231 phone (804) 236-3881 fax (804) 236-3882 www.Burnerparts.Com.