- DL manuals

- Eco Angus

- Boiler

- Evo Multi Fuel Boiler

- Installation, Operation And Maintenance Manual

Eco Angus Evo Multi Fuel Boiler Installation, Operation And Maintenance Manual

Summary of Evo Multi Fuel Boiler

Page 1

Angus evo multi fuel boiler installation, operation and maintenance manual.

Page 2

Index information on the boiler plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 boiler dimensions, boiler packaging dimensions . . ....

Page 3

Installation, operation and maintenance manual 1 information on the boiler plate the boiler serial no. Is shown on the plate which is attached to the cover panel of the cast iron body. Fig.01.

Page 4

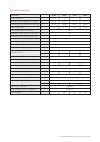

Installation, operation and maintenance manual 2 boiler dimensions fig.02 boiler packaging dimensions fig.03 ev-03 ev-04 ev-05 ev-06 l (mm) 609 709 809 909 ev-03 ev-04 ev-05 ev-06 l (mm) 665 765 865 965 notice: please obey to the meanings of the symbols on packaging for health care.

Page 5

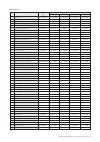

Installation, operation and maintenance manual 3 technical parameters series name ev-03 ev-04 ev-05 ev-06 number of elements pcs. 3 4 5 6 nominal heat output (black coal – walnut) kw 15-17 24-27 31-34 38-41 nominal heat output (hardwood – split logs) kw 12-14 18-20 25-27 30-33 minimum heat output kw...

Page 6

Installation, operation and maintenance manual 4 a table of the angus evo heating area *** for cold climate and low insulation houses, max heating area should be decreased approximately 10% *** for mild climate and strong insulation houses, max heating area should be increased approximately 10% for ...

Page 7

Installation, operation and maintenance manual 5 introduction 1. The boiler and all associated equipment must be installed and used in accordance with the installation design, all applicable legal regulations and technical standards and with the manufacturer’s instructions. The boiler may be used on...

Page 8

Installation, operation and maintenance manual 6 head loses fig.04 operating instructions angus evo series boiler – general features ■ angus evo series solid fuel fired boiler is designed for heating both residential and industrial buildings. ■ besides professional installation, precondition for cor...

Page 9

Installation, operation and maintenance manual 7 control and safety devices angus evo boilers are equipped with three main control elements: a chimney flap (fig. 05), by means of which the chimney thrust can be controlled, i.E. The discharge of combustion fumes into the chimney. The flap is situated...

Page 10

Installation, operation and maintenance manual 8 supply of secondary combustion air is controlled by an air rosette (fig. 08), situated in the boiler’s stoking door, which has a direct effect on the level of emission. Hot water temperature can be checked on a thermometer (fig. 09), which is situated...

Page 11

Installation, operation and maintenance manual 9 hydraulic connection diagram it is suggested hydraulic system should be installed according to following schemes. Open expansion tank system fig. 10 1. Safety heat exchanger (sht) 6. Mixing valve 2. Safety valve (ts 131, sts 20) 7. Ch pump 3. Cold wat...

Page 12

Installation, operation and maintenance manual 10 1. Boiler 4. Safety valve (ts 131, sts 20) 2. Open expansion tank 5. Four way mixing valve 3. Radiator fig. 11 1. Boiler 2. Laddomat 21-60 operated by flue thermostat – 50-300°c 3. Nad or nado accumulator tank 4. Immersion heater 5. Three way mixing ...

Page 13

Installation, operation and maintenance manual 11 fig. 13 fig. 14 1. Boiler 2. Laddomat 21-60 operated by flue thermostat – 50-300°c 3. Nad or nado accumulator tank 4. Immersion heater 5. Three way mixing valve 6. Circulating pump 7. Room thermostat 8. Heating system outlet 9. Open expansion tank 10...

Page 14

Installation, operation and maintenance manual 12 fig. 15 fig. 16 1. Boiler 2. Safety group (automatic air vent, pressure reducing valve and pressure gauge) 3. Dhw cylinder 4. Ch pump 5. Heating system 6. Four way mixing valve 7. Nrv 8. Expansion vessel 9. Accumulator tank 10. Three way valve 11. Va...

Page 15

Installation, operation and maintenance manual 13 putting the boiler into service checking the boiler before turning it on before putting the boiler into operation, the service technician must check: ■ whether the installation conforms with the design; ■ whether the boiler has been filled in and is ...

Page 16

Installation, operation and maintenance manual 14 stoking first shut the regulating hatch; this will shut supply of combustion air into the boiler. Then open the chimney flap completely. Partially open the stoking door and wait until all combustion gases have been sucked from the combustion chamber ...

Page 17

Installation, operation and maintenance manual 15 boiler cleaning when the boiler is used, soot and fine ash accumulates on the boiler walls, mainly on heat exchanger ribs and in the flue neck, which reduces heat transfer and the boiler output. The actual quantity of soot and fine ash will depend on...

Page 18

Installation, operation and maintenance manual 16 fig.19 fig.20 fig.21 fig.22.

Page 19

Installation, operation and maintenance manual 17 boiler repairs the boiler may be repaired by an authorised service technician or organisation only. The user or owner may do only normal maintenance and simple replacements of some parts – e.G. Sealing cords. Please note when repairing the boiler, or...

Page 20

Installation, operation and maintenance manual 18 installation instructions boiler installation – general information angus evo boilers must be put into service by an authorised services. A network of authorised service organisations which meet these conditions is available for all boiler installati...

Page 21

Installation, operation and maintenance manual 19 boiler location angus evo boilers can be located both on non-habitable premises (e.G. In boiler room, cellar, corridor) and in habitable rooms. The room in which the boiler is located must have a permanent supply of air necessary for the combustion p...

Page 22

Installation, operation and maintenance manual 20 boiler room disposition layout fig. 24 illustrates minimum distances which must be kept in order to ensure safe operation of the boiler room and allow manipulations with the boiler, such as cleaning and stoking. The distance between the front of the ...

Page 23

Installation, operation and maintenance manual 21 angus evo boiler parts fig.25 fig.26.

Page 24

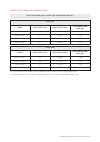

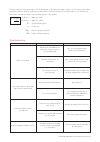

Installation, operation and maintenance manual 22 spare parts list item description drawing part number no ev-03 ev-04 ev-05 ev-06 1 front section ev 20080100 ev-md.060 ev-md.060 ev-md.060 ev-md.060 2 middle section ev 20080101 ev-md.050 ev-md.050 ev-md.050 ev-md.050 3 back section ev 20080102 ev-md...

Page 25

Installation, operation and maintenance manual 23 accumulator tank capacity note: the heat can be supplied for example by an accumulator tank. The following applies as a reference for the minimum storage boiler content: v sp : accumulator tank capacity in l q n : nominal heat output in kw t b : burn...

Page 26

Installation, operation and maintenance manual 24 flue pipe installation fig. 29 shows the proper flue gas connection with additional air equipment. Observe the following during the installation of the flue gas connection: ■ install a flue pipe connection with an inspection aperture for cleaning. ■ ...

Page 27

Installation, operation and maintenance manual 25 the figures below are only guide figures. The draft depends on the diameter, height, roughness of the chimney wall, and the temperature difference between combustion products and the outside atmosphere. We recommend the use of a chimney liner. Have p...

Page 28

For more information please visit our website www.Ecoangus.Co.Uk 01934 862642 07739 174511 07970 901273 ecoangus@aol.Com 2068. Designed and produced by.