- DL manuals

- Eco

- Heat Pump

- HCAT TE 0011

- Use And Maintenance Manual

Eco HCAT TE 0011 Use And Maintenance Manual

Summary of HCAT TE 0011

Page 1

Hcat te 0011 ÷ 0121 hcan te 0071 ÷ 0121 installation - use and maintenance manual cooling only air cooled condensing units and heat pumps with axial fans. G r o u p.

Page 3

General warnings 2 fundamental safety rules 2 identification 3 receiving and handling the product 3 description of standard unit 4 dimensional drawings 5 installation 6 refrigerant connections 6 sizing of refrigerant pipes 8 electrical connections 10 technical data 21 cooling performance hcat te 22 ...

Page 4

General warnings hcat te - hcan te 2 english 04/03 these appliances have been designed for cool- ing and/or heating and must be used for this pur- pose in applications compatible with their perfor- mance characteristics. Incorrect installation, regulation and mainte- nance or improper use absolve th...

Page 5

Hcat te - hcan te 3 english 04/03 hcat te and hcan te condenser units can be identi- fied by the: packaging label giving the data identifying the product. Rating plate giving the technical and performance data of the unit. If lost, ask the after sales service for a duplicate. Tampering with or the r...

Page 6

Hcat te - hcan te 4 english 04/03 description of standard unit the air-cooled condenser units with axial-flow fans oper- ate with r407c refrigerant and are suitable for outdoor installation in combination with hen se e hed se direct expansion terminals. The units conform to the essential requisites ...

Page 7

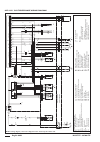

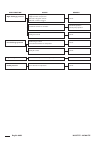

Ø35 8 n m ml w4 w1 w3 w2 e 6 7 c g f 5 e g 5 6 7 f unitÁ 101-121 unit 101-121 h == i = = 2 1 3 4 d a b sollevamento lifting n w1 w2 w4 w3 m l m g c e f = i = b a o = h = w1 83 84 106 107 w2 41 41 52 52 w3 38 38 49 49 w4 75 77 97 98 tot 237 240 304 306 weight distribution hcan te 0071 0091 0101 0121 ...

Page 8

Hcat te - hcan te 6 english 04/03 installation choice of installation site before installing the unit, agree the site where it will be installed with the customer, taking the following points into consideration: - check that the fixing points are adequate to support the weight of the unit; - pay scr...

Page 9

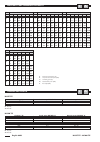

Hcat te - hcan te 7 english 04/03 1 gas line valve 2 liquid line valve 3 compressor 4 fan 5 finned coil 6 liquid receiver 7 cycle reverse valve 8 thermostatic valve 9 liquid indicator 10 filter 11 nonreturn valve 12 high pressure switch 13 low pressure switch 14 gauge connections 15 oil sump heater ...

Page 10

Hcat te - hcan te 8 english 04/03 fig. 2 fig. 3 fig. 1 max difference in level max difference in level 6 metr es models 0071÷0121 sizing of refrigerant pipes a i model 0011 0021 0025 0031 0041 0051 0061 0071 0091 0101 0121 sizing connection piping in relation to equivalent distance type of pipe 0-10...

Page 11

Hcat te - hcan te 9 english 04/03 equivalent corresponding length, 90° curve and complete siphon 90° curve m eq. 0,40 0,42 0,48 0,50 0,60 0,80 1,00 1,20 siphon m eq. 1,60 1,68 1,92 2,00 2,40 3,20 4,00 4,80 pipe diameter Øi / Øe 8/10 10/12 14/16 16/18 20/22 26/28 33/35 39/42 differenza di carica tra ...

Page 12

Hcat te - hcan te 10 english 04/03 checking for leaks 1. Check that the valves on the external unit are completely closed; 2. Connect the pressure gauge to the service outlet of the two external unit valves; 3. Fill with freon r407c gas at a pressure of 250 kpa; 4. Connect the nitrogen cylinder to t...

Page 13

Hcat te - hcan te 11 english 04/03 voltage must be within a tolerance of ±10% of the rated power supply voltage for the unit (for three phase units, the unbalance between the phas- es must not exceed 3%). If this is not the case, con- tact the electricity supply company. For electrical connections, ...

Page 14

Hcat te - hcan te 12 english 04/03 electrical panel the electrical panel is located inside the unit at the top of the technical compartment where the various components of the refrigerant circuit are also to be found.To access the electrical panel, remove the front panel of the unit by undoing the s...

Page 15

Hcat te - hcan te 13 english 04/03 electrical power connections for the functional connection of the unit, bring the power supply cable to the electrical panel inside the unit and con- nect it to the terminals, respecting the u-v-w as phases, n as neutral and pe as earth. Auxiliary connections all t...

Page 16

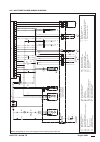

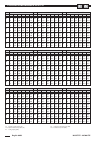

Hcat te - hcan te 14 english 04/03 n4 l2 u3 u1 a1 1 0 24vac 12vac 12vac power 3 2 e 1 r1 0 2 km1 4 0 2 12dc tk id3 st1 st2 st3 gnd gnd all alarm analog input digital input 1 c1 2 2 6 7 sa1 a 1 2 10 11 +po bp3 white brown rd1 digital output d1 2 yv1 0 ka1 keyb 26 24 25 a2 4 3 tc1 19 20 18 a6 ka1 3 0 ...

Page 17

Hcat te - hcan te 15 english 04/03 n4 l2 u3 u1 a1 u n u-v-w-n pe 400v-3n -50hz qf1 u-v-w-n l1-l2-l3-n 3~ m t1 t2 t3 l1 l2 l3 km1 qm1 z1 qs1 1 black brown grey 1 0 24vac 12vac 12vac power 3 2 e 1 r1 0 2 km1 4 0 2 12dc tk id3 st1 st2 st3 gnd gnd all alarm analog input digital input 1 c 1 2 2 6 7 sa1 a...

Page 18

Hcat te - hcan te 16 english 04/03 n4 l2 u3 u1 a1 1 0 12vac 230vac 11 12 12vac 12vac power 3 2 c 1 r1 km1 10 7 fu2 9 12dc tk id3 st1 st2 st3 st4 gnd gnd all alarm analog input digital input 1 e 3 4 2 6 7 sa1 e 5 6 10 11 +po bp3 rd1 1 digital output 1 2 yv1 7 ka1 1 2 3 keyb 26 24 25 a2 4 2 tc1 19 20 ...

Page 19

Hcat te - hcan te 17 english 04/03 n4 l2 u3 u1 a1 1 0 12vac 230vac 11 12 3 2 c 1 r1 km1 10 7 fu2 9 1 e 3 4 2 6 7 sa1 f 1 2 10 11 +po bp3 rd1 1 2 yv1 7 ka1 26 24 25 5 4 3 tc1 19 20 18 a6 ka1 9 23 7 30 11 12 21 22 23 24 25 29 27 30 fu1 22 30 22 23 21 ka1 24 25 9 26 7 25 30 29 21 29 27 30 6 18 18 14 14...

Page 20

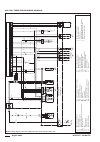

Hcat te - hcan te 18 english 04/03 n4 l2 u3 u1 a1 u v u-v-w pe 230v-3 -50hz qf1 u-v-w l1-l2-l3 1 3~ m 2 3 t1 t2 t3 l1 l2 l3 km1 qm1 z1 qs1 1 1 0 12vac 230vac 11 12 3 2 c 1 r1 km1 10 7 fu2 9 1 e 3 4 2 6 7 sa1 e 5 6 10 11 +po bp3 rd1 5 6 yv1 7 ka1 26 24 25 5 4 3 tc1 19 20 18 a6 ka1 9 23 7 30 11 12 21 ...

Page 21

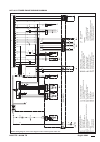

Hcat te - hcan te 19 english 04/03 u-v-w-n pe 400v-3n -50hz qf1 u-v-w-n l1-l2-l3-n 1 3~ m 2 3 t1 t2 t3 l1 l2 l3 km1 qm1 z1 qs1 u n n4 l2 u3 u1 a1 1 0 c4 1 12vac 230vac 21 22 12vac 12vac power 3 2 c 1 r1 km1 18 15 fu2 17 12dc tk id3 st1 st2 st3 st4 gnd gnd all alarm analog input digital input 1 e 3 4...

Page 22

Hcat te - hcan te 20 english 04/03 u-v-w pe 230v-3 -50hz qf1 u-v-w l1-l2-l3 1 3~ m 2 3 t1 t2 t3 l1 l2 l3 km1 qm1 z1 qs1 u v n4 l2 u3 u1 a1 1 1 0 c4 12vac 230vac 21 22 12vac 12vac power 3 2 c 1 r1 km1 18 15 fu2 17 12dc tk id3 st1 st2 st3 st4 gnd gnd all alarm analog input digital input 1 e 3 4 2 6 7 ...

Page 23

Technical data hcat te - hcan te 21 english 04/03 a i size hcan te 0071 0091 0101 0121 gas line connection mm-inch 22,22-7/8” 22,22-7/8” 28 28 liquid line connection mm-inch 15,90-5/8” 15,90-5/8” 18 18 no. Of fans n° 1 1 2 2 air flow m3/h 9800 9800 14000 14000 cooling capacity (1) kw 19,6 24,5 28,5 ...

Page 24

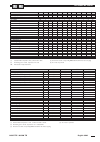

Hcat te - hcan te 22 english 04/03 cooling performance hcat te a i size hcat 0011 te ta sst 0,0 2,0 4,0 6,0 8,0 ta sst 0,0 2,0 4,0 6,0 8,0 pf 25 pa pat pf 30 pa pat pf 32 pa pat pf 35 pa pat pf 40 pa pat pf 43 pa pat 6,0 6,4 6,9 7,3 7,8 1,6 1,6 1,7 1,7 1,7 1,8 1,8 1,9 1,9 1,9 5,7 6,1 6,5 7,0 7,4 1,8...

Page 25

Hcat te - hcan te 23 english 04/03 ta: external air temperature (°c) sst: saturated intake temperature (°c) pf: cooling capacity (kw) pa: compressor absorbed power (kw) pat: total absorbed power (kw) size hcan 0071 te ta sst 0,0 2,0 4,0 6,0 8,0 ta sst 0,0 2,0 4,0 6,0 8,0 pf 25 pa pat pf 30 pa pat pf...

Page 26

Hcat te - hcan te 24 english 04/03 heating performance hcan te ta: external air temperature (°c) pa: compressor absorbed power (kw) tc: condensing point (°c) pat: total absorbed power (kw) pt: heat output (kw) size hcan 0071 te ta tc 40 45 50 55 60 ta tc 40 45 50 55 60 pt 21,4 21,2 21,1 - - -5 pa 5,...

Page 27

Hcat te - hcan te 25 english 04/03 calibration of protection devices high pressure switch hcat te 28,0 23,0 manual opens closes reset (bar) (bar) low pressure switch hcat te 0,7 1,7 automatic high pressure switch hcan te 28,0 18,0 manual low pressure switch hcan te 0,7 1,7 automatic checking and sta...

Page 28

Hcat te - hcan te 26 english 04/03 starting up for the first time (after two hours) before activating the condenser unit: - make sure the remote mains switch qf1 is in the off position; - remove the inspection panel; - remove the door of the electrical panel, setting qs1 to off - place the compresso...

Page 29

Hcat te - hcan te 27 english 04/03 activating: - press the on/off button on the keyboard in the figure. The indication "off" appears on the “values display”. Cooling if the internal unit has a cooling function, "on" will appear on the values display and the cooling led will come on. After a couple o...

Page 30

Activating and deactivating the unit hcat te - hcan te 28 english 04/03 displaying service parameters to display service parameters, proceed as follows: - press the on-off key; - press the on/off and mode keys together for one second; the tp parameter appears on the display; use the and keys to sele...

Page 31

Hcat te - hcan te 29 english 04/03 if the parameters set on the microprocessor require verifi- cation or modification, a password must be used to enter a higher level, accessible to authorised service centres only. Follow the instructions below: - press the on-off key; - press the on/off and mode ke...

Page 32

Hcat te - hcan te 30 english 04/03 cnf appliance configuration parameters value cp compressor parameters value fan fan parameters value all alarm parameters value list of accessible - displayable parameters parameter description unit of measurement note: while the parameters are being set, the compr...

Page 33

Operating characteristics hcat te - hcan te 31 english 04/03 start up and shut down to start up and shut down the unit, use the qs1 discon- nector switch. This turns on power to the compressor oil sump heater and places the electronic board in stand-by. In the event of temporary power failure, when ...

Page 34

Chemical washing you are recommended to chemically flush the plate heat exchanger after every 3 years of operation. For instruc- tions on how to carry out this operation, contact the man- ufacturer. Refrigerant gas content the condenser units are filled with r407c refrigerant gas and tested in the f...

Page 35

Troubleshooting hcat te - hcan te 33 english 04/03 a i no voltage supply voltage too low main unit switch in off position automatic switch in the off position no demand from internal unit check for presence of voltage check safety systems upstream of the appliance check power line position in on che...

Page 36

Hcat te - hcan te 34 english 04/03 malfunction cause remedy intake pressure low external air temperature check low discharge pressure insufficient gas content low external condenser air temperature check faulty fan control check high intake pressure thermostatic expansion valve faulty or open check ...

Page 40

Dé longhi group - via l. Seitz, 47 - 31100 treviso (italia) g r o u p cod .5774002100 (07/03).