- DL manuals

- Eco-Orlan

- Boiler

- Paxo Series

- Operating Manual

Eco-Orlan Paxo Series Operating Manual

Summary of Paxo Series

Page 1

1 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Operating manual paxo ® line of orlan® boilers. Wood gasification boilers from 18-80 kw (75-275k btu).

Page 2

2 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Table of contents 1. Safety 3 2. Boiler’s usage 3 3. System design considerations and sizing of the boiler 4 4. Wood and gasification process 4 5. Heat storage tank 4 6. Gasification 5 7. Technical data of a boiler 5 8. Boiler’s co...

Page 3

3 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Warning! Attention to safety is critical in all phases of boiler system design, installation, operation and maintenance. 1. Safety during installation the boiler and some components may be heavy or sharp. During operation parts of ...

Page 4

4 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 3. System design considerations and sizing of the boiler it is critical to size the paxo® boiler properly. A proper up to date heat load calculation is strongly advised. An accurate history of the building’s fuel usage over several...

Page 5

5 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 6. Gasification wood burned in gasification boilers gives almost three times more heat than ordinary boilers or chimneys nearly zero balance of co2 because the amount of carbon dioxide in emissions is very close to the amount of th...

Page 6

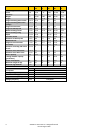

6 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Parameters units paxo® 18 paxo® 25 paxo® 40 paxo® 60 paxo® 80 power range btu 75k 85k 137k 205k 275k power kw 4-18 5-31 8-40 15-60 25-80 efficiency % 85 91 91 91 91 weight lb 1020 1280 1390 2070 2712 height a inch 44 51.75 62 62 60...

Page 7

7 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 8. Boiler’s construction 1. Chimney flue 2. Heat exchanger cleaning cover 3. Chimney flap 4. Hot water exit 5. Thermometer- sensor 6. Safe guard thermometer- sensor 7. Control panel 8. Upper door 9. Closing/opening door handle 10. ...

Page 8

8 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 9. Installation paxo ® wood boilers are designed to conform to and be installed in accordance with the very strict european regulations. The requirements are known as norm pn 87/b 02411 and norm pn 91/b 02411. When installed in the...

Page 9

9 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. The chimney flue connected to the paxo® boiler should conform to the specifications below. 1 inch = 2.54 mm 1 m = 3.28 ft 12. Combustion air the boiler requires fresh air for combustion. The air supply affects the quality of the bu...

Page 10

10 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Scheme of the paxo ® boiler, four-way mixing valve and water heater connected. 1. Four-way mixing valve 2. Circulating pump 3. Room thermostat 4. Paxo® boiler 5. Radiator 6. Okcv water heater vessel 7. Differential valve 8. Pressu...

Page 11

11 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 16. Filling the boiler and heating system the recommended fluid for filling the paxo® boiler and the system that the boiler is connected to is plain water. The easiest way to fill the boiler and the heating system is through a reg...

Page 12

12 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Um-1 module connection scheme 18. Temperature controller rk-2001ua the temperature of the boiler is kept at the level set by the user, by controlling the speed of the pressure fan. The controller monitors the temperature of water ...

Page 13

13 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. After turning the controller rk-2001ua on, all the elements of the display are lit for a while to check if they are working properly. The controller returns to its last state before turning off or before the power loss. 1 - master...

Page 14

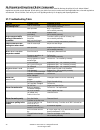

14 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Service parameter’s list display parameter min max step factory default n100 fan power or max fan power when nr 1 50 100 10% 100 n % of fan ramp down nh degrees ramp down starts nr 1 automatic fan speed control - .0 10 1 1 nn 5 fa...

Page 15

15 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. D) boiler’s work temperature setting minimal boiler temperature [l150] maximum boiler’s temperature [h195] boiler temperature hysteresis [h 10] - this parameter defines what value should the temperature of water in the boiler decr...

Page 16

16 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. H) device removal if the controller needs to be removed from the system: - turn the master switch off - disconnect the power from the boiler - remove the controller from the slot in the boiler - disconnect all connectors with cord...

Page 17

17 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 20. Boiler shutdown the boiler turns off in two ways: manually when the power switch on the controller is turned off, or automatically when the wood supply has burned out. Never turn the controller off for extended periods of time...

Page 18

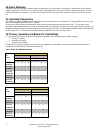

18 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. Model/ btu output % of air blower opening chimney draft 0.04 iwc chimney draft 0.08 iwc wood moisture % wood moisture % 15 20 25 30 35 15 20 25 30 35 paxo ® 18 75,000 btu 30 30 30 30 40 30 30 30 30 30 paxo ® 25 85,000 btu 50 50 50...

Page 19

19 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 24. Maintaining tight seals it is very important to maintain tight seals on the doors, heat exchanger cover plate and the firebox bypass chimney damper. Poor seals can result in smoke and gases leaking out of the boiler and lead t...

Page 20

20 ©2009 eco-orlan usa llc. All rights reserved. Revised august 2009. 26. Disposal and recycling of boiler components paxo® boilers contain steel, electronic components, insulation and other materials that may be subject to local, state or federal regulations as to their proper disposal. When retiri...