Ecoflam BLU TS 10000.1 PR HT Manual

Technical data

Operating instructions

Electric diagrams

Spare parts list

GAS BURNERS

EN

BLU TS 3000.1 PR HT

BLU TS 4000.1 PR HT

Gas train manual is separate

www.ecoflamburners.com

BLU TS 3000.1 PR TC SGT HT 230-50

3143084

BLU TS 3000.1 PR TL SGT HT 230-50

BLU TS 4000.1 PR TC SGT HT 230-50

3143198

BLU TS 4000.1 PR TL SGT HT 230-50

12-02-2016

Summary of BLU TS 10000.1 PR HT

Page 1

Technical data operating instructions electric diagrams spare parts list gas burners en blu ts 3000.1 pr ht blu ts 4000.1 pr ht gas train manual is separate www.Ecoflamburners.Com blu ts 3000.1 pr tc sgt ht 230-50 3143084 blu ts 3000.1 pr tl sgt ht 230-50 blu ts 4000.1 pr tc sgt ht 230-50 3143198 b...

Page 2: Index

Index general warnings - conformity declaration 3 burner designation - modular delivery system 4 burner description 5 electrical control panel 5 gas train - kit - accessories: assembly to the burner 6 technical data 7 gas category by country 7 test boiler - flame dimension 8 overall dimensions 9 gas...

Page 3

General warnings - conformity declaration declaration of conformity for gas burners we, ecoflam bruciatori s.P.A. Declare under our sole responsibility that the products: blu ts 3000.1 pr blu ts 4000.1 pr conform to the following standards: en 676: 2008 en 60335-1: 2008 en 60335-2-30: 2006 en 60335-...

Page 4: Burner Designation

Burner designation modular delivery system gas burners all gas burners are delivered in separate set/box, i.E. Burner body including combustion head and separate gas train with separate additional kit and accessories that shall complete the gas train or the burner according to the applicable standar...

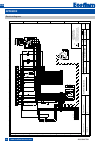

Page 5: Burner Description

Burner description gtcp legenda 1. Housing 2. Electrical control panel 6. Blast tube 7. Burner head 8. Burner fixing flange 9. Air flap regulation 12. Lifting eyebolts 13. Mechanical cam gas 15. Servomotor for gas and air 16. Gas train 19. Gas filter 20. Ball valve 23. Antivibration coupling 24. Tig...

Page 6: Burner Description

6 www.Ecoflam-burners.Com en 420010487501 burner description vgd 20.503 rp 2” / vgd 40.065 - 40.080 - 40.100 - 40.125 1. Main gas pipe 2. Ball valve acs 3. Antivibration coupling acs 5. Min gas pressure switch expor t gas train en676 6. Safety gas valve + 10. Actuator 7. Working gas valve + 11. Actu...

Page 7: Technical Data

7 www.Ecoflam-burners.Com en 420010487501 technical data gas category by country gas category country ii 2r , 3r be ch cz de dk es fi fr gb gr hu ie it lu nl pt se ee lt lv no pl sk si - ii 2h , 3p/b at - - - - - - - - - - - - - - - - - - - - - - - - i 3r cy mt - - - - - - - - - - - - - - - - - - - ...

Page 8

8 www.Ecoflam-burners.Com en 420010487501 test boiler - flame dimensions the burner/boiler matching does not pose any problems if the boiler is ce type- approved. If the burner must be combined with a boiler that has not been ce type-approved and/or its combustion chamber dimensions are clearly smal...

Page 9: Overall Dimensions

9 www.Ecoflam-burners.Com en 420010487501 overall dimensions 365 365 315 315 how to install the gas train into the burner and calculate the overall dimensions: refer to the dimension page and the gas train manual for all detailed information fixing hole dimensions are “i” and “l” as per dimension ta...

Page 10

Gas operating mode - general safety functions start-up mode as soon as the furnace system is required to supply heat, the burner control circuit will close and the program flow started. When the program has come to its end, the burner will be turned on. An automatic test is made for the tightness of...

Page 11: Installation

! Warning: handling and moving operations must be carried out by specialised personnel. Use the eyebolts to lift the burner in order that it will not overturn and fall down. Installation fitting the burner to the boiler to perform the installation of the burner into the boiler drill the boiler plate...

Page 12: Installation

12 www.Ecoflam-burners.Com en 420010487501 installation gas line gas connection pressure a minimum connection pressure must be available upstream of the burner gas valve to ensure the proper functioning of the burner. Warning: the total gas pressure loss must always be smaller than the available gas...

Page 13: Installation

13 www.Ecoflam-burners.Com en 420010487501 installation gas pressure loss diagram: combustion head - platform 320 the diagram provides combustion head pressure loss. To have pressure loss combined with the different type of gas train you must refer to the pressure loss diagrams. Warning: note that t...

Page 14: Installation

Installation gas pressure loss diagrams ! Pressure drop includes: “combustion head + gas train + gas governor & filter” as per en676 standard. Back pressure of boiler (or other applications) must be added/included in order to have the total min pressure drop. Legenda pf: back pressure of furnace pb:...

Page 15: Installation

Installation gas pressure loss diagrams ! Pressure drop includes: “combustion head + gas train + gas governor & filter” as per en676 standard. Back pressure of boiler (or other applications) must be added/included in order to have the total min pressure drop. Legenda pf: back pressure of furnace pb:...

Page 16: Installation

Installation electrical connections ! Warning: electrical wiring must be carried out with electrical supply disconnected and with burner switch in position off. Electrical supply must correspond to the one shown on the burner label. Applicable standard the electrical connection work comprising all t...

Page 17: Start-Up: Checking Procedure

Start-up: checking procedure checks before commissioning: • that the burner is assembled in accordance with the instructions given here. • setting the combustion components. • all electrical connections must be correct. • check the burner motor for correct direction of rotation. • the heat generator...

Page 18: Exhaust Gas Test

18 www.Ecoflam-burners.Com en 420010487501 exhaust gas test q f = q n = 1000 = 1136 kw volumetric gas flow rate at stp: v bn = q n = 1000 = 125 m 3 /h volumetric gas flow rate in operating condition: v bb = v bn t = p n = = 125 273+15 1013,25 = 123,9 m 3 /h to ensure an economically efficient and tr...

Page 19: Start-Up

19 www.Ecoflam-burners.Com en 420010487501 start-up select the gas operation in order to proceed with start up on the gas side. On the selector put the operation on minimum capacity. ! Kmv contactor: check the air fan motor rotation. If not correct invert the two phases on the power supply. Adjustin...

Page 20: Start-Up

0,4 0,6 0,9 3,0 1,5 2,1 1,8 2,4 2,7 1,2 a b c d 20 www.Ecoflam-burners.Com en 420010487501 start-up adjusting the intermediate burner capacity in order to adjust intermediate capacity of the burner use the selector on position 0 to stop the stroke and regulate the cam on the different screw position...

Page 21: Maintenance Program

21 www.Ecoflam-burners.Com en 420010487501 maintenance program ! Burner and boiler servicing must only be carried out by authorised and qualified personnel at least once a year. Depending on the type of installation, shorter maintenance intervals may be necessary. The system operator is advised to t...

Page 22: Maintenance Program

Maintenance program position of electrodes attention: check the position of the electrodes after any intervention as wrong position could cause ignition troubles. The ionization current is checked by inserting a microammeter with an end scale of 50 μa (d.C.) in series with the ionization probe. A fa...

Page 23: Troubleshooting Instructions

The list of faults/causes/possible solutions for a set of main failures is a guideline for professional personell authorised to carry out service and maintenance. Irregular burner operation or malfunction: check that every adjustment parameter is correctly set as per instruction on this manual. Trou...

Page 24: Operating Trouble

Operating trouble in case of operating trouble it should be checked whether the system is in proper working order. Make a check for the following: 1. Availability of fuel. Availability of gas in the line at sufficiently high pressure. Correct position of fuel selector switch. 2. Availability of elec...

Page 25: Appendix

Appendix control box - damper actuators control box lfl 1.../lgk... R: temperature or pressure controller m: fan motor z: ignition transformer bv: fuel valve(s) lr: load regulator lk: air damper rv: steadily adjustable fuel valve fs: signal of flame the lfl 1…/lgk... Type controller is designed to c...

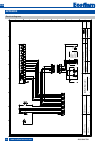

Page 26: Appendix

Appendix electrical diagrams t p st ab hlf line lo ad z fu sal hlb t sam a 12 3 0 ka hlb hlf fm v hlb 3 m mv wv u sa s .R 98 7 4 5 6 21 3 11 10 12 10 12 11 1 3 2 4 56 9 8 7 fm v 97 98 fm v 95 96 p t st c p t st s kmv f 1 e d 2 3 4 c b a 1 2 3 4 5 6 7 8 f e d 5 6 7 c b 8 a to t. Shee t shee t designe...

Page 27: Appendix

Appendix electrical diagrams conmut ador m anu al -a ut om atic o commut at ore m anu ale-a ut om atic o swit ch (m anu al -a ut om atic )) interrupteur m anuel -a ut om atique interrupt or de linea interrupteur de ligne working swit ch termost at o caldera thermost at cha udiere boiler thermost at ...

Page 28: Appendix

28 www.Ecoflam-burners.Com en 420010487501 appendix electrical diagrams s3 t2 n t1 l1 7 17 6 26 25 15 5 16 27 4 14 32 3 22 12 2 13 m 1 1 11 n 21 landis sqm 50.481a2 24 93 92 91 103 35 51 102 101 104 44 45 46 105 50 100 90 l1 s3 t1 n t2 t p sp a tv er t p spgmin blue yell ow-g reen black brown contro...

Page 29: Appendix

29 www.Ecoflam-burners.Com en 420010487501 appendix electrical diagrams t2 n t1 s3 l1 yell ow-green dungs vps 504 t8 t6 t7 brown b5 n blue l1 black l1 s3 t1 n t2 black 3 1 blue 13 14 brown dungs vdk 200-a yell ow-green ele tt rodo di rivelazione pressost at o aria air pressure swit ch ignition tr an...

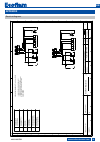

Page 30: Appendix

Appendix spare parts list 420010487501 en www.Ecoflam-burners.Com 30 19 23 2 4 2 b lu t s 3000 .1 - 4000 .1 p r 1 2 0 3 4 8 7 10 9 16 11 13 1 4 15 1 7 12 21 5 6 22 25 1 8 26.

Page 31: Appendix

Appendix spare parts list 420010487501 en www.Ecoflam-burners.Com 31 tc = short head tl = long head blu ts 3000.1 pr blu ts 4000.1 pr n° description code code 1 air pressure switch lgw10a2p 65323047 65323047 2 wieland plug 6 pin 65322072 65322072 3 down cover 65324765 65324765 4 up cover 65324766 65...

Page 32

Ecoflam bruciatori s.P.A. Via roma, 64 - 31023 resana (tv) - italy tel. +39 0423 719500 fax +39 0423 719580 http://www.Ecoflam-burners.Com e-mail: export@ecoflam-burners.Com società soggetta alla direzione e al coordinamento di ariston thermo s.P.A. Via a. Merloni, 45 - 60044 fabriano (an) - cf 0102...