- DL manuals

- EcoSpar

- Stove

- Auriga 23 kW

- Manual For Installation And Operation

EcoSpar Auriga 23 kW Manual For Installation And Operation

Summary of Auriga 23 kW

Page 1

Manual for installation and operation of auriga 23 kw.

Page 2

Table of contents 1.0. Precautions and safety ................................................................................................... 3 2.0. Technical characteristics ................................................................................................ 4 2.1 accessories .........

Page 3

Dear buyer, we thank you for choosing this product. This product is made with attention to all materials used and technologies employed. It was designed to satisfy your needs for a functional and safe product. By using this instruction manual you will learn how to use your pellet-burning stove prope...

Page 4

Avoid direct contact with hot parts of the product. Check if there are difficulties while turning the product on after a long period of non- operation (see chapter 6.0). The pellet stove is designed to work even in extreme weather conditions, however, in case of strong wind or frosty conditions, the...

Page 5

2.3 technical description the auriga 23 kw is designed for heating residence or office spaces, as well as an additional heating, at the same time contributing to the more pleasant ambience. Suitable for central space heating. Mantle heat exchanger. The hearth of the pellet stove is made of very thic...

Page 6

2.4 technical data and dimensions model of the pellet stove: kw 23 height mm 1250 width mm 585 depth mm 555 weight kg 160 diameter of air intake pipe mm 38 diameter of exhaust gas pipe mm 80 maximum heating (*) volume m 2 220 nominal thermal power (ptn) kw 23 decreased thermal power (ptr) nominal th...

Page 7

3.0 installation 3.1 general rules knowing that the proper assembly is very important, as well as the proper connection of the exhaust gas system and that the possible errors made during the assembly are not covered by the warranty of manufacturer , our company advices the installation to be made af...

Page 8

For proper operation and proper distribution of the temperature, the pellet stove should have sufficient air intake and to be placed on suitable place (a special hole for air intake can be made). The hole for air intake should be 100 cm 2 minimum and there should not be any obstacles. The air may be...

Page 9

3.6 installation schemes (optional) 3.7 rear end of the exhaust gas pipe the rear end of the exhaust gas pipe is intended for proper exhaust of the gases in the atmosphere, its protection against rain, snow or any other objects in order to guarantee excellent exhaust of the gases in windy conditions...

Page 10

Operational problems due to defects of the system capacity besides all influencing atmosphere agents, the wind is the most important agent for the system operation . 3.8 connection to the electrical power supply the product should be connected to the electrical power supply. Our pellet stoves are su...

Page 11

All specifications are listed below. Electrical power supply 230v, 50/60hz, maximum consumption 13/20 ma. Inputs : exhaust gas temperature – type j outer thermostat - contact probe ntc temperature room – ntc 10 k outputs: exhaust gas aspirator – 230 v exchanger - 230 v low-range gear lever – 230 v h...

Page 12

Recommended settings for auriga 23kw 0. Fuel ignition timeout --> [20] 36. Power 3 fan 2 speed --> [0] 73. User fuel feeder 1 on time factor --> [100] 1. Ignition test timeout --> [10] 37. Power 4 fan 2 speed --> [0] 74. User fuel fan 1 speed factor --> [100] 2. Fuel type --> [0] 38. Power 5 fan 2 s...

Page 13

Using fumis alpha keyboard fumis alpha keyboard with remote control figure 1: fumis alpha keyboard and remote control the fumis alpha capacitive touch keyboard is designed intuitively. It enables users at home to operate with the fumis alpha controller. Note for best performance keep the keyboard cl...

Page 14

Selected menu context is indicated with the corresponding icon at the top. In addition, these buttons are used in the edit mode. Edit buttons (plus and minus buttons) are used for navigating the submenus and increasing/decreasing values in the edit mode, when the selected value blinks. Enter button ...

Page 15

Note the fumis alpha menu structure depends on the configuration and options. The menu structure in figure 35 shows all possible menu entries. Depending on the selected configuration, some entries are not available. In such cases the menu entry is not included and submenus are renumbered accordingly...

Page 16

To view the current room temperature, press the menu button to enter the temperature context menu. The current room temperature value is shown on the display. To set the desired room temperature, in the temperature context menu press the enter button. The display shows the set target temperature in ...

Page 17

Desired room temperature for the selected time period. Confirm the program settings by pressing enter. Repeat the procedure to set the programs. Example: program 1 program 2 program 3 program 4 program 5 program 6 on off on off on off on off on off on off 5:30 7:30 8:00 11:30 12:00 23:00 17:00 23:00...

Page 18

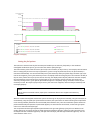

Time program/temperature setpoint p1 (20 °c) p2 (21 °c) p3 (22 °c) heating device on heating device off time legenda: p1 à 7:00h ( on ); 20:00h ( off ); temperature setpoint 20 °c p2 à 9:00h ( on ); 11:00h ( off ); temperature setpoint 21 °c p3 à 13:00h ( on ); 17:00h ( off ); temperature setpoint 2...

Page 19

Modifying the setup options in the setup menu context you can set the options for key lock, idle display brightness, idle display mode, beeper volume, manual feed and view the time to service (option, read only). To modify the setup options, press the menu button to enter the setup context. To move ...

Page 20

Servicing fumis alpha controller basic servicing procedures of the fumis alpha controller can be performed using the fumis alpha keyboard. For additional options and advanced diagnostic procedures use the fumis pc-pro application. Unlocking the service menu to enable the service menu, in fumis pc-pr...

Page 21

Service menu structure setup key lock service menu (unlocked) parameters digital inputs analog inputs digital outputs service counters logs parameter 0 parameter 1 parameter 105 . . . Security normal motor rotations digin2 inverted digin11 inverted pressureswitch normal tc1 internal pressure sensor ...

Page 22

Modifying the parameters the fumis alpha parameters are used to fine tune the operation of the combustion system with the fumis alpha controller. Set the parameter values of the fumis alpha controller, according to the selected configuration, to optimize the performance of the combustion system. Wit...

Page 23

Setting the time to service notification fumis alpha controller enables to set up the notification for regular maintenance. The time to service shows when the regular service should be performed. It counts down in hours, and when this counter reaches zero, the service icon starts blinking. Regardles...

Page 24

Troubleshooting the fumis alpha keyboard provides notifications and warnings for alerts and errors, which can occur when using the fumis alpha controller. The alarm icons indicate a problem. An alert notification is indicated with the blinking icons, errors are indicated with continuously lit icons....

Page 25

Solution: contact the service personnel to change the fumis alpha controller battery. Do not attempt to change the battery on your own. Fan 1 speed sensor failure indication: icon service is blinking code: a005 cause: the fan 1 speed sensor malfunctioned. The combustion system is still operational. ...

Page 26

Service is required indication: icon service is on cause: the combustion system malfunctioned and is not operational. This can be due to: code e001: keyboard error code e002: ir communication error code e003: rf communication error code e004: mb communication error code e101: fire error or water ove...

Page 27

The fire up phase. Off off more than 2minutes fire up phase the controller continues normally burning phase the controller checks the flue gases temperature. If the flue gases temperature dropped below par56, the combustion system restarts in the fire up phase, otherwise it continues in the burning ...

Page 28

Appendix a - operation phases operation phase operation sequence parameters off off par102 (anti-freeze temperature) keep fire par88 (feeder), par87, par89 (fan 1), par90 (repetition) fire up test fire par20 (fan 1), par29 (fan 2), par40 (fan 3) heat up par3, par4 (feeder), par21 (fan 1), par31 (fan...

Page 29

29 appendix b - list of parameters alarms timeout no. Parameter description 0 heat up timeout (phase2) ignition timeout (in minutes): maximum wait time for successful firing in the ignition phase. 1 ignition test timeout (phase3) test fire timeout(in minutes): maximum wait time for flame detection w...

Page 30

30 7 ignition test feeder 1 off time ignition test sequence feeder off time: defines the feeder pause during the ignition test sequence. 8 ignition test feeder 1 on time ignition test sequence feeder on time: defines the feeder dosing time during the ignition test sequence. Feeder: burning 9 power 1...

Page 31

31 fan 1 19 stop fire fan 1 speed fan1 speed in fire stop sequence: defines the fan 1 speed during the stop fire sequence. Stop fire is active when the heating device is turned off and flue gases are not cooled below par56. In burner configuration the stop fire runs until the flame sensor gives the ...

Page 32

32 note: not used when advanced regulation is selected. 27 power 4 fan 1 speed fan1 speed at power 4: defines the fan1 speed at power 4 (depends on the selected fan mode - open loop, closed speed loop or closed pressure loop). Note: not used when advanced regulation is selected. 28 power 5 fan1 spee...

Page 33

33 for each power pid regulator output. Maximum number of steps is 1024. Note: if the flue gases temperature is below par58 [⁰c] in fan2 for room heating mode, fan2 is switched off. 35 power 2 fan 2 speed fan2 speed at power 2: note: not used when advanced regulation is selected. Note: if the flue g...

Page 34

34 figure 6: fan 3 operation 40 stop fire fan 3 speed fan3 speed in stop fire sequence note: fan3 operates in on/off mode only. The valid settings for this parameter are 0 (fan3 off) or 255 (fan3 on at maximum speed). You must also set the par77 and an air temperature sensor (ntc) must be connected ...

Page 35

35 48 power 4 fan 3 speed fan3 speed at power 4 note: fan3 operates in on/off mode only. The valid settings for this parameter are 0 (fan3 off) or 255 (fan3 on at maximum speed). You must also set the par77 and an air temperature sensor (ntc) must be connected to i/o t02. Fan3 only operates when fan...

Page 36

36 figure 9: cool fluid exit temperature settings for boilers and burners no. Parameter description 50 cool fluid exit temperature difference cool fluid exit temperature difference(in °c): in stove mode: the heating device restarts after room temperature drops below [par51-par50]. Par50 is set in 0....

Page 37

37 cool fluid when air temperature exceeds [par51 (in °c) +par53 (in 0.1°c)]. In stove mode with water pump: the stop temperature based on the air temperature measurement is the same as above. The water stop temperature is defined with par95. In boiler/burner mode: this parameter defines the stop le...

Page 38

38 value in ui 200 200 actual parameter value 400°c 400°c 58 fan 2 as ambient minimum gases temperature fan2 stop gases temperature (in °c): if fan 2 as chimney is enabled, this parameter is ignored. If fan 2 for room heating is enabled, this par defines the threshold for fan2 operation, regardless ...

Page 39

39 68 off temperature / t1-t2 for max. Modul. Speed water pump turn off temperature (in °c): defines the water pump turn off temperature threshold (must be lower than par67 value). 69 anti-condensation exit temperature backwater temperature (in °c): defines the backwater temperature threshold if a b...

Page 40

40 external room temperatures no. Parameter description 77 2nd room temperature external room temperature (in °c): defines the external room temperature, regulated with fan3. Figure 10: fan 3 operation flame sensors in the burner configurations the flame sensor is used to detect flame in the burning...

Page 41

41 airflow if this parameter is 0, the underpressure/airflow error is enabled. If the underpressure in the burning chamber is lower than par82, the alarm is triggered after par83 seconds. 83 underpressure / airflow error delay time delay before triggering underpressure/airflow error (in seconds): de...

Page 42

42 feeder 2 settings feeder 2 is usually used for dosing secondary fuel or as pellets transporter from the main storage. It can also be used for mixing different fuels (pellets and olive stones, for example) in fixed proportions (%). For detailed description of feeder 2 operation refer to chapter er...

Page 43

43 defines the service due time. This parameter is used in connection with the service time counter. Par94 defines the service time period in days, but the service time counter counts the hours. This means that if you set the par94=1 (day), the service time counter displays 24 (hours). Maximum value...

Page 44

44 101 blow out duration time for ash blow out at stop fire (in seconds): after the stop fire and cool fluid, the fan1 will operate at maximum speed for par101 period. 102 anti-freeze temperature minimum air temperature to keep (in °c): only in stove mode and activated timer. Operation: the stove tu...

Page 45

45 5.2 pouring the pellets information and advices many of our clients ask how to recognize good pellets. Some of them say you should look at the color, if it is dark, the pellets are of good quality, and on the contrary, if their color is light, they are of poor quality. Some of them say that if th...

Page 46

46 - inspection and possible replacement of the door rope; - disassembling and cleaning of the t junction of the exhaust gas system; - inspection of all electronic parameters; - issue of a certificate for the completed inspection . Attention do not clean the system until completely cooled down. Peri...

Page 47

47 pellet reservoir it is recommended to periodically clean the reservoir (at least once a month); firstly you should empty it and then clean it using a vacuum cleaner. Gas system it is recommended to clean the general gas system once a year. To do it, it is necessary: - to open the door, to take ou...

Page 48

48 after cleaning, close the system. Fresh air intake system at the beginning of the heating season you should check the fresh air system, whether there is any obstacle in it. Exhaust gas system at the beginning of the heating season you should clean the exhaust gas system. If the electrical cable i...