- DL manuals

- EcoWater

- Water Filtration Systems

- ELC-1500

- User Manual

EcoWater ELC-1500 User Manual

Summary of ELC-1500

Page 1

Membrane system user manual elc – series elc – 1500 w.

Page 2

Elc – series user manual mktf – 506-a 2 03/18 this page intentionally left blank.

Page 3

Elc – series user manual mktf – 506-a 3 03/18 table of contents introduction ............................................................................................................ 4 safety ............................................................................................................

Page 4

Elc – series user manual mktf – 506-a 4 03/18 introduction your elc – series reverse osmosis system is a durable piece of equipment which, with proper care, will last for many years. This user manual outlines installation, operation, maintenance and troubleshooting details vital to the sustained per...

Page 5

Elc – series user manual mktf – 506-a 5 03/18 safety the safety section of this user manual outlines the various safety headings used throughout this manual’s text and are enhanced and defined below: indicates statements that are used to identify conditions or practices that could result in equipmen...

Page 6

Elc – series user manual mktf – 506-a 6 03/18 feedwater and operation specifications nothing has a greater effect on a reverse osmosis system than the feedwater quality. It is very important to meet the minimum feedwater requirements. Failure to do so will cause the membranes to foul and void the ma...

Page 7

Elc – series user manual mktf – 506-a 7 03/18 rejection, recovery and flow rates e lc – series reverse osmosis systems are designed to produce permeate water at the capacities indicated by the suffix in the system’s name under the conditions listed above. For example, the elc – 750 system produces 7...

Page 8

Elc – series user manual mktf – 506-a 8 03/18 system requirements and operation guidelines plumbing the membranes and high pressure pumps used on elc – series systems require a continuous flow of water with a minimum feed pressure of 40 psi, not to exceed 60 psi. Feedwater connection 1. Locate the 1...

Page 9

Elc – series user manual mktf – 506-a 9 03/18 electrical the motor used on the elc is available in 110 vac 60 hertz 1 phase. Each elc – series system is equipped with an eight –foot electrical cord with a three pronged electrical plug. Ensure that the electrical circuit supplying the system is compa...

Page 10

Elc – series user manual mktf – 506-a 10 03/18 membrane elements elc – series reverse osmosis systems are equipped with thin film composite (tfc) hf5 – ultra low energy membranes, unless otherwise specified. General membrane element performance characteristics are listed below. Hf5 – ultra low energ...

Page 11

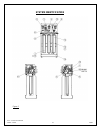

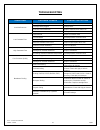

Elc – series user manual mktf – 506-a 11 03/18 system identification figure 1.

Page 12

Elc – series user manual mktf – 506-a 12 03/18 system identification item no. Axeon description axeon part no. Model(s) 1 cartridge, sediment, polypro, 2.5" x 20", 5 mic, sdf –25–2005 200626 750 - 1500 2 cartridge, carbon, block, 2.5" x 20", 10 mic, cbf –25–2010 200659 750 3 meter, flow, pm, 0.2 –2 ...

Page 13

Elc – series user manual mktf – 506-a 13 03/18 membrane installation, removal and replacement installation and replacing membranes in the pressure vessels is an easy process if you have the proper information and tools at hand. Please refer to the following instructions when removing and replacing m...

Page 14

Elc – series user manual mktf – 506-a 14 03/18 replacing the membrane element: the brine seal must be in the correct position for each membrane element housing. The brine seal is a rubber seal that protrudes on one side of the membrane and is always on the feed side of the membrane element. For elc ...

Page 15

Elc – series user manual mktf – 506-a 15 03/18 figure 2.

Page 16

Elc – series user manual mktf – 506-a 16 03/18 figure 3.

Page 17

Elc – series user manual mktf – 506-a 17 03/18 initial start –up carefully inspect your system before initial start –up. Check that all plumbing and electrical connections are not loose or have not come undone during shipment. Direct the permeate water line to drain for this procedure. 1. Fully open...

Page 18

Elc – series user manual mktf – 506-a 18 03/18 operating do's and don'ts do: • change the cartridge filters regularly. • monitor the system and keep a daily log. • run the system as much as possible on a continuous basis. • adjust the system recovery to the recommended value. • always feed the pump ...

Page 19

Elc – series user manual mktf – 506-a 19 03/18 product specifications models elc – 750 elc – 1500 design configuration single pass single pass feedwater source † tds up to 1,000 tds up to 1,000 nominal recovery rate up to 65% up to 75% rejection and flow rate ††† nominal salt rejection 98.5% 98.5% p...

Page 20

Elc – series user manual mktf – 506-a 20 03/18 operating limits †† design temperature 77°f maximum turbidity 1 maximum feed temperature 85°f maximum free chlorine (ppm) 0 minimum temperature 40°f maximum tds (ppm) 1,000 maximum ambient temperature 120°f maximum hardness (gpg) 1 minimum ambient tempe...

Page 21

Elc – series user manual mktf – 506-a 21 03/18 operation and maintenance the reverse osmosis process causes the concentration of impurities. The impurities may precipitate (come out of solution) when their concentration reaches saturation levels. Precipitation can scale or foul membranes and must be...

Page 22

Elc – series user manual mktf – 506-a 22 03/18 flushing the system the system should be flushed weekly to remove sediment from the surface of the membranes. To manually flush the system, follow these steps: 1. The system must be operating during the flush procedure. 2. Fully open the concentrate val...

Page 23

Elc – series user manual mktf – 506-a 23 03/18 preparing unit for storage or shipment prior to shipping or storing your system, the system should be cleaned with an appropriate cleaner, flushed with water and protected from biological attack with an appropriate solution for membrane elements. The me...

Page 24

Elc – series user manual mktf – 506-a 24 03/18 troubleshooting symptoms possible causes corrective action low inlet pressure low supply pressure increase inlet pressure cartridge filters plugged change filters solenoid valve malfunction replace solenoid valve and/or coil leaks fix any visible leaks ...

Page 25

Elc – series user manual mktf – 506-a 25 03/18 abnormal permeate flow permeate flow should be within 20% of the rated production, after correcting the feedwater temperatures above or below 77°f. Check the permeate flow meter to determine the permeate flow rate. To determine the temperature correctio...

Page 26

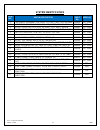

Elc – series user manual mktf – 506-a 26 03/18 operating log.

Page 27

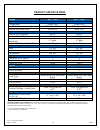

Elc – series user manual mktf – 506-a 27 03/18 temperature correction factors for membrane find the temperature correction factor (tcf) from the table below. Divide the rated permeate flow at 77°f by the temperature correction factor. The result is the permeate flow at the desired temperature. (see ...

Page 28

Elc – series user manual mktf – 506-a 28 03/18 if a system is rated to produce 5 gpm of permeate water at 77°f, the same system will produce more water at a higher temperature. It will also produce less water at a lower temperature. Use the temperature correction table to obtain the correct flow. Ex...

Page 29

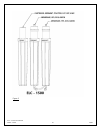

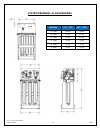

Elc – series user manual mktf – 506-a 29 03/18 models elc – 750 elc – 1500 “a” dim 36.62 36.62 “b” dim 17.20 17.20 “c” dim 17.00 17.00 “d” dim 15.00 15.00 “e” dim 12.00 12.00 “f” dim 11.76 11.76 system drawings, flow diagrams.

Page 30

Elc – series user manual mktf – 506-a 30 03/18 elc – 750 flow diagram.

Page 31

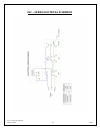

Elc – series user manual mktf – 506-a 31 03/18 elc – 1500 flow diagram.

Page 32

Elc – series user manual mktf – 506-a 32 03/18 elc – series electrical schematic.

Page 33

Elc – series user manual mktf – 506-a 33 03/18 system warranty one – year limited warranty warranty terms subject to the terms and conditions set forth hereinafter, manufacturer (hereafter “manufacturer”) warrants to the original purchaser (hereafter the “customer”) that the systems and products man...

Page 34

Elc – series user manual mktf – 506-a 34 03/18 required or replaced products or components shall be returned surface freight. In genuine emergency situations, manufacturer will at manufacturer ’s sole discretion) forward replacement parts to customer without waiting for authorized return of the ques...