- DL manuals

- ECR

- Boiler

- 075 97gb

- Installation, Operation & Maintenance Manual

ECR 075 97gb Installation, Operation & Maintenance Manual

Summary of 075 97gb

Page 1

An iso 9001-2008 certified company ecr international, inc. 2201 dwyer ave utica, ny 13501 p/n # 240008282, rev j [03/2014] condensing gas boiler models 075 & 100 wall mounted gas boiler installation, operation & maintenance manual.

Page 2

2 description item no. Illustration fully assembled boiler 1 metal wall bracket 2 lag bolt, 3/8" x 3" hex (4 ea) 3 *safety relief valve 4 3/4" elbow 90° 5 3/4" close nipple 6 3/4" f x 3/4" m npt tee 7 3/4" x 1/4" npt 90° elbow 8 air vent 9 **temperature pressure gauge 10 bushing 3/4" x 1/4" 11 3/4" ...

Page 3

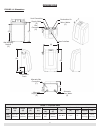

3 dimensions figure 1-1 dimensions wall hanging bracket (d) gas connection (g) supply water (e) return water (e) user interface (b) (a) alternate return water (e) alternate supply water (e) alternate gas connection (f) (c) (b) (f) table 1 : physical data size width (a) height (b) depth (c) bracket (...

Page 4

4 1 - introduction ............................................................................................................................... 5 2 - important safety information .................................................................................................... 6 3 - component l...

Page 5

5 information and specifications outlined in this manual in effect at the time of printing of this manual. Ecr international reserves the right to discontinue, change specifications or system design at any time without notice and without incurring any obligation, whatsoever. Check our website freque...

Page 6

6 notice used to address practices not related to personal injury. 2.3 installation shall conform to requirements of authority having jurisdiction or in absence of such requirements: • united states • national fuel gas code, ansi z223.1/nfpa 54. • national electrical code, nfpa 70. • canada • natura...

Page 7

7 3.1 component listing 1. User interface - displays information regarding boiler condition. Allows adjustment of boiler operating parameters. Note: does not replace thermostat used to control central heating space. 2. Combustion air inlet (2" pvc) (see section 6) 3. Return water from heating system...

Page 8

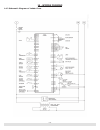

8 3 - component listing figure 3-1 boiler components (4) low voltage terminal strip (2) combustion air inlet- 2" pvc (25) vent connector - 2" pvc (23) safety relief valve (30) air vent (3) return water from heating system (in) (24) high voltage junction box (14) supply water to heating system (out) ...

Page 9

9 3 - component listing figure 3-2 boiler components (4) low voltage terminal strip (24) high voltage junction box (3) return water from heating system (in) 1-1/4" npt (5) igniter (7) sight glass (13) heat exchanger ball valve (16) condensate drain 1/2" pvc (18) gas shutoff valve (22) low water cuto...

Page 10

10 3 - component listing (33) internal access panel - closed (33) internal access panel - open (32) control module (34) central heating pump relay (35)transformer control module fuse and holder note: to open lift panel up then pull forward.

Page 11

11 table 2: boiler clearances dimension combustible materials (1) service (1)(2) top (a) 0" (0 cm) 14" (36 cm) left side (b) 6" (16 cm) 6" (16 cm) right side (c) 0" (0 cm) 1½" (4 cm) front (d) 0" (0 cm) 6" (16 cm) back (e) 0" (0 cm) 0" (0 cm) bottom (f) 0" (0 cm) 0" (0 cm) floor 12" (32 cm) for bott...

Page 12

12 4 - locating boiler figure 4-2 wall mount bracket engaged with bracket on boiler 4 slots for attaching wall mount bracket to studs center brackets. Avoid overhang on sides of wall mount bracket. 4.2 pre-pipe supply and return water connections with factory fittings before wall mounting. 4.3 wall ...

Page 13

13 5.1 general • install piping in accordance with authority having jurisdiction. Notice use two (2) wrenches when tightening and fitting to pipe boiler's threaded fittings. Boiler's internal piping can be damaged if subjected to excessive torque. • support system piping and safety relief valve disc...

Page 14

14 • systems with automatic fill valves require back flow prevention device. • install discharge piping from safety relief valve. See figure 5-2. • use ¾" or larger pipe. • use pipe suitable for temperatures of 375°f (191°c) or greater. • individual boiler discharge piping shall be independent of ot...

Page 15: F L O O R

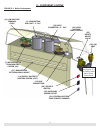

15 piping legend figure 5-4 system piping 5 - hydronic piping notice illustrations are meant to show system piping concept only. Installer responsible for all equipment and detailing required by authority having jurisdiction. System return system supply f l o o r table 3 - system piping configuratio...

Page 16

16 5 - hydronic piping figure 5-5 single boiler two-pipe zoned system with zone valves figure 5-6 single boiler two-pipe zoned system with zone pumps heat exchanger ball valve open (as shipped) heat exchanger ball valve open (as shipped) dhw pump ch/system pump dhw pump zone pump 3/8"/9.5 mm open en...

Page 17

17 5 - hydronic piping figure 5-7 single boiler using primary/secondary pumping with closed external primary loop or single boiler using primary/secondary pumping with open external primary loop 12"/305mm max. Apart 12"/305mm max. Apart limit length to 5'/1.6 m existing closely spaced tees in primar...

Page 18

18 5 - hydronic piping 5-8 typical multiple boiler piping - (see multiple boiler guide) ch/ system pump 12"/305mm max. Apart system temperature sensor size common piping according to maximum heat capacity of entire system up to 16 boilers all heat exchanger ball valves closed 3/8"/9.5mm open end wre...

Page 19

19 6.1 general this boiler requires a dedicated direct vent system. Install combustion air and vent piping in accordance with these instructions, authority having jurisdiction, and: • usa - national fuel gas code, ansi 223.1/nfpa 54. • canada - natural gas and propane installation code, can/csa b149...

Page 20

20 6 - combustion air and vent piping warning vent extending through exterior wall shall not terminate adjacent to wall or below building extensions such as eaves, balconies, parapets or decks. Failure to comply could result in death or serious injury. ! 6.4 pipe installation • minimum and maximum c...

Page 21

21 6.7 venting configurations various venting configurations can be applied to this boiler. For guidance see venting configuration table 7 and corresponding figures. Flue gas location combustion air location flue gas terminals corresponding figures roof roof two pipe figure 6-1 concentric figure 6-7...

Page 22

22 6 - combustion air and vent piping side wall terminations 3" (8 cm) minimum horizontal separation between combustion air intake and vent terminations. 8" (21 cm) minimum vertical separation between combustion air intake and vent terminations. 12" (30 cm) separation between bottom of combustion ai...

Page 23

23 1"(2.54cm) maximum combustion air vent figure 6-4 side wall concentric terminal figure 6-5 side wall concentric terminal multiple appliances 1" (25.4mm) maximum maintain 12" clearance above highest anticipated snow level or grade * see note below vent combustion air 1" (25mm) maximum roof overhan...

Page 24

24 concentric vent roof terminations glue inner vent pipe to prevent recirculation. Maintain 12" (305mm) us (18"(457mm) canada) minimum clearance above highest anticipated snow level. Maximum of 24"(610mm) above roof. Support must be field installed to secure termination kit to structure. Elbow, roo...

Page 25

25 figure 6-10 flue on sidewall, combustion air on roof figure 6-11 flue on sidewall, inside combustion air combustion air vent 12" (305mm) anticipated snow line 6 - combustion air and vent piping notice configurations of single pipe vent with flue on the sidewall, requires a tee as the vent termina...

Page 26

26 6 - combustion air and vent piping doors & windows combustion air and vent termination must be 12" (305mm) from or below doors, windows or gravity inlet. Forced air inlet terminate venting system 3’ (0.9m) above and 10' (3.0m) from any forced air inlet (except boiler’s combustion air inlet). "l" ...

Page 27

27 6 - combustion air and vent piping multiple family dwellings vent shall not terminate directly above paved sidewalk or paved driveway located between two single-family dwellings serving both dwellings. 7' (2.1m) minimum 3' (0.9m) minimum termination stones, balls, etc position combustion air and...

Page 28

28 6 - combustion air and vent piping 6.9 condensate piping • use materials acceptable to authority having jurisdiction. In absence of such authority: • usa - pvc or cpvc per astm d1785/d2845 cement or primer per asme d2564 or f493. • canada - csa or ulc certified pvc/cpvc pipe, fittings and cement....

Page 29

29 7.1 general • use piping materials and joining methods acceptable to authority having jurisdiction. In absence of such requirements: • usa - national fuel gas code, ansi z223.1/nfpa 54 • canada - natural gas and propane installation code, can/csa b149.1 • size and install gas piping system to pro...

Page 30

30 7-5 manual main gas shutoff valve outside boiler jacket option: gas connection may be located at bottom of boiler manual main gas shutoff valve 7.3 near boiler gas piping • select top or bottom gas connection. To convert from top connection to bottom connection: • remove bottom knockout by removi...

Page 31

31 8.1 general electrically bond boiler to ground in accordance with requirements of authority having jurisdiction. Refer to: • usa- national electrical code, ansi/nfpa 70. • canada - canadian electrical code, part i, csa c22.1: safety standard for electrical installations. 8.2 line voltage connecti...

Page 32

32 8 - electrical connections • outdoor sensor, if used. A. Provided with boiler in accessory kit. B. Locate outdoor sensor to protect against wind and direct sunlight. Mounting instructions provided with sensor. C. Maximum wire length is 100 ft (30m) for 22 ga. Wire, or 150 ft (45m) for 18 ga. Wire...

Page 33

33 9 1 fill boiler with water and purge air notice to maintain boiler efficiency and prevent boiling inside the heat exchanger, flush entire heating system until clean. • flush heating system, including all heating zones. • fill boiler with potable water. • fill boiler and system piping with water (...

Page 34

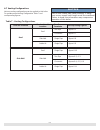

34 9 -2 user interface 9 - start up procedure 9.3 program boiler control key description - manual lockout reset - enter/exit user menu - go to previous screen - select a menu item - confirm new parameter value - scroll up to next menu item - increase value - scroll down to next menu item - decrease ...

Page 35

35 9.4 boiler start-up and operational test 1. Verify air is purged from hydronic piping 2. System test pumps - verify each pump is operational 3. Verify gas piping • confirm pressure test. See section 7.4. • visually inspect piping to determine there are no open fittings or ends, and all valves at ...

Page 36

36 verify burner, proper operation 1. Inspect burner flame through sight glass. See figure 9-5. 2. Operate boiler through several heating cycles, including domestic hot water, if used. Verify proper operation. 3. Reset control parameters to operating settings if adjusted to allow startup and operati...

Page 37

37 9-4 combustion analyzer port combustion analyzer port 9-5 burner flame flame flame burner 9 - start up procedure notice combustion analyzer port is provided. After use replace cover. Look for blue flame with slight yellow tips evenly spaced around burner 9 6 perform csd-1 compliance test (see par...

Page 38

38 9 - start up procedure figure 9-6control module j7 connector j7 connector 9.7 complete start up procedure 1. Reset control parameters to operating settings if adjusted to allow startup and operation test. 2. Follow instructions to turn off gas to appliance (page 39) if boiler is not being placed ...

Page 39

39 for your safety read before operating 10 - operating instructions 10-1 gas shutoff valve open position closed position warning if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. • this appliance is equipped wit...

Page 40

40 11.1 beginning of each heating season • check boiler area is free from combustible materials, gasoline, and other flammable vapors and liquids. • visually inspect combustion air and vent piping for proper operation. Check for and remove any obstruction to flow of combustion air or vent gases. Imm...

Page 41

41 11.2 annual shut down procedure • follow instructions “to turn off gas to appliance” unless boiler is also used to supply domestic hot water. See section 10 page 39. • drain system completely and add antifreeze when heating system is to remain out of service during freezing weather. • drain conde...

Page 42

42 11 - general maintenance and cleaning 11-3 condensate collector • loosen upper hose clamp securing condensate collector to flue pipe using 3/8" socket with 6" extension. • remove ¼-20 hex flange nuts securing condensate collector to heat exchanger using 7/16" deep well socket. See figure 11-3. • ...

Page 43

43 12 - ratings and capacities 12.1 ratings and capacities • constructed and hydrostatically tested for maximum allowable working pressure of 50 psig (pounds per square inch gauge) (345 kpa) in accordance with asme boiler and pressure vessel code, section iv, rules for construction of heating boiler...

Page 44

44 13 - trouble shooting.

Page 45

45 screen display explanation go to page for troubleshooting control has blocking error for more than 20 hours in a row. Go to page 47 three unsuccessful ignition attempts in a row go to page 48 open gas valve power circuit. May involve high temperature switch, gas valve, or gas valve relay in contr...

Page 46

46 screen display explanation go to page for troubleshooting low water cutoff sees no water. Go to page 53 flue temperature sensor sees temperature higher than 200°f. Go to page 54 return water temperature sensor sees temperature higher than 200°f. Go to page 55 control board internal error. Power d...

Page 47

47 _ _ _ _ _ lockout alarm a 0 0 blocking too long e rror enter installer menu, boil er status. Scr oll to most recent lockout alarm or blocking error. Di agnose corrective action usi ng appropriate trou blesh ooting tree. Unplug connector on supply sensor . Measure continuit y of high limit sensor ...

Page 48

48 13 - trouble shooting.

Page 49

49 error shows when safet y circuit is open. R emo ve j13 connector from control module. Check for continuit y between two pins connected to two pink wires, is continuit y a vailable? Yes no replace control module boiler fired without enough w ater flow through heat ex changer . Heat ex changer is o...

Page 50

50 13 - trouble shooting.

Page 51

51 disconnect harness f rom high temper ature supply s witch a nd control module j13. Check continuit y of both purple wires. Continuit y a vailable for both purple wires? 13 - trouble shooting.

Page 52

52 in sp ect bu rne r thro ugh sigh t gl as s. Is fla m e pr es en t? No ye s _ p _ _ _ blocking error e 3 5 fals e flame detect replace control module turn ga s sh utoff va lv e clockw ise to cl osed pos ition. Follow instructi ons to turn off g a s to appliance. Rep la ce gas va lv e. Turn of f ma...

Page 53

53 13 - trouble shooting connect ha rness to t ransf ormer . D isconnect harness f rom low w ater cutof f. Is 24 v ac at terminals 1 & 2 (between blue and y ellow wires)? Yes no repair s ystem piping, remo ve an y remaining air in system..

Page 54

54 read flue gas temper ature on user interface. Is temper ature higher than 200°f ? Yes no boiler is o ver fired. W ait for boiler to cool. Fix flow r ate problem if an y, purging all air out of the system. Replace flue gas sensor replace control module use thermal couple to measure flue gas temper...

Page 55

55 yes remo ve all liquid from connector . Check for leaks. Repair all leaks. Replace control module replace r eturn w ater sensor 13 - trouble shooting is correct harness connected to return sensor (2 brown wires)? Yes no correct wiring unplug molex connector on return sensor . Is there moisture or...

Page 56

56 is field wiring loose or fa ulty? Is power su pply betw een 59 and 61 hz? N o ye s _ p _ _ _ blocking error e 4 5 net frequency error correct wiring is p ow er s up pl y c ircu it br ea ke r loose or fa ulty? Prov ide frequency st abilize d power supp ly rated at 60 hz +/- 2% replace control m od...

Page 57

57 13 - trouble shooting is harness p lug ged into sup ply w at er sensor? Is harness p lugg ed into c ontr ol module j 5? _ p _ _ _ blocking error e 5 1 supply sens open inse rt h arne ss r epl ace supply water senso r disco nnect j5 fro m co nt rol mo dule. Using di gi tal m et er me as ur e check...

Page 58

58 13 - trouble shooting is ha rne ss plug ged in to return te m pe ra tu re s en so r? Is h ar ne ss p lu gg ed in to c on tro l module j5? _ p _ _ _ blocking error e 5 2 return sens open replac e re tur n tem pe ra tu re s en so r replace control module check con tin uity of brown wires between re...

Page 59

59 13 - trouble shooting supply w ater t emperature sensor resistance chart disconnect wire harness from high temperature supply switch. Measure resistance across terminals 2 and 4. Does temperature fall within ranges shown in chart?.

Page 60

60 disconn ect ha rne ss from contro l m odule j5. M easure resistan ce b etwee n brown wires at terminals j5 -4 a nd j5 - 12 . Is resistan ce le ss th an 50 oh ms? _ p _ _ _ blocking error e 6 0 return sens shorted disconn ect ha rne ss from re tu rn te mperat ure sensor. M ea su re re si st an ce ...

Page 61

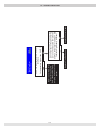

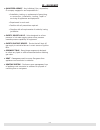

61 14 - wiring diagram 14.1 connection diagram.

Page 62

62 14 - wiring diagram 14.2 schematic diagram of ladder form.

Page 63

63 15 - glossary natural gas length of pipe - ft. Pipe capacity - btu per hour input includes fittings 1/2” 3/4” 1” 1 1/4” 20 92,000 190,000 350,000 625,000 40 63,000 130,000 245,000 445,000 60 50,000 105,000 195,000 365,000 propane gas length of pipe - ft. Pipe capacity - btu per hour input include...

Page 64

64 15 - glossary • qualified agency - any individual, firm, corporation, or company engaged in and responsible for: • installation, testing, or replacement of gas piping, or connection, installation, testing, repair or servicing of appliances and equipment. • experienced in such work. • familiar wit...

Page 65

65 1.1 introduction the boiler is equipped with a programmable electronic control and user interface module. 1.2 operation • display: 4x20 character lcd screen to show boiler status. • function keys operation with lcd character display module 1.3 status indication the following status screens can be...

Page 66

66 appendix a - control module 1.4 sequence of operation operational state user interface display explanation boiler operates in standby mode until demand for central heat (ch) or domestic hot water (dhw) is detected. Ch or dhw pump is turned based on type of heating demand. (ch call is illustrated)...

Page 67

67 1.4 sequence of operation operational state user interface display explanation if flame detected before gas valve opens during ignition boiler will lockout. Please refer to troubleshooting guide. Gas valve energized to deliver air/fuel to burner. If flame undetected after 3 seconds boiler will de...

Page 68

68 1.5 user menu user interface display explanation standby boiler operates in standby mode until demand for central heat (ch) or domestic hot water (dhw) is detected. User menu (press menu button on user interface to access user menu) user menu user menu structure includes: • ‘boiler status’ submen...

Page 69

69 user interface display explanation sett ings setting range: 104° f to 195° f (40° c to 91° c) default value: 140° f (60° c) adjust ch set point to hydronic system design while in operating in ch mode = 0 (ch with thermostat) or 3 (permanent demand). In ch mode = 1 (ch with thermostat and outdoor ...

Page 70

70 user interface display explanation installer menu inst aller menu installer menu structure includes: • user 'menu' can be accessed by pressing 'menu' key on user interface. • installer 'menu' can be accessed by pressing and holding the 'enter' key continue to hold and at the same time press and h...

Page 71

71 user interface display explanation installer menu bo iler status control module logs successful and failed ignition attempts. Information accessed in ‘ignition attempts’ screen as shown. Ignition attempts are stored in non-volatile memory and are retained in event of power failure. Figure a-1 typ...

Page 72

72 user interface display explanation bo iler status boiler stores information regarding total ch and dhw run time in hours. Data stored in non-volatile memory and retained in event of power failure. Boiler logs last 16 blocking errors and 16 lockout errors in non-volatile memory. Information retain...

Page 73

73 user interface display explanation bo iler co nfiguratio n two pump modes are available: 1. Pump mode = 0 ‘ch or ch&dhw’ • in this mode either ch or dhw pump terminal is energized depending on type of demand (ch or dhw). • ch and dhw pumps are never energized at the same time. • in the case of si...

Page 74

74 user interface display explanation ch settings 4. Central heating (ch) modes available: • ch mode = 0 ‘ch with thermostat’ • boiler will attempt to satisfy ch demand while ch thermostat input is closed. • boiler will modulate its firing rate to maintain ch set point and match system heat load. • ...

Page 75

75 b allowed boiler range: 35°f to 120 f (2°c to 49°c) default boiler setting: 100°f (37°c) allowed outdoor range: 35°f to 85°f (2°c to 29°c) default outdoor setting: 70°f (21°c) 1 0 0 a c d user interface display explanation ch set tings allowed range: 35°f to 100°f (2°c to 38°c) default setting: 7...

Page 76

76 user interface display explanation ch settings outdoor reset boost function increases ch set point by increment (‘temp’) if ch demand continues beyond pre-set time limit (‘time’). Ch set point will continue to increase until set point reaches 195°f / 91°c allowable temperature increment: 0..36 °f...

Page 77

77 user interface display explanation dhw sett ings allowed range: 1 to 60 minutes default setting: 30 minutes maximum time boiler operates in dhw mode limited by dhw maximum priority time setting. Priority timer starts when both ch and dhw demand is present. Boiler will switch from dhw back to ch o...

Page 78

78 notes.

Page 79

79 co mpany address & pho ne # company name & tech initials service perfo rmed dat e.

Page 80: Condensing

Ecr international, inc. 2201 dwyer ave. Utica, ny 13501 www.Ecrinternational.Com condensing gas boiler models 075 & 100