- DL manuals

- ECR

- Heat Pump

- CM

- Installation, Operation & Maintenance Manual

ECR CM Installation, Operation & Maintenance Manual

The Right Fit for Comfort

™

ECR International INC

2201 Dwyer Avenue

Utica, NY 13501

e-mail: info@RetroAire.com

An ISO 9001-2000 Certified Company

P/N 240008071, Rev. C [112309]

CM / CW / WM

R-410A High Efficiency Water Source Heat Pump

MODEL CM - Heat pump nominal capacities

8,000

12,000

15,000

Btuh

2.6

3.5

4.4

kW

MODEL CW - Straight cooling / heat pump nominal capacities

8,000

10,000

13,000

17,000

Btuh

2.6

3.5

4.4

5.3

kW

MODEL WM - Heat pump nominal capacities

9,000

12,000

15,000

Btuh

2.6

3.5

4.4

kW

Installation, Operation,

& Maintenance Manual

CM

Replacement for:

Freidrich and Climate Master "801"

Series Water Source

CW

New Construction

Replacement for:

Freidrich and Climate Master CW and

"800" Series Water Source

WM

Replacement for:

McQuay, Singer, or Climate Control WM

Series Water Source

Summary of CM

Page 1

The right fit for comfort ™ ecr international inc 2201 dwyer avenue utica, ny 13501 e-mail: info@retroaire.Com an iso 9001-2000 certified company p/n 240008071, rev. C [112309] cm / cw / wm r-410a high efficiency water source heat pump model cm - heat pump nominal capacities 8,000 12,000 15,000 btuh...

Page 2

Read this first to the installer retain this manual and warranty for future reference. Before leaving the premises, review this manual to be sure the unit has been installed correctly and run the unit for one complete cycle to make sure it functions properly. To obtain technical service or warranty ...

Page 3

Read this first (continued) general precautions danger electrical supply carefully read the rating plate located on the front panel. The retroaire replacement water source console units must: be properly connected • to electrical supply with the proper voltage as stated on the rating plate. Be prope...

Page 4

General product information product description all retroaire water source console units units are available as heat pump systems. Model cw is available as a straight cool unit. The retroaire water source console units: use r-410a refrigerant. • include high-efficiency rotary compressors, protected ...

Page 5

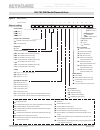

Cw chassis figure 2 cm chassis figure 1 thermostat fan speed switch (fss) system switch (ss) conditioned air h20 out h20 in thermostat fan speed switch (fss) system switch (ss) slave master low volt program relay high volt connection inlet air rating pla te wire diag ram conditioned air h20 out h20 ...

Page 6

Wm chassis (right) figure 4 wm chassis (left) figure 3 system switch (ss) fan speed switch (fss) thermostat system switch (ss) fan speed switch (fss) thermostat inlet air conditioned air h20 out h20 in inlet air conditioned air h20 out h20 in condensate drain stub filter filter high volt connection ...

Page 7

Cm, cw, wm model nomenclature product series [ cm series ] [ cw series ] [ wm series ] compressor code [ a = tech] [ l = lg] [ t = toshiba] cabinet options [ a = no cabinet ] [ b = with cabinet (cw series only) ] [ c = cabinet with locking door (cw series only ] [ d = front air intake (cw series onl...

Page 8

Features indoor coil freeze protection (standard) this feature will prevent the indoor coil from freeze up in the cooling mode. Indoor coil freeze up can occur due to a dirty air filter, restricted • or poor air flow, low refrigerant charge or low room or coil water temperatures. Low temperature wat...

Page 9

Preparing for the installation of the water source console units warning moving parts can cause personal injury. Avoid contact with moving parts when testing or servicing the unit. The existing front panels must be secured by screws that prevent contact with all parts. Minor dimensions of openings m...

Page 10: Top

Installation instructions — cm chassis top front water coil connections 5/8" id tube condensate drain connection h2o in h2o out j box high volt connections rating plate wire diagram cm chassis figure 6 water source console units • installation, operation, and maintenance manual • the right fit for c...

Page 11: Top

Installation for new construction installation instructions — cw cw chassis figure 7 wa t e r c o i l connections 5/8" id tube condensate drain connection top front rating plate wire diagram j box high volt connections water source console units • installation, operation, and maintenance manual • p/...

Page 12: Top

Installation instructions — wm left wm chassis figure 8 water coil connections 5/8" od pipe condensate drain connection top front install 2" x ¹∕₂" foam tape wire diagram rating plate j box high volt connections water source console units • installation, operation, and maintenance manual • the right...

Page 13: Top

Installation instructions — wm right wm right chassis and installation kit contents figure 9 top front wire diagram rating plate 5/8" od pipe condensate drain connection water coil connections j box high volt connections water source console units • installation, operation, and maintenance manual • ...

Page 14

Final inspection & start-up before operating the unit read and understand the contents of this manual. ☐ install the unit per the instructions outlined in this manual and ☐ all applicable local and national codes. Ensure the electrical supply matches the electrical requirements ☐ of the unit, and th...

Page 15

(*'eat' and ambient temp. Surrounding the unit are the same value) starting conditions unit will start and operate with entering air temperature(eat) of 50°f(10°c) and entering water temperature(ewt) of 60°f(16°c) with both the air and water at the flow rates used in the ari stan- dard 320/86 rating...

Page 16

Determine whether the fan operates during heating and cooling modes. If these checks fail to reveal a problem and the unit will not operate, contact a trained service technician for proper diagnosis or call the factory service department for assistance. E unit-mounted thermostat use the system switc...

Page 17

Notice the room temperature must be above 65°f (18°c) for the com- pressor to operate in cooling mode on water source console units with unit-mounted controllers. Caution when the unit is first powered up, high humidity conditions can cause condensation to form on the discharge grill. Keep doors and...

Page 18

Final inspection & start-up (continued) heating operation — heat pump units — enter- ing water temperature above 60°f (16°c) place 1. The thermostat or system switch in the "heat" position. Adjust the thermostat to a warmer temperature setting 2. Until the compressor and fan start running. Warm air ...

Page 19

Monthly inspection and maintenance danger electrical shock hazard — disconnect power to the retroaire replacement water source console units before servicing or accessing the control compartment. Failure to do so could result in severe personal injury or death. Warning it is illegal to discharge ref...

Page 20

Maintenance & troubleshooting (continued) warning do not use a solvent-based cleaner to clean coils, as some solvents will produce a noxious odor when the unit is in operation. Inspect and clean the drain pan and drain line(s). The use of an 13. Anti-fungicide tablet to keep the condensate system fr...

Page 21

Performance data table 1 performance data cm / cw / wm ** voltage model cooling heat pump indoor airflow cfm (l/s) shipping weight lbs (kg) btuh (kw) eer btuh (kw) cop 115v cmhg08 9,400 (2.7) 13.2 10,200 (3.0) 3.9 350 (165) 140 (64) cmhg12 12,900 (3.8) 12.9 13,100 (3.8) 4.2 450 (212) 140 (64) cwhg08...

Page 22

Electrical specifications important due to ongoing product development, designs, specifications, and performance are subject to change without notice. Please consult the factory for further information. Cw / cm - 8,000 btu table 2 electrical specifications power supply volt — 1–60 compressor indoor ...

Page 23

Important due to ongoing product development, designs, specifications, and performance are subject to change without notice. Please consult the factory for further information. Cw - cooling capacity 10,000 table 4 electrical specifications power supply volt — 1–60 compressor indoor fan motor electri...

Page 24

Important due to ongoing product development, designs, specifications, and performance are subject to change without notice. Please consult the factory for further information. Cw - cooling capacity 13,000 table 6 electrical specifications power supply volt — 1–60 compressor indoor fan motor electri...

Page 25

Electrical specifications important due to ongoing product development, designs, specifications, and performance are subject to change without notice. Please consult the factory for further information. Cw - cooling capacity 17,000 table 8 electrical specifications power supply volt — 1–60 compresso...

Page 26

Notes water source console units • installation, operation, and maintenance manual • the right fit for comfort 26 p/n 240008071, rev. B [112309].

Page 27

Notes water source console units • installation, operation, and maintenance manual • p/n 240008071, rev. B [112309] 27 made in usa.

Page 28

Ecr international llc 2201 dwyer avenue utica, ny 13501 e-mail: info@retroaire.Com an iso 9001-2000 certified company the right fit for comfort 28 p/n 240008071, rev. B [112309].