- DL manuals

- ECR International

- Heat Pump

- 18k

- Installation, Operation & Maintenance Manual

ECR International 18k Installation, Operation & Maintenance Manual

Summary of 18k

Page 1

Multi-zone ductless split system heat pumps installation, operation & maintenance manual ecr international, inc. 2201 dwyer avenue, utica ny 13501 phone: 800.325.5479 web: enviromaster.Com 18k 2 7 k, 36k , 45k pn 615000159 rev b , 01 / 0 1 /201 7 presents.

Page 2: Contents

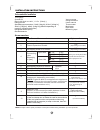

2 contents safety precautions warning ........................................................................................................................................... .........3 caution ..........................................................................................................

Page 3

Safety precautions warning read the follow safety precautions carefully before installation. Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model to be installed. Incorrect installation due to ignoring these i...

Page 4

4 outdoor unit if the outdoor unit is installed on a roof structure, be sure to level the unit. Ensure the roof structure and anchoring method are adequate for the unit location. Consult local codes regarding rooftop mounting. If the outdoor unit is installed on roof structures or external walls, th...

Page 5

5 note: except the above parts provided, the other parts needed during installation you must purchase. Installation instructions tools needed for installation: level gauge screwdriver electric drill,hole core drill ( φ 2.5in. [ 65 mm ] ) flaring tool set specified torque wrenches: 13 l bf t . [ 18kg...

Page 6

This illustration is for explanation purposes only. The actual shape of your air condtioner may be slightly different. Copper lines must be insulated independently caution use a stud finder to locate studs to prevent unnecessary damage to the wall. A minimum pipe run of 9.84ft. [ 3 metres ] is requi...

Page 7

7 settlement of outdoor unit anchor the outdoor unit with a bolt and nut φ 10 or φ 8 tightly and horizontally on a concrete or rigid mount. Fig. 5 install the outdoor unit on a rigid base to prevent increasing noise level and vibration. Determine the air outlet direction where the discharged air is ...

Page 8

Seal drain joint base pan hole of outdoor unit seal drain pipe oblique 。 90 roughness burr 1. Use the piping kit accessory or pipes purchased locally. 2. Measure the distance between the indoor and the outdoor unit. 3. Cut the pipes a little longer than the measured distance. 4. Cut the cable 4.9ft ...

Page 9

9 electrical work caution align the center of the pipes. Sufficiently tighten the flare nut with fingers, and then tighten it with a spanner and torque wrench as shown in fig. 1 1 & 1 2 tightening connection excessive torque can break nut depending on installation conditions. The 24 k indoor unit ca...

Page 10

10 electrical work fig. 1 4 connect the cable to the outdoor unit 1. Remove the electrical control board cover from the outdoor unit by loosening the screw as shown in fig. 1 4 2. Connect the connective cables to the terminals as identified with their respective matched numbers on the terminal block...

Page 11

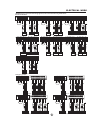

Electrical work 1 1 one-two models: note:please refer to the following figures,if the client want wire by themselves. Please run the main power cord through the lower line-outlet of the cord clamp. Power l n l(a) l(b) n(a) n(b) s(a) s(b) l1(a) l1(a) 1(a) 1(a) l1(a) l1(a) l1(b) l1(b) 1(b) 1(b) l1(b) ...

Page 12

Note: please refer to the following figures,if the client want wire by themselves. Electrical work 1 2 l n l(a)n(a)s(a) power l(b) n(b) s(b) l(c) n(c) s(c) l(d) n(d) s(d) model c model d to b l(1) 1 2(n) s to c l(1) 1 2(n) s to a l(1) 1 2(n) s to d l(1) 1 2(n) s l n l(a)n(a)s(a) power l(b) n(b) s(b)...

Page 13

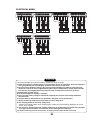

Electrical work 1 3 one-five models: l n l(a)n(a)s(a) power to a l n s to d l n s to c l n s l(c) n(c) s(c) l(d) n(d) s(d) to e l n s model a model b l(b) n(b) s(b) to b l n s l(e) n(e) s(e) l1 l2 s l2 l1(a) power to a to d to c to e to b l2(a) s(a) l1(b) l2(b) s(b) l1(c) l2(c) s(c) l1(d) l2(d) s(d)...

Page 14

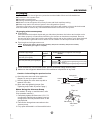

Electrical work 1 4 after the confirmation of the above conditions, prepare the wiring as follows: 1) never fail to have an individual power circuit specifically for the air conditioner. As for wiring, be guided by the circuit diagram posted on the inside of control cover. The screw which fasten the...

Page 15

Air and moisture in the refrigerant system have undesirable effects as indicated below: ● pressure in the system rises. ● operating current rises. ● cooling or heating efficiency drops. ● moisture in the refrigerant circuit may freeze and block capillary tubing. ● water may lead to corrosion of part...

Page 16

1 6 air purging starting evacuation, slightly loose theflare nut of the lo valve on the gas pipe side and check that the air is entering(operation noise of the vacuum pump changes and a compound meter indicates 0 instead of minus) 5. After the evacuation is complete, fully close the handle lo of the...

Page 17

A: lo packed valve b: hi packed valve c and d are ends of indoor unit connection. Caution ● gas leak check 1. Soap water method: apply a soap water or a liquid neutral detergent on the indoor unit connection or outdoor unit connections by a soft brush to check for leakage of the connecting points of...

Page 18: Iverter

Pn 615000208, rev a [06/30/2017] ecr international, inc. 2201 dwyer avenue • utica, new york 13501 phone: 800.253.9364 • web: emiretroaire.Com presents multi-zone programming requirement follow the steps below to program each air handler control: 1. Disconnect power of outdoor unit and indoor unit. ...

Page 19

Notes.

Page 20

Cs464-i 16122000001504 20150912 the design and specifications are subject to change without prior notice for product improvement. Consult with the sales agency or manufacturer for details..