- DL manuals

- ECR International

- Boiler

- CCB

- Application Manual

ECR International CCB Application Manual

Models

CHB/CCB

APPLICATION GUIDE

PN 240011074 REV C [11/01/2017]

WALL MOUNTED

GAS BOILER

This manual has been prepared for use with the appropriate Installation, Operation and

Maintenance Manual.

For use with CCB/CHB Boilers ONLY.

Manufactured by:

ECR International Inc.

2201 Dwyer Avenue, Utica, NY 13501

Tel. 800 253 7900

www.ecrinternational.com

Summary of CCB

Page 1

Models chb/ccb application guide pn 240011074 rev c [11/01/2017] wall mounted gas boiler this manual has been prepared for use with the appropriate installation, operation and maintenance manual. For use with ccb/chb boilers only. Manufactured by: ecr international inc. 2201 dwyer avenue, utica, ny ...

Page 2

2 pn 240011074 rev c, [11/01/2017] table of contents important safety information .....................................................................................................3 chb - hydronic piping - quick reference chart -chb boiler ............................................................

Page 3

3 pn 240011074 rev c, [11/01/2017] important safety information notice used to address practices not related to personal injury. Caution indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. ! Warning indicates a hazardous situation which, if not avoided, c...

Page 4

4 pn 240011074 rev c, [11/01/2017] chb - hydronic piping chb - piping legend notice illustrations are meant to show system piping concept only. Installer is responsible for all equipment and detailing required by authority having jurisdiction. Notice arrange piping to prevent water dripping onto boi...

Page 5

5 pn 240011074 rev c, [11/01/2017] chb - hydronic piping figure 1 - chb - single boiler primary/secondary series loop zoned system with zone valves and optional indirect tank cold w ater su pply boiler optional indirect d hw tan k *hot w ater su pply (t em per ed) cold water su pply ch /s ystem pump...

Page 6

6 pn 240011074 rev c, [11/01/2017] chb - hydronic piping figure 2 - chb -single boiler primary/secondary series loop zoned with zone pumps and optional indirect tank t & p relief valv e t o d rain cold water su pply optional indirect dhw t an k boiler cold w ater su pply zone pump 1 1 12” (305mm) ma...

Page 7

7 pn 240011074 rev c, [11/01/2017] chb - hydronic piping figure 3 - chb -single boiler primary/secondary series loop pumping and optional indirect tank ch s ystem pump tank se nsor or thermostat 1 12” (305mm) maximum separ ation no te 2 no te limit combined supply and return pipe lengths to maximum ...

Page 8

8 pn 240011074 rev c, [11/01/2017] chb boiler wiring diagrams all field wiring shall conform to the authority having jurisdiction or, in the absence of such requirements to: usa: national electrical code, ansi/nfpa 70, canada: canadian electrical code, part i, csa c22.1: safety standard for electric...

Page 9: Chb Boiler

9 pn 240011074 rev c, [11/01/2017] figure 4 - chb boiler with optional supply system pump single zone - no indirect tank (dhw) chb - wiring diagrams figure 5 - chb boiler single zone with dhw indirect tank and sensor power supply cord 120v/60hz s chb boiler l1 (hot) 2 4 3 5 6 8 key 370 key 72 t 10k ...

Page 10

10 pn 240011074 rev c, [11/01/2017] chb/ccb - wiring diagram figure 6 - isolation relay - pump circuit using system pump connections note if larger than 1 amp system supply pump is required, use an isolation relay 120 vac and separate 120 vac power supply. Manufacturer requires use of isolation rela...

Page 11

11 pn 240011074 rev c, [11/01/2017] d. Multi-zoned valve system: 1. If only central heating is required on multi-zone valve application - use factory supplied resistors on key 155 terminal strip: • boiler call for heat contacts (key 72) are wired to argo zone control x-x terminals. • zone thermostat...

Page 12: Chb Boiler

12 pn 240011074 rev c, [11/01/2017] chb - wiring diagram figure 7 - chb - boiler zoned system with multiple zone valves without indirect tank chb boiler argo az- 4cp low volt room thermostats valve valve valve valve low voltage zone valve(s) key 155 key 370 10k 1.8k power supply cord 120v/60hz facto...

Page 13: Argo Az- 4Cp

13 pn 240011074 rev c, [11/01/2017] chb - wiring diagram argo az- 4cp low volt room thermostats valve valve valve valve low voltage zone valve(s) set priority switch “off” lights figure 8 - chb - boiler zoned system with multiple zone valves with indirect tank remove two (2) factory installed resist...

Page 14

14 pn 240011074 rev c, [11/01/2017] chb - wiring diagram e. Multi-zone pump system using argo arm controller: 1 - if indirect storage tank is not applied to a multi-zoned piping system: • boiler thermostat contacts (key 72) are wired to argo arm zone pump control terminals (x-x) • zone thermostats a...

Page 15: Chb Boiler

15 pn 240011074 rev c, [11/01/2017] chb - wiring diagram zone pumps low volt room thermostats chb boiler set priority switch “off” t t g g g high voltage power supply 120v/60hz key 72 key 370 key 155 ch system pump (if used) l1 neu gnd system pump connection 10k 1.8k power supply cord 120v/60hz argo...

Page 16: Chb Boiler

16 pn 240011074 rev c, [11/01/2017] chb - wiring diagram zone pumps chb boiler power supply cord 120v/60hz indirect tank dhw sensor key 72 key 370 key 155 system pump connection l1 neu gnd ch system pump (if used) with dhw indirect tank key 307 low volt room thermostats set priority switch “off” t t...

Page 17: Chb Boiler

Power supply cord 120v/60hz important: priority switch mustbe on. Power supply 120v/60hz chb boiler tr ansformer 24v ac argo arm zone pump control *isolation relay dhw thermostat low voltage room thermostats zone pumps system pump connection ch system pump (if used) 10k 1.8k wire nuts *resistor wire...

Page 18

18 pn 240011074 rev c, [11/01/2017] ccb - hydronic piping notice arrange piping to prevent water dripping onto boiler. A. Piping installation, materials, and joining methods shall conform to requirements of authority having jurisdiction or in absence of such requirements: • usa - national fuel gas c...

Page 19: Warning

19 pn 240011074 [05/30/2015] warning burn and scald hazard! Manufacturer requires installation of field supplied anti-scald valve. Failure to follow these instructions could result in death or serious injury. ! Pn 615000152 rev a [07/20/2015] ccb-150 dhw anti-scald piping boiler cold water supply pi...

Page 20

20 pn 240011074 rev c, [11/01/2017] ccb - hydronic piping 1 12” (305mm) maximum separ ation no te 2 no te limit combined supply and return pipe lengths to maximum tota l linear length of 20 ft. (6.1 m) between boiler and closely spaced tees, when minimum 1” npt pipe siz e is used. Linear length ma y...

Page 21

21 pn 240011074 rev c, [11/01/2017] figure 13 - ccb -single boiler primary/secondary series loop zoned with zone pumps ccb - hydronic piping 1 12” (305mm) maximum separ ation no te 2 no te limit combined supply and return pipe lengths to maximum tota l linear length of 20 ft. (6.1 m) between boiler ...

Page 22

22 pn 240011074 rev c, [11/01/2017] ccb - hydronic piping 1 12” (305mm) maximum separ ation no te 2 no te limit combined supply and return pipe lengths to maximum tota l linear length of 20 ft. (6.1 m) between boiler and closely spaced tees, when minimum 1” npt pipe siz e is used. Linear length ma y...

Page 23: Ccb Boiler

23 pn 240011074 rev c, [11/01/2017] ccb boiler - wiring diagrams 1. Ccb boiler wiring diagrams all field wiring shall conform to the authority having jurisdiction or, in the absence of such requirements to: usa: national electrical code, ansi/nfpa 70, canada: canadian electrical code, part i, csa c2...

Page 24: Argo Az - 4Cp

24 pn 240011074 rev c, [11/01/2017] ccb boiler - wiring diagrams 4. Ccb - using multi-zone valve system boiler call for heat contacts (key 72) are wired to argo zone control (x-x) terminals. Zone thermostats and zone valves are to be wired to the argo zone controller. See figure 16. Set argo priorit...

Page 25

25 pn 240011074 rev c, [11/01/2017] 5. Ccb using multi-zone pump system wiring of argo control may include priority zone control. Boiler thermostat contacts (key 72) are wired to argo arm zone pump control terminals (x-x). Use argo arm zone pump controller and wire as shown in figure 17 or 18. 1. Wh...

Page 26: Argo Arm Zone

26 pn 240011074 rev c, [11/01/2017] figure 17 - ccb boiler with multiple zone pumps without dhw interface argo arm zone pump control key 307 power supply cord 120v/60hz ccb boiler ch system pump (if used) system pump connection power supply 120v/60hz key 72 secondary pumps will not shutoff during dh...

Page 27: Argo Arm Zone

27 pn 240011074 rev c, [11/01/2017] figure 18 - ccb boiler with multiple zone pumps with dhw interface ccb boiler - wiring diagrams argo arm zone pump control power supply 120v/60hz key 307 power supply cord 120v/60hz ccb boiler ch system pump (if used) system pump connection key 72 set priority swi...

Page 28

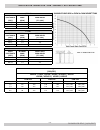

28 pn 240011074 rev c, [11/01/2017] application tables for : chb - indirect hot water tank 3/4" pipe equiv. Internal pipe length pump (feet) (gpm) 10 ft. 7.4 30 ft. 6.9 50 ft. 6.5 1" pipe equiv. Internal pipe length pump (feet) (gpm) 20 ft. 7.5 50 ft. 7.3 100 ft. 6.9 1- 1/4" pipe equiv. Internal pip...

Page 29

29 pn 240011074 rev c, [11/01/2017] application tables for : chb - indirect hot water tank ta ble b as ed on bo il er o ut put (bt uh/ hr) m ax . Bo il er o ut put (bt uh/ hr) m ax . Bo il er o ut put (bt uh/ hr) m ax . B oile r flow r at e = 7 .5 g pm 50, 000 60, 000 80, 000 85, 000 50, 000 60, 000...

Page 30

30 pn 240011074 rev c, [11/01/2017] venting options type i - venting (acceptable) type i- venting (acceptable) type i - venting (non-acceptable) type i- venting (non-acceptable) c h i m n e y dhw tank boiler outside air optional dhw tank dhw tank dhw tank boiler boiler boiler outside air optional b ...

Page 31

31 pn 240011074 rev c, [11/01/2017] optional equipment - sensors optional equipment 1. Outdoor air sensor, if used. A. See chart 1 for sensor data. Sensor part number fe013018x0. B. Locate outdoor sensor to protect against wind and direct sunlight. Mounting instructions provided with sensor. C. Maxi...

Page 32

32 pn 240011074 rev c, [11/01/2017] optional equipment - manufacturer recommended strainer.

Page 33

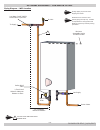

33 pn 240011074 rev c, [11/01/2017] optional equipment - low water cutoff low water cut off - heating only and combi boilers these guidelines are supplied when necessary to install an additional low water cut off (lwco), for sensing a low water level condition in a boiler, as required by the authori...

Page 34

138 - optional outdoor sensor 155 - optional indirect tank sensor notice *important: • before connecting the room thermostat, remove jumper on terminal block. (key 72) • before connecting optional indirect tank sensor, remove two resistors, (key 155) • before connecting the low water cutoff, remove ...

Page 35

35 pn 240011074 rev c, [11/01/2017] piping diagram - lwco location optional equipment - low water cutoff low water cutoff (lwco) air vent to supply safety relief valve 1 do not place isolation valve before lwco. Note 1 *pipe to drain * check local codes for maximum distance to floor . Arrange piping...

Page 36: Yes

36 pn 240011074 rev c, [11/01/2017] low water cutoff - detail optional equipment - low water cutoff no no yes.

Page 37

37 pn 240011074 rev c, [11/01/2017] addendum - instructions addendum - instructions following section includes: page #(s) domestic hot water sensor kit instruction (240010745).........................................39-42 instructions and wiring diagram for adding external pump (615000137).............

Page 38

38 domestic hot water sensor kit instructions for chb-100, chb-130, chb-150 kit #550002958 warning fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this instruction and understand all requirements, including requirements o...

Page 39

39 9. Restore power to boiler. Boiler will automatically recognize the sensor. 10. See installation, operation & maintenance manual for adjusting dhw tank temperature and operation. 11. Resume operation using installation, operation & maintenance manual. 12. Verify proper operation by following star...

Page 40

40 37 en 1k 81 32 95 278 1 4 120v 60hz 138 5 6 7 8 3 4 1 2 16 44 n l 138 370 95 278 t t 297 47 114 gnd +15v out 155 72 x1 x2 aux x4 x4 x11 x7 x5 x7 x6 x9 l l n n 1 1 dbm34 wiring diagram key 16 modulating fan 32 heating circulating pump 42 dhw temperature sensor (see kit) 44 gas valve 47 modulation ...

Page 41

41 domestic hot water sensor kit figure 5 - low voltage terminal strip, chb-130 shown figure 6 - low voltage terminal strip removed from boiler, chb -130 shown low voltage terminal strip low voltage terminal strip removed temperature deg f resistance in ohms 32 32505 60 15689 70 11935 77 10000 100 8...

Page 42: For Adding External Pump to

42 instructions and wiring diagram for adding external pump to chb/ccb boilers (without factory pump terminals) p/n 615000137, rev. C [06/09/2015] 1. Follow instructions to turn off gas to appliance found on operation instructions label on boiler or in installation, operation & maintenance manual. V...

Page 43

43 argo controller ar822-ii figure 1 - optional external pump/relay wiring factory installed jumper [do not remove] call for heat 15va transformer relay external circulator pump ref. Key 72 important: before connecting the argo controller, remove supplied jumper on terminal block. Field installed wi...

Page 44: Kit # 5612601

44 sealed combustion termination kit # 5612601 installation instructions warning fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this instruction and understand all requirements, including requirements of authority having...

Page 45: Replacement Instructions

45 kit installation shall be completed by qualified agency. Warning fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this instruction and understand all requirements, including requirements of authority having jurisdiction...

Page 46

46 to access to “ts” parameter: a. Press and hold reset button for 10 seconds. Display will read “ts”. Release button. B. Press reset button for 1 second. Display will read “p01”. C. Press heating buttons to scroll parameter list. Press dhw buttons to view or change a parameter. Set three (3) parame...

Page 47: Caution

Caution do not remove retaining clips on field installed water fittings. Removed fittings cannot be reinstalled. Do not solder on threaded joints. Heating the fitting will cause o-ring joint failure causing leaks. Boiler shown with jacket removed control is folded forward and down right side clip - ...

Page 48

Manufacturer recommended piping method: 1. Use piping accessories as shown in diagram below. 2. Do any necessary soldering away from the boiler, then thread soldered assembly to boiler connections. Female copper fitting copper pipe ( 6” min. Length manufacturer recommended) union piping diagrams cop...

Page 49: Altitude Affects On

Altitude affects on chb-100, chb-130, chb 150 and ccb-150 above curves show affect altitude will have on boiler delivery. Manufacturer has tested this boiler at altitude (sea level to 8,000 ft.) and determined that standard (ansi) derate input practices of re-orificing are not required for these mod...

Page 50

50

Page 51

51.

Page 52

52.

Page 53: Chb Boiler

Pn 240011270 rev b [03/11/2016] kit installation shall be completed by qualified agency. Warning fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this instruction and understand all requirements, including requirements of ...

Page 54

54 pn 240011270 rev b [03/11/2016] multi-zone pump system with dhw tank thermostat and isolation relay if dhw tank thermostat is applied to multi-zoned pump application secondary pump operation is controlled by argo priority switch position. Notice important: • before connecting to key72 terminals, ...

Page 55: Chb Boiler

55 pn 240011270 rev b [03/11/2016] figure 2 - chb boiler with secondary zone pumps and dhw thermostat figure 3 - resistor wire kit harness (dhw) chb boiler - dhw resistor harness kit blu brn chb boiler - dhw resistor harness kit terminal 7 key 155 white wire to relay contacts (normally closed) termi...

Page 56

56 figure 4 - chb -single boiler primary/secondary series loop zoned with zone pumps and optional indirect tank t & p relief valv e to dr ain 1 12” (305mm) maximum separ ation no te 2 no te limit combined supply and return pipe lengths to maximum tota l linear length of 20 ft. (6.1 m) between boiler...

Page 57

P/n 240011995 rev. A [11/03/2017] ccb/chb replacement combustion cover kit instructions 550003447 - ccb/chb 150 550003448 - chb 100 550003449 - chb 130 warning fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read these instruc...

Page 58

58 notes.

Page 59

59 notes.

Page 60

All specifications subject to change without notice. ©2017 ecr international, inc. Pn 240011074 rev. C [11/01/2017] ecr international inc. 2201 dwyer avenue, utica, ny 13501 tel. 800 253 7900 www.Ecrinternational.Com.