- DL manuals

- ECR International

- Boiler

- MGB-100J

- Installation, operation & maintenance manual

ECR International MGB-100J Installation, operation & maintenance manual

P/N

240011584

, Rev. A [07/30/2016]

An ISO 9001-2008 Certified Company

Manufactured by:

ECR International, Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

MGB

CAST IRON GAS FIRED BOILERS

FOR FORCED HOT WATER

with Honeywell Control

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

Models

MGB-50J

MGB-75J

MGB-100J

MGB-125J

MGB-150J

MGB-170J

MGB-200J

Tested For 100 psi.

ASME

Working Pressure

C.S.A. Certified

For Natural Gas

Or Propane

Summary of MGB-100J

Page 1

P/n 240011584 , rev. A [07/30/2016] an iso 9001-2008 certified company manufactured by: ecr international, inc. 2201 dwyer avenue, utica ny 13501 web site: www.Ecrinternational.Com mgb cast iron gas fired boilers for forced hot water with honeywell control installation, operation & maintenance manua...

Page 2

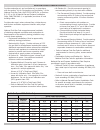

2 table 1 - dimensions boiler no. Natural gas inlet* dimensions pump size supply & return tappings a b c d** e f 50 ½" 11⅛" 5 ½ " 4" 30¾" 36¼" 5¾" 1¼" 75 ½" 15" 7 ½ " 5" 30¾" 37¾" 5¾" 1¼" 100 ½" 15" 7 ½ " 6" 30¾" 37¼" 6" 1¼" 125 ½" 18⅞" 9 ½ " 6" 30¾" 37¼" 6" 1¼" 150 ½" 18⅞" 9 ½ " 7" 30¾" 37¾" 6¾" 1¼...

Page 3

3 safety symbols & warnings the following defined symbols are used throughout this manual to notify the reader of potential hazards of varying risk levels. Safety symbols and warnings notice used to address practices not related to personal injury. Caution indicates a hazardous situation which, if n...

Page 4

4 table 2 - ratings and capacities boiler no. (1) input mbh (1) heating capacity mbh (2) net ahri rating water mbh afue no. Of burners (3) recommended air cushion tank water content (gals.) (1) high altitude input mbh 50j 50 42 37 83.5 1 15 2.4 45 75j 75 63 55 83.1 2 15 4.0 67.5 100j 100 83 72 83.0 ...

Page 5

5 1. Installation must conform to the requirements of the authority having jurisdiction or, in the absence of such requirements, to the national fuel gas code, ansi z223.1/nfpa 54, and/or natural gas and propane installation code, can/csa b149.1. 2. Where required by the authority having jurisdictio...

Page 6

6 ventilation & combustion air provide combustion air and ventilation air in accordance with the section “air for combustion and ventilation,” of the national fuel gas code, ansi z223.1/nfpa 54, or sections 8.2, 8.3 or 8.4 of natural gas and propane installation code, can/csa b149.1, or applicable p...

Page 7

7 connecting supply and return piping check local codes for maximum distance from floor or allowable safe point of discharge . Relief valve discharge line warning burn or scald hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns, scalding, or water damage due t...

Page 8

8 circulators in following illustrations are mounted on system supply side, mounting on system return side is also acceptable practice. 1. Boiler used in connection with refrigeration system, install so chilled medium is piped in parallel with boiler with appropriate valves to prevent chilled medium...

Page 9

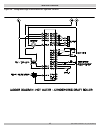

9 boiler water inlet alternate circulator location to system from system circulator shut-off valve pressure reducer valve check valve ball valve 3 way mixing valve air separator hose bib expansion tank 8. Installation using circulators and zone valves are shown in figures 6 through 9. For further pi...

Page 10

10 connecting supply and return piping figure 6 - single zone system with dhw figure 7 - multi zone system with circulators and dhw p/n 240011584 rev. A [07/30/2016].

Page 11

11 connecting supply and return piping figure 8 - multi zone system with zone valves and dhw (with circulator) figure 9 - multi zone system with zone valves and dhw (with zone valve) p/n 240011584 rev. A [07/30/2016].

Page 12

12 when an existing boiler is removed from a common venting system, the system is likely to be too large for the proper venting of the appliances sill connected to it. If this situation occurs, the following test procedure must be followed: 1. Vent pipe must slope upward from the boiler not less the...

Page 13

13 1. Verify only boiler is serviced by vent damper. Figure 11. 2. Clearance of not less than 6 inches (152mm) between vent damper and combustible material must be maintained. Additional clearance should be allowed for service of vent damper. 3. Vent damper must be in the open position when applianc...

Page 14

14 connecting gas service general x use piping materials and joining methods acceptable to authority having jurisdiction. In absence of such requirements: x usa - national fuel gas code, ansi z223.1/nfpa 54 x canada - natural gas and propane installation code, can/csa b149.1 x size and install gas p...

Page 15

15 electrical section electrical wiring see wiring diagrams on the following two pages for details. Electrically bond boiler to ground in accordance with requirements of authority having jurisdiction. Refer to: x usa- national electrical code, ansi/nfpa 70. X canada - canadian electrical code, part ...

Page 16

16 wiring diagram figure 13 - integrated high limit electronic ignition control i warning modification, substitution or elimination of factory equipped, supplied or specified components may result in personal injury or loss of life. ! P/n 240011584 rev. A [07/30/2016].

Page 17

17 wiring diagram figure 14 - integrated high limit electronic ignition control p/n 240011584 rev. A [07/30/2016].

Page 18

18 lighting instructions lighting procedure for boiler with intermittent pilot system a. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the appliance by hand. Caution what to do if you smell gas x do not try to light any appliance. X do n...

Page 19

19 normal sequence of operation general instructions thermostat actuates on call for heat, completing circuit to control. Completed circuit to control will first activate circulator and damper which will close end switch inside damper. Completes circuit to ignition system, ignition takes place. In e...

Page 20

20 general instructions figure 17 - gas burner flame figure 19 - gas burner pilot figure 18 - combustion chamber burners orifices gas valve x make visual inspection of main burner and pilot flames at start of heating season and again in mid-season. Main burner flame should have well defined inner bl...

Page 21

21 x adjust gas input to boiler by removing protective cap on pressure regulator , and turning screw clockwise to increase input and counterclockwise to decrease input. X manifold pressures are taken at outlet side of gas valve. X to check for proper flow of natural gas to boiler, divide input rate ...

Page 22

22 appendix a - control module a.1 installation environment considerations warning if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. X do not use this appliance if any part has been under water. Immediately call ...

Page 23

23 appendix a - control module a.5 operation module continuously monitors boiler water temperature and fires or shuts off burner based on this temperature data. 1. When “call for heat” occurs, control enables circulator and monitors boiler water temperature to determine whether thermostat can be sat...

Page 24

24 order state code number definition explanation 2. Other possible state codes h 4 pre-purge system is purging before ignition trial; includes pilot valve circuit diagnostics. On vent damper models, this is so quick it will typically be over before the display can flash this code, and therefore wil...

Page 25

25 appendix a - control module a.6 boiler high limit temperature controller x when water temperature reaches setpoint, controller ends heating cycle. X when water temperature drops below setpoint minus differential, controller restarts heat cycle to re-heat boiler water. X if water temperature excee...

Page 26

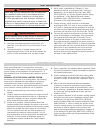

26 table 7 - troubleshooting error codes error code number definition error display clearing ( once error condition has disappeared) clears itself when root problem is solved cycle power off push any key up/down key when status is displayed explanation things to look for 4 flame current lower than t...

Page 27

27 appendix a - control module 59 line voltage error line voltage (or, possibly thermostat) is either to high or to low. Source problem is likely in the electrical external to the boiler. Control will clear itself and resume normal operation once the situation is resolved. Check both line power and ...

Page 28

28 a.9 intermittent pilot ignition system checks step 1: check ignition cable. X verify ignition cable does not make contact with metal surfaces. X verify only factory supplied ignition cable (or approved replacement) is used. X verify connections to ignition module and igniter or igniter-sensor are...

Page 29

29 appendix a - control module step 3: check spark ignition circuit. Disconnect ignition cable at spark terminal on module. Warning electrical shock hazard. Ignition circuit generates over 10,000 volts. Turn off electrical power supply at service panel before making electrical connections. Failure t...

Page 30

30 appendix b - vent damper b.1 vent damper harness - molex plugs warning do not negate the action of any existing safety orperational controls. Avoidance of these instructions could result in death or serious injury. ! Note when servicing controls, all wires must be labeled prior to disconnection. ...

Page 31

31 appendix b - vent damper troubleshooting b.2 vent damper troubleshooting guide warning do not negate the action of any existing safety orperational controls. Avoidance of these instructions could result in death or serious injury. ! Note when servicing controls, all wires must be labeled prior to...

Page 32

32 appendix b - vent damper troubleshooting problem possible cause recommended solution no power between 4 & 1 between 4 & 2 between 4 & 3 damper open no combustion 1. Is gas turned on 2. Operating limit, pressure control, low water cut off not on. 3. Blocked vent switch or flame roll out switch tri...

Page 33

33 notes p/n 240011584 rev. A [07/30/2016].

Page 34

34 notes p/n 240011584 rev. A [07/30/2016].

Page 35

35 co mpany address & pho ne # company name & tech initials service perfo rmed dat e p/n 240011584 rev. A [07/30/2016].

Page 36: Important

P/n 240011584 rev. A [07/30/2016] utica boilers 2201 dwyer avenue utica ny 13501 web site: www.Ecrinternational.Com important in accordance with section 325 (f) (3) of the energy policy and conservation act, this boiler is equipped with a feature that saves energy by reducing the boiler water temper...