- DL manuals

- ECR

- Air Conditioner

- RetroAire R90C

- Installation, operation & maintenance manual

ECR RetroAire R90C Installation, operation & maintenance manual

ECR International Inc

2201 Dwyer Avenue

Utica, NY 13501

e-mail: info@RetroAire.com

The Right Fit for Comfort

P/N 240010330, Rev. A [10/15/2013]

An ISO 9001-2008 Certified Company

™

R90C/H

Packaged Terminal Air Conditioner (PTAC)

Packaged Terminal Heat Pump (PTHP)

Installation, Operation,

& Maintenance Manual

Summary of RetroAire R90C

Page 1

Ecr international inc 2201 dwyer avenue utica, ny 13501 e-mail: info@retroaire.Com the right fit for comfort p/n 240010330, rev. A [10/15/2013] an iso 9001-2008 certified company ™ r90c/h packaged terminal air conditioner (ptac) packaged terminal heat pump (pthp) installation, operation, & maintenan...

Page 2

Table of contents information and specifications outlined in this manual in effect at the time of printing of this manual. Ecr international reserves the right to discontinue, change specifications or system design at any time without notice and without incurring any obligation, whatsoever. Notice r...

Page 3

Receiving information shipping damage must be reported to the carrier immediately. Examine exterior. Remove cover and examine compressor and piping for signs of damage. Inspection check shipment against bill of lading. Verify equipment received as ordered. Verify unit: • unit size and type correct p...

Page 4

Important safety information become familiar with symbols identifying potential hazards. All field wiring shall conform to requirements of authority having jurisdiction or in absence of such requirements: • united states - national electrical code, ansi/nfpa 70 • canada - csa c22.1 canadian electric...

Page 5

Table 1 performance data - cooling model r90c voltage cooling capacity eer sensible heat ratio indoor air flow fresh air inlet flow outdoor sound level shipping weight btuh (kw) cfm (l/s) cfm (l/s) dba lbs (kg) r_ _c 09 a 115 9000 (2.7) 9.0 0.79 440 (207.7) 35 (17) 75 140 (63.5) d 208/230 9400 (2.8)...

Page 6

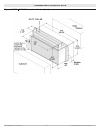

Dimensional/physical data figure 1 r90c r90h dimensions - inches (mm) duct collar the right fit for comfort 6 p/n 240010330, rev. A [10/15/2013].

Page 7

Figure 2 r90c r90h chassis product description option a option b option c fresh air switch (fas) line cord fan cycle switch (fcs) high pressure switch (hps) aquastat w/ jumper mtr valve hydronic no/nc switch valve orientation switch (vos) rating plate electrical diagram molex connector from control ...

Page 8

Product description • retroaire replacement packaged terminal air condition/heat pumps units are straight cooling (ptac) or heat pump systems (pthp). • both ptac and pthp configurations fit wall sleeves of units listed on front cover. • heat pumps (pthp) operate in mechanical heat mode down to outdo...

Page 9

Field-installed accessories • hydronic heat — coil assembly is shipped loose for field installation. • remote wall thermostat — digital 1-stage or 2-stage available. • wall sleeves, louvers, and cabinets. • control - delays fan start-up until coil reaches 100°f (38°c) to virtually eliminate "cold" b...

Page 10

Electrical power connection 1. Verify retroaire unit rating plate for circuit ampacity and required breaker or fuse size. 2. Verify existing breaker or fuse is correct size. • replace breaker or fuse if incorrectly-sized. • breakers shall be type hacr only. 3. Cord-connected units — verify wall outl...

Page 13

General r_ _c units are straight cool, single stage air conditioners available with electric or hydronic heat. R_ _h units are limited range, single stage heat pump. Mechanical compression heating (heat pump mode) is locked out at outdoor temperatures of approximately 35ºf (1.7ºc) and below. Below t...

Page 14

R_ _c / r_ _h; cooling operation ( for unit mount controls) 1. System switch [ss] set to “cool”, and fan cycle switch [fcs] set to “on” (continuous fan operation), indoor fan motor starts. 2. Fan cycle switch [fcs] set to “off” (cycling fan operation), indoor fan motor starts with call for cooling f...

Page 15

• r_ _h; auxiliary heating “electric” or “hydronic” 1. Outdoor coil temperature falls to 25ºf (-4ºc) or below for 180 seconds at anytime during heating call, compressor and outdoor fan motor are de-energized and auxiliary heat is energized. 2. Anti-short cycle timer is initiated, prohibiting compres...

Page 16

Before operating unit ☐ read and understand contents of this manual. ☐ install unit per instructions outlined in this manual and all applicable local and national codes. ☐ verify electrical supply matches electrical requirements of unit, and unit is properly grounded. ☐ examine control box. Verify a...

Page 17

Figure 8 test jumper (selects heat pump or straight cooling) electrical connections warning electrical shock hazard. Disconnect all power before removing chassis, performing any cleaning, servicing, or maintenance. Failure to do so could result in death or serious injury ! Refer to wiring diagram at...

Page 18

Start up 1. Verify unit is secure and level. 2. Heat pump units only — verify thermostatic drain pan valve is operating correctly. Valve should be closed if temperature is above 60°f and open if temperature is below 60°f. 3. Test optional fresh air damper. Set damper door switch to "yes" position, v...

Page 19

Heating cycle — electric option 1. Place thermostat or system switch in heat position. 2. Adjust thermostat for warmer temperature until indoor fan starts running and electric heater coil starts emitting heat. 3. Outdoor fan does not run during heating cycle. 4. After unit starts running and space g...

Page 20

3. After unit starts running and area is warmer, adjust thermostat to cooler temperature, hydronic valve will close and indoor fan will switch off after sixty-second purge time has elapsed. 4. For warmer room temperature, adjust thermostat to warmer temperature setting, which opens hydronic valve an...

Page 21

– after unit starts running and space gets warmer, hydronic valve closes and indoor fan switches off after sixty-second purge time has elapsed. 3. After unit starts running and space gets warmer, adjust thermostat to cooler temperature setting, hydronic valve closes and indoor fan switches off after...

Page 22

Maintenance monthly inspection and maintenance warning electrical shock hazard — disconnect power to replacement ptac/pthp before servicing or accessing control compartment. Failure to do so could result in severe personal injury or death. ! Notice it is illegal to discharge refrigerant into atmosph...

Page 23

• check fan motors and blower assemblies. Some units may require drop of light oil to motors and/or bearing assemblies ( look for oil cups ). Verify set-screws and motor mounting hardware are secure. • brush and/or vacuum centrifugal fan blades and blower cage assemblies. • inspect both indoor and o...

Page 24

Troubleshooting warning fire, explosion, and electrical shock hazard. Troubleshooting procedures shall be conducted by a qualified technician. Improper installation could result in death or serious injury. ! Symptom suggestion no heat or cooling • verify unit has power and thermostat is satisfied. I...

Page 25

Electrical specifications power supply volt — 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 115v 104 7.5 47 1.4 0.09 1.4 0.125 n/a n/a n/a n/a 10.5 n/a 12.4 15 5-15p 115v 104 8.0 45.6 1.4 ...

Page 26

Electrical specifications table 7 r90, - cooling capacity 15 electrical specifications power supply volt — 1–60 compressor indoor fan motor outdoor fan motor electric heat unit electrical ratings volt min rla lra fla hp fla hp htr # volt w ha tca tha mca mocp plug 208/ 230v 197 7.4 33 0.6 0.08 0.71 ...

Page 28

Ecr international inc 2201 dwyer avenue utica, ny 13501 e-mail: info@retroaire.Com an iso 9001-2008 certified company.