- DL manuals

- ECS

- Portable Generator

- 10kW

- Owner's Manual

ECS 10kW Owner's Manual - Menu System

31

Section 6 — Appendix

Air-cooled Generators

31

MAIN MENU

R

UN LOG

ALARM LOG

HIST

OR

Y

ST

A

TUS

COMMAND

S

TAT

E

VERSIONS

DISPLA

Y

GENERA

T

OR

FREQ

UENCY

ENGINE

HOURS

ENGINE

RPM

B

A

TTER

Y

V

O

LTA

G

E

DEB

UG

INPUTS

OUTPUTS

DISPLA

YS

ST

AR

TUP

DELA

Y

EDIT

CONTRAST

LANGU

A

GE

FREQ

UENCY

TIME/D

A

TE

EXERCISE

TIME

RESET

MAINTENANCE

ESC

Press the

“ESCAPE”

ke

y

to jump bac

k up thr

ough

the men

u le

vels.

+ / -

Use the

“+/-”

ke

y

to na

vigate thr

ough

the men

u.

ENTER

Use the

“ENTER”

ke

y

to select items or

enter data.

ESC

ESC

ESC

ESC

ESC

ESC

17 &

20kW

onl

y

English

or Other

60 Hz

The possib

le Status messa

g

es of the displa

y

are as f

ollo

ws:

• Switc

hed Off/Time & Date

• Read

y to Run/Time & Date

• Utility Loss Dela

y/P

ausing f

or X Seconds

• Cranking/Attempt # X

• Running in Ex

er

cise/Time & Date

• Running/Cooling Do

wn

• Running -

W

arning/W

arning Messa

g

e

• Running - Alarm/Alarm Messa

g

e

• Stopped - Alarm/Alarm Messa

g

e

• Stopped -

W

arning/W

arning Messa

g

e

• Cranking/P

ausing f

or X Seconds

• Running/Time & Date

• Running/W

arming Up

• Cranking -

W

arning/W

arning Messa

g

e

• Cranking - Alarm/Alarm Messa

g

e

The possib

le commands

on Line 2 of the displa

y

are as f

ollo

ws:

• Switc

hed Off

• Running Man

uall

y

• Stopped in A

uto Mode

• Running - Utility Lost

• Running in Ex

er

cise

• Running fr

om Radio

MENU SYSTEM

17 &

20kW

onl

y

17 &

20kW

onl

y

17 &

20kW

onl

y

Summary of 10kW

Page 1

Owner’s manual 8, 10, 14, 17 & 20kw air-cooled, automatic standby generators danger deadly exhaust fumes. Outdoor installation only! Not intended for use as primary power in place of utility or in life-support applications. Listed c us do not lift unit by roof!.

Page 2: Introduction

Introduction thank you for purchasing this compact, high performance, air- cooled, engine-driven generator. It is designed to automatically supply electrical power to operate critical loads during a utility power failure. This unit is factory installed in an all-weather, metal enclosure that is inte...

Page 3

Table of contents air-cooled generators 1 introduction .................... Inside front cover read this manual thoroughly .............................................Ifc contents ............................................................................Ifc operation and maintenance.................

Page 4: Warning:

2 study these safety rules carefully before installing, operating or servicing this equipment. Become familiar with this owner’s manual and with the unit. The generator can operate safely, effi- ciently and reliably only if it is properly installed, operated and maintained. Many accidents are caused...

Page 5

3 electrical hazards all generators covered by this manual produce dangerous • electrical voltages and can cause fatal electrical shock. Utility power delivers extremely high and dangerous voltages to the transfer switch as does the standby generator when it is in operation. Avoid contact with bare ...

Page 6: 1.1 Unpacking/inspection

Danger only qualified electricians or contractors should attempt such installations, which must comply strictly with applicable codes, standards and regu- lations. 1.1 unpacking/inspection after unpacking, carefully inspect the contents for damage. This standby generator set is ready for installatio...

Page 7: 1.4 Emission

Section 1 — general information air-cooled generators 5 1.4 emission information the environmental protection agency requires that this generator complies with exhaust emission standards. This generator is certi- fied to meet the applicable epa emission levels. Additional infor- mation regarding the...

Page 8: 1.5 The

6 section 1 — general information air-cooled generators 1.5 the generator data label (see sample) oil dipstick exhaust enclosure composite base oil filter battery compartment fuel regulator fuel inlet (back) air filter circuit breaker control panel data label (see sample) oil dipstick exhaust enclos...

Page 9: 1.6 Specifications

7 section 1 — general information air-cooled generators 1.6 specifications 1.6.1 generator model 8kw 10kw 14kw 17kw 20kw rated maximum power capacity (watts*) 7,000 ng 8,000 lp 9,000 ng 10,000 lp 13,000 ng 14,000 lp 16,000 ng 17,000 lp 18,000 ng 20,000 lp rated voltage 120/240 rated maximum load cur...

Page 10: 1.7 System Set Led

1.7 system set led the “system set” led (single cylinder) or "ready to run" on the display (v-twin) is ready when all of the following conditions are true: 1. The auto/off/manual switch is set to the auto position. 2. The utility voltage being supplied to the unit is being sensed by the pcb. If the ...

Page 11

9 1.10 reconfiguring the fuel system 1.10.1 8 kw, 410cc engine to reconfigure the fuel system from ng to lp, follow these steps (figure 1.4): note: the primary regulator for the propane supply is not included with the generator. A fuel pressure of 10 to 12 inches of water column (0.36 to 0.43 psi) t...

Page 12: 1.11 Location

10 3. Close the roof. 4. Reverse the procedure to convert back to natural gas. Figure 1.7 - 14, 17, & 20kw, gt-990/gt-999 (airbox cover removed) fuel selection lever - "in" position for natural gas fuel figure 1.8 - 14, 17, & 20kw, gt-990/gt-999 (airbox cover removed) fuel selection lever - "out" po...

Page 13

11 danger the engine exhaust fumes contain carbon mon- oxide, which can be deadly. This dangerous gas, if breathed in sufficient concentrations, can cause unconsciousness or even death. This generator must be installed properly, in strict compliance with applicable codes and stan- dards. Following i...

Page 14

12 section 1 — general information air-cooled generators figure 1.10 – installation guidelines 18 inches minimum distance 36 inches 36 inches 36 inches 60 inches 60 inches existing wall no windows or openings in the wall permitted within 5 feet from any point of the generator. Top of generator 48” m...

Page 15: 1.12 Battery Requirements

13 1.12 battery requirements see the specifications section for correct battery size and rating if the auto/off/manual switch is not set to its off position, the generator can crank and start as soon as the battery cables are connected. If the utility power supply is not turned off, spark- ing can o...

Page 16: 1.15 Battery Charger

14 be sure the auto/off/manual switch is set to the off position before connecting the battery cables. If the switch is set to auto or manual, the generator can crank and start as soon as the battery cables are connected. Be sure the utility power supply is turned off and the 7.5a fuse is removed fr...

Page 17

15 10. Connect an accurate ac voltmeter and a frequency meter across transfer switch terminal lugs e1 and e2. 8kw voltage should be 230-240 volts at a frequency of 61-63 hertz. 14, 17 and 20kw voltage should be 247-249 at a frequency of 59.5-60.5 hertz. 10kw voltage should be 220-230 volts at a freq...

Page 18: 2.6

16 2.5 engine governor adjustment if both ac frequency and voltage are correspondingly high or low, adjust the engine governor as follows: 2.5.1 8 kw units the engine must be off to perform steps 1 and 2. 1. Loosen the governor clamp bolt (figure 2.1). 2. Hold the governor lever at its wide open thr...

Page 19

17 section 3 — operation air-cooled generators 3.1 control panel interface 3.1.1 using the auto/off/manual switch (figures 3.1 & 3.2) 1. “auto” position – selecting this switch activates fully auto- matic system operation. It also allows the unit to automati- cally start and exercise the engine ever...

Page 20

18 10 to 20 kw - installation assistant upon first power up of the generator, the display interface will begin an installation assistant. The assistant will prompt the user to set the minimum settings to operate. These settings are sim- ply: current date/time and exercise day/time. The maintenance i...

Page 21

19 failure to start this is defined as any of the following occurrences during crank- ing. 1. Not reaching starter dropout within the specified crank cycle. Starter dropout is defined as four (4) cycles at 1,000 rpm. 2. Reaching starter dropout, but then not reaching 2200 rpm within 15 seconds. In t...

Page 22

20 5. To crank and start the engine, set the auto/off/manual switch to manual. 6. Let the engine stabilize and warm up for a few minutes. 7. Set the generator’s main circuit breaker to its on (or closed) position. The standby power source now powers the loads. Figure 3.3 – manual transfer switch ope...

Page 23: 3.6 Protection

21 figure 3.5 – open side compartment 120v gfci outlet 15 amp outlet breaker main circuit breaker led indicator lights 3.6 protection systems 3.6.1 alarms highest priority (latching) displayed on the control panel and the external red led (v-twins only). They must be cleared before the alarm message...

Page 24: 4.1 Fuse

22 clear alarm 8kw — clear the alarm by setting the auto/off/manual • switch to the off position and back to auto. 10 - 20kw — clear the alarm by setting the auto/off/manual • switch to the off position. Press the enter key to unlatch any active fault and clear the corresponding alarm message. 3.6.2...

Page 25

5. Install the dipstick. 6. Reset the auto/off/manual switch to its original position. 7. If the generator was running during a utility outage, first turn the generator's main circuit breaker back to the on position. Second, turn on needed loads in the residence. Figure 4.3 — oil dipstick and fill, ...

Page 26: 4.4 Changing The Engine

24 note: the oil drain hose may be routed in the opposite direction as shown in figure. 4.4 changing the engine air cleaner 4.4.1 14, 17 & 20kw generators see "the generator" section for the location of the air cleaner. Use the following procedures (figure 4.5): 1. Lift the roof and remove the door....

Page 27: 4.5 Spark

25 4.5 spark plug(s) reset the spark plug(s) gap or replace the spark plug(s) as neces- sary. See the service schedule section for maintenance require- ments. 1. Clean the area around the base of the spark plug(s) to keep dirt and debris out of the engine. 2. Remove the spark plug(s) and check the c...

Page 28: 4.8 Cooling

26 to check valve clearance: the engine should be cool before checking. If valve clearance is • 0.002" - 0.004" (0.05 - 0.1mm), adjustment is not needed. Remove spark plug wires and position wires away from plugs. • remove spark plugs. • make sure the piston is at top dead center (tdc) of its com- •...

Page 29: 4.10 Corrosion Protection

27 4.9 attention after submersion if the generator has been submerged in water, it must not be started and operated. Following any submersion in water, have a dealer thoroughly clean, dry and inspect the generator. If the structure (ex. Home) has been flooded, it should be inspected by a certified e...

Page 30: 4.12 Service Schedule

28 section 4 — maintenance air-cooled generators 4.12 service schedule attention: it is recommended that all service work be performed by the nearest dealer. System/component procedure frequency x = action r = replace as necessary * = notify dealer if repair is needed. Inspect change clean w = weekl...

Page 31

29 section 5 — troubleshooting air-cooled generators 5.1 troubleshooting guide problem cause correction the engine will not crank. 1. Fuse blown. 1. Correct short circuit condition, replace 7.5a fuse in generator control panel. 2. Loose, corroded or defective 2. Tighten, clean or replace battery cab...

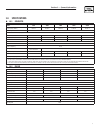

Page 32

30 6.1 menu system navigation to get to the menu, use the "esc" key from any page. It may need to be pressed many times before getting to the menu page. The currently selected menu is displayed as a flashing word. Navigate to the menu required by using the +/- keys. When the menu required is flashin...

Page 33: Menu System

31 section 6 — appendix air-cooled generators 31 main menu r un log alarm log hist or y st a tus command s tat e versions displa y genera t or freq uency engine hours engine rpm b a tter y v o lta g e deb ug inputs outputs displa ys st ar tup dela y edit contrast langu a ge freq uency time/d a te ex...

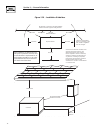

Page 34

32 section 7 — installation diagrams air-cooled generators typical non-service entrance type typical for all ea ton non-ser vice entr ance r ated tr ansfer switches. E1 e2 white green n1 n2 0 15b bc line customer l oad (distribution p anel) fuse 5 amp fuse 5 amp bc line bc line bc line n2 n1 e2 e1 t...

Page 35

33 section 7 — installation diagrams air-cooled generators typical service entrance type typical for all ea ton ser vice entr ance r ated tr ansfer switches. E1 e2 white green n1 n2 0 15b bc line customer l oad (distribution p anel) fuse 5 amp fuse 5 amp bc line bc line bc line n2 n1 e2 e1 t1 t2 n2 ...

Page 36

34 section 7 — installation diagrams air-cooled generators generator - drawing no. 0g8280-d.

Page 37

35 section 7 — installation diagrams air-cooled generators generator - drawing no. 0g8280-d.

Page 38

36 california emission control warranty statement your warranty rights and obligations the california air resources board (carb) and generac power systems, inc. (generac) are pleased to explain the emission control system warranty on your new engine.* in california, new utility, and lawn and garden ...

Page 39

37 emission control system warranty emission control system warranty (ecs warranty) for 1995 and later model year engines: (a) applicability: this warranty shall apply to 1995 and later model year engines. The ecs warranty period shall begin on the date the new engine or equip- ment is purchased by/...

Page 40

Part no. 0h4762 revision a (07/28/09) printed in u.S.A..