- DL manuals

- ECU Master

- Automobile Electronics

- EMU

- User Manual

ECU Master EMU User Manual

Summary of EMU

Page 1

Page 1.

Page 2

Attention ! • the ecumaster emu is designed for motorsport applications only and cannot be used on public roads! • electronic throttle modules are only to be used for operating stationary engines (generators, testbenches). For safety reasons, do not use electronic throttle modules in vehicular appli...

Page 3

Important ! • the manual below refers to the firmware version 1.1 of the ecumaster emu • modification of the tables and parameters should be performed only by people who understand the operation of the device and operation of modern fuel injection and ignition systems. • never short-circuit the wire...

Page 4: Table Of Content

Table of content ecumaster emu device.................................................................................................8 connector pinout details......................................................................................11 software..............................................

Page 5

Fueling parameters....................................................................................................53 general............................................................................................................................55 speed density...................................

Page 6

Configuration of outputs parameters.............................................................87 fuel pump........................................................................................................................87 coolant fan.............................................................

Page 7

Gear scale......................................................................................................................115 adjust scale....................................................................................................................115 adj. Cal...............................

Page 8

Ecumaster emu device ecumaster emu device is fully programmable, universal engine management unit for controlling spark-ignition engines using speed density or alpha-n algorithms, using wide range of fuels (pb/e85/lpg/cng). Due to utilizing modern technology and state of the art software, device can...

Page 9

Specification 1 power supply 6-20v, immunity to transients according to iso 7637 2 current requirement 400ma 3 operating temperature -40 do 100˚ c 4 supported number of cylinders 1-6 – full sequential injection and ignition 1-12 - wasted spark 5 max supported rpm 12000 6 injection time 0.1ms – 50ms,...

Page 10

Functions 1 fuel calculation algorithm speed density or alpha-n 2 fuel table 16x16, resolution 0,1% ve 3 injectors configuration phase and injection angle, injectors dead time calibration(16x1), injector flow rate configuration 4 afr table 16x16, resolution 0.1 afr, closed loop feedback 5 ignition t...

Page 11

Connector pinout details device view black gray 1 egt in #1 1 ignition coil #6 2 knock sensor in #1 2 stepper motor #1 winding a 3 analog in #2 3 stepper motor #2 winding a 4 clt in 4 aux 6 5 wbo vs 5 aux 3 6 camsync in #2 6 injector #4 7 primary trigger in 7 injector #1 8 ignition coil #5 8 ignitio...

Page 12

Software client for windows communication with ecumaster emu device is performed using usb aa cable, and microsoft windows based client software. Client allows to modify all settings (parameters, tables) stored in internal device flash memory as well as gathering real time data from engine sensors. ...

Page 13

Firmware upgrade to upgrade firmware please choose option upgrade firmware from file menu. After selecting proper firmware version press open button. The upgrade should begin immediately. Do not turn of the device during firmware upgrade! When upgrade is finish turn off the device. The process is fi...

Page 14

First connection during first connection to the emu device, there will appear a window with the device name. By default there will be device unique serial number which can be changed for any name. Based on this name there will be sub-directory created in directory my documents / emu. In this sub- di...

Page 15

User interface the picture below shows windows client after first launch. User interface is divided into 5 areas : 1. Menu 2. Tree view with device parameters (you can hide / show it with key f9) 3. Desktop 4. Event log (you can hide / show this area by keys combination shift + f9) 5. Status bar pag...

Page 16

Menu a menu bar consists of the following functions: file menu open project... Open previously saved project (*.Emu) save project as... Save current project (*.Emu) show full screen toggle full screen mode upgrade firmware upgrade internal firmware of emu device restore to default restore all emu de...

Page 17

Menu help contributors show contributors list window help show help window about information about software version. When the emu device is connected the information about device serial number and device region is also displayed in the menu tools, you can find the very useful tool “output assignment...

Page 18

Tree view parameter list on the left there is a list of all available emu functions grouped in functional blocks. Depending on firmware version there could be different set of functions. By expanding functional group user can access parameters and tables. Category sensors setup contains all options ...

Page 19

Description of basic controls the client of emu device consists of several basic controls, that facilitate the proper configuration of the device. We can divide it into particular types: icons description icon description wizard (creator) paramblock (parameter's block) table 2d table 3d visual log (...

Page 20

Paramblock (parameters’ block) it is a table, in which there are included particular options connected with the configuration of emu functions. Because of this, it is possible to set all parameters required for the configuration of the given function. Paramblock always has two columns, while the num...

Page 21

Table 2d 2d tables are used for representing 2 dimensional non-linear functions in an easy to use graphical form. The values corresponding to the graph are located in the table below it. Any of the cell values may be modified. The values from the upper row correspond to the vertical axis on the grap...

Page 22

Default keyboard short-cuts short-cut description = increase cell value shift = coarse increase cell value alt = fine increase cell value - decrease cell value shift - coarse decrease cell value alt - fine decrease cell value ctrl + c copy selected cells ctrl + v paste copied cells ctrl + h interpol...

Page 23

Table 3d tables 3d are used for representing three dimensional non-linear functions in an easy to use graphical form. Each 3d table is comprised of numerical values that define a variable (such as ignition timing) as it corresponds to values on two axes (such as load and rpm). There is a wizard avai...

Page 24

Track with the cursor current table position this options automatically increases cell values above the current rpm (cells are marked with white checker) if their value is lower than the value of the modified cell. This option is useful for creating the ve table change view to both table and 3d grap...

Page 25

X axis bins wizard this wizard is used for automatic generation of set points for the load axis (x). Parameter description load min value minimal value for axis x load max value maximal value for axis x interpolation type the way of dividing set points on axis x between the minimal and maximal value...

Page 26

Visual log using the parameters’ log we can real-time track the selected parameters of the engine’s work. Parameters are grouped according to the function, what facilitates tracking of the device’s functions (e.G. Idle control) gauges it is an informative tool, used to control particular parameters’...

Page 27

Graph log graph log is a tool to analyse any aspects of engine work and ecumaster emu device state. Data is shown as a graph in function of time. The detailed information about channel log value can be obtained by indicating interesting point on the graph. This tool is a key to create engine calibra...

Page 28

Description of default keyboard short cuts short cut description space pause / resume graph log refresh arrows left/right fine movement (left / right) of the graph log shift + arrows left/right fast movement (left / right) of the graph log page up / page down very fast movement (left / right) of the...

Page 29

Scope ecumaster emu has built in scope tool that allows measurement of signals present at primary trigger, cam#1 and cam#2 inputs. By using this tool it is possible to determine the trigger pattern for crankshaft and camshafts trigger wheels, to check if the polarity of the signal is correct and to ...

Page 30

Status bar status bar shows the most important parameters of emu device to allow easy trace of them. Description of status bar connection status disconnected - there is no communication with emu device connected - communication with emu device established ignition status information about synchroniz...

Page 31

Connecting the emu device when connecting the emu device, special attention should be paid to the connection of device’s grounds and their wiring in the car’s installation. Wrong connections can create loops, so called ground loops. Bad ground connections can cause many problems, such as noisy readi...

Page 32

Inputs and outputs ignition outputs ignition outputs can be used to control passive coils as well as active coils (with ignition module). The coil type is defined by the parameter ignition outputs / coil type. In the case of using passive coils the emu enclosure acts like a heat sink. The passive co...

Page 33

Analog inputs emu device has two kinds of analog inputs. The first type is fixed for given sensors like iat, clt and tps. The second type is universal one. It could be used to connect any sensor in the voltage range from 0-5v or as switch inputs for activating different strategies like als, launch c...

Page 34

Analog #1 - analog #4 in the case of analog input #x option, the activation is performed if the voltage on analog input is greater than 4v mux switch 1-3 the mux switch function allows to connect up to 3 switches to one analog input. More information can be found in sensors setup / mux switch sectio...

Page 35

Switch on cam#2 input there is an option to connect switch to cam#2 input. To use this option internal pullup of cam#2 input must be activated in ignition / cam #2 options page 35.

Page 36

Sensors in case of sensors used in cars’ electric installations, we are dealing with several types: – resistance sensors, – voltage sensors, – magneto-inductive sensors, – optical sensors / hall’s, resistance sensors are used to measure temperatures (e.G. Temperature of cooling liquid) or the positi...

Page 37

What is characteristic for this sensor is the fact that it has polarity, which is crucial when connecting it to emu. Inversely connecting it will prevent the synchronization of ignition. Signal from such sensor, especially with low speeds, where its amplitude reaches several hundred millivolts, is v...

Page 38

In the picture above the falling edges are marked with red colour, and the rising edges with green colour. Page 38.

Page 39

Sensors calibration calibration of analogue sensors is done from the sensors setup level. Coolant temperature sensor (clt) and intake air temperature (iat) sensors iat and clt sensors are in most cases the ntc thermistors. Ntc thermistor is a nonlinear resistor, whose resistance depends strongly on ...

Page 40

Predefined sensors – names of predefined sensors. In case of choosing the „user defined” sensor it is possible to add temperature values and resistance of own sensor. After selecting the sensor, you should press the ok button, what will create the calibration table. Warning ! To permanently save a c...

Page 41

Map sensor (manifold absolute pressure sensor) pressure sensors are used to measure pressure in the engine’s intake manifold (map sensor) and atmospheric pressure (baro sensor). Map sensor fulfils the following functions: 1. In algorithm speed density determines the engine’s load and is the basic pa...

Page 42

Parameter description use built in map when checked, internal map sensor is used built in map offset offset used to precisely calibrate internal map sensor readings map range measurement range of external map sensor in kpa of absolute pressure map offset offset used to precisely calibrate external m...

Page 43

Tps sensor should be connected as follows: oxygen sensor (lambda sensor) lambda sensor allows the determination of the composition of fuel-air mixture. Emu device supports both narrowband and wideband sensors (bosch lsu 4.2) the selection of the sensor is done in the set of parameters oxygen sensor ...

Page 44

Controller is used and linear signal is connected to emu. Fuel type oxygen sensor measures lambda value of mixture. To obtain adequate afr measurement, correct fuel type must be selected here. Heater kp sensor heater pid controller kp coefficient. Preset value should not be changed heater ki sensor ...

Page 45

In the case of lsu 4.2 probe, you should apply the following guidelines: - the probe must be installed in a place, where exhaust gas temperature (egt) does not exceed 750 degrees celsius. - in turbo cars we install oxygen sensor in down-pipe, - the sensor should be installed in a position close to v...

Page 46

It is also possible to connect narrow band oxygen sensor: in the case of using 1 wire oxygen sensor the voltage read by emu for stoichiometric mixture is 2.95v, for the 4 wire sensor it is 0.45v. Page 46 emu b5 narrow band oxygen sensor 1-wire lambda sensor wiring diagram 1 emu b5 b22 narrow band ox...

Page 47

Vss and gearbox vehicle’s speed sensor is usually placed in the gearbox. It is used by factory systems, e.G., speedometer or the system supporting the steering wheel (e.G., electrical support system). Vehicle’s speed can be also read from abs sensors. Ecumaster emu device uses the vss reading to reg...

Page 48

Vss sensor’s connection page 48 emu b14 b23 vss vss wiring diagram. Hall type sensor b18 +5v gnd out emu b14 vss vss wiring diagram. Vr type sensor b18 gnd out.

Page 49

Egt sensors emu device can use the k type thermocouple to measure the exhaust temperature. Sensor should be installed as close to head’s exhaust channels as possible. Attention! To maintain the accuracy of a thermocouple measurement system, k type thermocouple compensation cable is required to exten...

Page 50

Failsafe in case of failure of essential engine's sensors, emu device is equipped with a protection, enabling fail-safe operation of the engine under certain conditions. Smooth operation of the engine and its power will be significantly decreased, however this allows to keep the vehicle’s mobility, ...

Page 51

Extra sensors extra sensors configuration window allows you to select which inputs additional sensors are connected to. Example sensors that have special functions in emu software are oil pressure, oil temperature, fuel pressure and fuel level sensors. Parameter description oil pressure input analog...

Page 52

Mux switch mux switch function allows the connection of up to 3 switches to one analog input. Switches can activate various functions such as launch control, als, pit limiter and others. Switches connected with mux switch function are visible in software with names mux switch 1-3. Mux switch state c...

Page 53

Fueling parameters configuration of fuelling parameters is responsible for fuel dosing, both for the dose’s size and the fuel injection angle. The performing element in case of fuel dosage is the injector. It is the electro valve that allows the precise dosage of the sprayed fuel. Fuel dosage is reg...

Page 54

Selecting of injectors to determine required injector’s flow rate, you should know the engine's bsfc. Bsfc (brake specific fuel consumption) is the amount of fuel needed to generate 1 horsepower per hour. For naturally aspirated engines this value is about 5,25cm 3 /min, while for turbo engines abou...

Page 55

General fuelling general configuration window is used to set up general fueling strategy and parameters. Values entered here directly influence fuel dose, so it's important to enter values that reflect real engine parameters. Parameter description engine displacement engine displacement in cubic cen...

Page 56

Corrections fuel dose corrections (discussed in the following pages) accenrich acceleration enrichment injopeningtime the time it takes for an injector to open from the time it has been energized until it is fully open (value from the calibration map injectors cal.) alpha-n algorithm used in natural...

Page 57

Alpha-n with map multiplication algorithm combining features of speed density and alpha-n. The load is defined by tps, while ve value is multiplied by the value of absolute pressure in the intake manifold. It can be used for both naturally aspirated and turbocharged engines. Pw = inj_const * ve(tps,...

Page 58

Injectors phase injectors phase configuration window connects fuel injection start with ignition events. Injections starts n degrees before top dead centre of cylinder connected with ignition event, to which the injector is assigned. N is a base angle that is equal to trigger angle value from primar...

Page 59

Injectors trim injectors trim configuration is used to correct fuel dose for individual injectors. It's useful for precise fuel dose control for each individual cylinder. Fuel cut fuel cut parameters are responsible for setting up circumstances to occur for fuel cut to be executed. These can be exce...

Page 60

Ego feedback ego feedback configuration window is used to set up ego closed loop correction operation parameters. Both wideband and narrowband sensors can be used for correction. In case of narrowband sensor, it's only possible control mixture content around stoichiometric (nbo ref target). Use of w...

Page 61

Egt correction egt correction is fuel dose correction function used to protect engine from excessively high egt by enriching air fuel mixture. Per injector correction can be set by selecting egt sensors associated with particular injector. Value of correction can be set up in egt correction 2d table...

Page 62

Dfpr correction dfpr correction table is used to set up fuel dose correction related to fuel rail pressure delta. Delta pressure is pressure difference between fuel rail pressure and manifold air pressure. With properly working fuel system this delta pressure should always be constant. Dfpr corr. Fu...

Page 63

Configuration of ignition parameters configuration of ignition parameters is crucial from the point of view of the correct engine work and should be performed with the utmost care. Primary trigger primary trigger options are responsible for configuring the main sensor directing ignition system and b...

Page 64

Attention ! In case of vr sensors connecting the sensor with the device must be done with the shielded cable, while the shield must be connected to the ground only at one end! Attention ! In case of vr sensor the sensor’s polarity is important! Parameter description sensor type indicates the type of...

Page 65

First trigger tooth the tooth index that defines first ignition event. Detailed information about the first trigger tooth and trigger angle configuration can be found further trigger angle the angle defines the location of the first trigger tooth in relation to top dead center. This number will be a...

Page 66

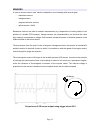

Trigger wheel configuration in the following example, trigger tooth is defined as 9th tooth, which is located 60 degrees before engines first cylinder top dead center (which is located at 19th tooth). Next ignition event is located on 39th tooth ( in 4 stroke engine ignitions are spaced by 180 degre...

Page 67

Supported trigger wheels parameter description toothed wheel with 2 missing teeth the toothed wheel with missing two teeth. The typical sample of such pattern is 60-2 toothed wheel. The tooth number 0 is the first tooth after the gap and does not depend on the camshaft synchronization what in this c...

Page 68

The camshaft synchronisation what in this case determines engine cycle dodge 18-2-18-2 ignition system specific to dodgde engines. The signal is converted to multitooth 36 but the tooth number 0 is determined and does not depend on the camshaft synchronization what in this case determines engine cyc...

Page 69

Trigger edge selection for proper signal processing, it's important that you select the correct trigger edge for the crankshaft and camshaft position sensors. The emu is equipped with a scope tool which is useful to verify that the signal is being decoded correctly. Attention ! Changing a trigger ed...

Page 70

Edge selection for camshaft trigger wheel signal frequently, when a variable valve timing system is present in an engine, incorrect signal edge selection makes proper signal decoding impossible. Incorrect scope for camshaft trigger wheel signal the scope above shows a camshaft trigger wheel signal d...

Page 71

Edge selection for multitooth trigger wheel signal when a trigger wheel with equal tooth spacing ( multitooth ) is connected to the primary trigger input, and synchronization is based on a camshaft trigger wheel signal, edges should be selected in a manner that gives the maximum distance between pri...

Page 72

Secondary trigger secondary trigger parameters are used to synchronize the crank position to the engine cycle phase. This allows you to use full sequential ignition and injection. Camshaft position sensors are also required for using vvti/vanos systems. The emu device supports several different seco...

Page 73

Supported trigger wheels parameter description do not use camsync do not synchronize with camshaft position 1 tooth a toothed wheel with the only 1 tooth that synchronize the engine cycle (cam sync). When using a multitooth primary trigger, the next tooth after camshaft tooth will have index 0. In t...

Page 74

2 symetrical tooth decoder for camshaft trigger wheel with two evenly spaced tooth. It allows to synchronize ignition system for wasted spark mode 2 missing teeth the synchronization (cam sync) occurs in the case the time between 2 previous teeth (prevdt) is less that the time between previous and c...

Page 75

Toothed wheel 12+1located on crankshaft, camsync n+1. N+1 cam docoder. Condition: prevdt > dt * 2. In this case prevdt=58ms, dt=19,6ms page 75.

Page 76

Cam #2 cam#2 trigger is required to control variable valve timing on the second camshaft. It is used for calculating cam angle in relation to crank shaft position (it is not used for synchronising engine phase). Emu supports hall/ optical and vr sensors. Attention ! We suggest that you use prim trig...

Page 77

Ignition outputs ignition output table is responsible for assigning ignition events to ignition outputs. Attention ! Selecting active coils in the software when using passive coils will lead to damage to the coils or emu device! Parameter description spark distribution this parameter defines spark d...

Page 78

Ignition outputs configuration for 8 cylinders engine, one ignition coil with distributor it is common that settings for primary and secondary triggers define the correct base ignition angle, but the spark at cylinder 1 is not executed during ignition event #1. In this case it is possible to use out...

Page 79

In case of active coils or using ignition modules, there is a chance to connect two coils or module inputs to one ignition output in order to do wasted spark ignition. Ignition event trims ignition event trims table defines ignition angle correction for each ignition event. Using this table you can ...

Page 80

Spark cut percent maximum percentage of cut spark at rev limit rpm. If this value is too small the soft rev limiter will not be able to limit the rpm ignition retard the ignition angle retard in the control range area. This parameter can be used to soften the rev limiter and protect the engine again...

Page 81

Ignition vs iat correction ignition va iat table defines the correction of ignition angle as a function of intake air temperature. Tps vs map correction tps vs map correction table defines the ignition angle correction as a function of throttle position and manifold absolute pressure. Ignition angle...

Page 82

Iatcorr ignition correction based on intake air temperature defined in ignition vs iat table cltcorr ignition correction based on intake air temperature defined in ignition vs clt table kscorr ignition angle correction connected to knock action idlecorr ignition angle correction connected to idle co...

Page 83

Configuration of engine start parameters settings in the parameter group engine start are used in the start-up phase of the engine. Parameters the engine start parameters menu defines parameters like ignition angle, injectors configuration and other important parameters related to the engine crankin...

Page 84

Cranking fuel 1 & 2 cranking fuel table is used to define the injectors opening time during engine start up (cranking). This time depends on engine coolant temperature and should be higher for lower engine temperatures. There are two cranking fuel tables that can be switched using other / tables swi...

Page 85

Enrichments afterstart enrichment afterstart enrichment function enables a fuel dose enrichment for a set number of engine cycles after engine start. Values in the table define the initial enrichment rate. With every engine cycle after start this value decreases linearly to zero. Initial enrichment ...

Page 86

The following 2d tables are connected with the function of acceleration enrichment. Acc. Dtps rate defines percentage of enrichment as a function of throttle opening speed (dtps). The faster the opening speed, the larger the enrichment should be. Acc. Tps factor defines how enrichment value will be ...

Page 87

Configuration of outputs parameters fuel pump fuel pump options determine which output is used to control the fuel pump relay and its control parameters. Parameter description after start activity specifies how long the fuel pump will run after the device is powered on (time in seconds). This time m...

Page 88

Coolant fan coolant fan options determine which output is used to control the radiator fan relay and its control parameters. Parameter description activation temperature cooling fan turn-on temperature hysteresis hysteresis which defines how many degrees the coolant temperature must fall below the a...

Page 89

Tacho output tacho output function is used to control electronic tachometers. Based on engine speed, the emu generates a square wave signal with a frequency proportional to the crankshaft speed. The tachometer should be connected to aux 4 which is equipped with a 10k pullup resistor connected to + 1...

Page 90

Speedometer output speedometer output function is used to operate an electronic speedometer. On the basis of vehicle speed, it generates a square wave signal with a frequency proportional to the vehicle speed. The speedometer can be connected to one of the outputs for stepper motor or free injector ...

Page 91

Param. Output parametric output strategy can be used to perform specific functions like alternator control, electric pumps, electric blow off valve, variable intake manifold length etc. Parametric output 1 has 3 conditions that control the state of the output, the other parametric outputs have only ...

Page 92

Pwm #1 the pwm #1 output is used to control an external solenoid with a predefined frequency and duty cycle (dc) defined in 3d pwm table. Parameter description output device output used for solenoid frequency the frequency of the pwm signal disable output if no rpm this option allows to disable pwm ...

Page 93

Honda clt dash output honda clt dash function is used to generate coolant temperature signal from emu to the electronic indicator on the dashboard of the honda s2000. Parameter description enable enable signal generation output output to which indicator is connected clt freq. Output the clt freq. Ou...

Page 94

Configuration of idle parameters idle parameters idle parameters are used to configure engine idle control options. A valve that regulates engine air flow during idle is the base device of idle control system. Base map for idle tuning is idle ref table which defines base opening of idle control devi...

Page 95

Pwm – valve with the possibility of the smooth change of opening through the modulation of impulses’ width. It is always a by-pass. Usually the increase of the duty cycle causes the increase of the amount of air flowing through the valve. In case of valves controlled by high frequency (e.G., bosch 0...

Page 96

Unipolar stepper motor - valve, which performing element is the unipolar stepper motor. It only requires the power supply during the change of the stepper motor position 3 wire pwm –valve using two windings (e.G., bosch 0280 140 505). When it is not powered, it is in the middle position. Depending o...

Page 97

Parameter description idle valve type on/off - the simplest valve which is opened when engine is cold and closed after warm-up. Pwm - valve which increases air flow with duty cycle of pwm controlling signal. Stepper - bipolar stepper motor ( 4 wire ), 3 wire pwm - pwm valve with two coils, unipolar ...

Page 98

Dbw idle range idle valve min dc minimum allowed signal duty cycle for pwm valve idle valve max dc maximum allowed signal duty cycle for pwm valve idle corr. Analog input defines which analog input is used to read and calculate correction value for idle device duty cycle. Correction value is defined...

Page 99

Ignition control idle ignition control function is used to control idle rpm by ignition angle modification. Advance of ignition angle leads to increase of rpm, retardation lowers rpm. Ignition control regulates ignition angle to achieve engine rpm defined in idle target rpm table. Idle control state...

Page 100

Idle ign. Correction idle ign. Correction is used to define ignition angle correction as a function of rpm error (difference between current rpm and target rpm). Target rpm can be set in idle target rpm table. Idle control by ignition angle change is activated in idle ignition control options. Idle ...

Page 101

Configuration of knock sensors parameters emu has the ability to work with common knock sensors and to take appropriate corrective actions when knock is detected. Common correction strategies are to enrich the fuel dose and to retard ignition timing. The emu employs advanced knock processors designe...

Page 102

Integrator time constant of signal integrator. -higher value gives better immunity to noise and lowers knock sensor value parameter. Too high a value can cause light engine knock to be filtered out. -lower values increases engine knocking sensitivity but it also increases susceptibility to noise. Th...

Page 103

Knock action action menu allows you to define which actions should be taken when knock is detected. The knock level is equal to knock sensor value - knock engine noise. Parameter description active activates engine knock protection min rpm minimal engine rpm for the system to be active max rpm maxim...

Page 104

Flex fuel sensor a flexfuel sensor measures the ethanol content of the fuel as it passes through the fuel system. Information about ethanol content can be utilized by the ecumaster emu to adjust the fuel dose, ignition advance, or boost pressure. The emu supports gm/continental frequency sensors. Th...

Page 105

Enable temp. Correction activate fuel dose correction in function of fuel temperature error frequency if the frequency of the flexfuel sensor is greater or equal error frequency, the sensor is not working correctly. In such cases the check engine light can be enabled (check engine) and the value fro...

Page 106

Vvt – variable valve timing typical variable valve timing system is based on pwm controlled solenoid that regulates the oil pressure applied to an actuator to adjust the camshaft position. Parameter description cam offset this parameter is used for camshaft starting position calibration. The correct...

Page 107

Solenoid this value define the dc when the camshaft position is stable. In practice this value defines when the camshaft changes its movement direction. In double vanos system this value should be 50% max dc maximum allowable dc value of camshaft control solenoid min dc minimum allowable dc value of...

Page 108

Vtec vtec control parameters are used for controlling variable timing and lift of the valves using on/off type solenoid. There is an option to automatic switch tables when the solenoid state changes. To do this in parameters tables switch/table switch mode option vtec switch must be enabled. Activat...

Page 109

Boost control boost control strategy allows for electronic boost pressure control. Boost pressure can be adjusted as a function of exhaust gas temperature, air temperature or vehicle speed. Boost control has two sets of 3d tables to permit switchable boost sets. These tables can be changed by a swit...

Page 110

Open loop control strategy open loop control allows you to control the boost pressure without pid. This strategy uses boost dc re map and does not use the boost target table. Closed loop control strategy closed loop control bases on pid control. The emu will aim to obtain boost pressure defined in b...

Page 111

Dc ref table boost dc reference table defines the duty cycle of the boost control solenoid as a function of throttle position and engine rpm. If closed loop control is enabled, boost pressure will maintain a defined boost target. Boost target table boost target table defines boost pressure as a func...

Page 112

Dbw attention ! The functions associated with operating the electronic throttle are only for testing stationary engines (generators, test benches, engine dynometers). For safety reasons, do not use the electronic throttle service on the road !!!! In order to use the electronic throttle (dbw) you nee...

Page 113

Table p table defines proportional gain of pid controller in function of current throttle position and position error (the difference between target and current position). I table i table defines integral gain of pid controller in function of current throttle position error (the difference between t...

Page 114

Traction control traction control strategy allows engine torque to be reduced in the case of wheel slip. Wheel slip is detected based on engine rpm increase. For the traction control strategy to work correctly a vss sensor or gear sensor is required. In addition to gear detection, a rotary switch (o...

Page 115

Gear scale gear scale table defines how to scale tc delta rpm raw depending on current gear. The lower the gear, the value in the table should also be lower. The value of 100% means no scale of tc delta rpm raw. Adjust scale adjust scale table is used to define how the tc delta rpm raw value should ...

Page 116

Other tables switch tables switch options are used to define how the tables will be change. The tables that can be switched have suffix #1 and #2. Tables can be change via switch or automatically when the vtec option is activated. There is also an option to interpolate between tables based on extern...

Page 117

Protection password protection isused to protect access to the emu device. The password is required to access any data and log. In the case of missing password it is possible to restore device to factory defaults, however all information will be lost. Parameter description enable password protection...

Page 118

Check engine check engine function is used to indicate possible sensor failures detected by emu device. Parameter description check engine light output output used for indication device (led, bulb, buzzer, etc.) invert output invert output state (can be used to test indicator) report failure of wbo ...

Page 119

Engine protection engine protection strategy is used to protect the engine by limiting the maximum rpm when the specific conditions are met. Parameter description enable over temp. Rev limit over-temperature engine protection. When clt temperature is higher than defined the new rev limit is used hig...

Page 120

Dyno dyno parameters are used to set up road dyno parameters ( dyno ). The accuracy of the generated power curve will largely depend on the preciseness of the values entered. Parameter description coefficient of drag coefficient of drag can be found in technical documentation of the car as a cx valu...

Page 121

Dyno tool attention ! The dyno tool is used for estimation of engine power (at the wheels) and to analyze boost pressure, afr, and iat as functions of engine rpm to generate estimated power and torque graphs, test runs must be made on a flat road. During the test run only one gear should be used. Th...

Page 122

Ext. Port extension port is used for emu communication with additional modules like the bluetooth, can- bus module and racing dashboards. The extension port is compatible with rs232 serial communication. With the bluetooth module connected to the extension port it is possible to use an android appli...

Page 123

Ecumaster serial protocol - ecumaster serial protocol allows to connect android based dashboard application. Can-bus - this device type should be selected for can-bus module support always reset emu device after selecting new device protocol! Can-bus speed speed of the can-bus send emu data over can...

Page 124

Appendix 1 – the list of available log channels log channel description acc. Enrichment current value (%) of acceleration enrichment acc. Enrichment pw current value (in ms) of additional injector pulse width due to acceleration enrichment acc. Ignition correction current ignition angle correction d...

Page 125

Boost dc pid correction the value of correction of dc of boost control solenoid resulting from pid control (closed loop control) boost table set current boost tables set boost target the final value of boost target for closed loop control (pid) or dc error correction table boost target from table th...

Page 126

Controller can egt #5 the temperature of egt #5 sensor connected to external egt2can controller can egt #6 the temperature of egt #6 sensor connected to external egt2can controller can egt #7 the temperature of egt #7 sensor connected to external egt2can controller can egt #8 the temperature of egt ...

Page 127

Position dbw out. Dc the dc value of signal controlling the electronic throttle module dbw pos current electronic throttle position dbw pot error the error resulting from the sum of the voltage from both potentiometers of electronic throttle dbw target required position of the electronic throttle de...

Page 128

Fuel ethanol content according to flex fuel crank fuel blend table ff blend ign the blending percent between ignition angle tables resulting from fuel ethanol content according to flex fuel ign blend table ff blend ve the blending percent between ve tables resulting from fuel ethanol content accordi...

Page 129

Idle pid dc correction dc correction according to idle control pid controller idle target the rpm target value according to idle rpm target table idle valve dc duty cycle of signal controlling idle control solenoid. In the case of stepper motor or electronic throttle this value defines percent of de...

Page 130

Nitrous active information about activation of nitrous control nitrous fuel scale fuel dose correction resulting from nitrous strategy according to nitrous fuel scale table nitrous ign. Mod. Ignition angle correction resulting from nitrous strategy according to nitrous ignition mod. Table none disab...

Page 131

Tps rate throttle position change rate tps voltage voltage value from tps sensor trigger error information about trigger errors connected to primary or/and secondary trigger trigger sync status information about state of ignition system no sync – no synchronization synchronising – trying to synchron...