- DL manuals

- Emheater

- Inverter

- EM8 Series

- User Manual

Emheater EM8 Series User Manual - Foreword

EM8 User's Manual

Foreword

Foreword

Thanks for using EMHEATER EM8 series inverter.

EM8 series inverter is China EM Technology Limited adopted the new concept to research and developed

high-performance product; With unique control model, this inverter can realize high torque, high precision,

wide variable speed and low noise drive; With more superior performance than similar products, EM8

inverters have practical PID regulation, simple PLC, flexible input and output terminals, parameter online

modification, automatic identification signal transmission failure, parameter storage of power outages and

stop, fixed length control, swing frequency control, main and auxiliary given control, field bus control and

a series of practical operation, control function, which provide a highly integrated solution for equipment

manufacturers and terminal customers, in speed, energy saving, protection, automatic control and other

aspects. EM8 inverter has great value to reduce the purchase and operating costs, enhance the reliability of

customers’ system.

Before installation, use and maintenance of this inverter, the relevant personnel please read the user manual

carefully, to ensure the correct installation and operation of this product, make it play its best performance.

As for any query of frequency inverter application or having special requirements, you can feel free to

contact my company's agents, but also can directly call our company after sale service department; we will

make effort to service well for you.

This manual copyright belongs to China EM Technology Limited; please forgive without notice of revise.

Version:201302

Summary of EM8 Series

Page 1

User’s manual china em technology limited address: no.80, baomin 2 road, xixiang, bao'an district,shenzhen ,china phone: 86-0755-29985851 fax: 86-0755-29970305 zip code: 518101 website : http://www.Emheater.Com china em technology limited emheater em8 series frequency inverter e m 8 s e r ie s i n v...

Page 2: Foreword

Em8 user's manual foreword foreword thanks for using emheater em8 series inverter. Em8 series inverter is china em technology limited adopted the new concept to research and developed high-performance product; with unique control model, this inverter can realize high torque, high precision, wide var...

Page 3: Table Of Contents

Em8 user's manual table of contents i table of contents 1. Caution ........................................................................................................................................................ 1 1.1 safety caution clause .......................................................

Page 4

Table of contents em8 user's manual ii 4.1 basic running parameters (group a) ............................................................................................... 21 4.2 intermediate running parameters (group b) ................................................................................

Page 5

Em8 user's manual table of contents iii 7.6.2.3 operating instructions ............................................................................................... 84 7.7 inverters constitute a closed-loop control system ...............................................................................

Page 6: 1. Caution

1.Caution em8 user's manual 1 1. Caution to ensure that you're personal, equipment and property safety, in use before frequency inverter, please be sure to read this chapter content, and comply with in the later carry, installation, running, debugging and maintenance, running process. Warning ● this...

Page 7

Em8 user's manual 1.Caution 2 caution ● the panel board, control circuit board, driving circuit boards installed the cmos integrated circuit, when using, please pay special attention, directly with finger touch circuit boards, electrostatic induction it might damage the circuit boards integrated chi...

Page 8

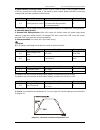

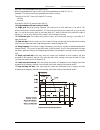

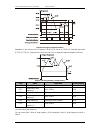

1.Caution em8 user's manual 3 diagram 1-2: the curve relationship of output current and altitude 1.2.9 about ip our inverter is ip20, you can add cabinet to improve its protection level. 1.3 end of life caution when you end of inverter life: the capacitor of main circuit and board can not burn, it w...

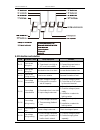

Page 9: 2. Installation And Wiring

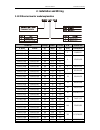

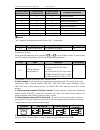

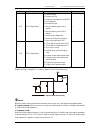

Em8 user's manual 2.Installation and wiring 4 2. Installation and wiring 2.1 em8 series inverter model explanation model no. Voltage power current g.W inverter size g series p series (v) (kw) (a) (kg) h/w/d(mm) em8-g1-d75 -- 220 0.75 5 2 150/85/115 em8-g1-1d5 -- 220 1.5 7.5 em8-g1-2d2 -- 220 2.2 10 ...

Page 10

2.Installation and wiring em8 user's manual 5 model no. Voltage power current g.W inverter size em8-g3-350 em8-p3-400 380 350 640 450 1828/981/496 em8-g3-400 em8-p3-500 380 400 690 em8-g3-500 em8-p3-630 380 500 860 em8-g3-630 -- 380 630 1100 2.2 specification items specification input rated voltage ...

Page 11

Em8 user's manual 2.Installation and wiring 6 items specification control character overvoltage prevention ensure not over-voltage in dec process. Low noise running carrier freq. Can be adjusted continuously form 1.5khz to 15.0khz, which can reduce the motor’s noise furthest. Speed tracking restart ...

Page 12

2.Installation and wiring em8 user's manual 7 items specification display running panel display running status output frequency, output current, output voltage, motor rotate speed, setting frequency, pid setting, pid feedback, model temperature, accumulative running time, analog i/o, terminal input ...

Page 13

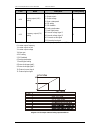

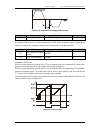

Em8 user's manual 2.Installation and wiring 8 inverter model w1 (mm) w (mm) h1 (mm) h (mm) d1 (mm) d (mm) screw standard g series em8-g1/g3 p series em8-p3 em8-g3-5d5 em8-p3-7d5 190 208 285 305 170 185 m4 em8-g3-7d5 em8-p3-011 em8-g3-011 em8-p3-015 190 240 372 390 220 235 m6 em8-g3-015 em8-p3-018 em...

Page 14

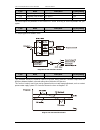

2.Installation and wiring em8 user's manual 9 the running panel disassemble and installation disassemble: put your finger into the hole above panel and gently press down the fixed shrapnel, and then take off key panel. Installation: put the panel into the slot until to hear a voice "click". Inverter...

Page 15

Em8 user's manual 2.Installation and wiring 10 model em8-g/p input side main circuit(mm 2 ) control circuit(mm 2 ) breaker(a) input cable output cable control cable g3/p3-037 125 25 25 1 g3/p3-045 160 35 35 1 g3/p3-055 160 35 35 1 g3/p3-075 250 50 50 1 g3/p3-090 250 70 70 1 g3/p3-110 315 70 70 1 g3/...

Page 16

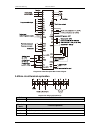

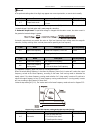

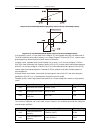

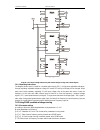

2.Installation and wiring em8 user's manual 11 diagram 2-8: em8 three phase 380v inverter diagram 2.6 main circuit terminal explanation diagram 2-9: main circuit terminal (1) series suitable inverter g1 em8-g1-d75~em8-g1-2d2 terminal mark function explanation l 1 ,l 2 single phase 220v ac power u,v,...

Page 17

Em8 user's manual 2.Installation and wiring 12 diagram 2-10: main circuit terminal (2) series suitable inverter g3 em8-g3-d75~em8-g3-2d2 p3 em8-p3-1d5~em8-p3-004 terminal mark function explanation p+ dc bus positive pole pb the braking resistor connect between p+ and pb r,s,t input three phase termi...

Page 18

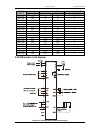

2.Installation and wiring em8 user's manual 13 diagram 2-13: main circuit terminal (5) series suitable inverter g3 em8-g3-037~em8-g3-630 p3 em8-p3-045~em8-p3-630 2.7 terminal of control circuit diagram 2-14: terminal of control circuit (1) series suitable inverter g1 em8-g1-d75~em8-g1-2d2 diagram 2-...

Page 19

Em8 user's manual 2.Installation and wiring 14 2.7.1 explanation of terminals of control circuit type terminal terminal function notes analog input +10v/v+ provide +5v/50ma power or +10v/10ma power to external selected by control panel jp1 (refer to the following diagram) -10v/v- provide -10v/10ma p...

Page 20

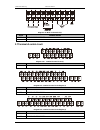

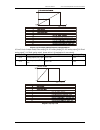

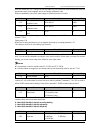

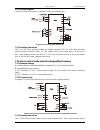

2.Installation and wiring em8 user's manual 15 2.8 jp jumper explanation the 0.4kw to 4kw jp on pcb board as following diagram 2-16: diagram 2-17: 0.4kw~4kw jumper the 5.5kw to 630 kw jp on pcb board as following diagram 2-17: diagram 2-18: 5.5kw~630kw jumper.

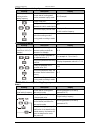

Page 21: 3. Operation And Running

Em8 user's manual 3.Operation and running 16 3. Operation and running 3.1 the panel layout diagram 3-1: panel can set frequency, control model, display and monitor 3.2 the em8 series frequency inverter parameter categories 3.2.1 basic parameter when you set "a-0" to "0", the inverter is under basic ...

Page 22

3.Operation and running em8 user's manual 17 3.3 working model of panel the panel can be divided into four control modes depends on the difference of content and command. Except digital control model, the control modes were switched by key. 3.3.1 monitoring state mode monitoring state is working sta...

Page 23

Em8 user's manual 3.Operation and running 18 items function description panel function rev and jog key. The detailed function of this key is selected by parameter [a-17]. When parameter [a-17] equals 0,this key will take effect as reverse startup. When parameter [a-17] equals 1, the key is used as j...

Page 24

3.Operation and running em8 user's manual 19 3.6.2monitor parameter inquiry running description display for example: looking over the setting frequency current state of running panel monitor parameter inquiry mode. D-0 (example) monitor code plus 1 d-1 modify monitor code to the parameter d-4 which ...

Page 25

Em8 user's manual 3.Operation and running 20 mode 2: running description display change the current digital setting frequency current state of running panel: state monitor mode. Running parameter (decided by parameter b-71) enter digital frequency modification mod. Digital setting frequency modify t...

Page 26

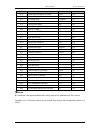

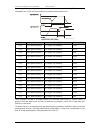

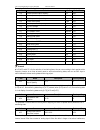

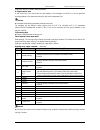

4.Function parameter list em8 user's manual 21 4. Function parameter list description of symbols in the list: " × " means that the parameter cannot be changed during running. " * " means that the parameter has relation to the model of inverter. "---" means that the parameter is the reserved one and ...

Page 27

Em8 user's manual 4.Function parameter list 22 code name description min. Unit factory setting change code addr. A-10 analog output (aoi) setting 0: output frequency 1: output current 2: output voltage 3: motor rotate speed 4: pid setting 5: pid feedback 6. Panel potentiometer 7. Panel digital setup...

Page 28

4.Function parameter list em8 user's manual 23 code name description min. Unit factory setting change code addr. A-16 oc2 output setting 14: internal counter reaches peak value 15: internal counter value reaches t the specified value 16: upper limit of pressure alarm 17: lower limit of pressure alar...

Page 29

Em8 user's manual 4.Function parameter list 24 code name description min. Unit factory setting change code addr. B-14 the voltage of dc braking stop 0~15% 1 5 × 20h b-15 jog frequency 0.00~upper limit frequency 0.01 10.00 21h b-16 jog acc. Time 0.1~6000s 0.1 10.0 22h b-17 jog dec. Time 0.1~6000s 0.1...

Page 30

4.Function parameter list em8 user's manual 25 code name description min. Unit factory setting change code addr. B-36 v1 input adjustment coefficient 0.01~5.00 0.01 1.00 36h b-37 v2 input lower-limit voltage -10.0v~[b-38] 0.1 0.0 37h b-38 v2 input upper-limit voltage [b-37]~10.0v 0.1 10.0 38h b-39 v...

Page 31

Em8 user's manual 4.Function parameter list 26 code name description min. Unit factory setting change code addr. B-57 carrier frequency 1.5~15khz 0.1 * 4bh b-58 frequency reach checkout amplitude 0. 00~20.00hz 0.01 5.00 4ch b-59 fdt (frequency reach detection) 0.00~upper-limit frequency 0.01 10.00 4...

Page 32

4.Function parameter list em8 user's manual 27 code name description min. Unit factory setting change code addr. B-71 monitor item selection 0~19 1 0 59h b-72 parameter revise protection 0: all parameters are allowed to be revised 1: prohibit to revise all parameters except for parameter [b-72] 2: p...

Page 33

Em8 user's manual 4.Function parameter list 28 code name description min. Unit factory setting change code addr. C-14 programmable multi-speed running setting led ten digital: simple plc running time unit: 1: min 0: second led first digital: plc running style: 0: no action 1: single loop 2: continuo...

Page 34

4.Function parameter list em8 user's manual 29 code name description min. Unit factory setting change code addr. C-34 step 7 running direction 0: fwd 1: rev 1 0 7eh c-35 step 7 acc/dec time 0.1~6000s 0.1 10.0 7fh c-36 jump frequency 1 0.00~upper-limit frequency 0.01 0.00 80h c-37 amplitude of jump f...

Page 35

Em8 user's manual 4.Function parameter list 30 code name description min. Unit factory setting change code addr. C-50 pid feedback channel selection 0: voltage input 1 (0~10v) 1: current input 2: pulse input 3: voltage input 2 ( -10v~10v ) 1 3 × 8eh c-51 feedback signal character 0: positive charact...

Page 36

4.Function parameter list em8 user's manual 31 code name description min. Unit factory setting change code addr. C-67 wake up threshold value 0.001~[c-68] 0.001 0.000 9fh c-68 sleep threshold value [c-67]~[c-62] 0.001 1.000 a0h c-69 pump switch time 0.1s~1000s 0.1 300.0 a1h c-70 electromagnetic swit...

Page 37

Em8 user's manual 4.Function parameter list 32 monitor code content unit address of code d-4 present setting frequency of inverter 0.01hz dfh d-5 dc bus voltage 1v e0h d-6 pid setting value 0.1%mpa* e1h d-7 pid feedback value 0.1%mpa* e2h d-8 running linear speed 0.01* e3h d-9 setting linear speed 0...

Page 38

4.Function parameter list em8 user's manual 33 4.5 protection and solution code probable cause fault description solution er. 01 over-current during acc 1. Acceleration time is too short. 2. Torque boost is too high or v/f curve is not suitable. 1. Extend the acceleration time. 2. Descend the torque...

Page 39

Em8 user's manual 4.Function parameter list 34 code probable cause fault description solution er. 09 inverter overload 1. Load is too heavy. 2. Acc time is too short. 3. Torque boost is too high or v/f curve is not suitable. 4. Electric network is too low. 1. Reduce the load or replace with higher c...

Page 40

4.Function parameter list em8 user's manual 35 code probable cause fault description solution er. 19 pid feedback fault 1. Pid feedback signal wire is disconnection. 2. The transistor which is used to detect the feedback signal, occurs the fault. 3. The feedback signal is inconsistent with the setti...

Page 41

Em8 user's manual 5.The concrete explanation of function parameters 36 5. The concrete explanation of function parameters 5.1 inverter running parameters (group a) code name description factory setting a-0 running parameter selection 0: basic running parameter 1: intermediate running parameter 2: se...

Page 42

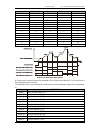

5.The concrete explanation of function parameters em8 user's manual 37 frequency channel is as the follow columns: frequency setting choose terminal-3 frequency setting choose terminal-2 frequency setting choose terminal-1 frequency input channel 0 0 0 panel potentiometer 0 0 1 panel digital setup 0...

Page 43

Em8 user's manual 5.The concrete explanation of function parameters 38 4: rs485 interface (stop key is valid).The basic function is same as mode 3; under this model, the panel stop key can be press to stop inverter, if user wants to restart inverter, please use rs485 to input stop command and input ...

Page 44

5.The concrete explanation of function parameters em8 user's manual 39 code name description factory setting a-10 analog output (aoi) setting 0: output frequency 1: output current 2: output voltage 3: motor rotate speed 4: pid setting 5: pid feedback 6. Panel potentiometer 7. Panel digital setup 8. ...

Page 45

Em8 user's manual 5.The concrete explanation of function parameters 40 diagram 5-3: the output content of frequency output terminal ao ao has 5 kinds of output mode(0:pulse output,1:0~10v analog output,2:2~10v analog output,3:0~20ma analog output,4:4~20ma analog output), please refer to b-14 explana...

Page 46

5.The concrete explanation of function parameters em8 user's manual 41 diagram 5-5: [a-13] = 5.00 [a-12],[a-13] is used set value of ao terminal output voltage and fm terminal output frequency. That is crosscourt slope ratio of diagram 5-4, diagram 5-5: code name description factory setting a-14 ana...

Page 47

Em8 user's manual 5.The concrete explanation of function parameters 42 code name description factory setting a-15 oc1 output setting 0: inverter running 1: frequency arrival 2: frequency level detection signal(fdt) 3: over-load alarm 4: external fault stop 5: output frequency upper limit is reached ...

Page 48

5.The concrete explanation of function parameters em8 user's manual 43 remark ● if the external power supply, the best selection is dc 24v/50ma. Diagram 5-7: frequency arrival signals 2: frequency level detection signal(fdt) when the inverter output frequency is more than fdt frequency level, after ...

Page 49

Em8 user's manual 5.The concrete explanation of function parameters 44 remark ● overload alarm level set by parameter b-61, when [a-0] = 0,the fixed is 110%. ● the alarm delay time is set by parameter b-62, when [a-0] = 0,fixed is 2s 4: external fault stop:when the inverter external fault input sign...

Page 50

5.The concrete explanation of function parameters em8 user's manual 45 0: constant torque curve: the inverter output voltage and the output frequency is proportional to the load, for the majority, by this way. 1: decreasing torque curve 1: the inverter output voltage and the output frequency is quad...

Page 51

Em8 user's manual 5.The concrete explanation of function parameters 46 remark ● torque boost setting value is too high, may appear over current protection, or cannot start normally. Code name description factory setting b-2 torque boost mode 0: manual 1: auto 0 0: manual boost: torque boost voltage ...

Page 52

5.The concrete explanation of function parameters em8 user's manual 47 0: start up from start frequency.After receiving startup command, the inverter will firstly run according to preset start frequency(set by b-7),and after the duration time of start frequency(set by b-8),and then run to set freque...

Page 53

Em8 user's manual 5.The concrete explanation of function parameters 48 code name description factory setting b-11 stop mode 0: deceleration stop mode: 1: free stop mode 0 0: deceleration stop mode:inverter stops according to deceleration time decrease and stop. 1: free stop mode: inverter cut off ou...

Page 54

5.The concrete explanation of function parameters em8 user's manual 49 jog frequency having the highest priority. Inverter in any state, as long as there is jog input, inverter immediately turn to jog running according to acceleration and deceleration time. Diagram 5-16: jog running code name descri...

Page 55

Em8 user's manual 5.The concrete explanation of function parameters 50 terminal 1 terminal 2 terminal 3 terminal 4 multi-step terminal 1 0 0 0 1 0 1 0 0 2 1 1 0 0 3 0 0 1 0 4 1 0 1 0 5 0 1 1 0 6 1 1 1 0 7 0 0 0 1 8 1 0 0 1 9 0 1 0 1 10 1 1 0 1 11 0 0 1 1 12 1 0 1 1 13 0 1 1 1 14 1 1 1 1 15 diagram 5...

Page 56

5.The concrete explanation of function parameters em8 user's manual 51 multi speed acc/dec time speed 13 acc/dec time1(a-7,a-8) speed 14 acc/dec time1(a-7,a-8) speed 15 acc/dec time1(a-7,a-8) the running mode, direction, and time of programmable multi-step speed can be set by parameter c-14~c-35. Th...

Page 57

Em8 user's manual 5.The concrete explanation of function parameters 52 x* is three line control terminal, parameter b-63~b-69 to select input terminal one terminal x1~x7, for example: select terminal x1,the wiring is as following diagram: trigger switch function explanation: 1. Sw2~forward trigger s...

Page 58

5.The concrete explanation of function parameters em8 user's manual 53 diagram 5-19: the relationship between single polarity control v2 ([b-41] = 0)and setting frequency diagram 5- 20: the relationship between bipolar control v2 ([b-41]=1) and setting frequency in single polarity control, v2 input ...

Page 59

Em8 user's manual 5.The concrete explanation of function parameters 54 code name description factory setting b-48 pulse input adjustment coefficient 0.01~5.00 1.00 to define pulse frequency range of pulse input channel, according to the actual situation of access signal set. The correction coefficie...

Page 60

5.The concrete explanation of function parameters em8 user's manual 55 parameters list of monitoring state code content unit code address d-0 inverter present output frequency hz dbh d-1 inverter present output current a dch d-2 inverter present output voltage v ddh d-3 present motor speed rpm deh d...

Page 61

Em8 user's manual 5.The concrete explanation of function parameters 56 leading to set frequency instability, user can improve the signal quality by increasing the filter time constant. Code name description factory setting b-56 frequency input channel combination refer to the detailed description of...

Page 62

5.The concrete explanation of function parameters em8 user's manual 57 set frequency=channel 1 set frequency* kx(scale factor of channel 2). When choose input analog channel 2 (parameter set 0~4),the scale factor calculation is as: kx=inx*ax kx: channel 2 scale factor inx: input analog set value (wh...

Page 63

Em8 user's manual 5.The concrete explanation of function parameters 58 code name description factory setting b-59 fdt (frequency reach detection) 0.00~upper-limit freq 10.00 b-60 fdt output delay time 0.0~20.0s 2.0 the parameter is used to inspect inverter frequency and output a signal, when output ...

Page 64

5.The concrete explanation of function parameters em8 user's manual 59 these parameters are used to select functions of programmable input terminal x1~x7, as following: set value terminal function 0 no function 1 multi-step speed 1 2 multi-step speed 2 3 multi-step speed 3 4 multi-step speed 4 5 for...

Page 65

Em8 user's manual 5.The concrete explanation of function parameters 60 the parameters are used to determine the running panel display content in the monitoring mode and on inverter just power on moment, please refer to the monitoring state parameter list. Code name description factory setting b-72 p...

Page 66

5.The concrete explanation of function parameters em8 user's manual 61 diagram 5-23: slip frequency compensation code name description factory setting c-1 over-load & over-heat protection mode 0: lock the output 1: limit-current running(alarm) 0 this parameter is used to control how the inverter is ...

Page 67

Em8 user's manual 5.The concrete explanation of function parameters 62 model g: 150 %×rated current, 1 minute model p: 120 %×rated current, 1 minute the setting value for this parameter is calculated as: [c-2]= ×100 remark ● when the inverter is working with several motors connected in parallel, the...

Page 68

5.The concrete explanation of function parameters em8 user's manual 63 remark ● to use self-recovery function, the inverter must has such function available and without any physical faulty. Code name description factory setting c-8 auto stable voltage 0: invalid 1: valid 2: invalid only at decelerat...

Page 69

Em8 user's manual 5.The concrete explanation of function parameters 64 diagram 5- 26: dead area time of changing rotation direction code name description factory setting c-11 internal timer set value 0.1~6000.0s 0.0 this parameter is used to set the clocking of the internal timer of the inverter. Th...

Page 70

5.The concrete explanation of function parameters em8 user's manual 65 code name description factory setting c-14 programmable multi-speed running setup led ten digital: simple plc running time unit: 1: min 0:second led first digital: plc running style: 0: no action 1: single loop 2: continuous loop...

Page 71

Em8 user's manual 5.The concrete explanation of function parameters 66 each step in the programmable multi-step running. When programmable multi-step function is valid, these parameters are valid ([c-14] ≠ 0). Parameter c-14 defines how the programmable multi-step is working: tens-digit of the led: ...

Page 72

5.The concrete explanation of function parameters em8 user's manual 67 diagram 5-29: single cycle and stop (mode 5) parameters of the running curve in diagram 5-28 and 5-29 are set as: [c-14]= 3, keep last step mode [c-27]= 0, [c-33 ]= 0, running time for step 5 and step 7 is 0, so these two steps a...

Page 73

Em8 user's manual 5.The concrete explanation of function parameters 68 diagram 5-31: hopping frequency and its amplitude remark ● hopping frequency means that the inverter will not running on certain frequency stably, but will use it during acceleration and deceleration. Code name description factor...

Page 74

5.The concrete explanation of function parameters em8 user's manual 69 code name description factory setting c-48 built-in pid control 0: no pid control 1: normal pid control 2: constant-pressure water-supply pid 3: double-pump constant pressure water-supply pid (need accessory) 4: triple-pump const...

Page 75

Em8 user's manual 5.The concrete explanation of function parameters 70 code name description factory setting c-50 pid feedback channel selection 0: voltage input 1 (0~10v) 1: current input 2: pulse input 3: voltage input 2 ( -10v~10v ) 3 it is valid only when using pid control. 0: external voltage i...

Page 76

5.The concrete explanation of function parameters em8 user's manual 71 code name description factory setting c-55 proportion gain 0.00~5.00 0.50 c-56 integration time constant 0.1~100.0s 10.0 c-57 differential gain 0.0~5.0 0.1 you should adjust the parameters of the internal pid control according to...

Page 77

Em8 user's manual 5.The concrete explanation of function parameters 72 code name description factory setting c-60 pid feedback wire-break detection threshold 0.0~20.0% 0.0 c-61 pid feedback wire-break action selection 0: stop 1: running as the digital setting frequency 2: running as the upper-limit ...

Page 78

5.The concrete explanation of function parameters em8 user's manual 73 code name description factory setting c-67 wake up threshold value 0.001~[c-68] 0.000 this parameter is used to define the pressure limitation for system to wake up from asleep. When the pressure of the pipeline is lower than thi...

Page 79

Em8 user's manual 5.The concrete explanation of function parameters 74 when the inverter will run. Timing from the very beginning, the inverter will stop automatically when the preset water supply time is elapsed, until a new running command is input. When this parameter is set to 24.0, water supply...

Page 80

5.The concrete explanation of function parameters em8 user's manual 75 this parameter is used to define the baud rate used in rs485 communication. Each party in the communication must use the same baud rate. 0: 1200 bps 1: 2400 bps 2: 4800 bps 3: 9600 bps 4: 19200 bps ode name description factory se...

Page 81: 6. Care And Maintenance

Em8 user's manual 6.Care and maintenance 76 6. Care and maintenance 6.1 daily inspections and maintenance high temperature, humidity, dust, vibration and aging parts may affect the steady running of the em8 series inverter. To avoid this, it is recommend to perform a periodic inspection every 3-6 mo...

Page 82

6.Care and maintenance em8 user's manual 77 warning ● only trained professionals are allowed to perform the maintenance and components replacement of the inverter. ● before opening the inverter, switch off all the electrical power supplies to the inverter, and wait led light off. ● measure the volta...

Page 83

Em8 user's manual 6.Care and maintenance 78 remark ● we only provide after sales service for our inverter under normal application. Within warranty period, regular maintenance cost is needed, when damages of inverter are caused by followings, we are not responsible for the applications: (1) not acco...

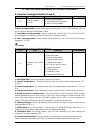

Page 84: 7. Application Examples

7.Application examples em8 user's manual 79 7. Application examples 7.1 panel control: start and stop, panel potentiometer set frequency 7.1.1 parameter settings according to the motor rated nameplate data, set the parameter a-5, a-6 for setting. Must set parameters as following: [a-1] = 0: paramete...

Page 85

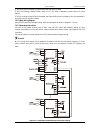

Em8 user's manual 7.Application examples 80 7.2.2 the basic diagram three lines control mode as shown in diagram 7-2 below (for reference only). Diagram 7-2: three lines control mode wiring 7.2.3 operating instructions fwd, x1, com closed, the motor forward run (forward command); rev, x1, com closed...

Page 86

7.Application examples em8 user's manual 81 run (reverse command). Fwd - com, rev - com and closed or open together, frequency inverter stop. Set frequency is by external voltage signal terminal 1 (v1). Remark ● according to the parameter a-1 setting, choose the external input v1 or v2 as signal for...

Page 87

Em8 user's manual 7.Application examples 82 [b-18]~[b-24]: multi-step speed frequency set value (a total of 7 steps). [c-14] = 1~7: parameter c-14 chooses arbitrary value. 1~7 is according to need. [c-15]~[c-35]: according to the running needs, set up simple plc multi-step speed running time, runnin...

Page 88

7.Application examples em8 user's manual 83 diagram 7-6: external voltage realizes many sets inverter linkage running control mode diagram 7.6.1.3 operating instructions the diagram shows, there is a need for a constant power supply (10 v), a high power adjustable resistance, through regulating adju...

Page 89

Em8 user's manual 7.Application examples 84 [c-80]: baud rate, all frequency inverters baud rate shall set to be same. [c-81]: host settings, master inverter (host) set to 1, the other a frequency inverter send to 0 (slave station). [c-82]: according to need to set up the master and slave machine ru...

Page 90

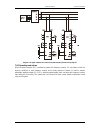

7.Application examples em8 user's manual 85 7.7 inverters constitute a closed-loop control system 7.7.1 parameter settings according to the motor rated nameplate data, to set parameter a-5, a-6. Must set parameters as following: [a-0] = 2: parameter a-0 set to 2 to select senior parameters running m...

Page 91

Em8 user's manual 7.Application examples 86 diagram 7-9: upper computer (pc) control many sets frequency inverters wiring diagram 7.8.3 operating instructions when the upper computer (pc) constitutes a system with frequency inverter, pc can always control the working conditions of each frequency inv...

Page 92: 8. Optional Accessories

8.Optional accessories em8 user's manual 87 8. Optional accessories 8.1 remote control cable and adapter if user only use extend cable connect with panel and inverter, the farthest distance is 15 meters. If user choose remote control adapter to remote control, the farthest distance can be 1000 meter...

Page 93

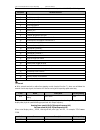

Em8 user's manual appendix 1:rs485 communication protocol 88 appendix 1: rs485 communication protocol 1. Summary em8 series inverter provide rs485 communication interface. Users can realize centralized monitoring through pc/plc (set the control command and monitor the running state of the inverter) ...

Page 94

Appendix 1:rs485 communication protocol em8 user's manual 89 (2)one start bit, eight digital bit, one stop bit, and odd parity check (3)one start bit, eight digital bits, one stop bit, even parity check default in the slave: one start bit, eight digital bits, stop bit, none check 2.2.2 baud rate 5 o...

Page 95

Em8 user's manual appendix 1:rs485 communication protocol 90 the master, response of the slave, setting frequency for the master running, actual frequency of the slave running. 2.3.1 master command frame the sending message from the master is called master command frame. It is the diagram below: sen...

Page 96

Appendix 1:rs485 communication protocol em8 user's manual 91 parameter data code value description master command code 2 change the parameter data: change the parameter data designated by the slave encoding address. This data cannot be saved if the slave loses the power supply. 3 change the paramete...

Page 97

Em8 user's manual appendix 1:rs485 communication protocol 92 code when users try to modify these parameters. 6: illegal function code it will return this error code when the code address in the message is invalid (it is not the specified encoding address in the status monitoring list and function pa...

Page 98

Appendix 1:rs485 communication protocol em8 user's manual 93 status word:(inverter → upper computer ) bit meaning function description 0 dc voltage state 1: normal dc voltage 0: abnormal dc voltage 1 motor direction 1: motor reverse 0: motor forward 2 output phase sequence 1: negative phase sequence...

Page 99

Em8 user's manual appendix 1:rs485 communication protocol 94 data type: hexadecimal notation, single byte. Method of calculation: accumulate all the bytes in the range from start bit to data of user. The checksum is the remainder of accumulated sum divide by 256(ff). Checksum fault will lead to comm...

Page 100

Appendix 1:rs485 communication protocol em8 user's manual 95 master sending frame: start bit slave address master command encoding address parameter value running word setting frequency value check sum 5a 00 03 34 0a00 1200 b8 0b 6f slave response frame: start bit slave address slave response encodi...