- DL manuals

- EMKO

- Temperature Controller

- ESM-4420

- Instruction manual

EMKO ESM-4420 Instruction manual

ESM-

48x48

DIN

1/16

T

emperature

Controller

4420

ESM-4420 48 x 48 DIN 1/16

Temperature Controller with Universal Input

- 4 digits process(PV) and 4 digits process set value

- Universal process input (TC, RTD )

- Adaptation of PID Coefficients to the system with Self-Tune

operation (Step Response Tuning)

- Programmable Heating or Cooling Functions for Control Output

- Alarm Functions for Alarm Output

(SV) display

- Configurable ON/OFF, P, PI, PD and PID control forms

Instruction Manual. ENG ESM-4420 02 V03 04/08

Summary of ESM-4420

Page 1

Esm- 48x48 din 1/16 t emperature controller 4420 esm-4420 48 x 48 din 1/16 temperature controller with universal input - 4 digits process(pv) and 4 digits process set value - universal process input (tc, rtd ) - adaptation of pid coefficients to the system with self-tune operation (step response tun...

Page 2

2 instruction manual of esm-4420 temperature controller consists of two main sections. Explanation of these sections are below. Also, there are other sections which include order information and technical specifications of the device. All titles and page numbers in instruction manual are in “ ” sect...

Page 3

1.Preface............................................................................................................................................ 2.Installation.................................................................................................................................... 3.E...

Page 4

4 manufacturer company name : emko elektronik a.S. Manufacturer company address: dosab, karanfil sokak, no:6, 16369 bursa, turkiye the manufacturer hereby declares that the product conforms to the following standards and conditions. Product name : temperature controller model number : esm-4420 type ...

Page 5: Esm-4420

Esm-4420 series temperature controllers are designed for measuring and controlling a process value. They can be used in many applications with their universal process input, control outputs and selectable alarm functions. Some application fields which they are used are below: 1.Preface 5 application...

Page 6

All order information of e s m - 4 4 2 0 t e m p e r a t u r e controller are given on the table at left. User may form appropriate d e v i c e c o n f i g u r a t i o n f r o m information and codes that at the table and convert it to the ordering codes. Firstly, supply voltage then other specifica...

Page 7

7 1.3 warranty emko elektronik warrants that the equipment delivered is free from defects in material and workmanship. This warranty is provided for a period of two years. The warranty period starts from the delivery date. This warranty is in force if duty and responsibilities which are determined i...

Page 8

8 in package , - one piece unit - two pieces mounting clamp - one piece instruction manual a visual inspection of this product for possible damage occured during shipment is recommended before installation. It is your responsibility to ensure that qualified mechanical and electrical technicians inst...

Page 9

2.1 general description 2.2 dimensions 9 esm-4420 aset temperature controller p pset °c °f po ao ps as 84 mm / 3.31 inch 48 mm/ 1.89 inch 48 mm/ 1.89 inch maximum 5 0.2 inch mm / 11 ± 1 mm /0.43 inch panel surface (maximum thickness 5mm / 0.2 inch) front panel ip65 protection nema 4x mounting clamps...

Page 10

2.3 panel cut-out 10 65 mm / 2.56 inch (min) 65 mm / 2.56 inch (min) 46 mm / 1.81 inch (min) 46 mm / 1.81 inch (min).

Page 11

C 11 1 2 3 during installation into a metal panel, care should be taken to avoid injury from metal burrs which might be present. The equipment can loosen from vibration and become dislodged if installation parts are not properly tightened. These precautions for the safety of the person who does the ...

Page 12

12 c c 1-loosen the screws. 2-pull mounting clamps from top and bottom fixing sockets. 3-pull the unit through the front side of the panel before starting to remove the unit from panel, power off the unit and the related system. Montage of the unit to a system must be done with it’s own fixing clamp...

Page 13

13 max. 2.5mm / inch wire size: 14awg/1mm² solid /stranded a 3.1 terminal layout and connection instructions torque 0.5 nm screw driver 0.8x3mm you must ensure that the device is correctly configured for your application. Incorrect configuration could result in damage to the process being controlled...

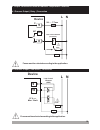

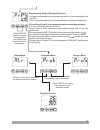

Page 14: 10 11 12

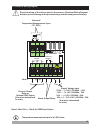

230 115 v ( ± 15% ) 50/60hz - 3va v ( ± 15% ) 50/60hz - 3va 24v ( ± 15% ) 50/60hz - 3va v v v 3.2 electrical wiring diagram c 14 13 a no c 5a@250v v alarm out supply voltage input (it must be determined in order.) alarm output relay cat ii y p/n : 442 esm- 0 c 8 9 10 11 12 14 temperature measurement...

Page 15: Cat Ii

15 3.3 view of the device label process out n l 5a@250v v p/n : esm-4420 y c a cat ii tc pt-100 no c 7 6 5 4 3 2 1 14 13 12 11 10 9 8 nc no c alarm out 5a@250v v 230v ±15% v 50/60hz 3va.

Page 16

3.4 supply voltage input connection of the device 16 note-1: external fuse is recommended. Supply voltage range must be determined in order. Device is produced different for low and high voltage. While installing the unit, supply voltage range must be controlled and appropriate supply voltage must b...

Page 17

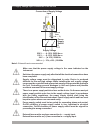

17 3.5 process input connection 3.5.2 rtd connection note 1 : note 2 : note 3 : in 3-wire system, use always cables of the same diameter (min 1mm²) always use wires of the same gauge and type whether a 2-wire or 3-wire system. Install a jumper between terminals 2 and 3 when using a 2-wire rtd. If th...

Page 18

18 3.6 galvanic isolation test values of esm-4420 temperature controller 2000 ( esm-4420 ) 5 v for .5..... V 00v ( for esm-4420.3..... ) v 13 14 ground 1 8 9 9 10 2000v v 2000v v 2000v v 2000v v 2000v v 2 3 2000v v 10 11 12 8 9 10 9 10 11 12 2 3 supply voltage process output (relay) process output (...

Page 19: Device

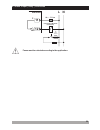

4. Output connection forms in esm- temperature controller 4420 4.1 process output ( relay ) connection 19 fuse load last control element (ssr) 9 device l n 10 fuses must be selected according to the application. C c 12 v max. 10ma z fuses must be selected according to the application. C device 9 8 f...

Page 20: Device

4.3 alarm output ( relay ) connection 20 fuses must be selected according to the application. C device 11 12 fuse load l n last control element (contactor) c 5a t fuse v no c.

Page 21

Esm-4420 aset temperature controller p pset °c °f po ao ps as 5.1 front panel definition process output status led alarm output status led this button is used to access to the process set value. If it is pressed for 5 seconds continuously programming section is entered. This button is used to access...

Page 22

When the power is applied to the device all led indicators and display segments are momentarily illuminated for testing. Software revision number of the controller on the bottom display is momentarily illuminated. 5.2 run the device and observation of software version on the displays 22 when power o...

Page 23

23 5.3 adjustment of process set value when pset button is pressed, ps led starts to blink, the information to indicate which set is shown is on top display, process set value is shown on bottom display. Change the process set value with increment and decrement buttons. Press aset/ok button for savi...

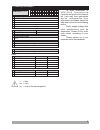

Page 24

6. Parameters 24 6.1 parameter list process menu title j type (fe,cu,ni) thermocouple, or -200°c,900°c -328°f,1652°f process input type selection ( default value = j type (fe.C.N) ) pt - 100 , -199.9°c,650.0°c or -199.9°f,999.9°f k type (ni,cr,ni) thermocouple , -200°c,1300°c or -328°f,2372°f r type...

Page 25

25 alarm menu title alarm hysteresis value. It can be adjusted from 0% of defined scale ( aupl- alol ) to 50% of defined scale ( aupl- alol ). ( default value = 0 ) output control period. It can be adjusted from 1 to 150 seconds. If process control type selection , then this parameter can be observe...

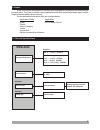

Page 26

26 6.2 parameters easy access diagram of for entering to the programming section, press pset/p button for 5 seconds. Password entering screen is shown when aset/ok button is pressed. Enter the password with increment or decrement buttons. °c °f po ao ps as p pset control menu proportional band integ...

Page 27

27 operation screen press pset/p button for 5 seconds for entering programming section aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as when 5secs is expired, programming section entering screen is shown. Aset p pset °c °f po ao ps as programming section entering screen press aset/ok butt...

Page 28

28 aset p pset °c °f po ao ps as process set value low limit minimum value of the process set value can be adjusted with this parameter. It can be adjusted from process input type minimum value to process high limit parameter value. It changes according to the process input type and scale. Aset p ps...

Page 29

29 aset p pset °c °f po ao ps as process value display offset it can be adjusted -10% of scale to 10% of scale . ( pupl- plol ) ( pupl- plol ) defined value is added to the process display value. Aset p pset °c °f po ao ps as process menu operation screen aset p pset °c °f po ao ps as control menu p...

Page 30

30 6.4 control menu operation screen press pset/p button for 5 seconds for entering programming section aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as when 5secs is expired, programming section entering screen is shown. Aset p pset °c °f po ao ps as programming section entering screen p...

Page 31

31 aset p pset °c °f po ao ps as 31 aset p pset °c °f po ao ps as process type selection process type selection can be selected or with increment and decrement buttons. Press aset/ok button for saving the parameter and accessing to the next parameter. Aset p pset °c °f po ao ps as hysteresis value p...

Page 32

32 aset p pset °c °f po ao ps as output control period it can be adjusted from 1 to 150 with increment and decrement buttons. If process control type selection = , then this parameter can be observed. Aset p pset °c °f po ao ps as control menu aset p pset °c °f po ao ps as alarm menu next menu can b...

Page 33

33 6.5 alarm menu operation screen aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as process menu aset p pset °c °f po ao ps as control menu aset p pset °c °f po ao ps as...

Page 34

34 aset p pset °c °f po ao ps as alarm menu aset p pset °c °f po ao ps as alarm hysteresis value press aset/ok button for accessing to the alarm menu. Aset p pset °c °f po ao ps as alarm type selection : process high alarm : process low alarm : deviation high alarm : deviation low alarm : deviation ...

Page 35

35 aset p pset °c °f po ao ps as alarm on delay time it can be adjusted from 0 to 9999 seconds with increment and decrement buttons. Aset p pset °c °f po ao ps as alarm set high limit value maximum value of alarm set is defined with this parameter. It can be adjusted from alarm set low limit paramet...

Page 36

36 6.6 protection menu operation screen aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as process menu aset p pset °c °f po ao ps as control menu aset p pset °c °f po ao ...

Page 37

37 aset p pset °c °f po ao ps as programming section entering password aset p pset °c °f po ao ps as protection menu aset p pset °c °f po ao ps as process menu aset p pset °c °f po ao ps as alarm menu press pset/p for exiting menu list and turn to operation screen. It is used for accessing to the pr...

Page 38

38 7. General information 7.1 tune operation esm-xx20 devices use (step response tuning) method to automatically determine pid parameters. Self tune starting the tune operation by the user ! ! ! Enter to the programming section select the parameter in menu, and turn to main operation screen. Observe...

Page 39

Aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as 39 aset p pset °c °f po ao ps as tune parameter aset p pset °c °f po ao ps as change tune parameter as with increment button. Aset p pset °c °f po ao ps as press aset/ok button for saving the parameter. Press p...

Page 40

40 if power is off while operation continues, pid parameters and parameter are not changed. When power is off and then on, device starts to complete the operation. Self tune self tune i for starting tune ( step response tuning ) operation 1- 2- 3- : control form must be p,pi,pd or pid. For heating t...

Page 41

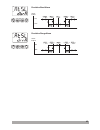

41 7.2 alarm types alarm types which are explained in section 6.5 alarm types selection parameter are explained below: process high alarm process low alarm deviation high alarm deviation low alarm on off alarm output process value on off alarm output process value on off alarm output process value (...

Page 42

Aset p pset °c °f po ao ps as aset p pset °c °f po ao ps as 42 deviation band alarm deviation range alarm on off alarm output process value ( + ) ( - ) on off alarm output process value ( + ) ( - ).

Page 43

°c °f po ao ps as aset p pset 8. Failure messages in esm- temperature controller 4420 43 please refer to section 6.3 for detailed information about the parameter i 1- sensor failure in analog inputs. Sensor connection is wrong or there is no sensor connection. For this example in menu = ; = ; = and ...

Page 44

9. Specifications device type housing&mounting protection class weight environmental ratings storage/operating temperature storage/operating humidity installation overvoltage category pollution degree operating conditions supply voltage and power process inputs thermocouple input types thermoresista...