- DL manuals

- EMKO

- Controller

- esm-4450

- Instruction Manual

EMKO esm-4450 Instruction Manual

ESM-445048x481/16DIN

ProcessController

- 4

4 digits process set (SV) display

(TC, RTD, mV

, V

, mA

)

- Dual or multi point calibration for

oltage / Current input

- Adaptation of PID coefficients to the system with Auto-tune and

Self-tune

- Manual/Automatic mode selection for control outputs

- Bumpless transfer

- Programmable heating, cooling and alarm functions for control

outputs

- Motorized valve control function

- 8 steps profile control ( Ramp & Soak ) function and start-hold-

stop by using logic input module

- Remote set point function by using analogue input modules

- Retransmission of process value or process control by using

0/4...20 mA

Current Output Module

- Hardware configuration by using input/output modules

Z

Z

Z

Z

Z

V

- Detection of heater failure by using 0...5A

CT input module

V

digits process (PV) and

- Universal process input

- Optional secondary sensor input

- Configurable ON/OFF, P, PI, PD and PID control forms

- Smart I/O module system

- RS-232 (standard) or RS-485 (optional) serial communication

with Modbus RTU protocol

ESM-4450 48 x 48 1/16 DIN

Universal Input PID Process Controller with

Smart I/O Module System

Instruction Manual. ENG ESM-4450 02 V09 10/05

Summary of esm-4450

Page 1

Esm-445048x481/16din processcontroller - 4 4 digits process set (sv) display (tc, rtd, mv , v , ma ) - dual or multi point calibration for oltage / current input - adaptation of pid coefficients to the system with auto-tune and self-tune - manual/automatic mode selection for control outputs - bumple...

Page 2

2 instruction manual of esm-4450 process controller consists of two main sections. Explanation of these sections are below. Also, there are other sections which include order information and technical specifications of the device. All titles and page numbers in instruction manual are in “ ” section....

Page 3

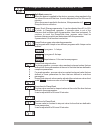

3 1.Preface............................................................................................................................................ 2.Installation.................................................................................................................................... 3...

Page 4

4 5.1.7 connection of emi-440 pt-100 input module 5.1.8 connection of emi-450 0...10v input module 5.2 connection wirings for output modules 5.2.1 emo-400 relay output module connection 5.2.2 emo-410 ssr driver module connection 5.2.3 emo-420 digital (transistor) output module connection 5.2.4 emo-4...

Page 5

5 manufacturer company name : emko elektronik a.S. Manufacturer company address: dosab, karanfil sokak, no:6, 16369 bursa, turkiye the manufacturer hereby declares that the product conforms to the following standards and conditions. Product name : process controller model number : esm-4450 type numb...

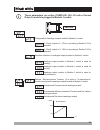

Page 6: Esm-4450

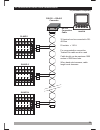

Esm series process controllers are designed for measuring and controlling temperature and any process value.They can be used in many applications with their universal process input, multifunction control outputs, selectable alarm functions, serial communication unit and input/output modules. Some ap...

Page 7

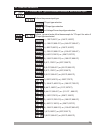

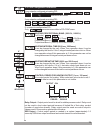

Esm-4450 (48x48 1/16 din) a bc d e fg hi / / u v w z / / 20 configurable (table-1) table-1 input type scale bc 1 relay output output-1 e table-1 41 42 43 44 45 0...50 mvz 0...5 vz 0...10 vz 0...20 maz 4...20 maz -1999 -1999 -1999 -1999 -1999 9999 9999 9999 9999 9999 input type ( voltage and current)...

Page 8

8 1.3 warranty emko elektronik warrants that the equipment delivered is free from defects in material and workmanship. This warranty is provided for a period of two years. The warranty period starts from the delivery date. This warranty is in force if duty and responsibilities which are determined i...

Page 9

In package , - one piece unit - one piece mounting clamp - one piece instruction manual a visual inspection of this product for possible damage occured during shipment is recommended before installation. It is your responsibility to ensure that qualified mechanical and electrical technicians install...

Page 10

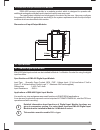

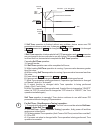

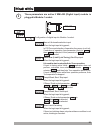

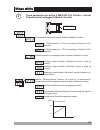

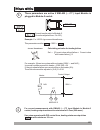

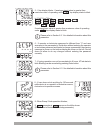

10 2.1 general description esm-4450 process controller set °c o1 °f o2 o3 remote ramp man auto 48mm/1.89inch 48mm / 1.89 inch maximum 5mm / 0.2 inch 2.2 dimensions panel surface (maximum thickness 5mm / 0.2 inch) front panel ip65 protection nema 4x mounting clamp product label terminal protection co...

Page 11

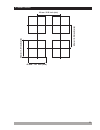

11 65mm/2.56inch(min) 65 mm / 2.56 inch (min) 46 mm / 1.81 inch (min) 46mm/1.81inch(min) 2.3 panel cut-out.

Page 12

12 operating temperature : max. Operating humidity : altitude : 0 to 50 °c 90 rh (non-condensing) up to 2000m. % operating conditions forbidden conditions: corrosive atmosphere explosive atmosphere home applications (the unit is only for industrial applications) during installation into a metal pane...

Page 13

13 1-loosen the screws. 2-lift the locking tabs located on both the right and left hand sides and pull the fixing clamp from the device while holding the unit in place. 3-pull the unit through the front side of the panel before starting to remove the unit from panel, power off the unit and the relat...

Page 14

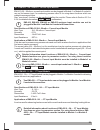

14 you must ensure that the device is correctly configured for your application. Incorrect configuration could result in damage to the process being controlled, and/or personal injury. It is your responsibility, as the installer, to ensure that the configuration is correct. Device parameters has fac...

Page 15

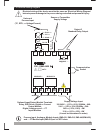

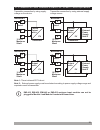

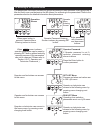

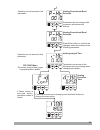

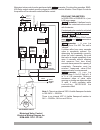

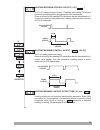

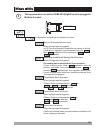

3.2 electrical wiring diagram universal process input (tc, rtd, voltage/current) z sensor or transmitter supply voltage output-3 standard relay output supply voltage input 100-240v (- ) 50/60hz 24 v (- 50/60hz - 6va 24v (- 12 v (- (it must be determined in order) v v z z 15%;+10% 15%;+10%) 15%;+10%)...

Page 16

Connection of universal supply voltage input connection of low voltage 24 v supply voltage input w supply voltage range must be determined in order. While installing the unit, supply voltage range must be controlled and appropriate supply voltage must be applied to the unit. Controlling prevents dam...

Page 17

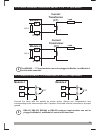

17 3.4.2 rtd connection note 1 : in 3-wire system, use always cables of the same diameter (min ) always use wires of the same gauge and type whether a 2-wire or 3-wire system. 1mm² install a jumper between terminals 2 and 3 when using a 2-wire rtd. If the distance is longer than 10 meters, use 3-wir...

Page 18

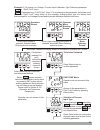

18 3.4.4 process input connection of 3-wire transmitters with current output transmitter transmitter external power supply note 1 maz pv pv 1 1 3 3 4 4 12 v max. 50ma z 12 v max. 50ma z transmitter connection by using supply voltage on the device transmitter connection by using external supply volta...

Page 19: L N

19 3.5 relay output connection fuses must be selected according to the application. C device fuse load l n last control element (contactor) c 3.4.5 connection of transmitters with voltage output to process input transmitter transmitter external power supply note 1 mv, vz mv, vz pv pv 1 1 2 2 4 4 12 ...

Page 20

Emo-430 0/4...20ma current outputmodule z 0...10 vz 2000vv 20 3.6 galvanic isolation test values of esm-4450 process controller and input/output modules supply input ground 1 output-3 relay output 5 6 emo-400 relay output module 7 8 9 10 emo-410 ssr driver module 2000v ( for esm-4450.1...... ) 5 . ....

Page 21

21 4.1 input modules dimensions of input/output modules 41.4mm 8.5mm 1.5mm 20.3mm 5mm 30.7mm 14mm 4.1.1 emi-400 digital input module specifications of emi-400 digital input module emi-400 digital input module can be installed to module-1 or module-2 socket for using the digital input functions. Appl...

Page 22

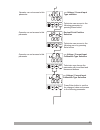

22 4.1.3 emi-420 0...5a ct input module v 4.1.2 emi-410 0/4...20ma current input module z specifications of emi-410 0/4...20ma current input module z input type : 0/4...20 ma current input accuracy : 0.3% dimensions : 14x30.7x41.4mm input resistance : 2r7 z w . Applications of emi-410 0/4...20ma cur...

Page 23

23 4.1.5 emi-440 pt-100 input module specifications of emi-440 pt-100 input module accuracy please refer to section 8.2.3 or 8.2.4 for selection of input type and scale dimensions : input resistance : 14x30.7x41.4mm greater than 10mw : 0.5% emi-410, emi-430, emi-440 or emi-450 analogue input modules...

Page 24

Emi-450 0...10v input module can be plugged in module-1 or module-2 socket to use as 2nd sensor input, for measuring process value or for using alarm functions which are related to measured value.(in some sections it is defined as analogue input module) also “remote set” function can be used by plug...

Page 25

4.2 output modules 4.2.1 emo-400 relay output module specifications of emo-400 relay output module output dimensions electrical life : 3a @ 250v , single open contact : 14x30.7x41.4mm : 100.000 operation (full load) v emo-400 relay output module can be plugged in module-1 or module-2 socket to use f...

Page 26

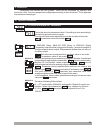

4.2.3 emo-420 digital (transistor) output module specifications of emo-420 digital (transistor) output module output : dimensions : maximum 40 ma, 15-18v 14x30.7x41.4mm z ±10%, isolated emo-420 digital (transistor) output module can be plugged in module-1 or module-2 socket to use functions which ar...

Page 27

First, detach all cable connections from the device and uninstall it from the panel. Suppress to the lock pins where top and bottom of the device pull the cover case with your other hand from front panel to rear side. Pull out the cover case from the device slide input/output modules into socket. Pu...

Page 28

Labels for input modules label which describes terminal connection of module that is plugged in module-1 socket is attached to this area. Label which describes terminal connection of module that is plugged in module-2 socket is attached to this area. Every module which is plugged in module-1 or modu...

Page 29

29 example : if user installs emo-400 relay output module to module-1 socket, emo-430 0/4...20ma current output module to module-2 socket and attach the appropriate labels on the device view will be like below : z 7 max.50ma 12v z tc pt-100 ptc, ntc 0 to 20maz 0 to 50mv 0 to 10v z z 100 to 240 vv mo...

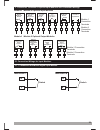

Page 30: Module-2

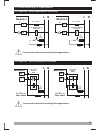

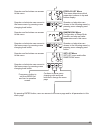

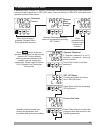

Pt-100 input module emi-440 pt-100 5.1.1 connection of emi-400 digital input module module-1 / module-2 optional input modules module-1 / module-2 optional output modules 5. Connection terminals of input/output modules and connection wirings 5.1 connection wirings for input modules switch 10 module-...

Page 31: Module-1

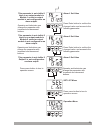

31 5.1.2 connection of 3-wire transmitter to emi-410 0/4...20 ma current input module z transmitter transmitter external power supply note 2 pv pv 8 8 module-1 module-1 7 7 4 4 note-1 note-1 12 v maximum 50ma z 12 v maximum 50ma z transmitter transmitter external power supply note 2 pv pv 10 10 modu...

Page 32: Module-2

Current output maz 5.1.3 connection of serial transmitter(loop powered) to emi-410 0/4...20 ma current input module z transmitter transmitter transmitter transmitter external power supply note 2 external power supply note 2 pv pv pv pv 10 8 8 10 module-2 module-1 module-2 module-1 9 7 7 9 4 4 4 4 32...

Page 33: Current

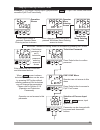

0...5av 0...5av 5.1.5 connection of emi-430 tc (thermocouple) or 0...50mv input module z two emi-420 ct input modules can not be plugged in module-1 and module-2 socket at the same time. V current transformer (ct) load 5.1.4 current transformer connection to emi-420 0...5 a ct input module v 33 8 mo...

Page 34: Module-1

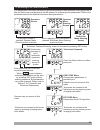

5.1.6 using emi-430 tc or 0...50mv input module as 0...50mv input z z 34 5.1.7 connection of emi-440 pt-100 input module 8 module-1 7 transmitter 0-50 mvz pv module-2 module-1 pt-100 pt-100 10 module-2 9 transmitter 0-50 mvz pv there is no line compensation in pt-100 input module emi-410, emi-430, e...

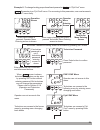

Page 35: Module-1

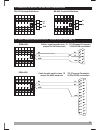

Fuse load last control element (ssr) 5.2 connection wirings for output modules 5.2.1 emo-400 relay output module connection 5.2.2 emo-410 ssr driver module connection 8 module-1 l n 7 fuses must be selected according to the applications. C 35 c fuses must be selected according to the applications. C...

Page 36: Module-1

5.2.3 emo-420 digital (transistor) output module connection 8 module-1 load 7 36 7 9 module-1 module-2 other device other device shunt = 500.0 w 0...10v output z 0...10v output z 8 10 5.2.4 emo-430 0/4... 20 ma current output module connection z 7 9 module-1 module-2 other device other device shunt ...

Page 37

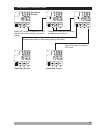

1 2 3 tx rx gnd 1 7 2 8 3 9 4 10 5 11 6 12 tx tx tx tx rx rx rx rx gnd gnd gnd gnd 1 7 2 8 3 9 4 10 5 11 6 12 1 7 2 8 3 9 4 10 5 11 6 12 1 2 d+ d- 3 1 7 2 8 3 9 4 10 5 11 6 12 6.1 cable connection between rs-232 terminal of the device and pc esm-4450 cable lenght must be max. 12 meters for 9600 baud...

Page 38

D+ d- 1 7 2 8 3 9 4 10 5 11 6 12 d+ d- 1 7 2 8 3 9 4 10 5 11 6 12 d+ d- 1 7 2 8 3 9 4 10 5 11 6 12 d+ rt master slave-1 slave-2 slave-n rt d- pc(personal computer) rs-232 rs-485 convertor Þ rs-232 connection cable 32 terminal can be connected in rs- 485 line rt resistor = 120 for communication conne...

Page 39

Rs-232 or rs-485 module rs-232 or rs-485 module a top card top card top card bottom card bottom card bottom card a a b b b pull the cover case with your hand through rear side as explained in “installing and pulling out input/output modules” section. Pull the modules in module-1 and module-2 socket ...

Page 40

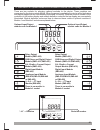

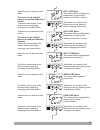

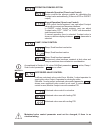

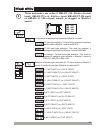

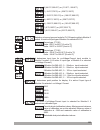

7.1 definition of front panel esm-4450 process controller set °c o1 sv °f o2 o3 at remote ramp man auto led indication of °c:centigrade unit led indication of °f fahrenheit unit led indication of units other than °c and °f led indication of output-1 status led indication of sv, process set value led...

Page 41

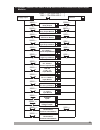

Ssr driver and digital output module (emo-410 ,emo-420) ssr driver and digital output module (emo-410,emo-420) relay output module (emo-400) relay output module (emo-400) 0/4...20ma current output module (emo-430) z 0/4...20ma current output module (emo-430) z analogue input module (emi-410,emi-430,...

Page 42

Esm-4450 process controller set °c sv °f o1 o2 o3 at remote ramp man auto when power on, display of the device is like below: esm-4450 process controller set °c sv °f at remote ramp man auto esm-4450 process controller set °c sv °f at remote ramp man auto esm-4450 process controller set °c sv °f at ...

Page 43

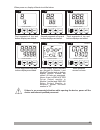

43 7.3 adjustment of process set value when set button is pressed sv led flashes, set value is shown in bottom display. Change set value with increment and decrement buttons. Press set button for saving set value. Press menu button to exit without saving set value. Operation screen set °c o1 sv auto...

Page 44

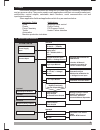

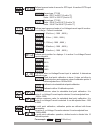

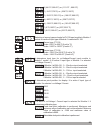

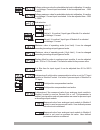

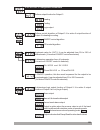

7.4 acessing to the operator menu the parameters have been divided into groups according to their functions. Every group has a title and firstly user must determine the title (menu) for accessing to the parameters. Refer to the parameters section for detailed information about parameters. Operator p...

Page 45

Operator or technician can access to the following menu by pressing menu changing next button. DÝsplay list menu this menu determines which parameter is shown in top and bottom display. Ramp&soak menu configuration of ramp/soak function and step set value parameters are in this menu. Set °c o1 sv au...

Page 46

7.5 accessing to the technician menu enter password with increment and decrement buttons press the enter button to confirm password. Operation screen set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto technician can access to the following menu by pressing menu...

Page 47

Technician can access to the following menu by pressing menu changing next button. Iop1 conf menu this menu defines configuration parameters of input/output modules in module-1 socket. Out3 conf menu this menu defines configuration parameters of output-3. Com conf menu this menu defines configuratio...

Page 48

Operator and technician menu changing next can access to the following menu by pressing button operator and technician can access to this menu. Set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto pass conf menu operator and technician passwords are in this menu....

Page 49

Pinp conf menu pinp conf menu exists after ramp/soak menu. Press menu button to exit from menu list and turn to operation screen. By pressing enter button, user accesses to the menu and to all parameters in this menu. Set °c o1 sv auto 49 operator can not access to this menu. Technician menu changin...

Page 50

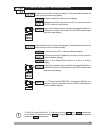

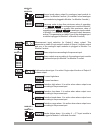

7.6 adjustment of alarm set values if standard output ( output-3 ), module-1 or module-2 is configured as an alarm output, alarm set values of these outputs are in “set lýst” menu. User can access to “set lýst” menu both from operator and technician menus. Enter password with increment and decrement...

Page 51

Set °c o1 sv auto set °c o1 sv auto press enter button to confirm the changed value and access to the following parameter. Operation menu alarm-1 set value alarm-2 set value 51 set °c o1 sv auto set list menu set °c o1 sv auto alarm-3 set value press menu button to turn to operation screen set °c o1...

Page 52

Enter password with increment and decrement buttons press enter button to confirm password operation screen set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto press enter button to access to pýnp conf menu set °c o1 sv auto set °c o1 sv auto parameter can be ch...

Page 53

Press enter button to confirm the changed value and access to the following parameter. Technician can access to the following menu by pressing enter button pinp conf menu when menu button is pressed, menu page can be accessed. If menu button is p r e s s e d a g a i n , operation screen is shown. Op...

Page 54

Enter password with increment and decrement buttons press enter button to confirm password operation screen set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto technician can access to the following menu by entering menu changing next button technician can acces...

Page 55

Parameter can be changed with increment and decrement buttons. Press enter button to confirm the changed value and access to the following parameter. Technician can access to the following menu by entering menu changing next button. Pid conf menu technician turns to menu page by pressing menu button...

Page 56

Enter password with increment and decrement buttons press enter button to confirm password operation screen set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto set °c o1 sv auto access to the parameters in pýnp conf menu by pressing enter button set °c o1 sv auto set °c o1 sv aut...

Page 57

Set °c o1 sv auto set °c o1 sv auto operator can not access to this parameter set °c o1 sv auto technician can access to the following parameter by pressing menu button technician can access to the following menu by pressing enter button technician can change the parameter with increment and decreme...

Page 58

Set °c o1 sv auto press enter button to confirm the changed value and access to the following parameter set °c o1 sv auto i f m e n u b u t t o n p r e s s e d a g a i n , operation screen is shown. Operation screen set °c o1 sv auto set °c o1 sv auto maximum value for selectable dual point calibrat...

Page 59

8.1.1 process and alarm set parameters parameters are divided into two groups. These can be accessed by operator and technician. Also, they are grouped into subgroups according to their functions. The subgroups are named as menu pages. This is the device’s process set value. Controlling is done acco...

Page 60

If ct input module (emi-420) is plugged in module-1 or module-2 socket and module-1 alarm type parameter which is explained in section 8.2.3 is , parameter can be adjusted from 0.0 to 100.0a v v if one of the analogue input modules is plugged in module-1 or module- 2 socket and measurement input sel...

Page 61

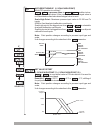

61 8.1.2 selection of pid tune and operation form tune selection by selecting one of the methods below, device can determine the pid parameters. Self tune (step response tuning) operation device operates according to the defined pid parameters auto tune (limit cycle tuning) operation auto-self tune ...

Page 62

62 auto tune (limit cycle tuning) operation ; process control output runs according to heating if heating or heating-cooling function and pid control form is selected, process control output runs according to cooling if cooling function and pid control form is selected. Canceling operation auto tune...

Page 63

63 if heating or heating-cooling function and pid control form is selected for the system; if set value is greater than process value, process output becomes active till to the value. When process value reaches to this value, process output reduces to temperature+[(set - temperature) / 2] 0% and it ...

Page 64

64 if it changes parameter. If parameter is it is changed to , if it is , it is changed to self tune operation is finished without any problem, device saves new pid parameters to memory and runs. Canceling operation : if sensor breaks ; if operation can not be completed in 8 hours ; while heating op...

Page 65

65 ramp / soak control ramp / soak function is not active. Ramp / soak function is active ramp / soak function is paused. Process set value becomes constant at last value and ramp or soak time does not take into consideration. Operation form selection automatic operation (close-loop control) device ...

Page 66

66 motorized valve control electrical wiring diagram for esm-4450.1.20.1.1/01.00 motorized valve control can be performed with parameter. For doing this operation, emo- 400 relay output module must be plugged in module-1 socket. Module-1 and output-3 controls the position of the valve with motorized...

Page 67

Bumpless transfer process output value in manual control is not taken into consideration while passing from manual control to automatic control. New control output that is measured in automatic control is applied to process output. Last %output value is taken output value of manual control and manua...

Page 68

68 8.1.3 function selection for top and bottom display it defines the function of the top display. This parameter determines which value is shown in top display. It defines the function of the bottom display. This parameter determines which value is shown in bottom display. Process value (pv) is sho...

Page 69

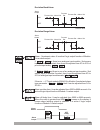

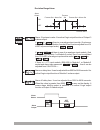

69 8.1.4 ramp/soak function and step set values configuration of 1.Program 1-4 steps ramp/soak program step selection parameter. One program with 8 steps or two different programs with 4 steps can be defined. Ramp / soak tolerance parameter. It can be adjusted from 0% to 50 ramp/soak operation, if p...

Page 70

Ramp/soak in normal operation : whatever operation form parameter is ; normal ramp/soak operation is started by selecting parameter . Ramp led becomes active. Ramp/soak operation can be paused by selecting parameter . Ramp/soak operation can be canceled by selecting parameter while ramp / soak opera...

Page 71

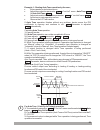

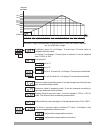

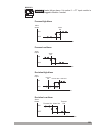

71 example : if ramp / soak step set , ramp time and soak time parameters = , = , = ; = , = , = ; = , = , = ; = , = , = ; are adjusted as on the left device operates as shown below: process set value pu-3 time start tr_1 ts_1 tr_4 ts_4 pu-1 pu-2 pu-4 pu-5 pu-6 pu-7 pu-8 tr_2 ts_2 tr_3 ts_3 4 ramp so...

Page 72

8.2.1 process input type and relevant parameters with process input defines the process input type. Defines type and scale of the thermocouple for tc input. It is active if tc input type is selected. Tc input type selection rtd input type selection 8.2 technician parameters 72 voltage/current input ...

Page 73

73 defines type and scale of sensor for rtd input. It is active if rtd input is selected. Defines input range and scale of voltage/current input. Z it is active if voltage / current is selected. Z 0...50mv ( -1999 ; 9999 ) z 0...5v ( -1999 ; 9999 ) z 0...10v ( -1999 ; 9999 ) z 0...20ma ( -1999 ; 999...

Page 74

74 unit selection unit is °c unit is °f process set value mvz 50 0-50 mv range are divided into 16 egual parts. Every “poxx” set value is defined 50 / 16 = 3.125 mv range. Z z po00 = 0 po01 po02 po03 po04 po05 po16 po06 po15 po07 po08 po09 po10 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3...

Page 75

Heating proportional band ( 000.0 , 999.9 ) % % full scale ( - ) %. If = 1000 °c, = 0 °c and = 50.0 then proportional band = ( - ) * / 100.0 proportional band = (1000-0)*50.0/100.0 = 500 °c 8.2.2 pid configuration parameters heating integral time (0000 sec, 3600 secs) it can be changed by the user. ...

Page 76

It is % of heating minimum output. If heating and cooling pid control functions operate together, this parameter is not considered. Even as a result of the heating pid calculation device calculates the % output value less than this parameter, heating output is active minimum for ollh parameter. It i...

Page 77

Cooling proportional band ( 000.0 , 999.9 ) % % full scale ( - ) % if = 1000 °c, = 0 °c and = 50.0 then proportional band = ( - ) * / 100.0 proportional band = (1000-0)*50.0/100.0 = 500 °c cooling integral time (0000 sec, 3600 secs) it can be changed by the user. When tune operation finishes, it can...

Page 78

Cooling output can not be active less than this parameter. Even if this parameter is 0, this parameter is accepted 50 msecs for security. While motorized valve control is running if parameter is selected heating or cooling, this parameter is not accessible. 78 ollc output period given output calcula...

Page 79

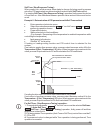

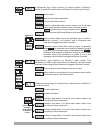

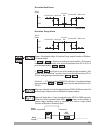

79 500 505 suof = 5°c suof = -5°c process output 100% 50% 0% process value °c 495 set value offset anti-reset windup (0, scale high point) - + while pid operation is running if condition is true, integral value is calculated. If the condition is not true, integral value is not calculated and last ca...

Page 80

This parameter is added to the %process output that is calculated at the end of the pid according to process set value. * / ( - ) if = 500°c , = 1000 , = 0 , = 5.0 * / ( - ) = 5.0 * 500 /(1000-0) = 2.5 2.5% is added to calculated process value. Example: °c % then % 80 (for heating pid 0.0 , 100.0 ) ...

Page 81

81 process value stabilization ( 1, scale high point) proportional band shifting ((- scale high point / 2 ) , ( scale low point / 2 ) ) if heating-cooling or only cooling function is performed ; cooling process set value is calculated by adding set value with parameter control form can be on/off or ...

Page 82

82 sensor break output value (for heating pid 0.0 , 100.0 ) (for cooling pid -100.0 , 0.0 ) (for heating-cooling pid -100.0 , 100.0 ) % % % % % % if > 0 (dead band) if process output 100% 50% 0% process value heating set value ( ) cooling set value ( + ) process output 100% 50% 0% process value cool...

Page 83

83 8.2.3 module-1 configuration parameters module-1 configuration parameters are arranged automatically by the device according to the module type in module-1 socket. These parameters are not accessible if there is no module in module-1 socket. Defines output function. Defines control algorithm of o...

Page 84

Current transfer ratio parameter for ct input module v 84 maximum value of operating scale display offset for measured value from analogue input module. Filter time for input signal it determines if cold junction compensation is active or not. It is active if input module is tc. Remote set function ...

Page 85

85 these parameters are active if emo-400 (relay output) , emo-410 (ssr driver) or emo-420 (digital output) module is plugged in module-1 socket. Defines output function for module-1 heating cooling logic output defines control algorithm of output module in module-1 socket. It is active if output fu...

Page 86

86 alarm output sensor break alarm output manual / automatic data output it determines logic output function of output module in module-1 socket. It is active if output function of module-1 is lout (logic output) output indicates that ramp/soak function has finished measurement input selection for m...

Page 87

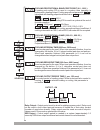

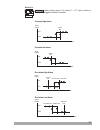

Hys on off alarm set alarm output process value process high alarm process low alarm hys on off alarm set alarm output process value 87 hys on off process set process set + alarm set alarm output process value deviation high alarm module-2 emi-420 hys on off process set process set - alarm set alarm...

Page 88

Hys process set - alarm set hys on off process set process set + alarm set alarm output process value hys process set - alarm set hys on off process set process set + alarm set alarm output process value deviation band alarm deviation range alarm 88 alarm status alarm output on delay off delay alarm...

Page 89

Configuration of analogue output module in module-1 socket. Function selection of analogue output module in module-1 socket. Defines “ (it is active if “ re-transmission” . Re-transmission” function function is selected for analogue output module in module-1 socket. Analogue output module in module-...

Page 90

90 configuration of digital input in module-1 socket. Ramp&soak, start / stop input. These parameters are active if emi-400 (digital input) module is plugged in module-1 socket. Manual / automatic selection input auto tune ( limit cycle tuning ) start/stop input. It is used to start or stop the auto...

Page 91

Configuration of analogue input module in module-1 socket. 91 selection of sensor type and scale for tc input module in module-1 socket. It is active if input type of module-1 is selected tc. Emi-430 these parameters are active if emi-410 (0 current input) , emi-430 (tc or 0...50mv input), emi-440 (...

Page 92

92 selection of sensor type and scale for pt-100 input module in module-1 socket. It is active if input type of module-1 is selected pt-100. Sensor type : pt-100 scale: -200°c to 650°c (if unit is °c) scale: -328°f to 1202°f (if unit is °f) sensor type : pt-100 scale: -199.9°c to 650.0°c (if unit is...

Page 93

Display offset for value in analogue input module. It can be adjusted from -10% to +10% of scale. This value is added to the process value. It is filter time for input signal. It can be adjusted from 0.0 to 900.0 seconds. 93 it decides if cold junction compensation is active or not for tc input modu...

Page 94

94 these parameters are active if emi-420 ( ct ) input module is plugged in module-1 socket. V current transfer ratio for module-1. It can be adjusted from 0 to 100 example : for 100:5a type current transformer ; this parameter must be = 100/5 = current transformer calculating set value for heating ...

Page 95

95 control output 200vv 1kw*3 heater 7 8 ct module-1 if a system operates with pid control form, heating minimum control time must be minimum 0.2 second. For correct measurements with emi-420 ( ct) input module in module-1 socket, heating output mut be active minimum for 0.2 sec (200 msec). V for ex...

Page 96

96 8.2.4 module-2 configuration parameters module-2 configuration parameters are arranged automatically by the device according to the module type in module-2 socket. These parameters are not accessible if there is no module in module-2 socket. Defines output function defines control algorithm of ou...

Page 97

97 maximum value of operating scale display offset for measured value from analogue input module. Filter time for input signal it determines if cold junction compensation is active or not. It is active if input module is tc. Remote set function emi-410,emi-430,emi-440,emi-450 emi-420 current transfe...

Page 98

These parameters are active if emo-400 (relay output) , emo-410 (ssr driver) or emo-420 (digital output) module is plugged in module-2 socket. Determines output function for module-2 heating cooling logic output it defines control algorithm of output module in module-2 socket. It is active if output...

Page 99

If process value is less than minimum value of operating scale for analogue input module in module-1 socket or greater than maximum value of operating scale for analogue input module in module-1 socket, process output becomes active.(this parameter is visible if one of the analogue input modules is ...

Page 100

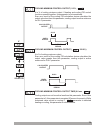

Heater failure alarm. It is active if ct input module is plugged in module-1 socket. V hys on off alarm set alarm output process value process high alarm process low alarm hys on off alarm set alarm output process value 100 hys on off process set process set + alarm set alarm output process value de...

Page 101

If there is ct input module (emi-420) in module-1 socket and alarm type parameter is , then it can be adjusted from 0.0 to 20.0a v v hys process set - alarm set hys on off process set process set + alarm set alarm output process value hys process set - alarm set hys on off process set process set + ...

Page 102

102 these parameters are active if emo-430 ( ) module is plugged in module-2 socket. 0/4...20ma current output z analogue output module in module-2 socket is used for cooling 0...20ma output or 0...10v according to section 5.2.5 is selected. Z 4...20ma output or 2...10v according to section 5.2.5 is...

Page 103

103 these parameters are active if emi-400 (digital input) is plugged in module-2 socket. Emi-400 ramp&soak, start / stop input manual / automatic selection input auto tune ( limit cycle tuning ) start/stop input ramp&soak, start / hold input when the logic input is triggered ; when the logic input ...

Page 104

Zvoltage / current input type selection. This must be selected if analogue input module in module-2 socket is emi-410 , emi-430 or emi - 450. 104 emi-430 emi - 410 emi - 440 emi - 450 emi - 430 these parameters are active if emi-410 ( ) , emi-430 ( ), emi-440 (pt-100 input) or emi-450 ( 0...10v inpu...

Page 105

It is active if voltage/current input is selected for module-2. It determines calibration type. Z it determines point position for display. It is active if input type of module-2 is selected voltage / current. Z if module-2 is emi-410 ; 4 ... 20ma input is selected. If module-2 is emi-430 ; 10 ... 5...

Page 106

No unit. It is active if input type of module-2 is selected voltage / current. Z unit is u. It is active if input type of module-2 is selected zvoltage / current. 106 display offset for value in analogue input module. It can be adjusted from -10% to +10% of scale. This value is added to the process ...

Page 107

107 control output 200vv 9 10 ct module-2 1kw heater emi-420 for correct measurements with emi-420 ( ct) input module in module-2 socket, heating output mut be active minimum for 0.2 sec (200 msec). V these parameters are active if emi-420 ( ct ) input module is plugged in module-2 socket. V current...

Page 108

108 control output 200vv 1kw*3 heater 9 10 ct module-2 for example ;if there is a system with three heater ( 200v and 1kw ) ; v in normal conditions current in heater ; [1000 / 200 ]*3 = 5a *3 = 15a if one of the heater is out of order, there is 5*2 = 10a current on two heaters. Current in heater fa...

Page 109

8.2.5 output-3 configuration parameters defines output function for output-3 defines control algorithm of output-3. It is active if output function of output-3 is heating or cooling. Hysteresis value for out-3. It can be adjusted from 0% to 50% of defined scale. ( it is active if on/off control is s...

Page 110

Heater failure alarm. It is active if ct input module is plugged in module-1 or module-2 socket. V it determines alarm type. It is active if logic output function of output-3 is alarm output. 110 alarm output runs according to the process input. Process high alarm process low alarm alarm output runs...

Page 111

Hys on off process set process set - alarm set alarm output process value hys process set - alarm set hys on off process set process set + alarm set alarm output process value deviation low alarm deviation band alarm 111 hys on off process set process set + alarm set alarm output process value devia...

Page 112

Alarm off delay time. It can be adjusted from greater 0000 to 9998 seconds. When the value is than 9998, is seen on the display. It means alarm latching output is selected. It is active if logic output function of output-3 is alarm output. 112 hys process set - alarm set hys on off process set proce...

Page 113

8.2.6 general parameters motor travel time. It can be adjusted from seconds. 5 to 600 (it is active if motorized valve control is selected) 113 minimum value for process set and alarm set values. It is named as low limit of set scale. 8.2.1 process input type and relevant parameters with process inp...

Page 114

8.2.7 parameters for configuration of serial communication 114 communication accessing address communication accessing address of device. It can be adjusted from 1 to 247. Parity selection for communication no parity. Odd parity. Even parity. Stop bit selection for communication communication baud r...

Page 115

8.2.8 operator and technician passwords 115 it is used for accessing to the operator parameters. It can be adjusted from 0 to 9999. If it is ; no password protection while entering to the operator parameters. If user does not enter password correctly: it turns to operation screen without accessing t...

Page 116

3 - if parameter is and parameter is and analogue input module is plugged in module-1 or module-2 socket, this is sensor failure of analogue input module. Sensor connection is wrong or there is no sensor connection. 116 9. Failure messages in esm-4450 process controllers 1 - sensor failure in analog...

Page 117

In “pýnp conf” menu ; = ; = ; = ; = ; = adjust Þ 117 6 - if operator or technician password is different from “0” and user accesses to the parameter by set button without entering the operator or technician password and wants to change a parameter, the warning message is shown on the bottom display ...

Page 118

118 set °c o1 sv auto 10 - when power is on ; not starting the normal operation and blinking the bottom display as shown on the left; it appears when two analogue input modules ( emi-410, emi-430, emi-440, emi-450 ) are plugged in module-1 and module-2 socket at the same time. For starting normal op...

Page 119

10. Specifications device type housing&mounting protection class weight environmental ratings storage/operating temperature storage/operating humidity installation overvoltage category pollution degree operating conditions supply voltage and power process inputs thermocouple input types thermoresist...