- DL manuals

- EMKO

- Temperature Controller

- ESM-9910

- Instruction Manual

EMKO ESM-9910 Instruction Manual

E

S

M

-9

9

1

0

9

6

x

9

6

1

/4

D

IN

T

e

m

p

e

ra

tu

re

C

o

n

tr

o

ll

e

r

- 3 D

- Selectable heating and cooling function

- Operating type selection with hysteresis

- Adjustment of temperature offset value

- Minimum pulling time adjustment for control outputs

- Password protection for programming mode

igits display

- NTC Input or,

PTC Input or,

J type thermocouple or,

K type thermocouple or,

PT-100 2-wire or 3-wire temperature input

( It must be determined in order )

- ON/OFF control form

ESM-9910 96 x 96 1/4 DIN

Digital, On/Off Temperature Controller

Instruction Manual. ENG ESM-9910 02 V07 07/14

Summary of ESM-9910

Page 1

E s m -9 9 1 0 9 6 x 9 6 1 /4 d in t e m p e ra tu re c o n tr o ll e r - 3 d - selectable heating and cooling function - operating type selection with hysteresis - adjustment of temperature offset value - minimum pulling time adjustment for control outputs - password protection for programming mode...

Page 2

Instruction manual of esm-9910 temperature controller consists of three main sections. Explanation of these sections are below. Also, there are other sections which include order information and technical specifications of the device. All titles and page numbers in instruction manual are in “content...

Page 3

Page 5 page 21 page 12 page 7 contents 1.Preface............................................................................................................................................ 1.1 general specifications 1.2 ordering information 1.3 warranty 1.4 maintenance 2.Installation...................

Page 4

4 manufacturer’s name : emko elektronik a.S. Manufacturer’s address : dosab, karanfil sk., no:6, 16369 bursa, turkey the manufacturer hereby declares that the product: product name : temperature controller unit type number : esm-9910 product category : electrical equipment for measurement, control a...

Page 5: Esm-9910

1.1 general specifications esm-9910 standard output-2 (relay output) output-1 (relay output) 1.Preface esm series temperature controllers are designed for measuring and controlling temperature. They can be used in many applications with on/off control form and heating and cooling selection. Some app...

Page 6

1.2 ordering information c 1.3 warranty emko elektronik warrants that the equipment delivered is free from defects in material and workmanship. This warranty is provided for a period of two years. The warranty period starts from the delivery date. This warranty is in force if duty and responsibiliti...

Page 7

In package , - one piece unit - two pieces mounting clamps - one piece instruction manual a visual inspection of this product for possible damage occured during shipment is recommended before installation. It is your responsibility to ensure that qualified mechanical and electrical technicians insta...

Page 8

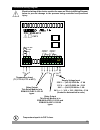

2.1 general description 2.2 front view and dimensions of esm-9910 temperature controller with one relay s 9 e m 0 91 - panel surface (maximum thickness 15 mm / 0.59 inch) 96 mm / 3.78 inch 9 6 m m / 3 .7 8 i n c h m- s 910 9 e et s et s ut o ro p g p front panel ip65 protection nema 4x mounting clam...

Page 9

2.4 panel cut-out 129 mm/5,08 inch (min) 1 2 9 m m /5 ,0 8 i n c h ( m in ) 9 2 m m / 3 .6 2 i n c h 92 mm / 3.62 inch 96 mm / 3.78 inch 9 6 m m / 3 .7 8 i n c h m- 10 s 99 e 2.3 front view and dimensions of esm-9910 temperature controller with two relays 12 ± 1 mm / 0.47 inch 84 mm / 3.31 inch maxi...

Page 10

1 2 3 91 s 0 e - m 9 c operating temperature : 0 to 50 °c max. Operating humidity : 90% rh (non-condensing) altitude : up to 2000 m. Operating conditions forbidden conditions: corrosive atmosphere explosive atmosphere home applications (the unit is only for industrial applications) 2.5 environmental...

Page 11

E 9 m- 10 s 9 1 2 1-loosen the screws. 2-pull mounting clamps from top and bottom fixing sockets. 3-pull the unit through the front side of the panel the unit is designed for panel mounting. 1-insert the unit in the panel cut-out from the front side. 2- insert the mounting clamps to the holes that l...

Page 12

3.1 terminal layout and connection instructions torque 0.5 nm a a max. 2.5 mm / 0.098 inch wire size: 14awg/1 mm² solid /stranded screw driver 0.8 x 3 mm you must ensure that the device is correctly configured for your application. Incorrect configuration could result in damage to the temperature be...

Page 13: P/n : Esm-9910

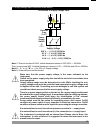

3.2 electrical wiring diagram electrical wiring of the device must be the same as ‘electrical wiring diagram’ below to prevent damage to the process being controlled and personnel injury. C temperature input is in cat ii class. Ii 13 temperature input 10 a a cat ii p/n : esm-9910 y c 1 2 3 11 (tc, p...

Page 14

3.3 labels for esm-9910 temperature controller with one relay rear label appearance of the device that have pt-100 (-19.9 ; + 99.9 ) scale o o c c rear label appearance of the device that have pt-100 (0 ; 400 ) scale o o c c rear label appearance of the device that have j type thermocouple ( 0 ; 800...

Page 15

3.4 labels for esm-9910 temperature controller with two relays rear label appearance of the device that have pt-100 (-19.9 ; + 99.9 ) scale o o c c rear label appearance of the device that have pt-100 (0 ; 400 ) scale o o c c rear label appearance of the device that have j type thermocouple ( 0 ; 80...

Page 16

3.5 supply voltage input connection of the device c c c make sure that the power supply voltage is the same indicated on the instrument. Switch on the power supply only after that all the electrical connections have been completed. Supply voltage range must be determined in order. While installing t...

Page 17

3.6.1 tc (thermocouple) connection 3.6 temperature input connection 3.6.2 rtd connections note 1 : in 3-wire system, use always cables of the same diameter (min 1mm²) its necessary to use cable in the same gauge and type for doing the line compensation properly. Note 2 : install a jumper between ter...

Page 18: Device

3.7 galvanic isolation test values of esm-9910 temperature controller supply input 10 11 ground 2 output-1 relay output 7 8 9 4 5 analogue inputs 1 3 output-2 relay output 2000v v 2000v v ( for esm-9910.5...,esm-9910.4.... ) 500v v ( for esm-9910.3....,esm-9910.2.... ) 2000v v 2000v v 2000v v 2000v ...

Page 19: Device

3.8.2 ssr driver output-1 connection fuse load last control element (ssr) 7 device l n 8 c max.15 v z max. 23ma 19.

Page 20: Device

3.9.1 output-2 (relay output) connection fuses must be selected according to the application c output-2 exists in device with two relays ii device 4 5 fuse load l n last control element (contactor) c 6 7a v t fuse c nc no 3.9 output-2 connections 3.9.2 ssr driver output-2 connection fuse load last c...

Page 21

E m- 1 s 99 0 4.1 front panel definition for esm-9910 with one relay led indication of output is active it is used to change the set value, enter to and exit from the programming mode it is used to change the set value and confirm the parameter in programming mode it is used to increase the value an...

Page 22

E m- s 9 10 9 led indication of output-1 is active it is used to enter to set2 value changing mode, and as ok button in set1 value changing mode, set2 value changing mode and programming mode it is used to increase the value and access to the parameter in programming mode it is used to decrease the ...

Page 23

Sm e 9 1 9 0 - 4.3 observation of esm-9910 temperature controller software revision “ r” Þ revision main operation screen is shown if there is an unexpected situation while opening the device, power off the device and inform a qualified personnel. C sm e 9 1 9 0 - when power is applied to the device...

Page 24

If no operation is done in programming or set value mode for 20 seconds, device turns to main operation screen automatically. I set value can be changed with increment and decrement buttons. Press enter button for saving set value. Press set button again to exit without saving set value. When set bu...

Page 25

4.4.2 esm-9910 with two relays i adjustment of set1 value set1 value screen set1 value screen when set1 button is pressed, set1 led lights on and set1 value is seen on display. Set1 value can be changed with increment and decrement buttons. Press set1 button again to exit without saving set1 value. ...

Page 26

I adjustment of set2 value set2 value screen set2 value screen when set2 button is pressed, set2 led lights on and set2 value is seen on display. Set2 value can be changed with increment and decrement buttons. Press set2/enter button for saving set2 value. Press set1 button to exit without saving se...

Page 27

4.5 entering to programming mode, changing and saving parameters 4.5.1 esm-9910 with one relay 27 press increment button for accessing to the password entering screen main operation screen programming mode entering screen password entering screen parameters can be observed by pressing enter button, ...

Page 28

Parameter value can be observed by pressing increment button. If enter button is pressed next parameter is shown. Parameter can be changed with increment and decrement buttons. Out set prog set out set prog set out set prog set out set prog set out set prog set hysteresis parameter hysteresis value ...

Page 29

Programming screen parameter value can be observed by pressing increment button. If enter button is pressed next parameter is shown. Parameter can be changed with increment and decrement buttons. Out set prog set out set prog set out set prog set out set prog set out set prog set operation type sele...

Page 30

Programming screen if enter button is pressed, next parameter is shown. Parameter can be changed with increment and decrement buttons. Programming screen process offset parameter press enter button for saving parameter value. Press set button to exit from programming mode. Out set prog set parameter...

Page 31

If enter button is pressed, next parameter is shown. Out set prog set parameter value can be observed by pressing increment button. Parameter can be changed with increment and decrement buttons. Out set prog set out set prog set out set prog set press set button to turn to the programming screen wit...

Page 32

Out set prog set if enter button is pressed, next parameter is shown. Out set prog set parameter value can be observed by pressing increment button. Parameter can be changed with increment and decrement buttons. Out set prog set out set prog set out set prog set out set prog set press enter button f...

Page 33

4.5.2 esm-9910 with two relays press increment button for accessing to the password entering screen main operation screen programming mode entering screen password entering screen parameters can be observed by pressing button, but parameters can not be changed. Set2/enter press set1 button to exit p...

Page 34

34 programming screen if set2/enter button is pressed, next parameter is shown. Press set1 button to exit from programming mode. Programming screen press set1 button to exit without saving parameter value. Press set2/enter button for saving parameter value. If set2/enter button is pressed, next para...

Page 35

Programming screen if set2/enter button is pressed, next parameter is shown. Press set1 button to exit from programming mode. Programming screen press set1 button to exit without saving parameter value. Press set2/enter button for saving parameter value. If set2/enter button is pressed, next paramet...

Page 36

If set2/enter button is pressed, next parameter is shown. Programming screen if set2/enter button is pressed, next parameter is shown. Parameter can be changed with increment and decrement buttons. Press set1 button to exit from programming mode. Programming screen press set2/enter button for saving...

Page 37

If set2/enter button is pressed, next parameter is shown. Programming screen if set2/enter button is pressed, next parameter is shown. Parameter can be changed with increment and decrement buttons. Press set1 button to exit from programming mode. Programming screen press set2/enter button for saving...

Page 38

Programming screen if set2/enter button is pressed, next parameter is shown. Parameter can be changed with increment and decrement buttons. Press set1 button to exit from programming mode. Programming screen press set2/enter button for saving parameter value. Process offset parameter parameter value...

Page 39

If set2/enter button is pressed, next parameter is shown. Programming screen if set2/enter button is pressed, next parameter is shown. Parameter can be changed with increment and decrement buttons. Programming screen parameter value can be observed by pressing increment button. Press set1 button to ...

Page 40

40 if no operation is done in programming or set value mode for 20 seconds, device turns to main operation screen automatically. I if set2/enter button is pressed, next parameter is shown. Programming screen if set2/enter button is pressed, next parameter is shown. Parameter can be changed with incr...

Page 41: Set1

I 5. Parameters 5.1 set parameters set1 set2 5.2 program parameters parameters are divided into two groups as set and program parameters. Set value for output-1. Control of output-1 relay is done according to this value. This value can be adjusted according to input type, minimum and maximum of scal...

Page 42

Operation type selection parameter of output-2. This parameter is not active in devices with one relay. Operation type of output-2 relay can be adjusted as “heating”. Normally energised. Operation type of output-2 relay can be adjusted as “cooling”. Normally de-energised. Process offset parameter (d...

Page 43

6. Failure messages in esm-9910 temperature controllers sensor failure in analogue inputs. It means sensor connection is wrong or there is no sensor. Esm 0 - 1 9 9 43.

Page 44

7.1.1 on/off control in esm-xx10 temperature controller 7.1 on/off control on/off control form in temperature control output which has heating function on off temperature temperature control output temperature set value hysteresis time time on/off control form in temperature control output which has...

Page 45

8. Specifications device type : temperature controller housing&mounting : 96 mm x 96 mm x 96 mm 1/4 din 43700 plastic housing for panel mounting. Panel cut-out is 92 x 92 mm type-1 enclosure mounting protection class : nema 4x (ip65 at front, ip20 at rear) weight : approximately 0.28 kg. Environment...

Page 46

9. Other informations 46 manufacturer information: emko elektronik sanayi ve ticaret a.Ş. Demirtaş organize sanayi bölgesi karanfil sk. No:6 16369 bursa/turkey phone : +90 224 261 1900 fax : +90 224 261 1912 repair and maintenance service information: emko elektronik sanayi ve ticaret a.Ş. Demirtaş ...