- DL manuals

- EMOTION

- 3D Printers

- i3 Metal Motion

- Assembly Instructions Manual

EMOTION i3 Metal Motion Assembly Instructions Manual

Summary of i3 Metal Motion

Page 1

Assembly instructions documentation version 1.1.0

Page 2

/ 2 version 1.1.0 introduction.

Page 3

/ 3 version 1.1.0 version 1.1.0 • target : provide a visual guide of the various steps required to assemble the «i3 metal motion» 3d printer. • designers of the i3 metal motion : emotion tech : http://www.Emotion-tech.Com hugo flye mohamad koubar tom lopez • author of this document : emotion tech : ...

Page 4

Introduction / 4 version 1.1.0 introduction 2 introduction 3 summary 4 presentation of the i3 metal motion 5 safety instructions 6 bill of material 7 a. Metallic parts 7 b. Mechanical parts 7 c. Plastic parts 8 d. Hardware 8 e. Electronic parts 9 f. Extruder kit 9 g. Hexagon kit 10 h. Cables and ext...

Page 5

/ 5 version 1.1.0 version 1.1.0 presentation of the i3 metal motion the latest creation of the emotion tech company, the i3 metal motion promises stability and accuracy. With all our knowledge and experience acquired with our previous printers, we wanted to propose an elegant and reliable solution t...

Page 6

Introduction / 6 version 1.1.0 safety instructions general safety instructions the nozzle can reach 270°c, do not touch the nozzle while the printer is working . A supervisor is needed when the printer is used with young people. Keep printer away from children and animals operate in a ventilated roo...

Page 7

Introduction / 7 version 1.1.0 version 1.1.0 bills of material a. Metal parts 1 x lower part 4 x rod Ø 8 x 290 mm 2 x rod Ø 8 x 360 mm 1 x frame 2 x reinforcement 1 x y axis carriage 1 x y axis plate 1 x z axis carriage right side 1 x z axis carriage left side 1 x x axis carriage b. Mechanical parts...

Page 8

Introduction / 8 version 1.1.0 d. Hardware 10 x m2,5 x 8 mm screw 5 x m2,5 x 12 mm screw 50 x m3 x 8 mm screw 30 x m3 x 12 mm screw 25 x m3 x 20 mm screw 4 x m3 x 22 mm screw 20 x m4 x 6 mm screw 15 x m3 nut 15 x Ø 3 mm x height 3 mm spacer 5 x Ø 3 mm x height 5 mm spacer 5 x Ø 3 mm x height 10 mm s...

Page 9

Introduction / 9 version 1.1.0 version 1.1.0 e. Electronic f. Extruder kit 1 x emotronic 1 x tf card 5 x nema 17 motor 3 x endstop (colored connector) 1 x 3 cm fan 1 x power supply 1 x eboard 1 x iec connector 1 x reset button 1 x body extruder 1 x mobile extruder 1 x m5 x 12 mm knurled screw 1 x dr...

Page 10

Introduction / 10 version 1.1.0 g. Hexagon kit (hotend) 1 x hexagon hotend 1 x 3 allen key 1 x 4.5 wrench 1 x silicon sleeve h. Cables and extensions i. Autres • 1 x bag of grease • 1 x bag of zip ties 1 x 20 mm motor’s cable 2 x 50 mm motor’s cable 1 x thermistor 1 x heater cartridge 1 x blue endst...

Page 11

Mechanical assembly / 11 version 1.1.0 version 1.1.0 mechanical assembly.

Page 12

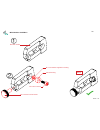

Mechanical assembly / 12 version 1.1.0 assembly of the lcd screen target : mount the lcd screen on the lower part needed parts : • lower part • lcd screen • lcd button • 4 x m3 x 12 mm screw • 4 x Ø3 x h5 spacer • 4 x m3 nut m3 x 12 mm Ø3 x h5 spacer m3 nut lcd screen lower part result result lcd bu...

Page 13

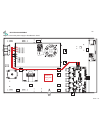

Mechanical assembly / 13 version 1.1.0 version 1.1.0 assembly of the electronic board target : mount the electronic board on the lower part needed parts : • lower part • emotronic board • 4 x m3 x 8 mm screw • 4 x Ø3 x h3 spacer m3 x 8 mm screw emotronic board Ø3 x h3 spacer result.

Page 14

Mechanical assembly / 14 version 1.1.0 assembly of the iec connector target : preparation of the two cables of the iec connector needed parts : • lower part • iec connector • 2 x short strap cable short strap cable iec connector insulated pod green cable = gnd red cable = phase black cable = neutral...

Page 15

Mechanical assembly / 15 version 1.1.0 version 1.1.0 iec connector «clips» result target : mount the iec connector on the lower part black cable = neutral.

Page 16

Mechanical assembly / 16 version 1.1.0 assembly of the reset button target : mount the reset button on the lower part needed parts : • lower part • reset button result reset button button nut.

Page 17

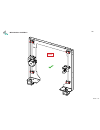

Mechanical assembly / 17 version 1.1.0 version 1.1.0 assembly of the y axis (part 1) target : mount the motor, pulleys and the y axis endstop on the lower part needed parts : • lower part • nema 17 motor • blue endstop • gt2 pulley • idler pulley • pulley bearing • 4 x m3 x 8 mm screw • 1 x m3 x 12 ...

Page 18

Mechanical assembly / 18 version 1.1.0 result the motor must be positioned towards the front of the machine.

Page 19

Mechanical assembly / 19 version 1.1.0 version 1.1.0 assembly of the power supply target : mount the power supply on the lower part needed parts : • lower part • power supply • 4 x m4 x 6 mm screw result m4 x 6 mm screw ! Power supply orientation.

Page 20

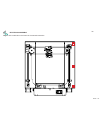

Mechanical assembly / 20 version 1.1.0 assembly of the y axis (part 2) target : mount rods, bearing blocks and holders on the lower part. Needed parts : • lower part • 4 x y axis rod holder • 2 x 8 x 360 mm rod • 3 x linear bearing block • 8 x m3 x 20 mm screw 8 x 360 mm rod 1 linear bearing block y...

Page 21

Mechanical assembly / 21 version 1.1.0 version 1.1.0 ! Block’s orientation m3 x 20 mm screw.

Page 22

Mechanical assembly / 22 version 1.1.0 result.

Page 23

Mechanical assembly / 23 version 1.1.0 version 1.1.0 assembly of the y axis carriage target : mount the different elements of the y axis carriage needed parts : • lower part • y axis carriage • y axis belt holder • 3 x m3 spacer • 2 x m3 x 20 mm screw • 12 x m4 x 6 mm screw ! Belt holder orientation...

Page 24

Mechanical assembly / 24 version 1.1.0 result m4 x 6 mm screw.

Page 25

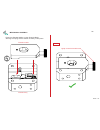

Mechanical assembly / 25 version 1.1.0 version 1.1.0 assembly of the belt of the y axis target : mount the y axis belt with the carriage and the lower part needed parts : • lower part • gt2 pulley place the carriage like this : place the belt around the pulleys like illustrated below : turn over the...

Page 26

Mechanical assembly / 26 version 1.1.0 result tension the belt by hand without forcing it by pushing the motor outwards and tightening the 4 screws.

Page 27

Mechanical assembly / 27 version 1.1.0 version 1.1.0 assembly of the y axis plate y target : mount the heating plate of the y axis on the machine needed parts : • lower part • y axis plate • heating patch • 3dbedfix patch • 3 x m3 x 8 mm countersunk heah screw chamfer = top face nothing = underside ...

Page 28

Mechanical assembly / 28 version 1.1.0 no chamfer = underside target : fix the heating patch on the lower side of the y axis plate remove the adhesive protection of the heating patch («3m» inscription side) fix the heating patch on the lower side of the y axis plate (pay attention to the orientation...

Page 29

Mechanical assembly / 29 version 1.1.0 version 1.1.0 make 4 loops with 4 zip ties through the eight holes as shown below. Move the board closer to the assembly heating plate cable prepare 4 zip ties loops ! Cable orientation.

Page 30

Mechanical assembly / 30 version 1.1.0 pass the plate’s cables in the zip ties loops make sure the cable does not exceed from the right-side of the plate tighten the zip ties to hold the cable.

Page 31

Mechanical assembly / 31 version 1.1.0 version 1.1.0 m3 x 8 mm countersunk screw result if the 3dbedfix patch is not already fixed to the heating plate, apply it by removing the «3m» adhesive protection first. Be carefull, the adhesive is very strong ! Result ! Make sure that the cable under the pla...

Page 32

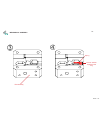

Mechanical assembly / 32 version 1.1.0 assembly of the z axis carriage (right side) target : mount the different parts of the right side z carriage needed parts : • z axis carriage right side • 1 x nema 17 motor • 2 x endstop • 1 x gt2 pulley • 1 x lmh bearing • 5 x m3 x 8 mm screw • 4 x m2.5 x 8 mm...

Page 33

Mechanical assembly / 33 version 1.1.0 version 1.1.0 ! Endstop lamella orientation m2.5 x 8 mm screw endstop result endstop with long lamella endstop with long lamella !.

Page 34

Mechanical assembly / 34 version 1.1.0 m3 x 8 mm screw nema motor result gt2 pulley result do not tighten the motor fixing screws for the moment motor’s connector the grub screw must be in contact with the flat part of the axis. Flat side screw 2 mm Ø 3 mm washer.

Page 35

Mechanical assembly / 35 version 1.1.0 version 1.1.0 assembly of the z axis carriage (left side) target : mount the different parts of the left side z carriage needed parts : • z axis carriage left side • idler pulley • 623 zz bearing • 1 x lmh bearing • 2 x m3 x 8 mm screw • 1 x m3 x 12 mm screw • ...

Page 36

Mechanical assembly / 36 version 1.1.0 printhead assembly 1°) thermistor into the heating block (fold the thermistor’s cables) 2°) silicon sleeve on to the heating block 3°) heater cartridge into the heating block 4°) grub screw in the heating block caution ! If the thermistor goes out of the hot en...

Page 37

Mechanical assembly / 37 version 1.1.0 version 1.1.0 result heater cartridge thermistor important: make sure that the red shrink sleeves on the cartridge cables are properly protecting the metal parts and preventing short circuits..

Page 38

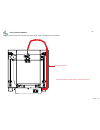

Mechanical assembly / 38 version 1.1.0 assembly of the x axis target : mount the different parts of the x axis carriage needed parts : • nema 17 motor • eboard • 3 cm fan • blower fan • x belt holder • fan duct • hexagon bracket • hexagon printhead • x axis carriage • 1 x extruder body • 1 x extrude...

Page 39

Mechanical assembly / 39 version 1.1.0 version 1.1.0 result x belt holder m3 x 8 mm result x carriage 3 cm fan m3 x 12 mm screw notch for cable fan passage ! Orientation fan cable & fan stator face = non visible rotor side = visible.

Page 40

Mechanical assembly / 40 version 1.1.0 extruder mobile m5 x 22 mm knurled screw Ø 3 mm washer supplied in the bag 693 zz bearing m3 x 8 mm screw result.

Page 41

Mechanical assembly / 41 version 1.1.0 version 1.1.0 extruder body spring Ø 3 mm washer supplied in the bag.

Page 42

Mechanical assembly / 42 version 1.1.0 place the «extruder mobile» on the «extruder body». Warning: the spring and the washer must stay in their place. Extruder mobile extruder body result lightly screw the knurled screw.

Page 43

Mechanical assembly / 43 version 1.1.0 version 1.1.0 m3 x 22 mm screw driving wheel emostruder nema motor hexagon printhead hexagon bracket result m3 x 12 mm screw the grub screw must be in contact with the flat part of the axis. Notch cable.

Page 44

Mechanical assembly / 44 version 1.1.0 m2.5 x 8 mm screw blower fan result fan duct m3 x 12 mm screw result.

Page 45

Mechanical assembly / 45 version 1.1.0 version 1.1.0 m3 x 8 mm screw filament guide result.

Page 46

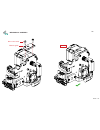

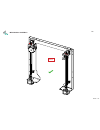

Mechanical assembly / 46 version 1.1.0 assembly of the z axis target : mount all the elements constituting the z axis needed parts : • 2 x nema 17 motor • 4 x z axis rod holder • frame • z axis carriages • 1 x grease bag • 2 x 8 x 290 mm rod • 2 x lead screw • 2 x trapezoidal nut • 2 x coupling • 6 ...

Page 47

Mechanical assembly / 47 version 1.1.0 version 1.1.0 rod holder x axis carriage right side rod x axis carriage left side m3 x 20 mm screw.

Page 48

Mechanical assembly / 48 version 1.1.0 result.

Page 49

Mechanical assembly / 49 version 1.1.0 version 1.1.0 coupling result flexible part without axis grub screw in contact with the flat side of the axis tighten the screws tighten the screws.

Page 50

Mechanical assembly / 50 version 1.1.0 result trapezoidal nut lead screw tighten the screws tighten the screws.

Page 51

Mechanical assembly / 51 version 1.1.0 version 1.1.0 m3 x 8 mm screw place the carriages at the top.

Page 52

Mechanical assembly / 52 version 1.1.0 b result.

Page 53

Mechanical assembly / 53 version 1.1.0 version 1.1.0 assembly of the x axis target : mount the x axis with the z axis needed parts : • 4 x rod holder axe x • frame • x axis carriage • 2 x 8 x 290 mm rod • 1 x lmh bearing • 1 x gt2 pulley • 2 x m3 x 8 mm screw • 8 x m3 x 12 mm screw m3 x 12 mm screw ...

Page 54

Mechanical assembly / 54 version 1.1.0 result adjust the height of the two carriages by turning the aluminum couplers so that the rod is as parallel as possible to the horizontal edge of the frame..

Page 55

Mechanical assembly / 55 version 1.1.0 version 1.1.0 keep the x carriage in place.

Page 56

Mechanical assembly / 56 version 1.1.0 m3 x 8 mm screw result.

Page 57

Mechanical assembly / 57 version 1.1.0 version 1.1.0 m3 x 12 mm screw rod holder result.

Page 58

Mechanical assembly / 58 version 1.1.0 result place the belt around the pulleys and as shown below :.

Page 59

Mechanical assembly / 59 version 1.1.0 version 1.1.0 place the belt around the pulleys and as shown below : cut off the end of the belt belt tension next page cut off the end of the belt ! !.

Page 60

Mechanical assembly / 60 version 1.1.0 tension the belt by hand without forcing it by pushing the motor outwards and tightening the 3 screws.

Page 61

Mechanical assembly / 61 version 1.1.0 version 1.1.0 m3 x 8 mm result ! Frame orientation.

Page 62

Mechanical assembly / 62 version 1.1.0 result reinforcement place the reinforcements in their notches notch n°1 notch n°2 notch n°3.

Page 63

Mechanical assembly / 63 version 1.1.0 version 1.1.0 result m3 x 12 mm screw m3 nut.

Page 64

Mechanical assembly / 64 version 1.1.0 result repeat the fixing operation for each of the reinforcements !.

Page 65

Mechanical assembly / 65 version 1.1.0 version 1.1.0 assembly of the leveling sensor target : mount the leveling sensor needed parts : • sensor holder • leveling sensor • 2 x m2.5 x 12 mm screw sensor holder leveling sensor m2.5 x 12 mm screw result result make a loop with the sensor cable and inser...

Page 66

Electronic assembly electronic assembly / 66 version 1.1.0

Page 67

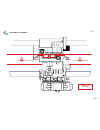

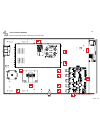

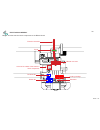

Electronic assembly / 67 version 1.1.0 version 1.1.0 target : place and stick the thirteen cable ties on the lower part 4 2 3 1 5 6 7 8 9 10 11 12 13 on the side of the frame.

Page 68

Electronic assembly / 68 version 1.1.0 target : connect the additional motor driver above the first intended for the z axis motor’s driver electronic board.

Page 69

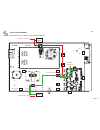

Electronic assembly / 69 version 1.1.0 version 1.1.0 target : pass the z axis motor cables in their dedicated fasteners z1 axis motor z2 axis motor * motor’s connector motor’s connector z1 motor connector z2 motor connector z2 motor cable = 20 cm z2 motor cable = 20 cm z1 motor cable = 50 cm z1 moto...

Page 70

Electronic assembly / 70 version 1.1.0 target : connect the x and y axis motor and endstop sensors * * * * * * to the outside of the frame y motor z endstop y endstop x endstop close the fasteners marked with a * to y endstop pass the cable through the notch y motor cable = 50 cm y motor cable = 50 ...

Page 71

Electronic assembly / 71 version 1.1.0 version 1.1.0 ext1 ext0 x2 x1 target : connect the lcd screen and the reset button to the emotronic board * close the fasteners marked with a *.

Page 72

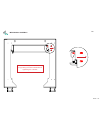

Electronic assembly / 72 version 1.1.0 target : connect the heating patch cables to the emotronic board thermistor to the heating plate zip ties.

Page 73

Electronic assembly / 73 version 1.1.0 version 1.1.0 target : connect the iec connector to the power supply n l.

Page 74

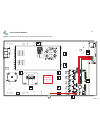

Electronic assembly / 74 version 1.1.0 v+ v+ v+ v- v- v- * * target : connect the power supply to the emotronic board close the fasteners marked with a *.

Page 75

Electronic assembly / 75 version 1.1.0 version 1.1.0 target : pass the extruder’s cable into its dedicated passage connect the extruder cable place the cable against the frame from this clip connect the motor’s cable extruder extension through the notch to the outside of the frame * * * close the fa...

Page 76

Electronic assembly / 76 version 1.1.0 target : fix the cable ties on the frame for the extrusion extension 1 2 3.

Page 77

Electronic assembly / 77 version 1.1.0 version 1.1.0 target : pass the extrusion extension along the frame, make a loop and go to the eboard extruder extension close the cable ties to secure the extruder extension.

Page 78

Electronic assembly / 78 version 1.1.0 if excess cable remains, secure it to the inside of the extrusion block with a cable tie target : pass the cables of the components of the extrusion block.

Page 79

Electronic assembly / 79 version 1.1.0 version 1.1.0 heating cartridge thermistor printhead fan blower fan extrusion extension zip tie eboard connector target : wire the extrusion block components on the eboard board arrival of the cables of the extrusion block components.

Page 80

Electronic assembly / 80 version 1.1.0 target : pass the x axis cable along the left brace, loop up, fix everything and connect to the components zip tie zip tie x motor cable, x and z endstop 2 x zip ties 1 °) connect the motor cable to the motor 2 °) the yellow cable connector on the z endstop (lo...

Page 81

Congratulations ! Your 3d printer is now fully assembled ! Now, please follow the user’s guide ! Electronic assembly / 81 version 1.1.0 version 1.1.0 / 81 you can now apply the white grease on the lead rods and also on the smooth rods without fear of putting the grease everywhere..

Page 82

Thank you for choosing the 3d printer i3 metal motion ! Www.Emotion-tech.Com electronic assembly / 82 version 1.1.0