- DL manuals

- Empire

- Indoor Fireplace

- DVCC32BP30N-2

- Installation Instructions And Owner's Manual

Empire DVCC32BP30N-2 Installation Instructions And Owner's Manual

Page 1

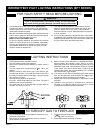

DIRECT VENT ZERO CLEARANCE GAS

FIREPLACE HEATER SERIES

MILLIVOLT (MV)

DVCC(32,36,42)BP3(0,2)(N,P)-2

INTERMITTENT PILOT (IP)

DVCC(32,36,42)BP7(0,2)(N,P)-2

GAS-FIRED

UL FILE NO. MH30033

INSTALLATION INSTRUCTIONS

AND OWNER’S MANUAL

This appliance may be installed in

an aftermarket, permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by state or

local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

— Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be per-

formed by a qualified installer, service

agency or the gas supplier.

INSTALLER: Leave this manual with the ap-

pliance.

CONSUMER: Retain this manual for future

reference.

HOT GLASS

DO NOT TOUCH

NEVER

WILL

CAUSE BURNS.

GLASS

UNTIL COOLED.

ALLOW CHILDREN

TO TOUCH GLASS.

WARNING

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

WARNING

If not installed, operated and maintained

in accordance with the manufacturer’s

instructions, this product could expose

you to substances in fuel or from fuel

combustion which can cause death or

serious illness.

Summary of DVCC32BP30N-2

Page 1

Page 1 direct vent zero clearance gas fireplace heater series millivolt (mv) dvcc(32,36,42)bp3(0,2)(n,p)-2 intermittent pilot (ip) dvcc(32,36,42)bp7(0,2)(n,p)-2 gas-fired ul file no. Mh30033 installation instructions and owner’s manual this appliance may be installed in an aftermarket, permanently l...

Page 2: Before You Start

35920-1-1015 page 2 before you start samples and definitions: danger indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury. Caution indicates a hazardous si...

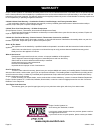

Page 3: Carton Contents

35920-1-1015 page 3 carton contents 1 2 6 7 3 nat lp 3 4 5 8 index number description quantity supplied dvcc(32,36,42)bp3 series dvcc(32,36,42)bp7 series 1 receptacle cover 1 2 2 receptacle 1 2 3 flue restrictor assembly - nat or lp 1 1 4 no. 10 x 1/2 phillips screw 8 8 5 #8 x 1 self-drilling drywal...

Page 4: Table of Contents

35920-1-1015 page 4 table of contents section page introduction ........................................................................................................................... 5 specifications ..................................................................................................

Page 5: Introduction

35920-1-1015 page 5 instructions to installer 1. Leave the instruction manual with owner after installation. 2. Have owner fill out and mail the product registration card supplied with the fireplace or register online. 3. Show owner how to start and operate the fireplace. This direct vent gas firepl...

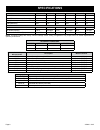

Page 6: Specifications

35920-1-1015 page 6 specifications dvcc32nat dvcc32lp dvcc36nat dvcc36lp dvcc42nat dvcc42lp input btu/hr maximum 24,000 22,000 24,000 24,000 28,500 26,500 input btu/hr minimum (millivolt only) 18,000 18,000 18,000 19,000 21,000 22,000 kwh (maximum) 7.03 6.45 7.03 7.03 8.35 7.77 kwh (minimum) 5.27 5....

Page 7: Accessories

35920-1-1015 page 7 accessories model number description fbb10 blower, auto variable-speed lk6 lighting kit, 120 v dg1bkp decorative glass, crushed, black dg1buc decorative glass, crushed, blue dg1clf decorative glass, crushed, clear attention: this unit requires a ceramic fiber decorative accessory...

Page 8

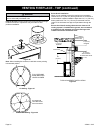

35920-1-1015 page 8 fbb10 blower kit installation (optional) bench installation (before installed in wall) 1. With power completely turned off, remove plate and four screws from left panel. See figure 1. Figure 1 2. Install the blower onto the pre-bent brackets on the blower plate. Ensure the velcro...

Page 9

35920-1-1015 page 9 fbb10 blower kit installation (optional) 3. Disengage glass frame by pulling in an upward swinging position. See figure 6. Figure 6 4. Remove the modern burner cover by lifting off. See figure 7. Figure 7 5. Remove the two screws securing the liner brackets to the firebox as show...

Page 10

35920-1-1015 page 10 9. Remove seven screws and lift burner assembly. See figure 12. Figure 12 10. Remove the four #10 x 1/2 screws securing the latch assembly to the underside of the firebox and set aside. See figure 13. Figure 13 11. Install blower through firebox cutout. See figure 14. Figure 14 ...

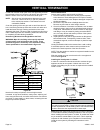

Page 11: Vent System Identification

35920-1-1015 page 11 pipe length wall strap ceiling fire stop 90° elbow 90° elbow or 45° elbow wall thimble horizontal termination (maximum of three 90 elbows vertical termination (maximum of three 90 elbows) storm collar roof flashing figure 16 special venting components (simpson duravent) see empi...

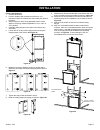

Page 12: Fireplace Dimensions

35920-1-1015 page 12 figure 17 fireplace dimensions g i j c gas line access p b e d q vent collar nailing flanges side spacer barrier screen assembly & glass frame assembly gas line access rating plate and labels inside gas control and switches inside a k l left view front view top view right view p...

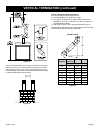

Page 13: Clearances

35920-1-1015 page 13 clearances clearance to combustibles (dimensions in inches) back 0 side 0 floor 0 top framing edge see below see mantle chart for maximum mantel depth glass front top framing ledge finished wall (non-combustible) see mantel chart for minimum height of mantle above unit 2" x 4" h...

Page 14: Locating Fireplace

35920-1-1015 page 14 figure 22 note: island and room divider installation is possible as long as the horizontal portion of the vent system does not exceed 20 feet with a minimum vertical run of 8 feet. See details in venting section. When you install your direct vent fireplace in room divider or fla...

Page 15: Gas Supply

35920-1-1015 page 15 gas supply the gas pipeline can be brought in through the right or left side of the appliance. Consult the current national fuel gas code, ansi z223.1 can/cga-b149 (.1 or .2) installation code. 2” 4 5/8” side of firebox figure 23 recommended gas pipe diameter pipe length schedul...

Page 16: Gas Supply

35920-1-1015 page 16 gas supply checking manifold pressures both propane and natural gas valves have a built-in pressure regulator in the gas valve. Natural gas models will have a manifold pressure of approximately 3.5-in w.C. (.871 kpa) at the valve outlet with the inlet pressure to the valve from ...

Page 17: Installation

35920-1-1015 page 17 installation framing the appliance 1. Choose unit location. 2. Frame in fireplace with a header across the top. It is important to allow for finished face when setting the depth of the frame. 3. Attach fireplace to frame using adjustable frame. Preset depth to suit facing materi...

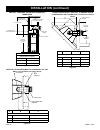

Page 18: Installation (Continued)

35920-1-1015 page 18 installation (continued) vent pipe clearance for horizontal vent, maintain a minimum 2-in clearance to the bottom and sides of the vent, and 3-in clearance to combustibles above the vent pipe. See figure 31. Vent pipe 2” minimum clearance around vent pipe figure 30 top of vent 3...

Page 19: Installation (Continued)

35920-1-1015 page 19 installation (continued) flush wall installation front trim or non-combustible material (installation is optional) joint between finished wall and unit sealed with 300° f, 149° c sealant material (sealant is optional) 24” to top of chase 2 x 4 header finished wall (combustible) ...

Page 20: Installation (Continued)

35920-1-1015 page 20 installation (continued) vertical, 90 degree elbow with horizontal termination 24” to top of chase “a” distance to bottom of unit 3” (76mm) minimum clearance to combustibles vent cap/ thimble wall firestop 12” rise required finished wall (non-combustible) finished wall (combusti...

Page 21: Venting Fireplace - Top

35920-1-1015 page 21 to use the vent graph 1. Determine the height of the center of the horizontal vent pipe. Using this dimension on the sidewall vent graph, locate the point it intersects with the slanted graph line. 2. From the point of this intersection, draw a vertical line to the bottom of the...

Page 22

35920-1-1015 page 22 full open and four indicated holes aligned 2/3 open and two indicated holes aligned warning use flue restrictor for vertically terminated units only. Do not use for horizontally terminated units. Figures 40 to 42 show the location and recommended openings for the flue restrictor...

Page 23

35920-1-1015 page 23 venting fireplace - top (continued) example of possible venting systems using one 90 degree elbow eight feet is listed as minimum vertical vent run with 20 feet of maximum horizontal vent run. Vertical dimensions are based on center line to center line of pipe. Horizontal dimens...

Page 24

35920-1-1015 page 24 venting fireplace - top (continued) positioning the fireplace determine the exact position of the appliance so the direct vent termination will be centered (if possible) between two studs. This will avoid any extra framing. All vent kit pipes should be assembled on the unit afte...

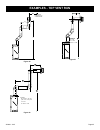

Page 25: Examples - Top Vent Run

35920-1-1015 page 25 examples - top vent run ” ► ▲ ◄ ► ▼ ◄ h2 v1 24” minimum clearance to combustibles figure 49 example h2 – 3ft, h3 – 1ft = 4ft (90° + 90° + 90°) = 6ft v1 = 21ft h = 10ft v = 21ft figure 50 example h1 = 2ft v1 = 20ft h=2ft v = 20ft figure 51.

Page 26: Vent Terminal Clearances

35920-1-1015 page 26 figure 52 vent terminal clearances canadian installations1 us installations2 canadian installations1 us installations2 a= clearance above grade, veranda, porch, deck, or balcony 12 in (30 cm) 12 in (30cm) i= clearance to service regulator vent outlet 3 ft (91 cm) 6 ft b= clearan...

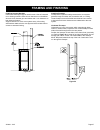

Page 27: Framing And Finishing

35920-1-1015 page 27 framing and finishing installing support brackets install a horizontal pipe support used for each 3 feet of horizontal run to framing members. Allow 6-inch clearance to combustibles above 6-5/8-in diameter pipe and elbows and 1 inch clearance on both sides and bottom. Support ve...

Page 28

35920-1-1015 page 28 framing and finishing (continued) vertical firestops vertical runs of this system which pass through ceilings require the use of one ceiling firestop at the hole in each ceiling through which the vent passes. Position a plumb bob directly over the center of the vertical vent com...

Page 29: Termination Clearances

35920-1-1015 page 29 termination clearance for buildings with combustible and noncombustible exteriors. Vertical sidewall installations important! Minimum clearance between vent pipes and combustible materials is 3 inch(75 mm) on top, and 2 inch (50 mm) on bottom and sides. Important! When vent term...

Page 30: Vertical Termination

35920-1-1015 page 30 vertical termination locate and mark the center point of the vent pipe using a nail on the underside of the roof. Drive the nail through the center point. Mark the outline of the roof hole around this center point. Note: size of the roof hole dimensions depend on the pitch of th...

Page 31

35920-1-1015 page 31 figure 61 if two vertical terminations are run near each other, they may be placed a minimum of 12 inches between them if they are at the same height. See figure 62. If two vent terminations are not at the same height, they must be positioned at least 24 inches apart to minimize...

Page 32

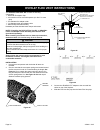

35920-1-1015 page 32 dvvk-4f flex vent instructions the dvvk-4f flex vent kit includes the following components: 1 - horizontal termination cap 1 - 4-foot section of flex vent with spacers (4-in flue/7-in outer pipe) 1 - 4-in diameter flue adapter collar 1 - 7-in diameter outer vent adapter collar 1...

Page 33

35920-1-1015 page 33 5. Install the wall firestop/thimble assembly as required through the wall. Refer to the venting charts in the fireplace manual to determine the proper height and size of the vent opening. The minimum opening should be 11-in wide by 11-in high. The minimum combustible clearance ...

Page 34

35920-1-1015 page 34 standing pilot operating instructions remote/off/on switch the fireplace is equipped with a remote/off/on switch. A wire harness is attached to the remote/off/on switch. The red, black and green (wires) female push-ons attach to the remote/ off/on switch. At the opposite end of ...

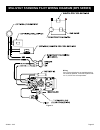

Page 35

35920-1-1015 page 35 figure 71 millivolt standing pilot wiring diagram (bp3 series) wiring if any of the original wire as supplied with this unit must be replaced, it must be replaced with no. 18, 150°c wire or its equivalent..

Page 36

35920-1-1015 page 36 1. Stop! Read the safety information above. 2. Set remote/off/on switch to off. 3. Turn off all electric power to the appliance (if applicable). 4. Lower bottom louver assembly. 5. Push in gas control knob slightly and turn clockwise to "off." note: knob cannot be turned from "p...

Page 37

35920-1-1015 page 37 with proper installation and maintenance, your new direct vent gas fireplace will provide years of trouble-free service. If you do experience a problem, refer to the trouble shooting guide below. This guide will assist a qualified service person in the diagnosis of problems and ...

Page 38

35920-1-1015 page 38 ipi electronic system operating instructions (bp7 series) 5.25 vdc electronic control valve the electronic control valve system includes the ability to switch the pilot from a standing pilot mode to an intermittent pilot mode. • ipi mode - in the intermittent pilot mode, when th...

Page 39

35920-1-1015 page 39 ipi electronic system wiring diagram (bp7 series) (gnd) pilot cpi/ipi switch gas control valve electronic control module battery holder battery back-up red black red black green white white blue blue white orange green yellow orange white ac/dc power adaptor remote receiver (opt...

Page 40

35920-1-1015 page 40 to turn off gas to fireplace 1. Stop! Read the safety information above. 2. Turn off electric power to the appliance. 3. Remove front surround panel assembly or bottom louver if included. 4. Turn gas supply knob counterclockwise to “on” position. 5. Wait ten minutes to clear out...

Page 41: (Bp7 Series)

35920-1-1015 page 41 brief description of the components the gas valve is fitted with a manual hi/lo knob to allow for manual modulation of the gas outlet pressure to the appliance burner. The controls are designed to be used with either lpg or natural gas and can be converted by use of an oem suppl...

Page 42: (Bp7 Series)

35920-1-1015 page 42 intermittent pilot control system troubleshooting (bp7 series).

Page 43: (Bp7 Series)

35920-1-1015 page 43 intermittent pilot control system troubleshooting (bp7 series).

Page 44: Maintenance And Service

35920-1-1015 page 44 note it is normal for appliances fabricated of steel to give off some expansion and/or contraction noise during the start up or cool down cycle. Similar noises are found with your furnace heat exchanger or car engine. It is normal for your gas fireplace to give off some odor the...

Page 45: Maintenance And Service

35920-1-1015 page 45 maintenance and service install glass door and barrier screen 1. When installing the glass door assembly, make sure that the door top flange is hooked over the firebox top flange as illustrated in the “correct” view in figure 75. Important: do not allow the gasket across the top...

Page 46

35920-1-1015 page 46 caution all wiring should be done by a qualified electrician and shall be in compliance with all local, city and state building codes. Before making the electrical connection, make sure that main power supply is disconnected. The appliance, when installed, must be electrically g...

Page 47: How to Order Repair Parts

35920-1-1015 page 47 to order parts under warranty, please contact your local empire dealer. See the dealer locator at www.Empirecomfort. Com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the problem with the unit. To or...

Page 48

35920-1-1015 page 48 millivolt parts list - dvcc(32,36,42)bp3 index no. Part number description dvcc32 dvcc36 dvcc42 1 35918 35918 35918 insulation box 2 r12177 r12177 r12177 insulation top, center 3 35997 35997 35997 bracket, shipping (qty. 2) 4 35894 35901 35908 outer wrapper top 5 r12174 r12175 r...

Page 49

35920-1-1015 page 49 millivolt parts view - dvcc(32,36,42)bp3 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 37a 38 35 39 1 2 4 5 6 7 8 11 13 14 15 17 18 9 10 12 3 3 9 9 9 36 40 41 42 43 44 16 18 37b 42 45 46.

Page 50

35920-1-1015 page 50 ip parts list - dvcc(32,36,42)bp7 index no. Part number description dvcc32 dvcc36 dvcc42 1 35918 35918 35918 insulation box 2 r12177 r12177 r12177 insulation top, center 3 35997 35997 35997 bracket, shipping (qty. 2) 4 35894 35901 35908 outer wrapper top 5 r12174 r12175 r12176 i...

Page 51

35920-1-1015 page 51 ip parts view - dvcc(32,36,42)bp7 1 2 3 4 5 6 7 8 9 9 12 14 19 18 9 10 13 47 48 49 50 15 21 20 23 24 25 26 27 28 29 30 31 32 33 34 35 40 36 38 41 39 42 44 43 45 46 37a 37b 3 9 11 16 17 18 20 22 47 51.

Page 52

35920-1-1015 page 52 important safety information warning read and follow these safety precautions prior to operating this appliance. Failure to follow these precautions may result in death, injury, or property damage. Safety precautions before enclosing the vent pipe assembly, operate the appliance...

Page 53

35920-1-1015 page 53 important safety information • do not place clothing or other flammable material on or near the appliance. • do not place debris or other articles on the log set during operation. • during manufacture, fabricating, and shipping, components of this appliance are treated with oils...

Page 54

35920-1-1015 page 54 safety information for users of lp gas propane (lp-gas) is a flammable gas which can cause fires and explosions. In its natural state, propane is odor- less and colorless. You may not know all the following safety precautions which can protect both you and your family from an ac...

Page 55

35920-1-1015 page 55 requirements for massachusetts for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth and where the side wall exhaust v...

Page 56: Warranty

35920-1-1015 page 56 warranty empire comfort systems inc. Warranties this hearth product to be free from defects at the time of purchase and for the periods specified below. Hearth products must be installed by a qualified technician and must be maintained and operated safely, in accordance with the...