- DL manuals

- Empire

- Indoor Fireplace

- DVX36DP31

- Installation Instructions And Owner's Manual

Empire DVX36DP31 Installation Instructions And Owner's Manual

LUXURY DIRECT VENT

GAS FIREPLACE HEATER

MODEL SERIES

MILLIVOLT STANDING PILOT

DVX36DP31(N,P)-1

DVX42DP31(N,P)-1

DIRECT IGNITION

DVX36DP51N-1

DVX42DP51N-1

INTERMITTENT PILOT

DVX36DP71(N,P)-1

DVX42DP71(N,P)-1

REMOTE RF

DVX36DP91(N,P)-2

DVX42DP91(N,P)-2

UL FILE NO. MH30033

INSTALLATION INSTRUCTIONS

AND

OWNER’S MANUAL

WARNING: If not installed, operated and maintained

in accordance with the manufacturer’s instructions,

this product could expose you to substances in fuel or

from fuel combustion which can cause death or seri-

ous illness.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA only)

or mobile home, where not prohibited by state or local

codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certified

kit is used.

The Studio Series Direct Vent Zero

Clearance Gas Fireplace Heater

GAS-FIRED

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas sup-

plier.

WARNING: If the information in these instructions

are not followed exactly, a fire or explosion may re-

sult causing property damage, personal injury or

loss of life.

WARNING

HOT GLASS

DO NOT TOUCH

NEVER

WILL

CAUSE BURNS.

GLASS

UNTIL COOLED.

ALLOW CHILDREN

TO TOUCH GLASS.

EMPIRE

EMPIRE

Comfort Systems

Page 1

Summary of DVX36DP31

Page 1

Luxury direct vent gas fireplace heater model series millivolt standing pilot dvx36dp31(n,p)-1 dvx42dp31(n,p)-1 direct ignition dvx36dp51n-1 dvx42dp51n-1 intermittent pilot dvx36dp71(n,p)-1 dvx42dp71(n,p)-1 remote rf dvx36dp91(n,p)-2 dvx42dp91(n,p)-2 ul file no. Mh30033 installation instructions and...

Page 2: Table Of Contents

26412-0-1009 page 2 important safety information ................................................................................................................................................................3 safety information for users of lp gas .....................................................

Page 3

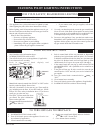

26412-0-1009 page 3 do not operate this appliance without glass front panel installed before enclosing the vent pipe assembly, operate the appliance to ensure it is venting properly. • if this appliance is installed directly on carpeting, tile or other combustible material other than wood flooring t...

Page 4

26412-0-1009 page 4 some people cannot smell well. Some people cannot smell the odor of the chemical put into the gas. You must find out if you can smell the odorant in propane. Smoking can decrease your ability to smell. Being around an odor for a time can affect your sensitivity or ability to dete...

Page 5

26412-0-1009 page 5 requirements for massachusetts for all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth and where the side wall exhaust ve...

Page 6: Introduction

26412-0-1009 page 6 instructions to installer 1. Installer must leave instruction manual with owner after installation. 2. Installer must have owner fill out and mail warranty card supplied with the fireplace. 3. Installer should show owner how to start and operate the fireplace. This direct vent ga...

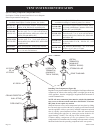

Page 7: Specifications

26412-0-1009 page 7 figure 1 left side view front view right side view electrical access vent collar top view gas line access a c j g i gas line access h d e b vent collar standoffs nailing flanges glass frame assembly gas line access rating plate and labels gas controls and switches remote control ...

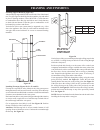

Page 8: Clearances

26412-0-1009 page 8 mantel chart (figure 3) figure 3 clearances (figure 4) clearance from top front edge of fireplace to ceiling is 36" clearance from side of fireplace to adjacent sidewall is 6". 36” (914mm) 6” (152mm) figure 4 figure 5 note: island (c) and room divider (f) installation is possible...

Page 9: Gas Supply

26412-0-1009 page 9 figure 6 the gas pipeline can be brought in through the right or left side of the appliance. Consult the current national fuel gas code, ansi z223.1 can/cga-b149 (.1 or .2) installation code. Installing a new main gas cock each appliance should have its own manual gas cock. A man...

Page 10: Installation

26412-0-1009 page 10 framing and finishing 1. Choose unit location. 2. Frame in fireplace with a header across the top. It is important to allow for finished face when setting the depth of the frame. 3. Attach fireplace to frame using adjustable nailing flange. Preset depth to suit facing material (...

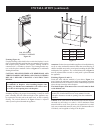

Page 11: Installation (Continued)

26412-0-1009 page 11 figure 11 attention: if a base is not used and the appliance is installed directly on tile or other combustible material other than wood flooring, it shall be installed on a metal or wood panel extending the full width and depth of the appliance. The vertical dimension in figure...

Page 12

26412-0-1009 page 12 flush wall installation figure 12 combustible surround installation figure 13 vent runs (figures 14, 15, and 16) in planning the installation for the fireplace, it is necessary to install certain components before the appliance is completely positioned and installed. These inclu...

Page 13: Installation (Continued)

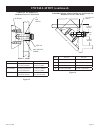

26412-0-1009 page 13 corner installation vertical, 90° elbow to horizontal out the wall figure 16 vertical, 90° elbow to horizontal out the wall figure 15 90º elbow “a” pipe length vent cap wall firestop/ thimble “c” “b” “a” “b” “d” 9” (229mm) minimum vent cap 6” (152mm) minimum wall firestop/ thimb...

Page 14: Venting Fireplace - Top

26412-0-1009 page 14 to use the vent graph (figure 17) 1. Determine the height of the center of the horizontal vent pipe. Using this dimension on the sidewall vent graph, locate the point it intersects with the slanted graph line. 2. From the point of this intersection, draw a vertical line to the b...

Page 15

26412-0-1009 page 15 venting fireplace - top (continued) installation of flue heat shield 1. Remove flue insulation. 2. Remove (2) screws on outside of inlet vent adapter. See figure 18. 3. Lift top shield placing flue heat shield around flue. 4. Replace (2) screws on outside of inlet vent adapter. ...

Page 16

26412-0-1009 page 16 figure 21 examples of possible venting systems using two (2) 90° elbows. V is listed as minimum vertical dimensions and h1 + h2 is listed as total of maximum horizontal dimensions. The maximum vertical and horizontal distances for two (2) 90° elbows as shown in figure 22 is 22 f...

Page 17

26412-0-1009 page 17 figure 25 figure 24 minimum hole location dimensions for through the wall horizontal installations with 90 degree elbow off top of fireplace positioning the fireplace determine the exact position of the appliance so the direct vent termination will be centered (if possible) betw...

Page 18: Examples - Top Vent Run

26412-0-1009 page 18 figure 28 figure 26 figure 27 example h2 3ft, h3 1ft = 4ft (90° + 90° + 90°) = 6ft v1 = 21ft h = 10ft v = 21ft example h1 = 2ft v1 = 20ft h = 2ft v = 20ft examples - top vent run.

Page 19

26412-0-1009 page 19 installation instructions this termination kit can only be used with empire comfort systems direct vent fireplaces listed for use with dvvk-4fv vertical flex vent kit. Please review the instructions packaged with your fireplace and verify the fireplace model number. Check that t...

Page 20

26412-0-1009 page 20 pre-installation information: items required for installation: tools building supplies phillips screwdriver hammer saw and/or saber saw level measuring tape electric drill and bits pliers square tin snips framing materials wall finishing materials caulking material (noncombustib...

Page 21

26412-0-1009 page 21 1. Unpack vent components and check all items for shipping damage. 2. For this venting system to operate as designed it is depen- dent on the use of all parts and procedures detailed in these instructions. Failure to follow these instructions may poten- tially affect the perform...

Page 22

26412-0-1009 page 22 10. With the flex vent assembly and the 48” long hard pipe com- ponents laid out on the floor, begin securing these parts to- gether. First, apply a generous bead of silicone sealant to the inside of the 4” diameter flex flue (not the end with the pre- installed connector), then...

Page 23

26412-0-1009 page 23 17. To attach the vent connections at the fireplace, be sure the 7” diameter adapter collar has been installed per step 3. Apply a bead of silicone sealant to the 4” diameter flex connector, then slide the flex pipe adapter collar into the fireplace flue collar and secure by ins...

Page 24

26412-0-1009 page 24 vertical termination 4’ long rigid pipe roof flashing roof exterior clamps at flue & inlet vent connections storm collar (use to keep insulation out of thimble assembly) firestop/thimble 4” dia. Flue connector 7” dia. Adapter collar with gasket & clamps direct vent fireplace not...

Page 25

26412-0-1009 page 25 vertical flex termination kit item number item description repair part no. Quantity supplied 1 4”/7” vertical termination cap mf100038 1 2 roof support kit mf100503 1 3 2 ply alum flex 4” diameter by 6 ft. Mf04ala2f006 1 4 2 ply alum flex 7” diameter by 6 ft. Mf07ala2f006 1 5 4”...

Page 26

26412-0-1009 page 26 caution: sharp edges, use protective gloves when installing. Tools needed for installation: sheet metal snips 5/16” nut driver phillips head screwdriver - #2 high temperature sealant or furnace cement rated for continuous use at 1,000 o f minimum measuring tape parts verificatio...

Page 27

26412-0-1009 page 27 7. Remove outside mounting plate with tube attached from wall. Mark and cut the extra length of the 6 5/8” (168 mm) diameter tube from the opposite end. Do not crimp or enlarge tube. 8. Attach the 4” (102 mm) diameter flue outlet tube onto the rigid venting system or directly to...

Page 28

26412-0-1009 page 28 follow correct option according to venting method. Connecting directly to fireplace if the air inlet and flue outlet tubes are to be connected directly to the unit (no rigid venting system is being used), then the gasket provided must be used to seal the 4” (102 mm) flue outlet ...

Page 29

26412-0-1009 page 29 installation 1. Unpack vent components and check that all items are included. 2. Check to see that the vent spacer springs are located around the flue vent at 8" and 12" intervals along its length. See figure 42. If not, stretch the spacer springs to about 15" long and wrap them...

Page 30: Termination Clearances

26412-0-1009 page 30 termination clearance for buildings with combustible and noncombustible exteriors. Vertical sidewall installations important! Minimum clearance between vent pipes and combustible materials is three (3") (76 mm) on top, and (1") (25 mm) on bottom and sides. Important! When vent t...

Page 31: Vent Clearances

26412-0-1009 page 31 figure 47 vent terminal air supply inlet area where terminal is not permitted a = *clearance above grade, veranda, porch, deck or balcony [*12 inches (30cm) minimum] b = clearance to window or door that may be opened [*12 inches (30cm) minimum for appliances c = clearance to per...

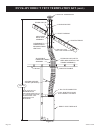

Page 32: Vent System Identification

26412-0-1009 page 32 vertical termination (maximum of three 90° elbows) storm collar roof flashing wall thimble horizontal two 90° elbows) termination (maximum of 90° elbow or 45° elbow 90° elbow ceiling firestop wall strap pipe length installing vent components (figure 48) begin the vent system ins...

Page 33: Framing And Finishing

26412-0-1009 page 33 installing support brackets (figure 49) a horizontal pipe support must be used for each 3 feet of horizontal run. The pipe supports should be placed around the pipe and nailed in place to framing members. There must be a 3 inch clearance to combustibles above flue pipe and elbow...

Page 34

26412-0-1009 page 34 a b nails, 4 required ceiling firestop existing ceiling joists new framing ceiling below b a nails, 4 required ceiling firestop a b framing and finishing (continued) vent size a b 6 5/8" 10" 10" 8" 10 1/2" 10 1/2" vent size a b 6 5/8" 10" 10" 8" 10 1/2" 10 1/2" vent size a b 6 5...

Page 35: Horizontal Termination

26412-0-1009 page 35 note: termination cap should pass through the wall firestop from the exterior of the building. Adjust the termination cap to its final exterior position on the building. Warning: termination cap must be positioned so that arrow is pointing up. Attach the termination cap with the...

Page 36

26412-0-1009 page 36 installation 1. Unpack vent components and check that all items are included. 2. Check to see that the vent spacer springs are located around the flue vent at 8" and 12" intervals along its length. See figure 55. If not, stretch the spacer springs to about 15" long and wrap them...

Page 37: Vertical Termination

26412-0-1009 page 37 locate and mark the center point of the venting pipe. Using a nail on the underside of the roof and drive this nail through this center point. Make the outline of the roof hole around this center point. Note: size of the roof hole dimensions depend on the pitch of the roof. Ther...

Page 38

26412-0-1009 page 38 vertical through the roof applications (figure 62) your gas fireplace has been approved for: a) vertical installations up to 40 feet in height. B) two sets of 45 degree elbow offsets within these vertical installations. From 0 to a maximum of 8 ft. A vent pipe can be used betwee...

Page 39: Log Identification

26412-0-1009 page 39 log identification rear bottom log (a) rear top log (b) part number - r9228 part number - r9222 bottom left log (c) bottom left center log (d) part number - r9227 part number - r9372 bottom right center log (e) bottom right log (f) part number - r9225 part number - r9229 front l...

Page 40: Log Placement (13 Log Set)

26412-0-1009 page 40 6. Place bottom left log (c) on far left pin of burner. The "lip" of the log will hang off the side of the burner. 7. Place bottom left center log (d) on second and third pins from left side of the burner. 8. Place bottom right center log (e) on fourth and fifth pins from the le...

Page 41: Log Placement (13 Log Set)

26412-0-1009 page 41 log placement (13 log set) 9. Place bottom right log (f) on far right pin on the burner. The "lip" of the log will hang off the side of the burner. 10. Place front left log (g) on (c) log pin. End of (g) log will rest on firebox bottom. 11. Place center log (h) on pin on (a) log...

Page 42: Log Placement (13 Log Set)

26412-0-1009 page 42 log placement (13 log set) 15. Place front center log (l) between third and fourth grates on the burner. The short "y" branch will point left and the bottom of the "y" resting on the firebox bottom. 16. Place front right log (m) on the fifth grate from the left with the top rest...

Page 43: Log Placement (13 Log Set)

26412-0-1009 page 43 log set parts list index letter part number description a r9228 rear bottom log b r9222 rear top log c r9227 bottom left log d r9372 bottom left center log e r9225 bottom right center log f r9229 bottom right log g r9223 front left log h r9373 center log i r9230 top left log j r...

Page 44: Operating Instructions

26412-0-1009 page 44 the owner should carefully read and follow these operating instructions at all times. Lower the door assembly to view the gas controls for the fireplace. Initial lighting upon completing the gas line or turning the gas valve on after it has been in the “off” position, a small am...

Page 45

26412-0-1009 page 45 standing pilot operating instructions remote/off/on switch the fireplace is equipped with a remote/off/on switch. A wire harness is attached to the remote/off/on switch. The red, black and green (wires) female push-ons attach to the remote/off/ on switch. At the opposite end of ...

Page 46

26412-0-1009 page 46 figure 69 remote control receiver gas valve remote/off/on switch (optional) remote control receiver remote/off/on switch remote off on thermopile if any of the original wire as supplied with this unit must be replaced, it must be replaced with no. 18, 150°c wire or its equivalen...

Page 47

26412-0-1009 page 47 1. Stop! Read the safety information above. 2. Set remote/off/on switch to off. 3. Turn off all electric power to the appliance (if applicable). 4. Lower bottom louver assembly. 5. P u s h i n g a s c o n t r o l k n o b s l i g h t l y a n d turn clockwise to "off." note: knob ...

Page 48

26412-0-1009 page 48 with proper installation and maintenance, your new direct vent gas fireplace will provide years of trouble-free service. If you do experience a problem, refer to the trouble shooting guide below. This guide will assist a qualified service person in the diagnosis of problems and ...

Page 49: Optional Remote Control

26412-0-1009 page 49 led light led lumiÈre black noir green vert white blanc red rouge black noir gas valve valve de gaz (optional) wall switch interrupteur mural (facultative) 120 vac line 120 vac rtn junction box jonction boÎte spark ignitor Étincelle allumer (optional) remote control receiver 120...

Page 50

26412-0-1009 page 50 a. Before lighting smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on the floor. What to do if you smell gas • do not try to light any appliance • do not touch any electrical switch • do not use...

Page 51

26412-0-1009 page 51 1. Remove glass door and place away from the fireplace. 2. Turn on gas shut off valve. Follow ignition procedure. 3. If burner does not light after spark sequence has ended, use an insulated jumper wire between terminal locations 12 and 13 for fast reset function. 4. Interrupt p...

Page 52

26412-0-1009 page 52 the conversion shall be carried out in accordance with the requirements of the provincial authorities having jurisdiction and in accordance with the requirements of the csa b149.2 installation code (canada) and with the requirements of the national fuel gas code z223.1/nfpa 54 (...

Page 53

26412-0-1009 page 53 direct ignition propane/lp gas conversion model air shutter settings burner orifice opening "a" propane/lp orifice dvx36 full open 1.65 mm dvx42 full open 1.80 mm regulator fitting note: stamped with gas type set for use maxitrol valve conversion figure 71 figure 72 a.

Page 54

26412-0-1009 page 54 1. To wire junction box receptacle, remove the tab on the side of the receptacle (hot side) to split receptacle. This will be required to separate blower and valve circuits. 2. Power for switched and live sides of duplex receptacle must come from the same power source. (one circ...

Page 55: Lighting Instructions

26412-0-1009 page 55 for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance is equipped with an ignition device which automatically lights the pilot. Do ...

Page 56

26412-0-1009 page 56 general: all fireplaces have been fire-tested to check for proper operation. This includes, main burner flame, pilot flame, fan operation, fan control, limit control and automatic valve operation. If the fireplace fails to function on initial installation, it is advisable to re-...

Page 57

26412-0-1009 page 57 spark generator powered first valve (pilot) operator opens pilot burner lights. Module senses flame current. Pilot burner operation module s8600h * lockout timing is stamped on module. Response after 90 seconds*pilot valve closes, spark stops. Or if flame current sensed spark ge...

Page 58

26412-0-1009 page 58 important 1. The following service procedures are provided as a general guide. 2. Meter readings between gas control and ignition module must be taken within the trial for ignition period. Once the igni- tion module locks out, the system must be reset by setting the thermostat d...

Page 59

26412-0-1009 page 59 intermittent pilot troubleshooting (continued).

Page 60

26412-0-1009 page 60 intermittent pilot troubleshooting (continued) green led status codes green led flash code (x + y) a indicates next system action recommended service action off no “call for heat” not applicable none flash fast startup-flame sense calibration not applicable none heart beat norma...

Page 61: Rf Operating Instructions

26412-0-1009 page 61 rf operating instructions rf valve operation (af-4040 electronic gas valve sys- tem only) please refer to the separate instructions for detailed operation and programming of the multi-function remote control. The af-4040 electronic gas control valve features a remote controlled ...

Page 62: Rf Maintenance Instructions

26412-0-1009 page 62 rf maintenance instructions maintenance maintenance frequency must be determined individually for each application. Some considerations are: • exposure to water, dirt, chemicals and heat can damage the gas control and shut down the control system. • cycling frequency. Appliances...

Page 63: Rf Wiring Diagram

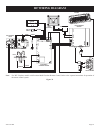

26412-0-1009 page 63 figure 76 rf wiring diagram motor comm. G light s aux fan main pilot learn motor comm. Power ipi continuous pilot off/o n remote/off s i adj. (gnd) stepper motor orange white black orange green white brown transformer blower pilot light (optional) on/off switch gas control valve...

Page 64

26412-0-1009 page 64 for your safety read before lighting warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury, or loss of life. A. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow t...

Page 65: Maintenance And Service

26412-0-1009 page 65 please note it is normal for appliances fabricated of steel to give off some expansion and/or contraction noise during the start up or cool down cycle. Similar noises are found with your furnace heat exchanger or car engine. It is not unusual for your gas fireplace to give off s...

Page 66: Maintenance And Service

26412-0-1009 page 66 glass removal and replacement (figures 77 and 78) 1. Remove decorative front doors (where applicable) by opening and lifting straight up. 2. Remove decorative front by tilting lower portion forward to release ball catch and lifting front off mounting bracket. See figure 74. 3. R...

Page 67: Parts View

26412-0-1009 page 67 parts view 1 2 3 6 4 5 12 8 18 24 25 26 13 17 19 27 28 7 9 14 15 16 22 11 10 23 21 20 blower assembly 48 49 52 51 50 3 6 6 6 53 66 67 36 29 30 42 37 35 34 32 43 31 33 54 40 39 41 rf valve assembly 38 60 61 59 62 63 64 65 39 40 46 47 44 45 millivolt valve assembly 38 41 ip valve ...

Page 68

26412-0-1009 page 68 use only manufacturer’s replacement parts. Use of any other parts could cause injury or death. Dvx36dp(31,51,71,91) parts list index no. Part number description dvx36dp31 dvx36dp51 dvx36dp71 dvx36dp91 1 r9347 r9347 r9347 r9347 insulation, top shield 2 23437 23437 23437 23437 top...

Page 69

26412-0-1009 page 69 use only manufacturer’s replacement parts. Use of any other parts could cause injury or death. Dvx36dp(31,51,71,91) parts list 39 r2423 r2423 r2423 r2423 5/16" male connector 40 r7578 r7733 r5746 r10415 gas valve (lpg) 40 r7577 r7733 r5745 r10415 gas valve (nat) 41 17161 20207 2...

Page 70

26412-0-1009 page 70 dvx42dp(31,51,71,91) parts list index no. Part number description dvx42dp31 dvx42dp51 dvx42dp71 dvx42dp91 1 r9348 r9348 r9348 r9348 insulation, top shield 2 23437 23437 23437 23437 top shield 3 23219 23219 23219 23219 top standoff (qty. 2) 4 r7567 r7567 r7567 r7567 vent adapter ...

Page 71

26412-0-1009 page 71 dvx42dp(31,51,71,91) parts list 39 r2423 r2423 r2423 r2423 5/16" male connector 40 r7578 r7733 r5746 r10415 gas valve (lpg) 40 r7577 r7733 r5745 r10415 gas valve (nat) 41 17161 20207 25640 26307 gas valve bracket 42 23502 23502 23502 23502 grate assembly (qty. 2) 43 23070 26634 ...

Page 72

26412-0-1009 page 72 attention: install blower assembly before connecting gas inlet supply line note: junction box on right side of fireplace must be pre-wired at time of fireplace installation for use with blower assembly. It is recommended that an on/off wall switch be installed that will activate...

Page 73

26412-0-1009 page 73 110 volt ac junction box white speed control fan switch ground black fan 1 fbb4 b l o w e r a s s e m b ly complete 2 r7649 fan control 3 r4192 speed control knob 4 r4186 speed control fbb4 variable speed blower installation caution: all wiring should be done by a qualified elec...

Page 74: Accent Lamp

26412-0-1009 page 74 accent lamp 12 volt side 120 volt side your luxury direct vent gas fireplace comes equipped with our "accent lamp." the light has been pre-wired and is controlled from the rheostat. If in the event the lamp or lens needs to be replaced, follow the instructions below: 1. Unplug t...

Page 75: Accessories

26412-0-1009 page 75 decorative accessories accessories the following accessory parts must be obtained from your empire comfort systems dealer. If you need additional information contact your dealer. Simulated stone panels left right back the simulated stone panels were designed to enhance the appea...

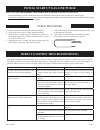

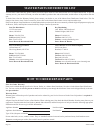

Page 76: How To Order Repair Parts

26412-0-1009 page 76 to order parts under warranty, please contact your local empire dealer. See the dealer locator at www.Empirecomfort.Com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the problem with the unit. To ord...

Page 77: Empire

26412-0-1009 page 77 36” (914mm) 6” (152mm) web site www.Empirecomfort.Com empire comfort systems 918 freeburg avenue belleville, illinois 62220-2623 clearances to combustibles the studio series direct vent gas fireplace heater millivolt standing pilot: dvx36dp31(n,p)-1; dvx42dp31(n,p)-1 direct igni...

Page 78: Empire

26412-0-1009 page 78 web site www.Empirecomfort.Com empire comfort systems 918 freeburg avenue belleville, illinois 62220-2623 framing dimensions firebox dimensions left side view front view right side view electrical access vent collar top view gas line access a c j g i gas line access h d e b vent...

Page 79: Service Notes

26412-0-1009 page 79 service notes.

Page 80: Empire

26412-0-1009 page 80 empire empire comfort systems empire comfort systems inc. 918 freeburg ave. Belleville, il 62220 if you have a general question about our products, please e-mail us at info@empirecomfort.Com. If you have a service or repair question, please contact your dealer. Www.Empirecomfort...