- DL manuals

- FAAC

- Gate Opener

- 415 L LS 24V

- User Manual

FAAC 415 L LS 24V User Manual

Swing Gate Operator

FAAC International Inc.

Headquarter & East Coast Operations

5151 Sunbeam Road

Suites 9-11

Jacksonville, FL 32257

Tel. 866 925 3222

www.faacusa.com

FAAC International Inc.

West Coast Operations

357 South Acacia Avenue

Unit 357

Fullerton, CA 92831

Tel. 800 221 8278

415 L LS 24V

UL325 - UL991

Summary of 415 L LS 24V

Page 1

Swing gate operator faac international inc. Headquarter & east coast operations 5151 sunbeam road suites 9-11 jacksonville, fl 32257 tel. 866 925 3222 www.Faacusa.Com faac international inc. West coast operations 357 south acacia avenue unit 357 fullerton, ca 92831 tel. 800 221 8278 415 l ls 24v ul3...

Page 2

2 faac model 415 l ls 24v swing gate operator contents faac model 415 l ls 24v - rev: 02 - jun 2012 read this instruction manual before you begin installing the product. = information regarding personal safety and proper maintanence of the product. Important safety information 3 important safety ins...

Page 3

3 faac model 415 l ls 24v swing gate operator 1. Install the gate operator only when the following condi- tions have been met: • the operator is appropriate for the type and usage class of the gate. • all openings of a horizontal slide gate have been guarded or screened from the bottom of the gate t...

Page 4

4 faac model 415 l ls 24v swing gate operator gate construction vehicular gates should be constructed and installed in accordance with astm f2200: standard specifica- tion for automated vehicular gate construction. For more information, contact astm at: www.Astm.Org installation • if you have any qu...

Page 5

5 faac model 415 l ls 24v swing gate operator residential vehicular gate operator class i a vehicular gate operator system intended for use in a single family dwelling, garage or associated parking area. Ul325 gate operator classifications commercial / general access vehicular gate operator class ii...

Page 6

Model 415 l ls 24v swing gate operator 1. Description 2. Dimensions built-in security and anti-crushing measures of the 415 operator include built in reverse on contact and a torque adjustment that controls the force transmitted to the gate leaf through the 415 operator. The manual release mechanism...

Page 7

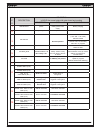

3. Technical specifications 4. Installation pos. Description cables 1 operators 2 x awg 14 (max 30’) awg 12 (max 50’) awg 10 (max 100’) 1 limit switches 3 x awg 20 2 control unit 3 x awg 14 (ac power) 3 tx photocells 4 x awg 20 4 rx photocells 2 x awg 20 5 key-operated switch 2 x awg 20 6 flashing l...

Page 8

Guidelines for determining installation dimensions • for 90° leaf openings: a+b=l • for leaf openings exceeding 90°: a+b • smaller a and b dimensions provide higher periph- eral leaf speed. • limit the difference between a and b dimensions to less than 1.5 inches. Greaterdifferences may cause speed ...

Page 9

6. Turn the rod one half revolution clockwise (fig. 9, ref. 2). 7. Assemble the front bracket as shown in fig. 10. 8. Fix the operator to the rear bracket by means of the sup- plied pins as shown in fig. 11. Attention: allow the bracket to cool before fastening the operator to it. 9. Close the leaf ...

Page 10

Limit switches wiring in- structions: limit switches are wired in the same terminal block where the motor wiring has been in- stalled. Wire the limit switches as follows: 1. Open the second pre- drilled hole in the cover, see fig. 15. 2. Fit the supplied cable gland, see fig. 15. 3. Insert the cable...

Page 11

5. Reposition the cap (fig. 18 ref. B) and tighten the fastening screw (fig. 18 ref. A). 4.7. Start-up attention: cut power before performing any work on the system or operator. Carefully observe the general safety rules. Following the indications in fig. 3, lay the proper cable conduits and make th...

Page 12

415 l ls 24vdc table parts list 1/1/1900 start date 1/1/9999 end date 415 l ls 24v code electro-mechanical automation for residential description page 1 pos. Code qty. Q.Ty per avaibility description 001 72200165 1 1 y 413/415 rear bracket 002 72840065 1 1 y 413/415 rear bracket plate 003 718366 1 1...

Page 13

Setting + j24 dl19 dl20 dl21 dl22 dl14 dl15 dl16 dl17 dl18 main power supply 115/230 v~ 50/60 hz switchable secondary power supply 24 vdc - 16 a max. (min. 20 vdc. - max. 36 vdc.) power consumption stand-by = 4w max. = 400 w max load per motor 7 a accessory power supply 24 vdc - 500 ma battery charg...

Page 14

A b stp cl op open fsw fig. A2 pin label function 2 easy 2 easy input for bus 2easy accessories (encoder) 1 open a n.O. Contact for total opening command 2 open b / close open b: n.O. Contact for opening of leaf 1 only (with only one leaf the opening stops at 50% of traveling) close (logic b-c): n.O...

Page 15

Fsw stp cl op how to connect normally open contacts. (connect them in parallel) how to connect normally close contacts. (connect them in series) the photocells must be connected depending on which area they must protect. (see fig. A5) closing safety d : these photocells protect the area covered by t...

Page 16

Fsw stp cl op fsw stp cl op connection of two pairs of closing photocells connection of a pair of closing photocells, a pair of opening photcells and a pair of opening/closing photocells other optional safety devices to connect in series fig. A7 fig. A8 to use the fail-safe mode connect the negative...

Page 17

8 8 fsw stp cl op fsw stp cl op fsw stp cl op fsw stp cl op to use the fail-safe mode connect the negative power supply of the transmitters to out (pin 9), and set dip- switch 11 and 12 to on on ds1 connection of a pair of closing photocells and a pair of opening photocells fig. A9 connection of no ...

Page 18

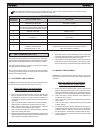

4. Programming operating logic ds 1: sw 1 - sw 2 - sw 3 logic sw 1 sw 2 sw 3 pause time description e (default) semiautomatic off off off no one command opens, the next one closes. A command du- ring opening stops the gate a automatic on on on 0 - 4 min one command opens, waits for the pause time an...

Page 19

6 tr 3 – speed adjustment for motor1 and motor 2 turn clockwise to increase the opening and closing speed tr 4 – sensitivity adjustement for obstacle detection for motor 1 and motor 2 turn clockwise to increase the sensitivity for obstacle detection. With this trimmer you can adjust the reaction tim...

Page 20

Board setup ds 1: sw 4 to sw 12 opening delay sw 4 the opening of leaf 2 is delayed after the opening of leaf 1. This is to avoid that the gate’s leafs interfere with each other during the initial part of the movement. In case there is only one leaf is has no effect. 0 sec (default) off 2 sec on rev...

Page 21

Ds2 setting + j24 1 2 3 4 5 6 7 8 9 10 dl19 dl20 dl21 dl22 dl14 dl15 dl16 dl17 dl18 ds 2 operator selection operator type sw 1 sw 2 sw 3 s450h, s800h off off off s418 off off on 415, 390, 770 on off off ds 2 lock output mode output mode sw 4 active only for 3 sec. After an open impulse (from gate cl...

Page 22

A11 l e d description led status in bold the normal state with gate closed and working on steady off blinking 1 led battery board working on ac power board working on battery power or ext supply battery charging 2 led +24 main power present main power off 3 led set-up normal operation slow blink (1 ...

Page 23

Warning: if the time learning setup is done automatically then the slow down points are set by the board on his own move the leafs to the mid position very important for a good result 1. Press and hold the setup button until the setup led lights up, wait about 3 sec. Until it turns off and then rele...

Page 24

The obstacle detection function is achieved by controlling the current absorption and / or through the encoder connected to the motors. If the gate encounters an obstacle during the movement of opening or closing, the obstacle detection function is activated and the operator reverses the direction o...

Page 25

Ac power connection to connect ac power to the controller: 1. Turn the circuit breaker for the ac gate operator power off before connecting the ac input wires. 2. Turn off the power switch located on the left side of enclo- sure before connecting the ac input wires. 3. Connect the ac input wires to ...

Page 26

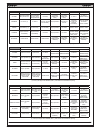

Logic “e” pulses system status open a open b close stop fsw op fsw cl fsw cl/op closed opens the leaves opens leaf 1 no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disa- bled) opening stops operation (1) stops operation recloses leaves immediately stops opera...

Page 27

Logic “ep” pulses system status open a open b close stop fsw op fsw cl fsw cl/op closed opens the leaves opens leaf 1 no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disabled) opening stops operation (1) stops operation recloses leaves immediately stops operat...

Page 28

Logic “b” pulses system status open a open b close stop fsw op fsw cl fsw cl/op closed opens the leaves no effect no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disa- bled) opening no effect closes leaves closes leaves stops operation reverses at closure no e...

Page 29

A18 e024u control board to the original purchaser only: faac international, inc., warrants, for twenty- four (24) months from the date of invoice, the gate operator systems and other related systems and equipment manufactured by faac s.P.A. And distributed by faac international, inc., to be free fro...