Ma y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c o ntrol pa ne l i ns tal la ti on ma nua l contents t h e 4 1 5 l l s o p e r a t o r a n d 4 5 5 d c o n t r o l p a n e l : i n s t a l l a t i o n m a n u a l faac international, inc. 303 lexington avenue cheyenne, wy 82007 www.Faacusa.Com important...

Pag e 2 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l both the installer and the owner and/or operator of this system need to read and understand this installation manual and the safety instructions supplied with other components of the gate system. This ...

P age 3 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l 6. It is extremely unsafe to compensate for a damaged gate by increasing hydraulic pressure. 7. Devices such as reversing edges and photobeams must be installed to provide better protection for person...

Pag e 4 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l t echnical d ata t he 415 l ls o perator parameter measure voltage required, vac 115vac duty type residential maximum duty cycle (cycles per hour) 25 maximum leaf length, ft (m) 15 (4.5) maximum leaf s...

P age 5 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l u npacking the o perator when you receive your 415 l ls operator, complete the following steps. Inspect the shipping box for physical damage such as a torn carton. Then inspect the operator after you ...

Pag e 6 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l t he 415 c ompact o perator g eneral c haracteristics the faac 415 l ls operator is an automatic gate operator for a swinging gate leaf. The 415 l ls operator is useful in residential applications and ...

P age 7 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l 3. Turn the manual release knob clockwise 1/2 turn. 4. To re-engage the operator, perform the procedure in reverse. Now the 415 l ls operator is manual released. You can move the gate freely. A ttach ...

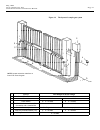

Pag e 8 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l a ttach the r ear m ounting b racket inward swinging gate: you need to determine whether to attach the rear mounting bracket directly to the post (or wall) or to notch the post and install a recessed l...

P age 9 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l figure 9. Important mounting dimensions for inward-swinging mounting dimensions 90-deg swing 110-deg swing a 7 5/8in. (195 mm) 6 5/8 in. (170 mm) b 7 5/8 in. (195 mm) 6 5/8 in. (170 mm) c 37 1/8 in. (...

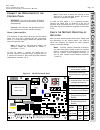

Pag e 10 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l i nstalling the 455 d c ontrol p anel locate the control panel in the most convenient position possible, considering the movement of the gate. Figure 14 shows a basic layout for a two-leaf gate with t...

Page 11 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l 1 5 3 6 8 2 4 9 7 3 5 1 a a b a b c c d a figure 14. The layout of a sample gate system note: locate activation switches at least10 ft from the gate. 6 7 8 operator wire gauges for given voltage contr...

Pag e 12 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l the 415 l ls operator 415 l ls.

P age 13 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l parts list 415 l ls operator pos part no. Description qty 1 7220015 rear mounting bracket 1 2 7284005 rear mounting plate 1 3 718366 long pin with c clips 1 4 7182075 short pin 1 5 n/a hex nut 1 6 72...

T he 455 d c ontrol p anel g eneral d escription the faac 455 d control panel is used to operate the following models. Swing gate operators: 400 415 402 750 422 760 barrier gate operators: 615 the 455 d programming controls the following: operating logic: a, s, e, ep, b, ap and c logics available. R...

P age 15 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l t he 455 d c ontrol p ane l i ns t a ll at ion i n str uc ti on s ra d io 1-455d115 = 115v 1-455d = 230v f2 f1 m m k + op - cl +24 v fsw nc - b - stop a + tx fs w w. L. Lock 9 10 11 12 13 14 15 16 17...

Note : in order to c om ply wi th ul 325, two s ets of fa a c photobeams m us t be ins talled. One s et s hould be 6 in. Outs ide the c los ed gate(s ) and ac t as a c l os ing rev ers ing dev ic e. A nother s et s hould be 6 in. Bey ond the s wi ng of the gate(s ) and ac t as an openi ng rev ers in...

F s w o p f s w c l o p _ a o p _ b s t o p f c a 1 f c a 2 f c c 1 f c c 2 fswop fswcl op_a op_b stop fca1 fca2 fcc1 fcc2 this display shows the normal status of the control panel. This display shows the meaning of each led. Figure 18. The 455 d display. P age 17 m a y, 20 06 4 1 5 l ls ope ra tor ...

• e (semi-automatic): this mode requires a command to open and a command to close. A second command during opening stops the gate. A second command during closing reopens the gate. • ep (semi-automatic, step by step): this mode requires a command to open and a command to close. A second command duri...

P age 19 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l no = normally open, nc = normally closed, c = common, tx = transmitter, rx = receiver figure 19. Common accessories wired to 455 d control panel t he 45 5 d c ont r ol p ane l i ns ta ll a t io n i n...

Pag e 20 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l however, if enabled, you cannot adjust this opening delay of the operator connected to motor 2. The closing leaf-delay time is adjustable from 0 to 4 minutes. N ote : if the opening/closing time is se...

Page 2 1 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l t he 45 5 d c ont r ol p ane l i ns ta ll a t io n i nstructions f ail s afe : if this function is activated, it en- ables a function test of the photo- cells before any gate movement. If the test fa...

L earning of n ormal t imes normal learning (i.E. Without gatecoders) can be done in two different ways: s imple l earning ( without s low d own ) close the gates, enter “b asic p rogramming ”, select the time learning function and press the + push-button for 1 second the display begins flashing and...

Page 23 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l t he 45 5 d c ont r ol p ane l i ns ta ll a t io n i nstructions • when gate operator (2) reaches the positive stop and the desired motor run time has been reached, an open command must be given to sh...

T he 45 5 d c on tr o l p an el i ns t a lla t io n i ns t r u c ti ons pag e 24 m a y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l a (automatic) logic (455 d) gate status open a open b stop opening reversing device(s) closing reversing device(s) warning light...

Page 25 m a y, 20 06 4 1 5 l ls ope ra tor a nd 4 5 5 d c ontrol pa ne l i nsta ll a ti on ma nua l e (semi-automatic) logic (455 d) gate status open a open b stop opening reversing device(s) closing reversing device(s) warning light closed opens both leaves opens single leaf connected to motor 1 no...

M a y, 20 06 4 15 l ls ope ra tor a nd 4 5 5 d c o ntrol pa ne l i nsta lla ti on ma nua l t he 415 l ls o perator the faac 415 l ls operator requires no maintenance. Periodically inspect the operator, however, to ensure continued proper operation. T he 455 d c ontrol p anel keep the control panel f...

P age 27 ma y, 20 06 4 1 5 l ls ope ra tor and 4 5 5 d c o ntrol pa ne l i nsta lla ti on ma nua l t roubleshooting p roblem : t he gate does not respond to an activating signal . S olution : you should have at least one operator wired to terminals 1,2 and 3. Be sure that you have the motor start ca...

To the original purchaser only: faac international, inc., warrants, for twenty-four (24) months from the date of invoice, the gate operator systems and other related systems and equipment manufactured by faac s.P.A. And distributed by faac international, inc., to be free from defects in material and...