Summary of C850

Page 1

C850 c850

Page 2: Control Board

C850 2 532015 - rev.B english t ranslation of the original instructions manufacturer: faac s.P.A. Address: via calari, 10 - 40069 zola predosa bologna - italy declares that: operator mod. C850 is built to be integrated into a machine or to be assembled with other machinery to create a machine under ...

Page 3: Warnings For The Installer

C850 3 532015 - rev.B t ranslation of the original instructions english 1) attention! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. 2) carefully read the instruc...

Page 4: Index

C850 4 532015 - rev.B english t ranslation of the original instructions index 1 general ............................................................................................................................................................. 5 2 description and technical specifications ............

Page 5: C850

C850 5 532015 - rev.B t ranslation of the original instructions english c850 we thank you for choosing this product. We are certain that it will fully meet your needs as to the performance it has been designed for. This product has been designed and built for vehicle access control. Avoid any differ...

Page 6

C850 6 532015 - rev.B 295 mm 256 mm 510 mm 467 mm english t ranslation of the original instructions 3 dimensions 5 installing the automated system 5.1 preliminary checks for the safety and correct operation of the automated system, ensure that the following conditions are met: • the gate structure m...

Page 7

C850 7 532015 - rev.B 50 mm abb. 6 300 530 1500 120 270 Ø100 80,5 550 140 abb. 6 t ranslation of the original instructions english 5.2 walling in the foundation plate 1. Assemble the foundation plate as shown in fig. 4. 2. The foundation plate must be positioned as shown in fig. 5 (right- hand closi...

Page 8

C850 8 532015 - rev.B 25 19 47 160 10 english t ranslation of the original instructions 5.3 mechanical installation 1. Lift the cover to remove it (fig. 8 ref. ). 2. Position the operator on the foundation plate and secure it without tightening the nuts, grover screws and washers supplied with the f...

Page 9

C850 9 532015 - rev.B t ranslation of the original instructions english 5.4 installing the rack 5.4.1 weld-on steel rack (fig. 13) before installing the rack, release the gearmotor, as described in paragraph 8. 1. Install the three threaded pawls on the rack element, positioning them on top of the s...

Page 10

C850 10 532015 - rev.B c c8 c8 50 50 1 1 off l n l l l l l l l l l l l l n pe english t ranslation of the original instructions important notes for installing the rack: check that during gate travel, all the rack elements remain on the pinion. Do not weld the rack elements together or to the spacers...

Page 11

C850 11 532015 - rev.B t ranslation of the original instructions english 6.2 final adjustment of the limit switches to correctly adjust the limit switches, the control unit must be installed and correctly connected with all the control and safety accessories. The stopping and deceleration of the gat...

Page 12

C850 12 532015 - rev.B fcc f f rcl rcl rop fco fcc fco rop english t ranslation of the original instructions 14. Set the f003 deceleration time and a021 operating speed in the inverter (see section 12.2) 15. Do not modify the deceleration points (rop/rcl) and/or stops (fco/fcc) before having set the...

Page 13

C850 13 532015 - rev.B t ranslation of the original instructions english 9 maintenance we recommend checking system operation every six months, with special attention to the safety devices (including the motor thrust power, which must comply with the regulations in force) and release devices. 10 rep...

Page 14

C850 14 532015 - rev.B english t ranslation of the original instructions 11 e850 electronic control unit 11.1 warnings important: before carrying out any work on the control unit (connections, maintenance) always cut off the electrical power. • always install a differential magnetothermic switch wit...

Page 15

C850 15 532015 - rev.B t ranslation of the original instructions english fsw op fsw cl rcl fcc fco fsw cl ef rop inverter l limit switch unit to connect the photocells and safety devices, refer to paragraph 11.4.2. Fig. 28 11.4.1 terminal board j1 - accessories (fig. 28) j6=fcc - fco - manoeuvre sto...

Page 16

C850 16 532015 - rev.B j1 fsw op fsw cl j1 +24 gnd +24 gnd safe tx rx 1 2 5 4 3 1 2 fsw op fsw cl j1 +24 gnd +24 gnd safe tx rx 1 2 5 4 3 1 2 tx rx 1 2 5 4 3 1 2 +24 gnd +24 gnd fsw op fsw cl ds1 dl1 dl2 bus bus rx - tx dl2 ds1 on on bus bus ds1 dl1 dl2 bus bus dl2 ds1 on on bus bus 2ea sy 18 19 ds1...

Page 17

C850 17 532015 - rev.B rp / rp2 e850 e850 j4 t ranslation of the original instructions english after positioning the bus-technology photocells, proceed with selecting the address for each pair using various combinations of the dip-switches located on each photocell. Set the same chosen dip-switch ad...

Page 18

C850 18 532015 - rev.B english t ranslation of the original instructions right to left connections to the e850 board are factory set for gates designed to open toward the right. If at installation the gate requires left-hand opening, the connections will be inverted on site, as shown in figures 36 a...

Page 19

C850 19 532015 - rev.B t ranslation of the original instructions english fig. 37 right-hand opening (default) left-hand opening.

Page 20

C850 20 532015 - rev.B english t ranslation of the original instructions 11.5 programming to program automated system operation, you must access “programming” mode. Programming is divided into three levels: basic, advanced and expert. Changes to the programming parameters become immediately effectiv...

Page 21: Fsw Open

C850 21 532015 - rev.B t ranslation of the original instructions english fig. 38 fig. 41 fig. 42 fig. 40 11.5.2 changing the pre-settings changing the parameter df lets you automatically load a configuration which will modify all the programming values at every level with pre-set values. This option...

Page 22

C850 22 532015 - rev.B english t ranslation of the original instructions 11.5.4 advanced programming level to access advanced programming level, press f and, holding it, press + : • when + is released, the name of the first function will be displayed. • releasing both + and f, the display will show ...

Page 23

C850 23 532015 - rev.B loop 1 loop 2 mm mm t ranslation of the original instructions english 11.5.5 setting the integrated loop detector the e850 features an integrated metal mass detector for the induction detection of vehicles. Specifications: • galvanic separation between the detector electronics...

Page 24

C850 24 532015 - rev.B english t ranslation of the original instructions fig. 45 11.8 expert programming level the expert programming level is used only if you wish to perform an advanced customisation of the operating logics. Before making changes at this level, ensure that the parameters you wish ...

Page 25

C850 25 532015 - rev.B t ranslation of the original instructions english display funzione impostazione 13 when this function is activated, the close command during opening stops operation, otherwise the close command commands immediate reverse or when opening is completed (see also parameter 14 ) y ...

Page 26

C850 26 532015 - rev.B english t ranslation of the original instructions “a” logic pulses automated system status open a close stop fsw op fsw cl fsw cl/op closed opens and closes after the pause time no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disabled) a...

Page 27

C850 27 532015 - rev.B t ranslation of the original instructions english tab. 1/e tab. 1/f “c” logic pulses automated system status open a close stop fsw op fsw cl fsw cl/op closed opens the gate no effect no effect (open disabled) no effect (open disabled) no effect no effect (open disabled) at ope...

Page 28

C850 28 532015 - rev.B english t ranslation of the original instructions 12 omron inverter control unit 12.1 description of the inverter control panel name description power led on when the control circuit is powered. Alarm led on when there is an inverter fault. Run led (during a run command) on wh...

Page 29

C850 29 532015 - rev.B t ranslation of the original instructions english name description mode key lets you go to the following modes: monitor ( d000 ), basic operation ( f000 ) and extended operation ( a000 , b000 , c000 , h000 ). This key also lets you change visualisation as shown below. [further...

Page 30

C850 30 532015 - rev.B english t ranslation of the original instructions 12.2 programming the inverter warning: do not change parameters other than those indicated in this section. Incorrect changes can be dangerous for people, things or the c850 motor. The inverter parameters have all been set on d...

Page 31

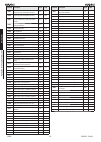

C850 31 532015 - rev.B t ranslation of the original instructions english 12.3 12.3 inverter defaults contents description value unit a001 reference frequency selection 02 a002 run command selection 01 a003 basic frequency 50 hz a004 maximum frequency 120 hz a005 o/io selection 02 a011 o start freque...

Page 32

C850 32 532015 - rev.B english t ranslation of the original instructions contents description value unit b052 “no stop deceleration level stop in case of temporary power interruption function” 0.0 v b053 “no deceleration time stop in case of temporary power interruption function” 1.0 sec b054 “no de...

Page 33

C850 33 532015 - rev.B t ranslation of the original instructions english 12.4 inverter error alarm code alarm name alarm description e 05 stop due to overload excessive motor strain troubleshooting: 1. Sliding leaf too heavy. 2. Obstacle preventing correct movement of the sliding leaf. Alarm code al...

Page 34

C850 34 532015 - rev.B abb. 47 english t ranslation of the original instructions 12.5 optional accessories 12.5.1 external programming keyboard the external programming keyboard is an optional accessory for remotely programming the inverter parameters using the provided rj45 standard cable connectio...

Page 35: User’S Guide C850

C850 35 532015 - rev.B fig. 1 fig. 2 read the instructions carefully before using the product and keep them for future consultation. General safety rules if installed and used correctly, the c850 automated system will ensure a high degree of safety. Some simple rules regarding behaviour will avoid a...

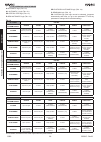

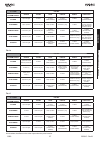

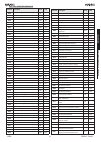

Page 36: Maintenance Register

Maintenance register da te description of job signa tur es _____________________________________________ _____________________________________________ _____________________________________________ _____________________________________________ te chnician customer ____________________________________...

Page 40

Sede - headquarters faac s.P.A. Via calari, 10 40069 zola predosa (bo) - italy tel. +39 051 61724 - fax +39 051 758518 www.Faac.It - www.Faacgroup.Com subsidiaries austria faac gmbh salzburg - austria tel. +43 662 8533950 www.Faac.At faac tubular motors tel. +49 30 56796645 faactm.Info@faacgroup.Com...