Summary of D1000

Page 1

D1000 d1000

Page 2

Leggere completamente questo manuale di istruzioni prima di iniziare l’installazione del prodotto. Il simbolo evidenzia le note importanti per la sicurezza delle persone e l’integrità dell’automazione. Il simbolo richiama l’attenzione sulle note riguardanti le caratteristiche od il funzionamento del...

Page 3: Index

1 english index general safety instructions for installation and maintenance ....................................... P. 2 tools and materials ........................................................................................................................ P. 2 declaration of conformity .........

Page 4

2 english general safety instructions for installation and maintenance for an efficient and safe automated door, correctly observe the installation procedures and instructions for use. Incorrect installation and use can cause serious damage to persons and property. Carefully read the whole installat...

Page 5

3 english 1) attention! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. 2) carefully read the instructions before beginning to install the product. 3) do not leave...

Page 6: Automated System D1000

4 200 145 2168 / 2768 / 3368 360 english the level of noise emission of operator d1000, referred to the work station, is 52 db(a). These instructions apply to model faac d1000. The d1000 automated systems make it possible to automate balanced sectional doors of single garages for residential use. Th...

Page 7

5 english 5. Preliminary checks - the structure of the door must be suitable for fitting automation. In particular, check that the door dimensions conform to those indicated in the technical specifications, and that it is sufficiently sturdy. - check if the door conforms to standards en12604 and en1...

Page 8

6 english 6. Assembly 6.1. Sliding guide if you use a sliding guide in two pieces, you must assemble it, as explained below. If you have a pre-assembled guide, go on to paragraph 6.2. 1) assemble the two pieces of the sliding guide, fitting them in the central joint (fig. 6 ref. A) until they come t...

Page 9

7 햲 english 6.3. External release (optional) if the external release system has to be installed, the cable must be placed in its seat before beginning to install. 1) release the carriage (see par. 7.4 point 3), and take it to the slot on the top of the sliding guide. 2) fit the cable terminal on the...

Page 10

8 english position the fitting on the door so that the through-element of the release cable is facing toward the left side of the door (ref. Fig. 17). 2) close the door and take the carriage near to it. 3) position the fitting on the door, centred with respect to its mid-point. 4) make sure that the...

Page 11

9 15°/20° english 7.3. Operator when you have assembled the rear fitting to the sliding guide and finished installing the sliding guide, you can install the operator: 1) while keeping the operator inclined at 15/20° (fig. 20), insert the gearmotor shaft in the coupling on the rear fitting of the sli...

Page 12

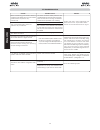

10 j7 j8 j4 j1 j2 j5 j3 j12 ds1 set up open ld6 ld5 ld4 open b open a ld3 ld2 ld1 tr2 tr1 english 8.3. Terminal-boards and connectors 8.2. E1000 board components 8. E1000 control board 8.1. Technical specifications fig. 25 8.4. Ds1 programming dip-switches 8.5. Operating logics logic a (automatic) l...

Page 13

11 english fig. 26 9. Courtesy light - the courtesy light stays lighted for 2 minutes after the end of the manoeuvre (cannot be modified). Fig. 27 open a other safety devices 10. Connections important: before attempting any work on the board (connections, maintenance), always cut off power. - to pre...

Page 14

12 open a stop fsw set up open a open b radio set up english 11. Programming 11.1. Setting the board set the appliance with dip-switch ds1 to obtain the operation you require, referring to chapter 8.4. If you wish to manually set the thrust force, turn on dip-switch 3 of ds1 and adjust potentiometer...

Page 15

13 english during these 5 seconds, in order to lighten the load on the release system, you can send open pulses within a time interval of 2 seconds from each other, in order to reverse the carriage. One pulse corresponds to a 5 millimetre travel. N.B.: the carriage can be seen reversing only during ...

Page 16

14 open b open a radio set up english the 3 types of radio codes (ds, lsh, lc) cannot coexist. Only one radio code can be used at a time. To change over from one code to another, you must delete the existing one (see paragraph on deletion), and repeat the memory-storage procedure. A maximum of two c...

Page 17

15 english - quickly press twice in succession the memory stored radio control push-button . The automated system performs one opening operation. Make sure that the automated system is free of any obstacle created by persons or things. 12.3 memory storage of radio controls lc (for some markets only)...

Page 18

16 english 17.2. Key-operated release the external release can be installed with the lever system (fig. 35 ref. A) or the key system (fig. 35 ref. B). See instructions in par. 6.3 and par. 7.5. Fig. 35 14. Parachute cables connect the parachute cables to the rear door and to the ceiling lamp to prev...

Page 19

17 english 18 . Troubleshooting trouble possible causes solution when the learning procedure is started, the set up led flashes but the automated system does not perform any manoeuvre the stop and fsw safety devices are enabled also during the learning stage. Non-connection or wrong connection preve...