- DL manuals

- Factory Cat

- Scrubber

- 290 Series

- Operator And Parts Manual

Factory Cat 290 Series Operator And Parts Manual

Summary of 290 Series

Page 1

A www.Factorycat.Com r.P.S. Corporation phone: 1-800-634-4060 p.O. Box 368 fax: 1-866-901-3335 racine, wisconsin 53401 c actory 2 9 0 /3 5 0 s e r ie s operator and parts manual 29o rider scrubber 350 rider scrubber chadv 11/23/2005 9:54:13 am.

Page 2: 290/350 Rider Scrubbers

These tough, compact scrubbers combined the productivity of riders with the maneuverability of walk-behinds. Factory cats are designed to clean schools, malls, warehouses, retail outlets, while standing up to the rigors of contract cleaning. With two specialized cleaning systems to choose from, fact...

Page 3: Machine Information

Page 23-24 page 25-26 page 27-28 page 29-30 page 31-32 page 33-34 page 35-36 page 37-38 page 39-40 page 41-42 page 43-44 page 45-46 machine information please fill this area out at the time of installation for future reference. Model number____________________________________________________________...

Page 4: Warranty Registration Form

Warranty registration form ***complete form immediately and fax back to (886)-901-3335*** dealer:________________________________________________________ serial number:_________________ location (city, state):_________________________________________ install date:____________________ customer:______...

Page 5: 350

350 poly 3/16" steel 12" x 5" 12" x 4" 61" x 35" 35", 38", or 45" 810 lbs. 1,320 lbs. (2) 18 inches direct 35 inches (2) 1.0 hp 350 rpm 350 rpm (2) 28 inch or (2) 32 inch chain 28 inches or 32 inches 2.0 hp 800 rpm 800 rpm 0-250 lb. (5) automatic settings 38 gal 0-1.75 gpm 40 gal 1.0 hp 2.0 hp 2.0 i...

Page 6: Common Wear Parts

Common wear parts page 4 item brush type brushes super-grit tough-grit midi-grit light-grit poly (.028) nylon (.016) tampico pad driver extra pad driver retaining clip: 40-433 brush repair kit: 40-423 replacement locating clip for all disk brushes pads super black black brown green blue red white sq...

Page 7: Safety Messages

Safety messages your safety, and the safety of others, is very important, and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided operating procedures and other safety information in the manual. This information informs you of...

Page 8: !! Safety Precautions!!

!! Safety precautions!! Warning: hazardous voltage. Shock, burns or electrocution can result. Always discon- nect the batteries before servicing machine. Warning: batteries emit hydrogen gases, explosion or fire can result. Keep sparks and open flames away. Warning: charge unit in a well ventilated ...

Page 9

Machine controls and features page 7 43 42 41 35 34 30 31 32 33 26 28 29 27 21 20 19 18 22 23 25 24 13 14 15 16 10 9 11 12 figure 2. Figure 3. Figure 4. Figure 5 figure 6a. 38 7 6 8 2 1 4 3 5 figure 1. Figure 6b. 37 36 39 40 17 chadv 11/23/2005 9:54:13 am.

Page 10: Controls And Functions

Page 8 controls and functions see figures (1-6b) on page 7 see figure 1 1. Steering wheel: steers the machine. 2. Adjustable seat with arm rests: your machine is equipped with an adjustable seat with arm rests for comfort 3. Recovery tank: holds up to 40 gallons of dirty water recovered by the machi...

Page 11: Machine Setup

Machine setup uncrating machine carefully check the crate for any signs of damage. Batteries are in the unit. To uncrate the machine, remove banding from around the crate. Take off the top and sides and dispose of properly. Remove banding from machine. Remove the chocks around the drive wheels. Fold...

Page 12

Page 10 6. When both brushes are engaged replace the brush access door and tighten it back down with the wingnuts. (see figure 15.) *** for correct pad application , call your local dealer*** attaching cylindrical brushes 1. Turn on machine power 2. Raise the scrub deck by depressing the brush switc...

Page 13: One Pass Scrubbing

Page 11 one pass scrubbing steps: (see figure 17.) 1. Turn machine on with the key switch. 2. Lower squeegee by pressing the switch. 3. Lower scrub head to the floor, use the top half (+) of the brush switch. 4. Turn on the solution switch and adjust the solution lever to the desired setting. 5. Beg...

Page 14

Page 12 operating hints 1. Observe the amount of solution the machine is dispensing on the floor and adjust to the desired flow. To increase the solution flow rate, move the solution lever to the operators right. To shut the solution off completely, use the switch, or just release the foot pedal. 2....

Page 15: Battery

Page 13 battery charging caution: the following instructions are intended for the 24v charger supplied with the machine. Do not use any other charger with this machine. Charger specifications output voltage of 24 volts. Output current of 36 amps max. Input voltage of 110 volts/60 hz. Automatic shut ...

Page 16: Monthly

Page 14 monthly maintenance 1. Check scrub head and squeegee lifting cables for wear and spring tension. 2. Check machine for water leaks and loose nuts and bolts. 3. Check to see if battery cables are tightened (tighten if needed) 4. Check parking brake 5. Check condition of scrub deck lifting cabl...

Page 17

Page 15 preventative maintenance records use this form to make copies for your internal records preventative maintenance checked note rotate brushes _____________ ____________________________________ rotate side brooms _____________ ____________________________________ drain solution tank __________...

Page 18

Page 16 preventative maintenance records use this form to make copies for your internal records preventative maintenance checked note rotate brushes _____________ ____________________________________ rotate side brooms _____________ ____________________________________ drain solution tank __________...

Page 19: Lcd Screen Menu Displays

Page 17 figures 22-25. 1. Battery level indicator - indicates the energy level remaining in the batteries. (shown on all menu displays) 2. Scrubbing deck down pressure gauge - sets the down pressure on the brushes. (see figure 22.) 3. Vacuum on - tells you when the vaccum is on. (see figures 22. And...

Page 20

Page 18 troubleshooting central command (figure 26.) (figure 27.) (figure 28.) (figure 29.) note: this machine is operated by a sophisticated electronic "brain" that has many fail-safes within it. The brain self-analyzes problems and flashes a four-digit numeric code of what is wrong in the lcd wind...

Page 21

Page 19 9. All other error codes. Turn off the key, and disconnect the positve battery cable from the batteries for more than one minute (the time is needed to drain the brain's on-board capacitor). Reconnect cables, being sure that it is tight. Too loose and you will burn battery. If you overtighte...

Page 22: Trouble Shooting

Trouble shooting page 20 problem no power, nothing operates brush motor(s) do not operate drive motor does not operate vacuum motor does not operate drive motor runs incorrectly insufficient solution flow cause faulty key switch batteries need charging faulty battery loose battery cable main circuit...

Page 23: Trouble Shooting

Trouble shooting page 21 problem no solution flow poor water recovery poor water recovery on turns rear tires noisy poor traction short run time cause no solution in tank solution valve off solution switch off solution screen clogged faulty solution solenoid faulty solution switch recovery tank is f...

Page 24: Model 290/350

Page 22 model 290/350 machine parts section some parts are made in red and yellow. If you need yellow parts use the alternate part number which will start with (291-xxxx). If you need red parts, use the normal part number that will start with (290-xxxx). If there is only one part number, that is the...

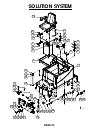

Page 25: Solution System

To scrubhead 12 26 47 20 14 51 25 2 9 4 38 3 7 16 17 18 19 13 22 23 24 6 5 27 28 30 31 34 33 35 36 37 11 39 41 42 43 44 45 46 29 1 43 42 10 33 21 15 36 35 26 40 34 40 8 48 49 50 solution system page 23.

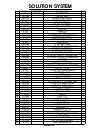

Page 26: Page 24

Item part no. Alt. Part no. Part desription qty 1 290-4140 291-4140 solution tank 1 2 290-1480 battery tray 1 3 290-2110 battery 6 volt 395 ah 4 4 290-1300 battery comp't cover 1 5 290-4152 solution tank lid 1 6 290-4153 sol tank lid gasket 1 7 h-01519 1/4-20 x 1.75 " u bolt 2 8 290-4151 lid strap 1...

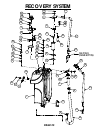

Page 27: Recovery System

10 14 3 22 7 1 12 13 16 5 4 17 18 19 20 21 6 23 9 25 8 27 29 38 31 32 38 9 28 26 20 18 26 18 34 15 20 18 26 26 2 13 11 26 35 36 37 24 33 26 35 36 37 24 30 see item 9 (frame bottom) 39 recovery system page 25.

Page 28: Page 26

Item part no. Alt. Part no. Part desription qty 1 290-7010 291-7010 recovery tank 1 2 5-920 drain hose end tube 1 3 290-4112 recovery tank lid 1 4 290-4110 vac screen inlet 1 5 290-7390 vac inlet gasket 1 6 5-7180 drain hose bracket 1 7 290-7420 rec tank lid gasket 1 8 290-1120 front tank support 1 ...

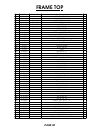

Page 29: Page 27

4 43 27 5 19 21 17 44 13 42 10 28 26 22 31 26 26 28 41 23 22 21 19 9 12 2 47 45 46 18 38 39 20 24 15 23 22 6 32 30 11 14 36 34 34 27 29 40 25 16 35 8 3 37 7 48 25 49 1 33 frame top 22 44 43 50 15 cenrtal command ii cenrtal command page 27.

Page 30: Page 28

Item part no. Alt. Part no. Part desription qty 1 290-1100 frame weldment 1 2 290-1610 non skid floor plate 1 3 290-1170 291-1170 lower steering tower 1 4 290-1171 291-1171 upper steering tower 1 5 290-1172 291-1172 cover 1 6 290-1173 drive cover 1 7 290-1180 291-1180 front apron 1 8 290-7050 index ...

Page 31: Frame Bottom

Frame bottom 5 9 10 12 disc pos. 11 30 34 18 29 33 na 1 4 6 35 30 30 31 35 18 17 20 25 17 12 cyl pos. 2 19 31 30 27 17 30 35 36 3 23 14 26 25 26 25 24 23 44 8 7 41 22 21 45 14 16 25 26 14 23 20 32 28 42 43 37 13 20 32 15 15 39 20 46 21 47 38 40 34 22 21 note: splash curtains are used on disk machine...

Page 32: Page 30

Item part no. Alt. Part no. Part desription qty 1 290-6040 rear axle 1 2 290-6180 290-6185 rear wheel (grey std.) (black opt.) 2 3 290-6187 lug nut, 1/2"- 20 1 4 290-6186 1/2-13 x 1-1/4 " u bolt 4 5 290-5000 axle mount 1 6 290-5001 squeegee drag brace 1 7 290-1253 rear splash curtain 1 8 290-1254 re...

Page 33: Door/wiper/roller Assembly

Door/wiper/roller assembly 2 3 1 4 5 7 6 8 9 15 11 36 26 24 24 26 18 26 22 27 10 29 26 16 34 28 32 23 33 26 22 26 22 21 25 20 20 13 21 20 22 31 33 35 13 12 19 19 12 33 35 14 24 35 33 35 22 use pn 290-1235 for 290 & 350 cyl's left side use pn 290-1235 for 290 cyl's right side use pn 290-1236 for 350 ...

Page 34: Page 32

Item part no. Part desription qty 1 290-1270 front lh pod 1 2 290-1280 rear lh pod 1 3 290-1290 lh pod top support 1 4 290-1230 left wiper 1 5 290-1271 front rh pod 1 6 290-1281 rear rh pod 1 7 290-1291 rh pod top support 1 8 290-1231 right wiper 1 9 290-1220 door 2 10 290-1126 roller bracket 2 11 2...

Page 35: Steering/traction Assembly

26 16 5 17 28 3 11 12 13 10 32 29 11 10 9 17 9 7 20 8 6 2 27 27 steering/traction assembly 31 24 14 15 33 37 36 22 18 23 35 35 21 4 34 19 30 27 38 page 33 39 40 41 1 25 42.

Page 36: Page 34

Page 34 item part no. Part desription qty 1 290-7315 290-7320 black tire (optional) grey tire (standard) 1 2 290-7326 pivot plate 1 3 290-7110 u-joint 1 4 290-7090 steering shaft, upper 1 5 290-7120 steering shaft, lower 1 6 37-7314 large steering sprocket 1 7 37-7315 drop plate 1 8 37-7316 pivot sh...

Page 37: Actuator Slide Assembly

Actuator slide assembly page 35 8 25 9 18 1 19 1 5 9 20 24 9 16 21 9 7 6 3 4 2 14 15 6 14 5 23 22 5 11 2 17 26 9 9 3 13 12 3 24.

Page 38: Page 36

Page 36 item part no. Part desription qty 1 h-37408 kn #10-32 4 2 290-7660 actuator channel 1 3 h-33374 shaft collar, 1/2" id 16 4 5-772 pulley, nylon 3 5 h-11219 hcs 1/2"- 13 x 4.0" 8 6 290-7710 cable trolley 2 7 5-223 limit switch 4 8 290-2210 actuator; 1000 lb. Load (20:1) 1 9 h-36152 hn 1/4"- 28...

Page 39: Disk Scrubhead Assembly

4 3 2 5 1 6 7 8 9 10 11 12 13 18 20 19 16 5 15 17 10 21 8 14 22 23 24 25 disk scrubhead assembly 16 4 see 290-1265 frame bottom brush (see common wear parts) 15 note: 40-423-disk brush repair kit & 40-433-retainer ring are not shown. Page 37 26 27 26 17 26 27 17 5 26.

Page 40: Page 38

Page 38 item part no. Part desription qty 1 7-402 scrub head platform 1 2 38-222 motor 1 hp x 350 rpm 2 3 5-124 lateral arm 4 4 h-70110 hcs 3/8"- 16 x 1-3/4" ss 8 5 h-70712 hn 3/8"-16 ss 11 6 7-4034 reinf. Hose 5/8 id x 18" lg 1 7 h-70105 hcs 3/8"- 16 x 1" ss 7 8 5-447 1/2 npt x 1/2" barb elbow 2 9 ...

Page 41: Cylindrical-Deck

Cylindrical-deck 49 56 39 53 7 8 9 10 11 12 13 14 15 16 18 20 21 22 23 26 28 29 34 35 36 46 40 41 42 2 4 47 48 1 50 51 5 54 55 3 57 58 59 60 61 33 25 8 31 24 52 11 23 38 30 30 25 49 49 32 19 19 32 26 31 28 55 24 see item 12 (frame bottom) 17 62 page 39 17 31 45 idler door assembly 5-8010 1 44 6 32 2...

Page 42: Page 40

Page 40 item part no. Part description qty 1 32-9000 32" cyl brush head 1 2 25-9050 28-9050 7-811 25" hopper 28" hopper 32" hopper 1 3 25-8320 28-8320 5-832 hopper rail, 25" hopper rail, 28" hopper rail, 32" 1 4 290-8355 290-8360 290-8365 drive shaft, 25" cyl drive shaft, 28" cyl drive shaft, 32" cl...

Page 43: Cylindrical-Mechanical

Cylindrical-mechanical 34 22 21 35 20 18 33 27 28 36 32 30 23 29 26 31 19 2 4 6 7 8 10 11 13 3 15 16 17 32 23 23 36 14 1 12 35 34 30 23 24 36 30 25 5 page 41.

Page 44: Page 42

Page 42 item part # description qty 1 1-305 bearing housing 2 2 22-7970 movable idler arm 1 3 22-8300 drive chain 1 4 22-9021 chain guard 1 5 290-8260 10 tooth sprocket 1 6 4-317 idler pulley 1 7 4-319 tension spring 1 8 5-793 idler spacer 1 9 5-796 grease (use only oem grease - not shown) 1 10 5-79...

Page 45: Squeegee Assembly

Squeegee assembly 5 4 10 6 1 25 27 9 30 33 31 34 2 44 3 19 38 46 39 40 35 8 23 11 13 14 15 16 41 26 21 43 38 32 32 7 18 17 18 24 20 22 12 29 36 37 31 34 30 45 47 38 24 42 31 34 31 35 48 28 13 see item 6 (frame bottom) page 43 squeegee wheel assembly 5-760 back up wheel kit 5-757.

Page 46: Page 44

Page 44 item part no. Part desription qty 1 22-7181 25-7181 28-7181 290-7181 30" squeegee weldment 35" squeegee weldment 38" squeegee weldment 45" squeegee weldment 1 2 22-755g 25-755g 28-755g 290-756g 30" squeegee blade, front 35" squeegee blade, front 38" squeegee blade, front 45" squeegee blade, ...

Page 47: Central Command Ii

Central command ii 7 32 40 31 28 29 36 19 24 21 3 1 10 16 17 15 19 13 8 9 22 27 30 6 12 12 12 26 4 11 35 34 5 2 31 33 20 41 37 38 39 14 23 19 19 19 18 19 25 page 45 42.

Page 48: Page 46

Page 46 item part no. Part description qty 1 290-2010 control panel 1 2 290-2001 access cover 1 3 290-2006 hardware panel 1 4 290-2891 lcd screen 1 5 290-2004 access cover gasket 1 6 290-2015 one touch button 1 7 290-2815 cir. Breaker - 15a, 24v 2 8 290-2300 low solution (amber) 1 9 290-2310 full re...